Baumax RMD650 User manual

Operator’s Manual

Track Dumper RMD650 / RMD650-B

Do not use this device until you have fully read and

understood these instructions!

www.geargb.co.uk [email protected]

28

Do not use this equipment if you are under the influence of drugs, alcohol

or any kind of medication that can affect your reactions.

Table of Contents

Chapter

1. Introduction

2. Safety

3. Hazards, risks & behaviours

4. Operator requirements

5. Applications

6. Conditions and intended operation

7. Before starting

8. Start-up

9. Driving the Track Dumper

10. Tipping the skip

11. Shut down

12. Care and maintenance

13. Steering and braking adjustment

14. Track tensioning

15. Maintenance intervals

16. Technical Data

17. Description - Engine

18. Tightening torques

19. Fault finding

20. Exploded diagram Track Dumper RMD650

21. Service record

EC Declaration of Conformity

Page

3

3

4

6

6

6

8

9

12

12

13

13

15

15

16

17

18

19

19

21

22

23

©Technickhandel Echterdingen Ltd., Esslinger Str 7, 70771 Leinfedlen-Echterdingen.

All right reserved. E&OE.

2

23

27. Service Record for Model _________ Purchase Date: _________

Date

Work carried out

Signature

Date

Work carried out

Signature

Date

Work carried out

Signature

Date

Work carried out

Signature

Date

Work carried out

Signature

Date

Work carried out

Signature

Date

Work carried out

Signature

Date

Work carried out

Signature

This machine should only be used by a competent person who

has read and understood this manual!

1. Introduction

This manual contains information and procedures for the safe operation and safe

maintenance of your machine. Improper operation or incorrect maintenance can lead

to dangerous situations. For your safety, you must thoroughly familiarise yourself with

the safety information described herein and always adhere to it. Repair work must be

performed by authorised specialists. Defective parts must be replaced immediately.

We reserve the right to make technical changes.

Our goal is to provide construction equipment that provides the operator with efficient

and safe operation. Caution and good judgment are the best protection against

injury. It is not possible to cover all potential risks here; we have compiled the most

important for you in this manual. Every operator should always be working with the

necessary care. Warnings and safety instructions attached to the equipment and/or

provided by the employer or the responsible trade association must be noted. The

operator must always read the safety instructions carefully and follow them.

2. Safety

The machine is designed in accordance with recognised safety regulations for

construction. However, improper use may cause danger to life and limb of the

operator or other persons. Furthermore, improper use can also cause damage to the

machine or other property.

Therefore take time to make yourself familiar with the machine, even if you have

already worked with similar machines in the past! Try the machine carefully before

you beginning daily tasks! Get a feel for the machine and learn how it works, the

possibilities, limitations and potential risks! Take particular care to be familiar with

how the machine should be switched off as quickly as possible!

Thank you for purchasing our product!

26

3

Never allow anyone to operate the machine without prior instruction! Make sure

that all operators have read and understood the operating instructions and that

they act in accordance with the instructions given here! The incorrect and

imprudent use of the machine can result in serious injury. Due to the machine’s

weight, it must be lifted with utmost caution using suitable equipment!

3. Hazards, Risks and Behaviours

Mechanical Hazards!

Use this machine only when all the necessary safeguards are in place! Avoid contact

with rotating and moving parts as they can cause injury or even crushing and

amputation of limbs!

Make sure the engine ignition switch in the "OFF" position and that the ignition cable

is disconnected from the spark plug before removing guards or performing any

maintenance or adjustment work!

Make sure that the machine is set down on a flat surface so that overturning,

overbalancing or slipping during start up is avoided!

Never leave an operating machine unattended!

Before starting to work, ensure that the walls of a trench are stable and that machine

vibrations cannot cause a collapse! In particular, when working on slopes and

edges, consider that the soil bearing capacity can be greatly reduced by the effects

of vibration.

Make sure there are no cables, gas and/or water pipes that the bottom of the work

area which could be damaged by being run over!

Pay attention to the correct posture when working with this machine, because the

periodic vibrations and repetitive work motions can be harmful to hands and arms.

Never carry out checks on the machine while it is in operation!

Warning! Do not increase the set full load maximum speed without prior permission

of the manufacturer! Any speed increase can cause bodily injury and/or damage to

the machine.

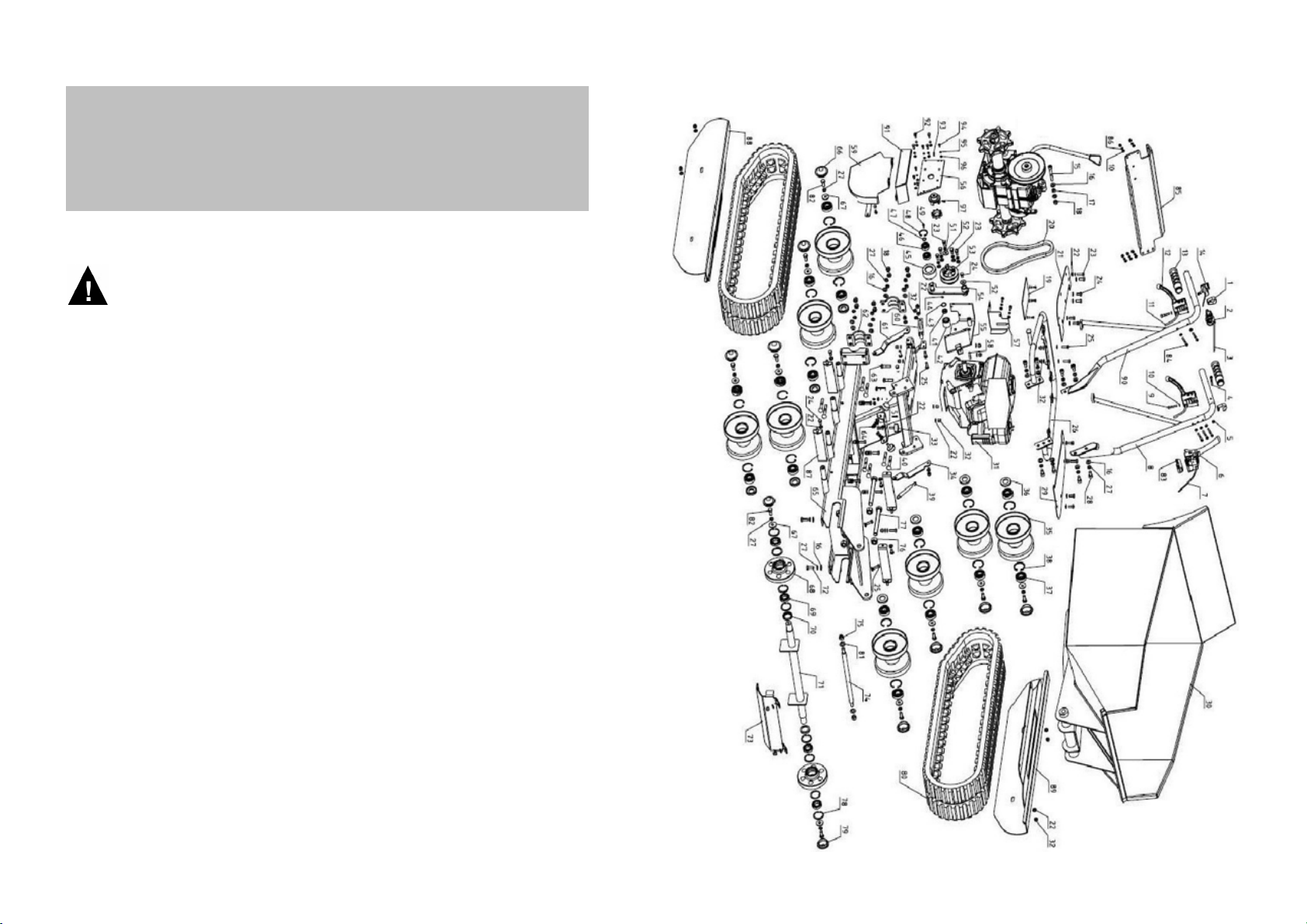

20. Exploded Diagram Track Dumper RMD650 / RMD650-B

4

21

Noise Hazard

Warning! Excessive noise can lead to temporary or permanent hearing loss. Always

wear appropriate hearing protection which has been approved to the relevant safety

regulations to limit noise pollution!

Make sure that you do not come into contact with the exhaust or other hot parts!

Touching these parts can result in serious burns.

Only allow the machine to be repaired and adjusted by trained personnel!

20

5

Fire and Explosion Hazards

Chemical Hazards

Petrol is highly flammable and explosive under certain conditions. Only store petrol

only in an appropriate container! Never refuel a petrol engine while it is operating or

before it has cooled down! Never refuel in the vicinity of sparks, open flames or

smoking persons! Avoid overflowing and spilling petrol when refuelling!

When refuelling, ensure you are in a safe position for the machine and the operator

in order to avoid petrol spills! If fuel is spilled, make sure that the area on which you

start the machine is dry, because gasoline or gasoline vapours can ignite. Make sure

that the fuel cap is securely closed after refuelling!

Do not operate or refuel any diesel or petrol engine in poorly ventilated areas, such

as deep holes or enclosed spaces! Inhalation of fuel vapours and exhaust fumes

can cause death. If you are working in trenches, ensure there is adequate

ventilation! If necessary, are set up fans.

Mineral oils and fuels are harmful to health. Therefore you should always wear

suitable protective equipment, such as Safety goggles and protective gloves, when

handling any these substances. Direct skin contact should be avoided.

In the event of skin contact: wash immediately with soap and water. If fuel or oil

comes into contact with your eye, you must seek immediate medical attention.

Petroleum and fossil fuels are harmful to the environment. Only dispose of

discharged and spilled mineral oils or fuels in accordance with the applicable local

and national environmental regulations.

Air filter dirty

Clean / replace air filter

Blocked carburettor

Clean carburettor and nozzle

Defective spark plug

Replace spark plug

Engine losing power

Belt loose

Tighten belt

Engine speed too low

Refill with new fuel

Spark plug wet

Adjust engine speed

Park brake does not release

Adjust or replace park brake cable

Belt broken or defective

Replace belt

Fuel regulation faulty

Check / adjust throttle control

Decreased traction or no

traction

Hydraulic oil level too low

Check level / top up hydraulic oil

Flow control valve fully turned

Loosen flow control valve

Hydraulic hoses / connections loose

Secure / tighten hydraulic hoses &

connections

Skip does not tip / lower (or

does not tip / lower fully)

Protective Clothing

Other Risks

Slips, trips and falls are the main causes of serious or even fatal injuries.

Avoid uneven or slippery work surfaces!

Avoid working near unprotected holes or trenches!

4. Operator Requirements

Only qualified and trained personnel over 18 years are allowed to operate the

machine. The operator must be physically and mentally healthy and productive.

The operator must have carefully read and understood the operating instructions and

be familiar with the necessary safety precautions and safety devices before using the

equipment.

5. Applications

Earthwork and bulk transport

Landscaping and paving

Roads, paths and civil engineering

Forestry

6. Conditions and Intended Operation

Requirements for the use of the Track Dumper:

•Only operate with perfect technical condition.

•Regular maintenance should be carried out according to the specifications of

this manual.

•All relevant safety conditions are met.

Intended Use of the Track Dumper:

•Transport of bulk materials

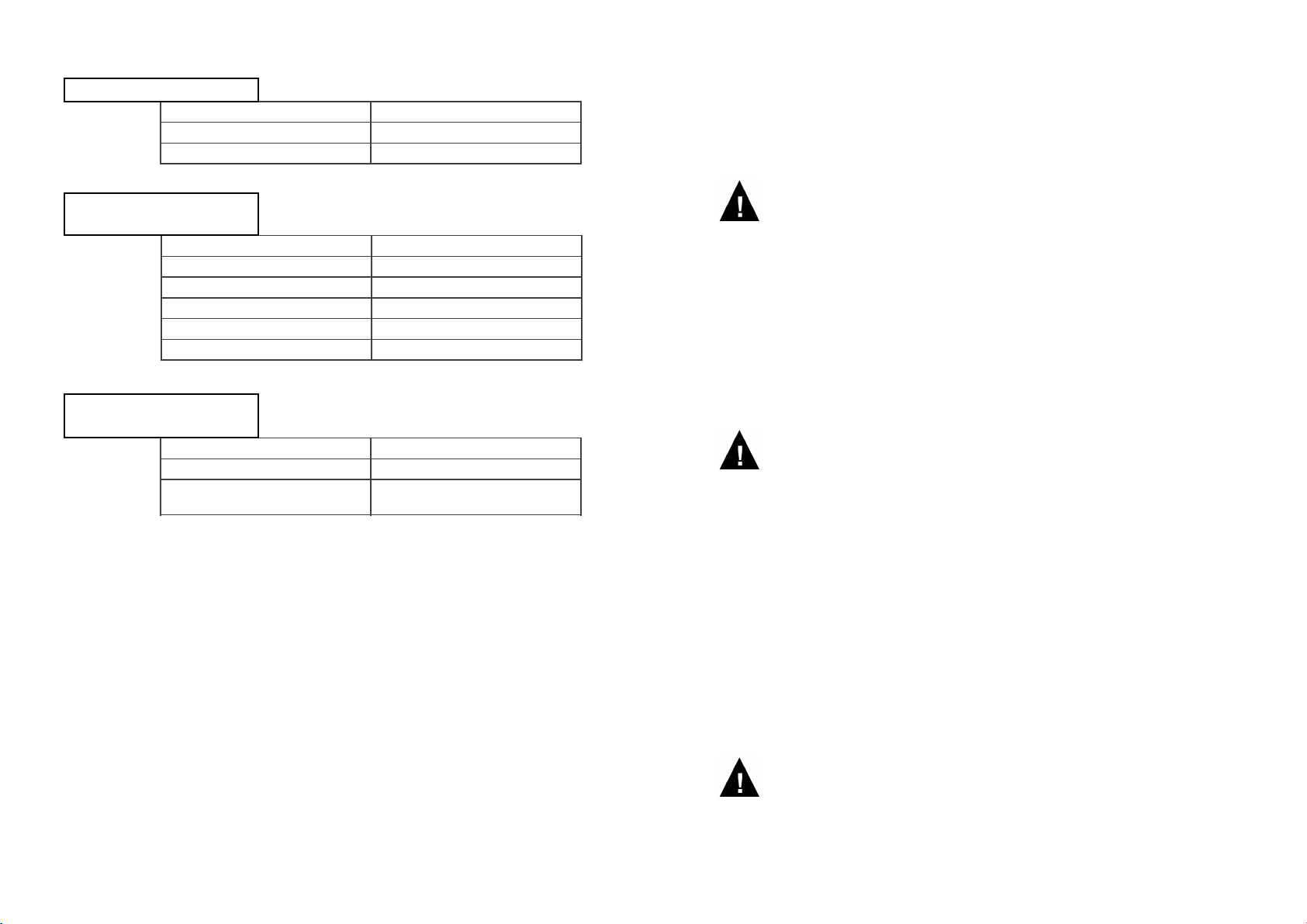

18. Tightening Torques

6

19

Always wear ear protection!

Wear goggles and dust mask in dusty environments!

Always wear safety shoes and proper protective clothing!

Wear a Helmet!

Tensile Strength

4.6

8.8

10.9

12.9

Tightening Torque (Nm)

Thread Size

M6

3.5

10

15

18

M8

8.4

25

36

43

M10

17

49

72

84

M12

29

85

125

145

M16

71

210

310

365

19. Fault Finding

Fault Cause Solution

Engine emits black smoke

Air filter dirty

Replace air filter

Air filter dirty

Replace air filter

Old fuel

Refill with new fuel

Spark plug wet

Dry spark plug

No ignition spark

Check ignition / ignition switch

Clogged carburettor

Clean carburettor and nozzle

Low engine oil level

Add oil to the correct level

Engine doesn’t start

Air filter dirty

Replace air filter

Choke closed

Check position of the choke lever

Fuel supply blocked

Check fuel supply / carburettor

Engine stalls

This Track Dumper Is Not Suitable For:

•Transport of people

•Transport of overhanging cargo

•Transport of liquids

Intended Use

The operator must be located, and must control the device carefully from, behind the

unit with hands on the controls during operation. The operator must wear proper

protective equipment such as hearing protection, safety helmet, safety goggles and

protective shoes. There should be no other people in the immediate vicinity of the

device, because of the risk of injury from moving parts and possibly from ejected

material. If the operator leaves the working position, the machine must be shut

down.

The machine may only be operated fully assembled in operation. If any parts are not

fully assembled or need replacing, e.g. Air filter, possibly battery cover, ... etc. and in

particular protective equipment such as belt guard, heat protection, exhaust or on/off

switch, the equipment must not be operated.

Operate the machine in such a way as to remove any overturning or risk of falling on

edges or embankments. The machine is to be guided such that the operator is not in

the direction of fall if an unforeseen tilting of the machine occurs.

When working on an incline, always take care not to exceed the maximum

admissible inclination stated in the technical data.

Transport

Always turn off the machine and allow the engine to cool before transporting the unit.

Prevent the unit from overturning, slipping or falling during transport with suitable

tested, lashing equipment. The lashing belts may only be fixed to the places

designated below:

17. Description - Engine

18

7

Lashing Attachment

Points (rear)

Lashing Attachment

Points (front)

1. Filler cap

2. Fuel tank

3. Throttle

4. Starter handle

5. Pull starter

6. Air filter

7. Valve cover

8. Spark Plug Cap, Spark plug

9. Exhaust and silencer

10. Choke

11. Low oil sensor

12. Oil filler and dipstick

13. Oil drain plug

14. ON / OFF switch

15. Fuel tap

Loncin G270F

Lifting

Use only suitable and approved hoists, slings and lifting accessories with sufficient

capacity. Use only permissible lifting points according to the instruction manual and

ensure that the machine is secured reliably on the hoist. There must be no persons

in the immediate vicinity of the machine when lifting.

Storage

After operation, the cooled device should be protected from the weather and stored

out of the reach of children. For storage of more than one month, the fuel must be

drained during storage. For petrol engines, the carburettor must be emptied.

16. Technical Data

For damage caused by improper use, handling, disregard of

operating instructions, impermissible overspeed, deficient or

insufficient maintenance or separate structural changes carried out

without approval of the manufacturer, machine warranty, and the

liability of the manufacturer and the dealer, will be voided. The risk in

case of these events is solely with the operator.

Be sure to read the safety instructions and commissioning

instructions before starting the machine for the first time!

7. Before Starting

1. Read the Safety section of the Operating Instructions!

2. Check the engine oil level prior to each start-up!

3. Make sure that the machine is clean, especially the cooling air inlet of the engine

and the air filter! If the air filter is dirty it must be replaced!

4. Check all nuts and bolts are tight. Normal operating vibrations can loosen

screws/nuts/bolts and this can lead to serious accidents and/or damage to the

machine.

Check the Engine Oil

1. Place the switched off machine on a flat, level surface.

2. Remove dipstick and wipe.

3. Replace the dipstick again, then remove it and read the oil level.

4. If the oil level is low, add engine oil according to the "Technical Data” section!

8

17

Model RMD650 RMD650-B

Operating weight - Unladen (kg) c. 305 c. 300

Engine Loncin G270F Briggs & Stratton 900

Single-Cylinder 4-Stroke Petrol OHV

Rated capacity (kW) 6.6 not stated by B&S

Max permitted speed (rpm) 3600 3600

Engine oil content (l) 1.0 (SAE10W-40) 0.59 (SAE10W-30)

Spark plug E7RTC QC12YC

Electrode spacing (mm) 0.7 0.76

Fuel Unleaded Petrol (RON95) or Super E10

Tank capacity (l) 5.5 2.8

Max. permitted inclination 20º 20º

Gears 3 Forward, 1 Reverse

Engine starting Recoil Recoil

Skip tipping Hydraulic Hydraulic

Max. angle of tip 110º 110º

Skip dimensions (mm) 970x710x465 970x710x465

Track width (mm) 180 180

Dimensions LxWxH (mm) 1660x720x980 1660x720x980

Lash

Intake Valve (mm) 0.15 0.15

Outlet Valve (mm) 0.20 0.28

20

19. Explosionszeichnung BAUMAX® VP16/44

9

4. Wenn der Ölstand zu niedrig ist, Motoröl entsprechend dem Kapitel „Technische

Daten“ nachfüllen!

Kraftstoffkontrolle

Benzintank öffnen und den Kraftstofffüllstand prüfen. Beim Nachtanken einen Filter

verwenden, damit kein verunreinigtes Benzin eingefüllt wird. Kein Benzin überlaufen

lassen. Wenn doch etwas daneben gelaufen ist, gründlich wegwischen, bevor der

Motor gestartet wird!

Keilriemenkontrolle

Niemals die Keilriemenspannung prüfen, während der Motor läuft! Wenn die Hände

von den Keilriemen oder der Kupplung erfasst und mitgerissen werden, können

schwere Verletzungen entstehen. Daher ist vor der Keilriemenkontrolle bei

Maschinen mit Benzinmotor der Zündkerzenstecker von der Zündkerze zu

entfernen. Bei den Arbeiten zur Keilriemenkontrolle immer Schutzhandschuhe

tragen. Um die Keilriemenspannung zu prüfen, die Schrauben der

Keilriemenabdeckung entfernen und die Abdeckung abnehmen. Die Keilriemen sind

richtig gespannt, wenn sie sich in der Mitte (zwischen beiden Riemenscheiben) ca.

10-30 mm eindrücken lassen.

8. Inbetriebnahme

Voraussetzungen für den Start

Genügend Kraftstoff befindet sich im Kraftstofftank.

Es befindet sich die richtige Menge an Motoröl im Kurbelgehäuse des Motors.

Der Luftfilter ist sauber.

Vorgehensweise beim Start

1.

Kraftstoffhahn öffnen, indem man

den schwarzen Hebel nach rechts

(in Pfeilrichtung) bis zum

Anschlag bewegt.

Ausnahme: Typ VP10/31 – kein

Kraftstoffhahn vorhanden

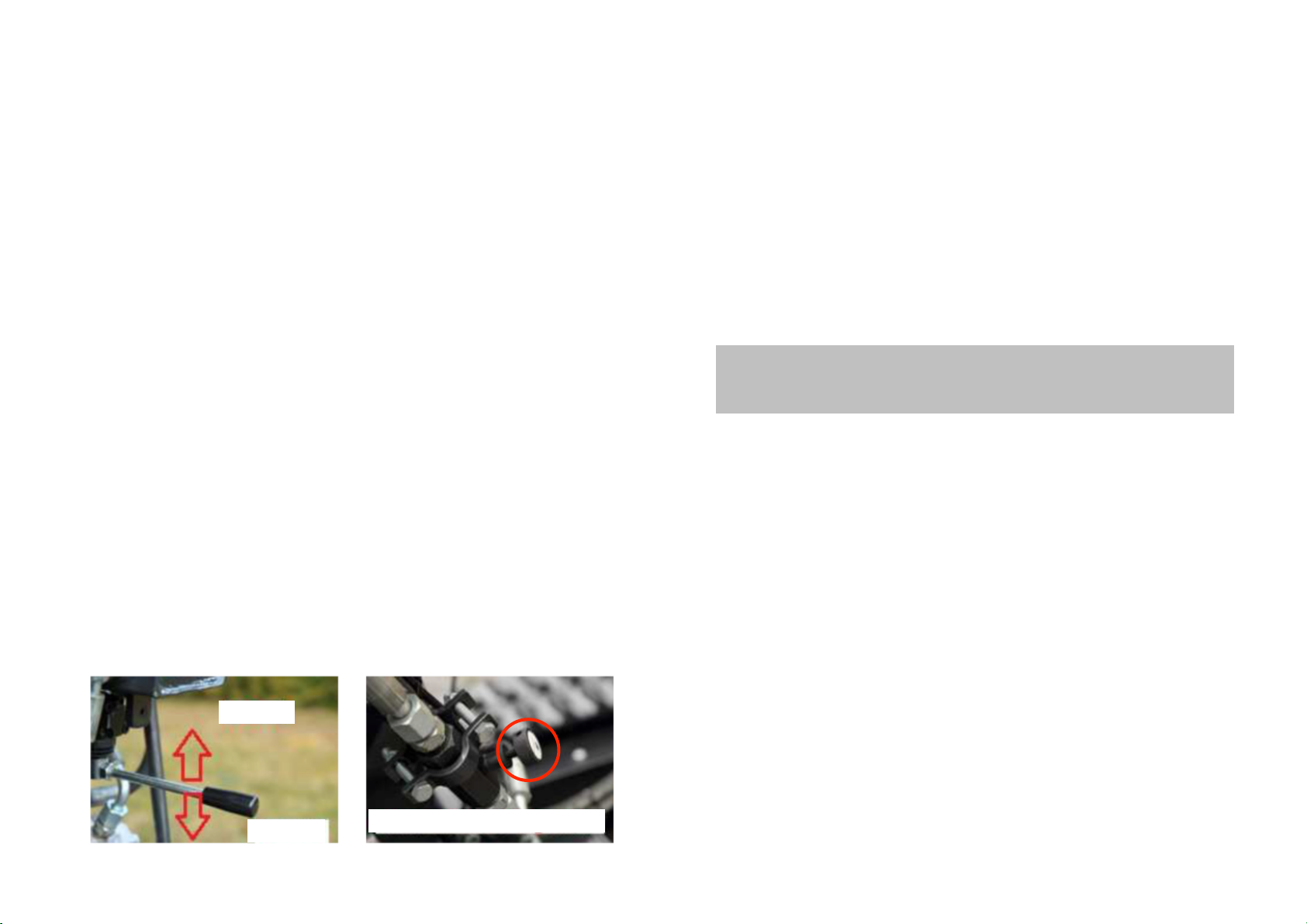

Tracks Tensioning Bolts

Check the Fuel Level

Open fuel tank and check the fuel level. When refuelling, always use a filter to

ensure that no contaminated fuel enters the tank. Do not allow petrol to overflow! In

the event that any fuel is spilled, thoroughly wipe off before the engine is started!

Check the Belt Tension, Drive Clutch Setting

Never check the belt tension while while the engine is running! If your hands are

caught in the belt or the clutch, serious injury can result. Therefore, before checking

the belt tension, always remove the petrol engine spark plug cap from the spark

plug. Always wear protective gloves when checking the V-belt tension.

A belt which is too loose will affect the efficiency of the machine. For details on

tightening belt tension, see Chapter 12 - Care and Maintenance.

8. Start-up

Preconditions for Starting

There is sufficient fuel in the petrol tank.

The engine crankcase has the correct oil level.

The air filter is clean.

How To Start

1.

Open the fuel tap:!

Loncin G270F engine - move black lever to the right (arrow direction) until it stops.

Briggs & Stratton 900 engine - turn red knob to the left.

16

9

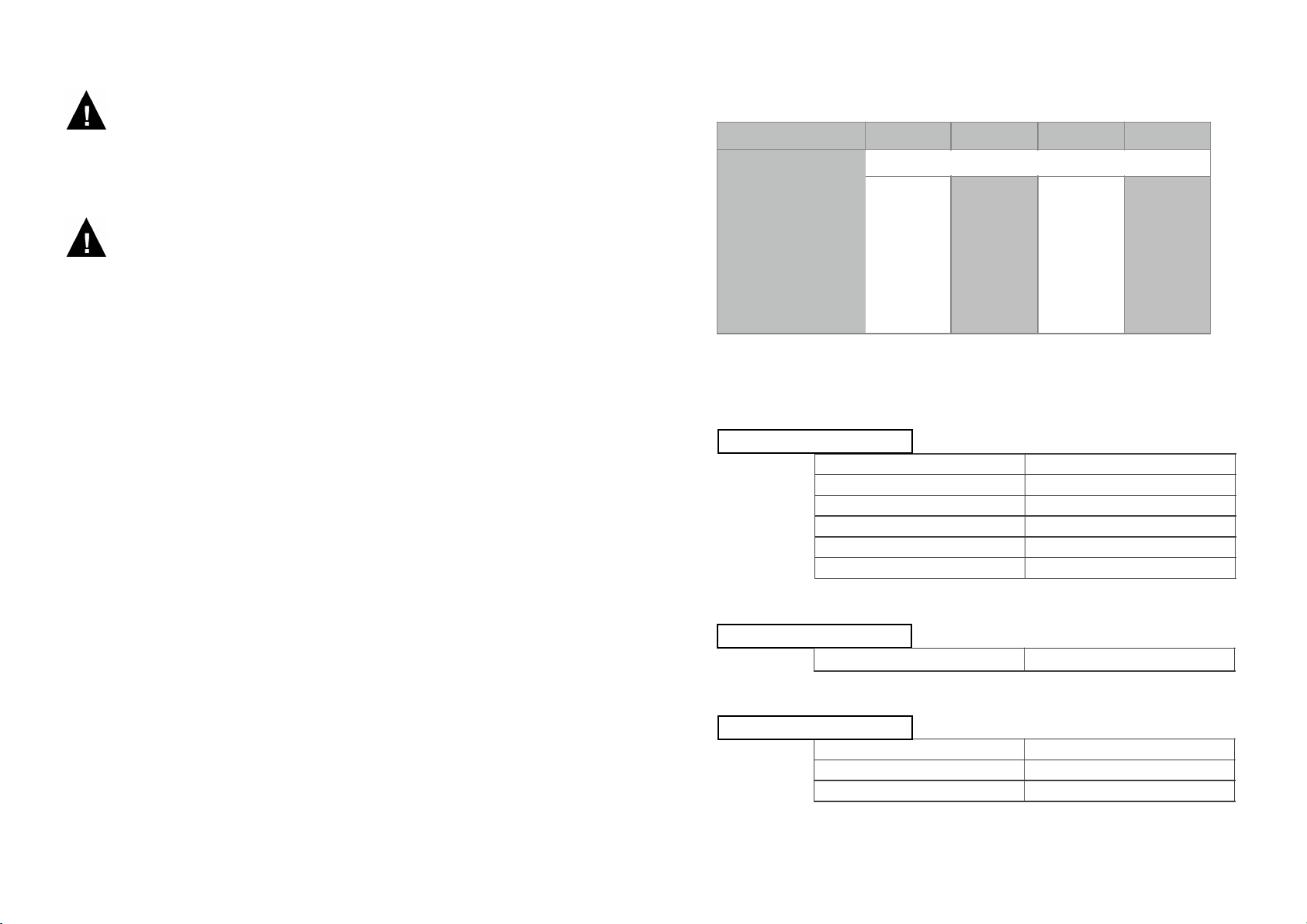

12. Maintenance Intervals

All maintenance must be carried out at the listed time

or working hours interval, whichever comes first!

Before every

use

After first 5 hrs

Every 3 months

or 50 hrs

Every 6 months

or 100 hrs

Every year or

200 hrs

Engine Oil (SAE10W-70)

Check level

X

Change

X

X

Air filter

Check

X

Clean

If dirty

Replace

X (1)

Hydraulic oil

Check level

X

Transmission oil (SAE80)

Change

X

Fuel line and connections

Check

X

X

Fuel tank and filter

Clean

X

Spark plug

Check / Adjust

X

Replace

X

Idle speed

Check / Adjust

X

Full throttle speed

Check / Adjust

X

X

Engine cooling fins

Clean

If dirty

Screws and bolts

Check / re-tighten according

to torque table

X

X

Recoil start

Clean

X

Cable

Check for damage

X

Valve clearance

Check / Adjust

X

Belt tension

Check / Adjust tension

As required, if driving force of Track Dumper reduces

Steering Brakes

Check / Adjust

If Track Dumper steering is biased to left or right

Throttle

Adjust friction

As required

(1) Replace more frequently in dusty environments (at the latest, as soon as the filter material has a greyish discolouration).

2.

Turn the red On / Off switch on the right-hand guide handle to the “ON” position.

ATTENTION! For version with Briggs & Stratton 900, also move the red ignition

switch on the engine to the “I” position.

3.

Loncin G270F Engine

Move the grey Choke Lever left to the

“START” position. This causes the fuel-

air mix to be enriched and is necessary

for cold start of the engine.

Once the engine is started and running,

m o v e t h e C h o k e L e v e r t o t h e

“OPERATION” position, which provides

the correct fuel-air mix for normal work.

Briggs & Stratton

Move the black Choke Lever right to the

“START” position. This causes the fuel-

air mix to be enriched and is necessary

for cold start of the engine.

Once the engine is started and running,

move the Choke Lever to the “RUN”

position, which provides the correct fuel-

air mix for normal work.

10

15

Briggs & Stratton 900 engine both engine variants

START

OPERATION

Loncin G270-F engine

Briggs & Stratton 900 engine

START

13. Steering and Braking Adjustment

If the Track Dumper does not steer left and right correctly, readjust the steering

Bowden cables on the left and right steering levers.

1. Loosen the lock nuts of the Bowden cable adjusting screws on the steering

levers.

2. Unscrew the Bowden cable adjusting screw to loosen them further.

3. Perform a test drive and check steering characteristics by alternately pressing

the left and right steering levers.

4. The steering brakes are correctly adjusted when approximately 2/3 of lever

travel steers the Track Dumper in the desired direction.

5. If the setting is too tight it will block the steering brake.

6. When both steering brakes are evenly adjusted, tighten the lock nuts on the

Bowden cables to prevent slip.

14. Track Tensioning

The crawler tracks can stretch and/or require tightening after some time.

How to Check the Track Tension

1. Park the Track Dumper on a flat, level surface.

2. Lift the top of the track in the middle by hand.

3. If the track can lift by more than 5-6cm relative to the horizontal, the tracks

should be tightened.

Retightening the Tracks

1. Start the engine and tilt the skip far enough forward that the clamping bolts are

easily accessible.

2. Stop the engine and remove the spark plug cap to prevent accidental engine

starting.

3. Position the gear lever in the “NEUTRAL” position.

4. Chock the Track Dumper to prevent unintended rolling back or forth.

5. Secure the skip against unintentional lowering (e.g. with a prop).

6. Loosen the locknuts on the tensioning bolts and wind the tensioning bolts

clockwise to increase the track tension.

7. While tightening, check frequently the track tension by lifting the top of the track

in the middle (as described above) and check the lift.

8. Tighten both tracks equally, and then secure the locknuts.

9. The correct tension is achieved when both tracks have about 3-4 cm lift in the

middle, relative to the horizontal.

4.

Set the throttle to half throttle position.

7.

After cold start, if the engine runs smoothly, move the choke lever slowly back to

the “OPEN” position after around 5-15 seconds.

After warm start, move the choke lever to the “OPEN” position immediately.

14

11

8.

After warm-up, move the throttle lever towards full throttle position until resistance is

felt.

If making repeated attempts to start, always wait for the engine to come to a

complete stop before trying again.

5.

Pull the starter rope out slowly until a

slight resistance is felt; then pull the cord

rapidly.

PULL START

6.

Place the throttle back to the idle position and allow the engine to warm up for 1-2

minutes depending on the ambient temperature.

ATTENTION! The throttle lever must not be forced past the full

throttle position, otherwise the engine speed limit will be too high,

resulting in damage. This can lead to incorrect resonance on other

components and thus damage the entire machine. The same applies

to increasing the maximum speed setting.

ATTENTION!

DO NOT pull the starter rope all the way out to the end!

Make sure that the cable is retracted as quickly as possible without letting

go of it during retraction - so that it is drawn all the way in to the housing.

ATTENTION! Operation of the machine with too heavily soiled, defective, or

incorrectly seated air filter will cause damage to the engine. Such operation will

void the warranty and guarantee.

Belt

ATTENTION! Never try to tension the belt while the engine is running! Serious

injury can occur from moving belts! Always remove the spark plug from machines

with petrol engines before starting any maintenance to avoid accidental starting of

the engine!

Tighten the belt when transmission power feels low or disappears (e.g. if there is a

problem in overcoming gradients).

Adjusting the Belt Tension

1. Loosen the engine bolts.

2. Move the engine manually back until the right belt tension is achieved.

3. Re-tighten the engine bolts.

4. IMPORTANT! After adjusting the belt tension, check that the brakes disengage

correctly.!

Try to rotate the brake drum on the left side of the transmission with one hand,

while operating the red clutch lever with the other hand.!

While holding the red clutch lever, the brake drum must turn freely in its fixture. !

When the red clutch lever is released, the brake drum must not rotate in its

fixture.!

If necessary, the brake cable connection must be adjusted on the belt tensioner.

Transmission Oil Change

Remove the oil drain plug at the bottom of the left side of the gearbox. Using a

suitable hoist, slightly tilt the Track Dumper to the left and allow all the oil to drain

into a suitable container. Always dispose of drained oil in accordance with local and

national environmental regulations for disposal. To refill, slightly tilt the Track Dumper

to the right using a suitable hoist and fill with gear oil as specified in the technical

data. Replace the oil drain plug and tighten.

ATTENTION! When the transmission power deteriorates noticeably, the belt

tension must be checked and adjusted!

11. Shut Down

1. Set throttle to idle position.

2. Turn the engine ignition switch to the “OFF” position.

3. Always close the fuel tap after turning off.

12. Care and Maintenance

Before carrying out any maintenance work, turn off the engine and allow to cool.

For devices with petrol engines remove the spark plug and, if necessary, disconnect

the battery. If disassembly of any safety equipment is required for maintenance, it

must be assembled and checked again immediately after completion of the work.

Check for loose screws and tighten according to the specified tightening torques.

12

13

9. Driving the Track Dumper

Select the desired gear using the shift lever.

If selection is not easy/possible, press and release the clutch lever then try again.

When the desired gear has been engaged, grip and hold the red clutch lever to start

driving.

To stop the Track Dumper, slowly release the clutch lever - this disengages drive and

applies the brake!

On steep inclines always select 1st gear to avoid excessive load on the belt drive.

The Track Dumper is steered by means of the two clutch handles below the left and

right guide handles. Grip the lever on the right guide handle to cause the Track

Dumper to veer or rotate to the right. Grip the lever on the left guide handle to cause

the Track Dumper to veer or rotate to the left.

Depending on the load and the on the incline of any slope to be climbed, different

levels of force are required to actuate the levers. In extreme cases (e.g. on a slope

and with a full load) the clutch lever can no longer be operated because the force to

be transmitted is simply too large.

When driving forwards downhill (i.e. with the load at the front) take care that the

Track Dumper does not tilt because of the centre of gravity being so far forward. If in

doubt, always use reverse gear.

IMPORTANT! Gears may only be switched/selected when the red clutch lever is

NOT engaged.

10. Tipping the Skip

Pulling upwards on the lever of the hydraulic valve under the oil tank causes the skip

to be raised.

Pushing downwards on the lever of the hydraulic valve under the oil tank causes the

skip to lower. The speed of lowering is controlled by the built-in Flow Control Valve

(see photo) - adjust as necessary. Turn the screw clockwise to reduce the lowering

speed.

ATTENTION! The valve must never be closed completely otherwise the hydraulic

pump will be overloaded!

RAISE

LOWER

FLOW CONTROL VALVE

ATTENTION! If the machine will not be used for more than 3 weeks, empty the

fuel tank and carburettor! (Drain plug: angled screw on gold float housing below

the carburettor).

Engine Oil Change

Remove the oil drain plug at the bottom of the engine (note: there are two). Using a

suitable hoist, tilt the device forward and allow all the oil to drain into a suitable

container. Always dispose of drained oil in accordance with local and national

environmental regulations for disposal. Oil changes are best carried out with a warm

engine, as warm oil flows much better and the crankcase is better drained. Then,

replace the oil drain plug(s) and tighten according to the technical data

specifications, and fill the appropriate amount of engine oil in the dipstick hole.

Alternatively, the oil can be sucked out from the dipstick hole by means of a plastic

syringe and a suction hose.

Air Filter

The air filter element should be replaced - whenever necessary - because dirty air

filters causes starting problems, reduced engine performance, and can significantly

shorten the life of the engine. To replace the air filter, undo the wing nut on the air

filter housing. After removing the cover, undo the second wing nut (not available with

VP10/31) and take out the filter element. Insert a new filter element, lock with a wing

nut and mount the cover in reverse order. When inserting and securing the filter

element ensure the correct position and cleanliness of the sealing surfaces!

This manual suits for next models

1

Table of contents