The Handy THGT500-A User manual

226KG (500LB)

TIPPER TOWED TRAILER

Model No: THGT500-A -- Product No: 193843001

ASSEMBLY REQUIRED

SAVE THESE INSTRUCTIONS

SPARES & SUPPORT: 01793 333212

Please read & understand this manual, paying particular attention to the safety instructions,

before use.

The manufacturer reserves the right to change the product specification and livery

according to continued product improvements.

Images used are for illustration purposes only

INSTRUCTION MANUAL

CONTENTS

SAFETY INSTRUCTIONS

SPECIFICATIONS

CONTROLS & FEATURES

OPERATING INSTRUCTIONS

MAINTENANCE & STORAGE

COMPONENTS

ASSEMBLY

PARTS DIAGRAM & LIST

WARRANTY

ASSEMBLY IS REQUIRED

This product requires assembly before use. See the “Assembly” section for instructions.

Please check that all parts required for the assembly of this spreader are included. If for any reason

you believe a part for the assembly is missing or damaged, please contact us.

If you require any assistance with regards to the contents or operation of

your machine, please contact us:

TEL: 01793 333212

(MON –FRI 8.00AM TO 5.30PM EXCL. BANK HOLIDAYS)

SPECIFICATION

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

Model

THGT500-A

Product Number

193843001

Weight

38.7kg

Working Width

81cm

Internal Dimensions

97cm x 71.5cm x 30.5cm

Maximum Capacity

500LB (226kg)

Wheel & Tyre

16”Pneumatic

Tyre PSI (Recommended)

25 PSI (Do not exceed)

IMPORTANT INFORMATION

INTENDED USE

The product is intended for domestic gardens. This product is not intended for commercial use.

Generally acknowledged accident prevention regulations and enclosed safety instructions must be

observed. Only perform work described in these instructions for use, any other use is incorrect. The

manufacturer will not assume responsibility for damage resulting from such use.

GENERAL SAFETY INSTRUCTIONS

Read and understand the owner’s manual

and labels affixed to the product. Learn its

application and limitations as well as the

specific potential hazards. Retain these

instructions for future reference. The

operator is responsible for following the

warnings & instructions in this manual and

on the product.

READ THE MACHINE MANUAL

Read the vehicle owner’s manual and vehicle

safety rules, and know how to operate the

vehicle before using this equipment.

STAY ALERT

Do not operate the machine while under the

influence of drugs, alcohol, or any medication

that could affect your ability to use it properly.

Do not use this machine when you are tired or

distracted from the job at hand. Be aware of

what you are doing at all times. Use common

sense.

USERS

Never allow children to operate the towing

vehicle or de-thatcher. Do not allow adults to

operate without having read these instructions.

TYRE INFLATION

Only use HAND or FOOT operated tyre inflation

machines, not mechanical and do not exceed

recommended PSI.

PASSENGERS

Do not allow anyone to ride or sit on the de-

thatcher frame or on the towing vehicle.

BEWARE BYSTANDERS/PETS

Keep the area of operation clear of all persons,

particularly children and also pets.

HANDLE WITH CARE

Always handle with care and wear sturdy

footwear when operating this attachment.

AVOID DANGEROUS CONDITIONS

Make sure there is adequate surrounding

workspace. Cluttered areas invite injuries.

Keep your work area clean with sufficient light.

Keep the area around the machine clear of

obstructions, grease, oil, rubbish & other debris

which could cause persons to fall onto moving

parts.

DO NOT FORCE TOOL

Always work within the rated capacity. Do not

operate for a purpose for which it was not

intended.

INSPECT YOUR MACHINE

Check all bolts, nuts & screws for tightness

before each use, especially those securing

guards & drive mechanisms. Vibration during

use, may cause these to loosen. Replace

damaged, missing or failed parts before using.

CRUSH AND CUT HAZARDS

Always keep your hands and feet clear from

moving parts while operating. Always keep the

work area clean and clear when operating.

CONDITIONS

Always operate up and down a slope, never

across the face of a slope. This equipment

should be operated at reduced speed on rough

terrain, along creeks and ditches and on

hillsides, to prevent tipping and loss of control.

Do not drive too close to a creek or a ditch. Do

not tow this equipment on a highway or any

other public thoroughfare.

Always begin with the transmission in first (low)

gear & the engine at low speed. Gradually

increase the speed as conditions permit. The

vehicle braking and stability may be affected

with the sweeper attached. Be aware of

changing conditions on slopes.

Refer to safety rules in the vehicle owner's

manual, concerning safe operation on slopes.

DRESS PROPERLY

Do not wear loose clothing, gloves, scarfs,

neckties or jewelry (rings, wrist watches), which

can be caught in moving parts.

DO NOT OVERREACH

Never stand on the machine. Serious injury

could occur if tipped or moving parts are

unintentionally contacted. Do not store anything

above or near the machine, where anyone might

stand on the machine to reach them.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Keep hands & feet out of the way of all moving

parts. Do not place any part of your body or

any tool e.g. in moving parts of the machine

during operation.

MAINTAIN YOUR MACHINE WITH CARE

Clean the machine immediately after use. Keep

the machine clean to ensure it operates to its

full & safest performance. When maintaining

this machine, only the manufacturer’s original

replacement parts should be used. The use of

non-original manufacturer parts may invalidate

your warranty.

PROTECT THE ENVIRONMENT

Take left over materials to an authorised

collection point or follow the stipulations in the

country where the machine is used. Do not

discharge into drains, soil or water.

STORE IDLE EQUIPMENT

When not in use, the machine should be stored

in a dry location. Keep the machine away from

children & others not qualified.

OPERATION SPEED

Do not exceed 10mph, to avoid personal injury

and/or equipment damage.

SAFETY SYMBOLS

Safety alert symbol. Used to alert you to

potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in serious

injury.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in serious

injury

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

CAUTION

Used without the safety alert symbol indicates a

potentially hazardous situation which, if not

avoided, may result in property damage.

Read & understand

operator’s manual before

using the machine. Failure

to follow instructions could

result in death or serious

injury.

Risk of Slicing.

Keep hands out of the way

of all moving parts.

Wear gloves to protect your

hands

Wear foot protection

COMPONENTS

Please check the contents of the carton are correct BEFORE assembling your new product.

If any parts are missing, contact our Customer Service Team

•Telephone: 01793 333212

•Email: customerservice@handydistribution.co.uk

TOOLS REQUIRED

•Pliers

•Screw Driver –Phillips Head

•10mm & 14mm Wrench

Left Bottom Panel x1

Right Bottom Panel x1

Right Side Panel x1

Left Side Panel x1

Front Panel x1

Rear Panel x1

Wheel Axle Support x2

Tow Bar & Hitch x1

Wheel x2

Draw Bar Support x1

Wheel Axle x1

Support Tube x2

Rear Panel Slot x2

Release Pedal x1

Latch Spring x1

Hinge Pin x6

Hex Bolt M6x90 x1

R-Pin Ø3 x2

Flat Washer Ø16 x4

Spacer x2

Screw M6x16 x4

Screw M8x16 x8

Screw M8x20 x2

Screw M8x35 x4

Lock Nut M8 x14

Lock Nut M6 x5

ASSEMBLY

Remove the hardware pack and all loose parts from the carton and verify that all the components

are included. If you are missing any parts, please contact us on 01793 333212 for assistance.

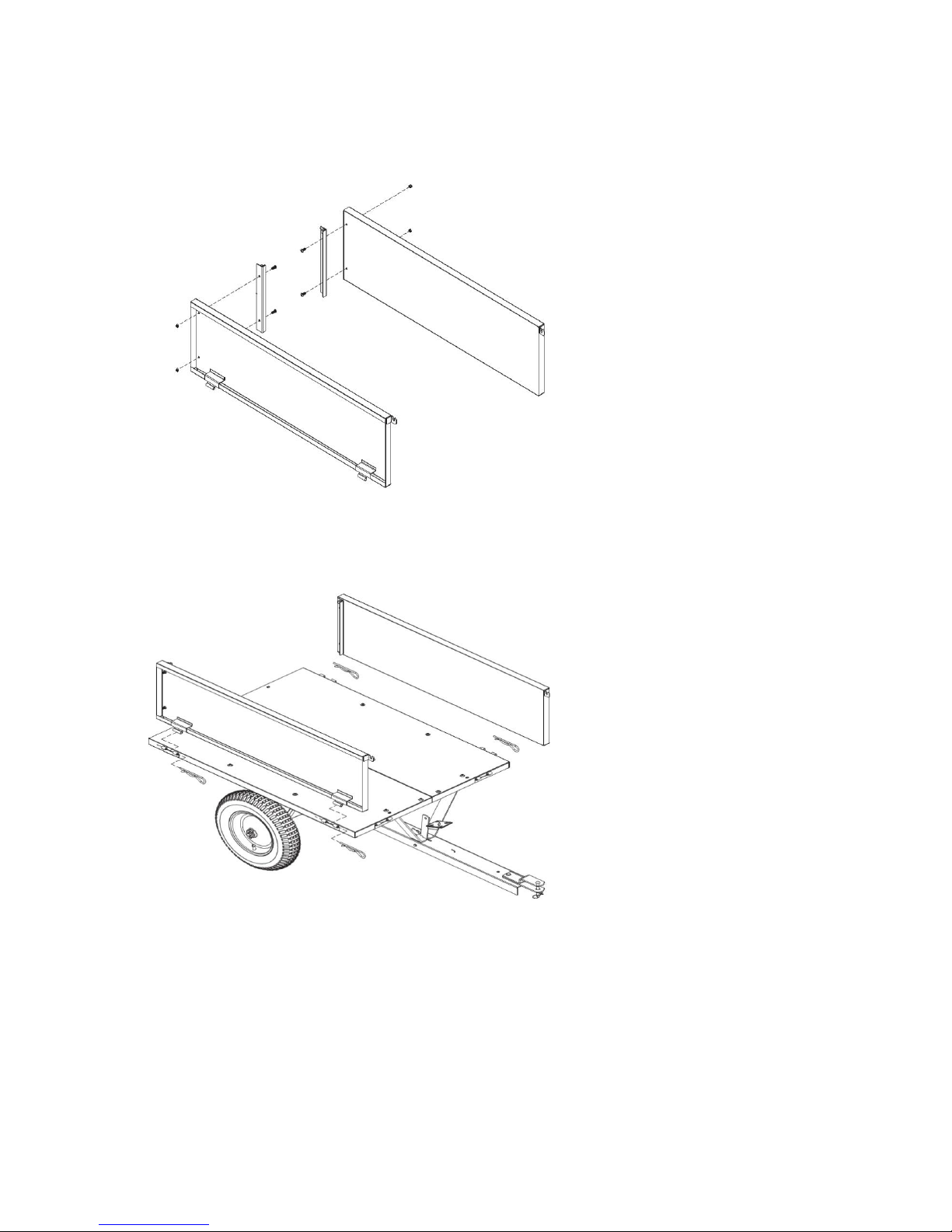

STEP 1 - Attach the Bottom Panels and Support Tubes

•Lay the left and right bottom panels, face down

•Attach the baseboard support tubes to the panels using four sets of M8x35 screws & M8 nylon

lock nut.

•Hand tighten the nuts.

STEP 2 - Attach the Draw Bar Support

•Attach the V-Shaped draw bar support to the bottom panels using two M8x20 screws & M8 lock

nuts

•Hand tighten the nuts

STEP 3 - Attach the Wheel Axle Support

•Connect the two-wheel axle supports and attach them to the bottom panels using eight M8 lock

nut & screw M8x16.

•Hand tighten the nuts.

STEP 4 - Attach the Release Pedal

•Insert the release pedal into the tow bar and secure using the two spacers either side of the

release pedal & the M6x90 hex bolt and M6 lock nut.

•Attach the latch spring hook onto the bottom hole of the release pedal and tow bar.

•Hand tighten the nuts.

STEP 5 - Attach the Wheel Axle

•

Insert the tow bar assembly into the central slot in the wheel axle support.

•

Insert the axle through the hole and slide it through both the axle support and the Tow Bar

assembly.

•

Now tighten all nuts & bolts in steps 1 through to 4.

STEP 6 - Attach the Wheels

•

Put a Ø16 Flat Washer on the axle; slide the wheel over the end, followed by a second Ø16 flat

washers and secure with a Ø3 R-pin through hole within the wheel & axle.

•

Repeat the process for the other side of the axle.

STEP 7 - Attach the Rear Panel Slots and Lock Support Tube

1. Attach the left and right rear panel slots on the left and right panel using four sets of the

M6x16 screws and M6 lock nuts.

STEP 8 - Attach the Side Panel

•Attach the left and right side panel to the bottom panel using the four hinge pins.

STEP 9 - Attach the Front Panel

•

Attach the front panel to the bottom panel and secure using two hinge pins.

•

Lock the left and right side panel assemblies in place using the top handles.

STEP 10 - Attach the Rear Panel

•Slide the rear panel through the slots on the back side panels.

NOTE: The rear panel pins must go through the holes on the side panels to lock the panel in place.

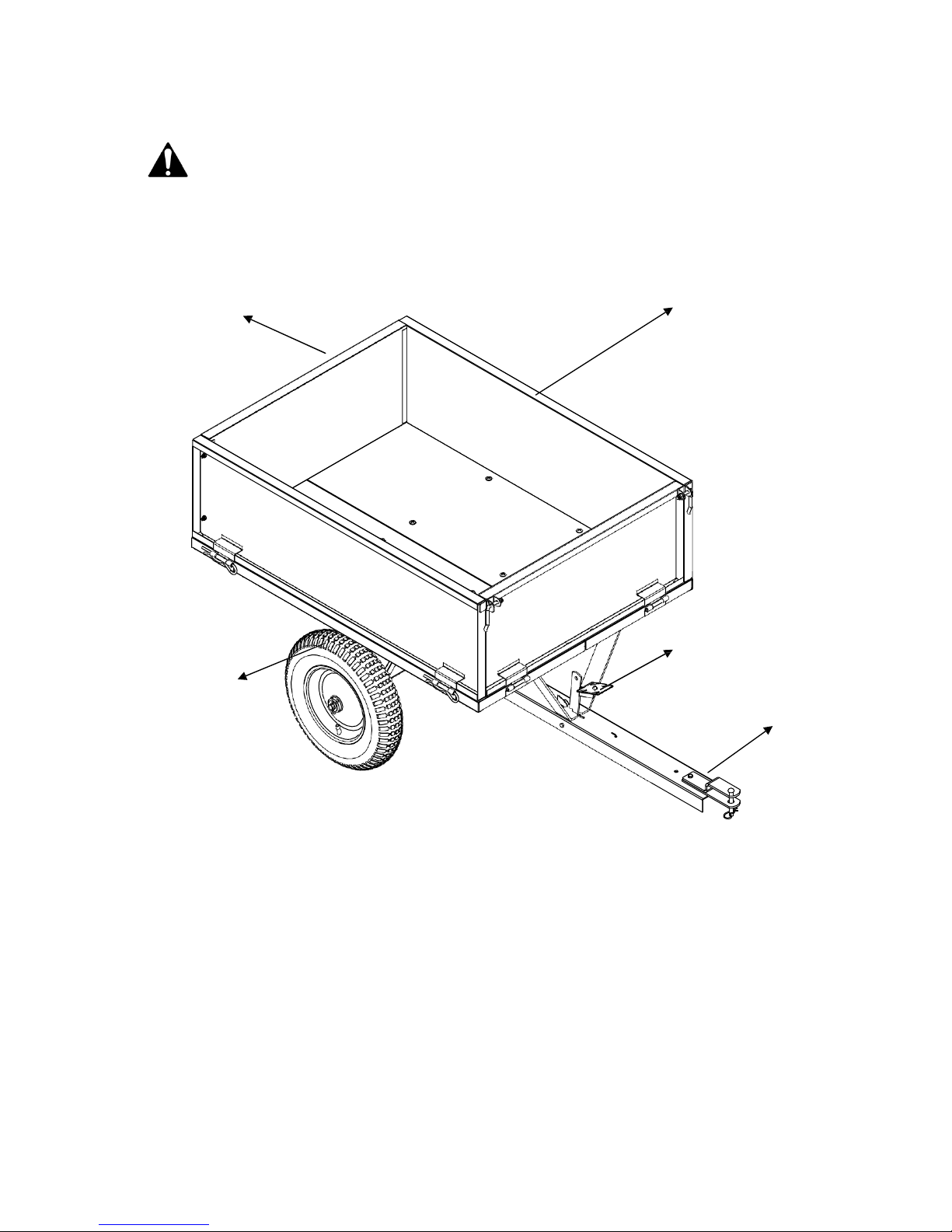

CONTROLS & FEATURES

CAUTION

Read & follow all instructions for assembly & operation. Failure to properly assemble this equipment

could result in serious injury to the user of bystanders, or cause equipment damage.

Familiarise yourself with the location& function of the controls and features.

Keep the manual in a safe place for future reference.

3

1.

Removable Tailgate –Push up to remove for loading and unloading.

2.

Trailer Box –Do not exceed rated load capacity 500lb (226.8kg).

3.

Tyres / Wheel –Check and inflate the tyres. We recommend the use of FOOT or HAND

inflation devices only. Do not inflate above the recommended 25psi.

4.

Hitch –Pin-type design, use only with approved vehicles.

5.

Release Pedal –Releases the Trailer bed for tipping.

1

2

4

5

OPERATION / ADJUSTMENT

DANGER

The product must only be put into operation if no defects are found. It is crucial that defective

parts are replaced before the product is used again. Check the safety equipment and the safe

condition of the product: Check all parts to make sure that they fit tightly. Check whether there

are any visible defects: broken parts, cracks, etc.

•THIS TRAILER CANNOT BE ATTACHED BY TOW BALL OR BEHIND A ROAD GOING VEHICLE.

•Never allow children to handle the trailer.

•Never allow anyone to ride on the trailer.

•Always wear footwear when working with the trailer.

•Never operate if the trailer is damaged, repair before continuing to operate.

•DO NOT exceed the rated capacity of 226kg (500lb).

•ALWAYS secure and lock the Trailer to the vehicle hitch before operating.

•ONLY use approved vehicles when towing the Trailer (Lawn/Garden Tractors & ATVs)

•NEVER tow the Trailer with the box raised.

•DO NOT over fill the Trailer. This could cause the Trailer and towing vehicle to lose traction

and skid out of control.

•ONLY fill the Trailer to a manageable dumping load. Extremely heavy loads will be difficult to

operate the tipping mechanism.

•ONLY use the Trailer for its intended purpose.

•ALWAYS make sure that the combined weight of the tow vehicle and the operator is greater

than the load of the Trailer. If the Trailer is heavier it may be difficult to control.

•DO NOT use the Trailer on public roads.

•NEVER exceed 10mph when towing the Trailer.

•DO NOT make sharp turns as this may cause the Lawn/Garden Tractor or ATV tyres to rub against

the Towed Trailer.

•ALWAYS slow down before turning.

•ALWAYS use caution when reversing the Trailer. To avoid the Trailer “jack-knifing” always

reverse in a straight line.

ATTACHING THE TRAILER TO THE TOW VEHICLE

•Park the tow vehicle and trailer on level ground.

•Set the height adjustment handle to middle of its adjustment.

•Insert the hitch pin through the sweeper hitch brackets and towing eye of the tow vehicle and

secure with the cotter pin.

EMPTYING THE TRAILER

•Stop the tow vehicle and turn off the engine.

•Stand to the side of the trailer.

•Ensure your footing is secure and use your foot to apply pressure to the release pedal. Ensuring

the tipping trailer does not come into contact with you.

•Release carefully to rehouse trailer to frame. Ensure it is correctly housed before starting the

engine of the towing vehicle.

MAINTENANCE

WARNING

Improper maintenance & storage of the trailer may void your warranty.

MAINTENANCE

•After each use clean any material out of the Trailer.

•Rinse/dry inside and outside of the Trailer after each use.

•Before operating make sure the tyres have the recommended tyre pressure of 25 PSI (Do not

exceed). We recommend the use of FOOT or HAND inflation devices only.

•Grease the axle and the wheel bearing area regularly with Multi-purpose grease.

•Periodically check all nuts & bolts for tightness.

•Annually clean and lightly lubricate parts with Maintenance spray.

•Use a glossy enamel spray paint to touch up scratched or worn painted metal surfaces.

•Never exceed the load capacity rating of 500lb (226.8kg) this will damage the Trailer.

IMPORTANT:

Only use the manufacturer’s original replacement parts. Non-original replacement parts will

invalidate your warranty and may result in a safety hazard or poor operation.

Parts are available by calling 01793 333212.

STORAGE

•Never allow material to remain in the Trailer for extended periods of time.

•For years of trouble free service, make sure the Trailer is clean and dry before storing.

•Store indoors or in a protected area during severe weather and winter months.

•When storing outside always keep the draw bar a little higher than the back of the Trailer to

allow any moisture to run out of the back and not to accumulate in the carry area.

PARTS DIAGRAM & LIST

PARTS LIST

Ref

Part No.

Description

Qty

Ref

Part No.

Description

Qty

1

TH177-1

Left Bottom Panel

1

20

TH177-22

Draw Bar Support

1

2

TH177-2

Right Bottom Panel

1

21

TH177-23

Pin

2

3

TH177-3

Wheel

2

22

TH177-24

Handle A

1

4

TH177-4

Wheel Axle Support

2

23

TH177-25

Handle B

1

5

TH177-5

Left Side Panel

1

24

TH177-26

Handle Sleeve

2

6

TH177-6

Right Side Panel

1

25

TH177-27

R Pin Ø4

3

7

TH177-12

Rear Panel

1

26

TH177-28

Screw M8x35

4

8

TH177-13

Release Pedal

1

27

TH177-29

Screw M8x20

2

9

TH177-9

Front Panel

1

28

TH177-33

Hex Bolt M8x16

8

10

TH177-10

Left Rear Panel Slot

1

29

TH177-31

Screw M6x16

4

11

TH177-11

Right Rear Panel Slot

1

30

TH177-30

Screw M6x35

4

12

TH177-14

Wheel Axle

1

31

TH177-34

Hex Bolt M6x90

1

13

TH177-15

Hinge Pin

6

32

TH177-35

Flat Washer Ø6

2

14

TH177-16

Support Tube

2

33

TH177-36

Flat Washer Ø8

2

15

TH177-17

Hitch Pin

1

34

TH177-37

Flat Washer Ø16

4

16

TH177-18

Hitch Bracket 1

1

35

TH177-38

Nylon Lock Nut M6

5

17

TH177-19

Latch Spring

1

36

TH177-39

Nylon Lock Nut M8

18

18

TH177-20

Spacer

2

37

TH177-40

Hex Nut M6

2

19

TH177-21

Draw Bar

1

38

TH177-41

Hitch Bracket 2

1

39

TH177-42

Large Washer Ø8

2

NOTE: Parts Lists are supplied for information purposes only, not all parts are stocked individually & we recommend

you contact our Spares Team on 01793 333212 for expert advice.

GJ HANDY & CO LTD USER WARRANTY POLICY

Users Statement of Warranty

Each new machine is warranted against defective material or assembly of material under normal

usage. The warranty applies to the original purchaser and covers faulty parts and the labour involved

in replacing and repairing those parts, which are of original manufacture.

Period of Warranty

All Webb, Handy Pro (Brushcutter & Long Handle Hedgecutter only) and Sanli domestic products.

2 years from the original date of sale to the first domestic user.

90 days from the original date of sale to the professional/commercial user.

90 days from the original date of sale when used for hire.

A reduced warranty period of 90 days applies to those items which are subject to normal wear and

tear (e.g. wheels, tyres, cutter bars, cylinders, bottom blades, belts, cables, grass bags, spark plugs).

Engines as per the manufacturer’s warranty statement which will be supplied with the machine.

90 days from the original date of purchase for Replacement Spare Parts (unless normal wear & tear

component, which are covered for 30 days).

All machines’ must be serviced within the first 12 months from the original date of purchase to

comply with the warranty, failure to do so will invalidate the 2nd year of the warranty.

All Handy, Handy Pro (All others), Mowerland and Q-Garden domestic products.

1 year from the original date of sale to the first domestic user.

90 days from the original date of sale to the professional/commercial user.

90 days from the original date of sale when used for hire.

A reduced warranty period of 90 days applies to those items which are subject to normal wear and

tear (e.g. wheels, tyres, cutter bars, cylinders, bottom blades, belts, cables, collection bags, spark

plugs).

Engines as per the manufacturer’s warranty statement which will be supplied with the machine.

90 days from the original date of purchase for Replacement Spare Parts (unless normal wear & tear

component, which are covered for 30 days).

All warranty repairs must be undertaken by an authorised service dealer. These dealers have been

accredited by GJ Handy & Co Ltd and agree to only use genuine parts and follow our repair

procedures.

Version 3 05-16

GJ HANDY & CO LTD USER WARRANTY POLICY

Not covered by this warranty

a) The warranty policy does not cover any depreciation or damages caused by ordinary wear,

rusting or corrosion, lack of correct maintenance or operation, misuse, abuse, lack of

transportation or accident.

b) The warranty policy does not cover any costs necessary for the standard periodic maintenance

services instructed by the operator’s manual, or service parts replacement which would include

oil, filters, tyres, belts, brake linings, fuses, blades, seals and other service parts unless it can be

proven that the item has evidence of faulty manufacture.

c) The warranty policy will not cover failure or damage caused as a result of parts or accessories

being modified without the written approval of GJ Handy & Co Ltd.

d) The warranty policy will not cover the unit if non-genuine parts have been fitted and as a result

damage has occurred to the unit.

e) The warranty policy is non-transferable and is only applicable to the original purchaser.

Disclaimer

a) This warranty is only a remedy for defect of products. GJ Handy & Co Ltd will never warranty in

terms of the merchantability or the fitness for a particular purpose.

b) No person is authorised to make any warranties, representations or promises, expressed or

implied, on behalf of GJ Handy & Co Ltd, or to modify the terms conditions or limitation of this

warranty policy in any way.

c) Neither GJ Handy & Co Ltd nor any company affiliated with GJ Handy & Co Ltd shall be liable in

any event or manner whatsoever for incidental or consequential damages or injuries, including,

but not limited to, loss of crops, loss of profit, out of pocket expenses or profits, rental of

substitute equipment or other commercial losses.

General

a) Most warrantable failures show up within the first few weeks of use. These failures are usually

straightforward and warranty assessment is relatively easy.

b) Failures relating to cutter decks and belts need careful investigation, as the cause may not

always be straightforward. Look for damage to blades and pulleys especially when the cutter

belt or blade boss have snapped or cracked as this could be due to impact damage.

c) Customers should always refer to the operator/instruction manual when any disputed problem

arises, you will find most areas covered within the manual.

For spares or support of your handy product,

please contact us:

Tel: 01793 333212

(Mon –Fri 8.00am to 5.30pm excl. Bank Holidays)

Email: customerservice@handydistribution.co.uk

To see our range of garden machinery & equipment visit:

www.thehandy.co.uk

Making gardening easier & affordable since 1938

Distributed by Handy Distribution, Murdock Road, Dorcan, Swindon, SN3 5HY

Other manuals for THGT500-A

1

This manual suits for next models

1

Table of contents

Other The Handy Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Demountable Concepts

Demountable Concepts Warehouse On Wheels Quick reference guide

Madill

Madill 3000 Operation & maintenance manual

Global

Global ANV-400 Instructions for use

Polaris

Polaris RANGER RZR XP 4 900 2013 Owner's manual for maintenance and safety

DR

DR VERSA TRAILER PRO XL2000 Safety & Operating Instructions

Chapman

Chapman TF350 Original instructions