baxter 35700BAX Instructions for use

Table of contents

Other baxter Water Pump manuals

baxter

baxter Flo-Gard 6301 User manual

baxter

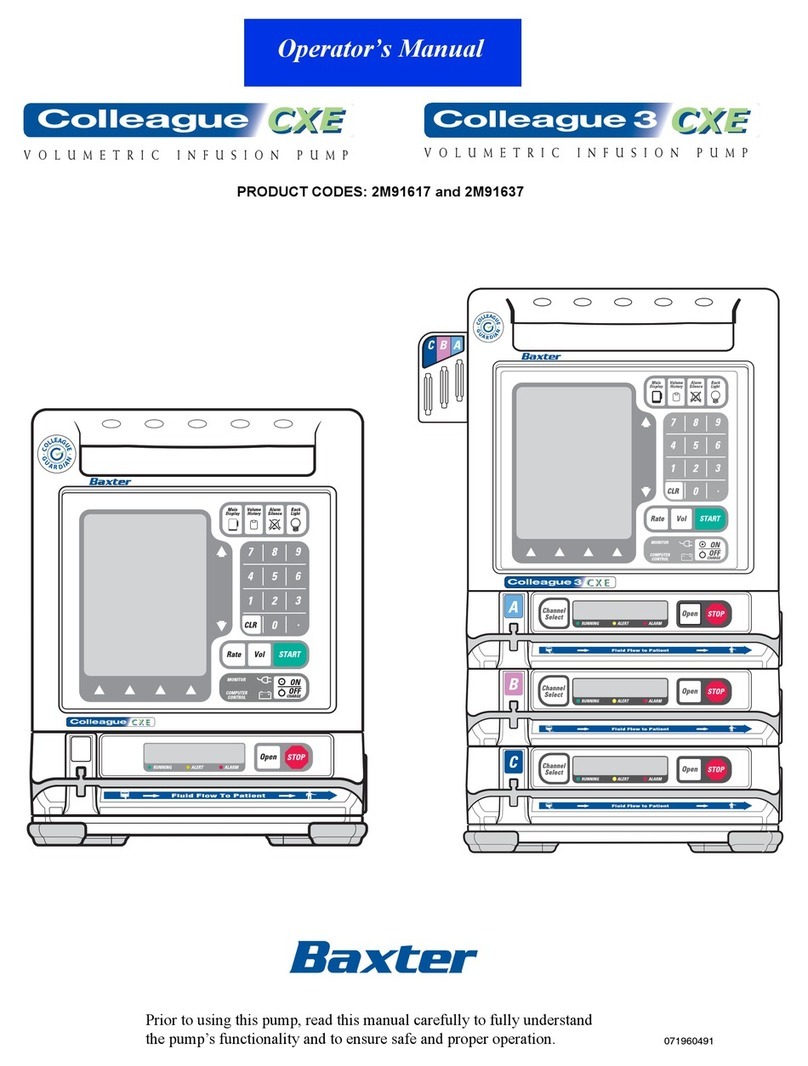

baxter Colleague CXE User manual

baxter

baxter 35700BAX2 User manual

baxter

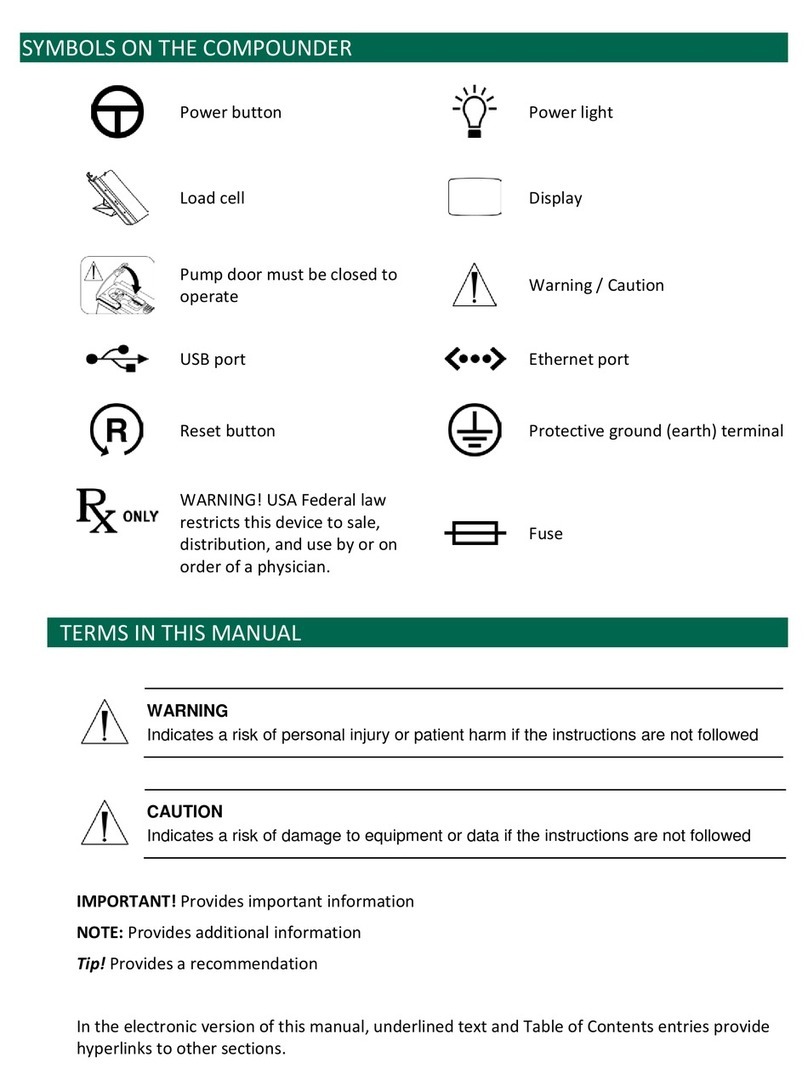

baxter ExactaMix 2400 Compounder User manual

baxter

baxter Auto Syringe AS50 User manual

baxter

baxter Auto Syringe AS50 User manual

baxter

baxter PCA II User manual

baxter

baxter Flo-Gard 6201 User manual

baxter

baxter Flo-Gard 6301 User manual

Popular Water Pump manuals by other brands

mbp

mbp TEL 15BBL Instructions and parts list

Crane

Crane Barnes 10 ICU-1 Installation and operation manual

Pentair

Pentair Fairbanks Nijhuis Series Installation, operation and maintenance manual

Ion Technologies

Ion Technologies WC33 Operation manual

AMT

AMT IPT 2P5X Series Specifications information and repair parts manual

Ribimex

Ribimex Ribiland PRPVC753AS User and maintenance manual

Tuthill

Tuthill nextec FILL-RITE NX25-120 Series Installation and operation manual

Briggs & Stratton

Briggs & Stratton WP2-60 manual

Pentair

Pentair JUNG PUMPEN HEBEFIX 100 instruction manual

Vogel

Vogel MFE5-KW3-2 manual

Graco

Graco Husky Sanitary Series Instructions-parts list

Schmalz

Schmalz SXP Series operating instructions