Schmalz X-Pump OperatingInstructions

CONTENTS

1Safety Notes....................................................................................... 1-5

Symbols used in this manual.................................................................................. 1-5

Trademark - TM...................................................................................................... 1-5

General safety notes............................................................................................... 1-6

Use for the intended purpose.................................................................................. 1-6

2Description......................................................................................... 2-7

Overview of variants................................................................................................. 2-7

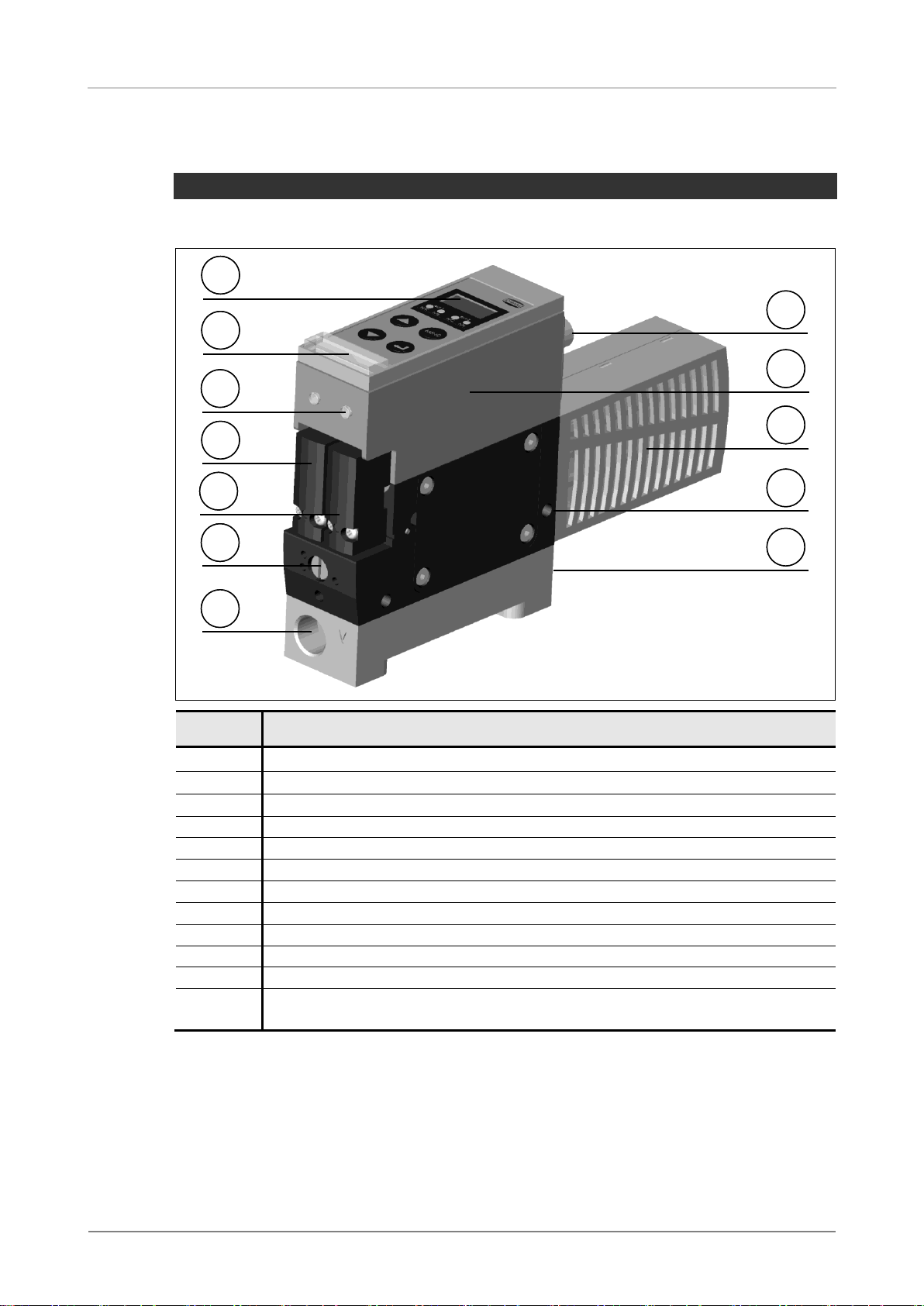

Basic module .......................................................................................................... 2-8

Expansion modules................................................................................................. 2-9

General functional description ................................................................................ 2-10

Putting into service................................................................................................... 2-11

Installation and operation........................................................................................ 2-11

Mounting................................................................................................................. 2-12

Electrical connections............................................................................................. 2-12

Pneumatic connections........................................................................................... 2-13

3Basic Settings.................................................................................... 3-15

Controls and Indicators........................................................................................... 3-15

Controls................................................................................................................... 3-16

Basic menu................................................................................................................ 3-17

Setting the threshold values [H-1], [h-1], [H-2], [h-2]............................................... 3-18

Setting the zero point (calibration) [CAL]................................................................ 3-19

PIN for basic menu [Pn1]........................................................................................ 3-20

Internal cycle counters [ct1], [ct2], [ct3]................................................................... 3-21

Displaying the internal counters.............................................................................. 3-22

Resetting the internal cycle counters...................................................................... 3-22

Leak detection function (LSF)................................................................................. 3-23

4Expert configuration ......................................................................... 4-24

Configuration menu [SEt], [out], [ctr], [t-1], [-L-], [bLo]............................................ 4-24

Unlocking the extended configuration menu........................................................... 4-25

Display settings......................................................................................................... 4-26

Setting the unit of measurement [uni]..................................................................... 4-26

Setting the reaction time......................................................................................... 4-26

Eco mode [Eco]....................................................................................................... 4-27

Setting the bus system options............................................................................... 4-27

PIN for the extended configuration menu [Pn2]...................................................... 4-28

Clearing all settings (clear all) [rES]........................................................................ 4-30

Outputs ...................................................................................................................... 4-31

Configuring the outputs [out]................................................................................... 4-31

Hysteresis mode –output type NO......................................................................... 4-33

Hysteresis mode –output type NC......................................................................... 4-33

Comparator mode –output type NO........................................................................ 4-34

Comparator mode –output type NC....................................................................... 4-34

Setting the reaction time [dLY]................................................................................ 4-35

Air saving and diagnostic functions....................................................................... 4-36