BaySaver BayFilter Guide

1

BayFilter

Design Manual

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

INTRODUCTION

Clean water is essential to quality of life. BaySaver Technologies is 100% committed to minimizing pollution in

stormwater which helps protect our water resources. By collaborating with the regulatory and engineering community

to develop products and processes, BaySaver continually develops state of the art stormwater filters that are proven

to effectively remove pollutants such as sediments, phosphorous, metals, nitrogen, trash, and hydrocarbons.

2

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

TABLE OF CONTENTS

INTRODUCTION ...............................2

BAYFILTER ...................................3

BASIC PRINCIPLES OF FILTRATION...............4

BAYFILTER PRODUCTS .........................6

BAYFILTER OPERATION ........................8

SYSTEM DESIGN & SIZING .....................10

INSTALLATION ...............................15

INSPECTION & MAINTENANCE ..................17

AVAILABILITY & COST .........................18

BAYFILTER SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 18

3

BAYFILTER

The BayFilter cartridge system is an ongoing commitment to state of the art stormwater treatment. The compound

spiral media configuration allows for a large filter surface area in a compact footprint. This configuration results

in the most efficient and effective stormwater filter available in the marketplace. The BayFilter is available in

multiple sizes with multiple media configurations to meet any flow rate and design consideration while being able

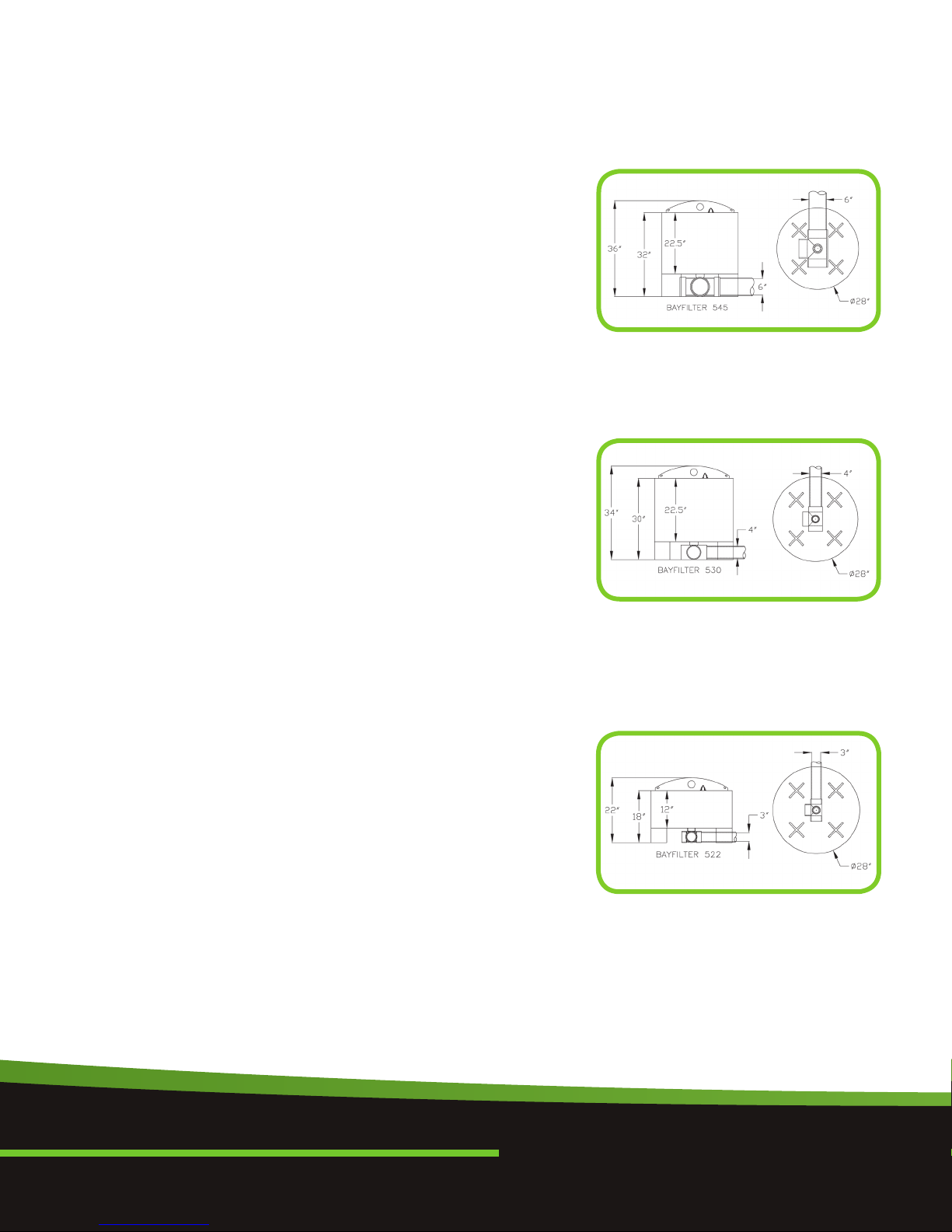

to target specific pollutants. A BayFilter System is typically a concrete structure (precast vault, manhole, or cast

in place structure) with a single or multiple BayFilter cartridges. Inside the structure the BayFilters are connected to

an outlet manifold through which the treated water exits the system.

BayFilter Cutaway

Plan View Profile View

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

4

Stormwater treatment has unique requirements, which

often require the treatment of large volumes of water at

relatively high flow rates to high levels of pollutant removal

with long periods of time between maintenance intervals.

At BaySaver we believe it is our responsibility to engineer

a balance within these variables to provide effective

stormwater treatment at an exceptional value to our clients.

What makes for an effective and efficient stormwater filter?

A filter must be able to remove the pollutants of concern

and function for a reasonable period of time as defined by

industry and regulatory standards. A filter system should also

be designed to limit re-suspension or release of pollutants

that have been collected between maintenance periods.

The traditional pollutants of concern in stormwater is

sediment. Phosphorous, metals, turbidity, nitrogen, fecal

coliform, and bacteria are also pollutants of concern although

they are not commonly regulated nationwide. BaySaver

Technologies has completed both field and laboratory testing

of the BayFilter. Testing demonstrates BayFilter’s effectiveness

and efficiency at capturing the pollutants listed above.

Settling and filtration are the two primary methods to

remove pollutants from stormwater. Some settling of

particles and pollutants occurs as the influent enters the

filter vault. Settling typically removes the larger particles

and debris, it does not remove the small particles or any

dissolved materials. It is the filter which performs the

work of removing the very small particles, and dissolved

nutrients and metals. The media within a filter must be small

enough to intercept the tiny sediment particles which won’t

settle (fig. 1), and be capable of attracting and attaching

charged and elemental particles through ion exchange.

The area of media provided by a stormwater filter is an

important factor to consider when selecting and specifying a

filter system. The more surface area provided by the media,

the greater the potential flow through and across the media

and the greater the pollutant removal potential of the filter.

The vertically oriented and patented compound spiral media

BASIC PRINCIPLES OF STORMWATER FILTRATION

Figure 1: Coarse Industry Media

Figure 2: BayFilter Media

5

configuration of the BayFilter maximizes a media filter’s area

potential. The particle size of the media is also important with

respect to pollutant interception and adsorption. A tightly

packed, fine media (fig 2) captures a greater percentage of

fine and dissolved pollutants when compared to a loosely

packed, coarse media or a membrane media. A fine and

tightly packed media not only minimizes the interstitial

spaces between the media particles to optimize interception

of pollutants, it also maximizes the amount of surface area

in a given volume provided by the media for ion exchange.

The quantity of sediment a filter is capable of capturing is

a significant component to filter longevity. A filter must be

able to treat large quantities of sediment while maintaining

claimed flow rates and removal efficiencies. The sediment

loading capacity of the BayFilter is 350 pounds (158.7 kg) for

the 45 gpm (170.3 lpm) and 30 gpm (113.6 lpm) cartridges.

Surface area and loading rate contribute significantly to filter

longevity. Greater filter surface area (sf) allows for a reduced

loading rate (gpm/sf of filter media), which in turn increases the

service life of the filter. For example, a 10 square foot (0.9 m2)

filter with a loading rate of 1 GPM (3.8 l/min) per square foot

of filter area will pass 10 GPM (37.9 l/min). A 20 ft2filter with a

loading rate of 0.5 GPM (1.9 l/min) per square foot of filter area

will also pass 10 GPM (37.9 l/min). If one gallon of treated water

will occlude one square foot of filter area every 10 days, a 10 ft2

(0.9 m2) filter flowing at one GPM (3.8 l/min) will be expired in

100 days. A 20 ft2(1.9 m2) filter flowing at 0.5 GPM (1.9 l/min)

will be expired in 400 days. Increasing media area and

reducing flow rate has a beneficial impact on pollutant removal

and filter longevity and these are some of the core engineering

principles on which the BayFilter design is based.

BaySaver Technologies is committed to the purpose of

protecting public waterways. Permanently capturing

pollutants, effectively backwashing media, allowing media to

drain between storm events, and providing an economically

reasonable maintenance interval are key design parameters

for properly functioning stormwater filtration systems. The

BayFilter cartridge system helps meet and exceed these

key requirements needed to protect our water resources.

Bottom of Cartridge

Top of Cartridge

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

6

BAYFILTER PRODUCT DETAILS

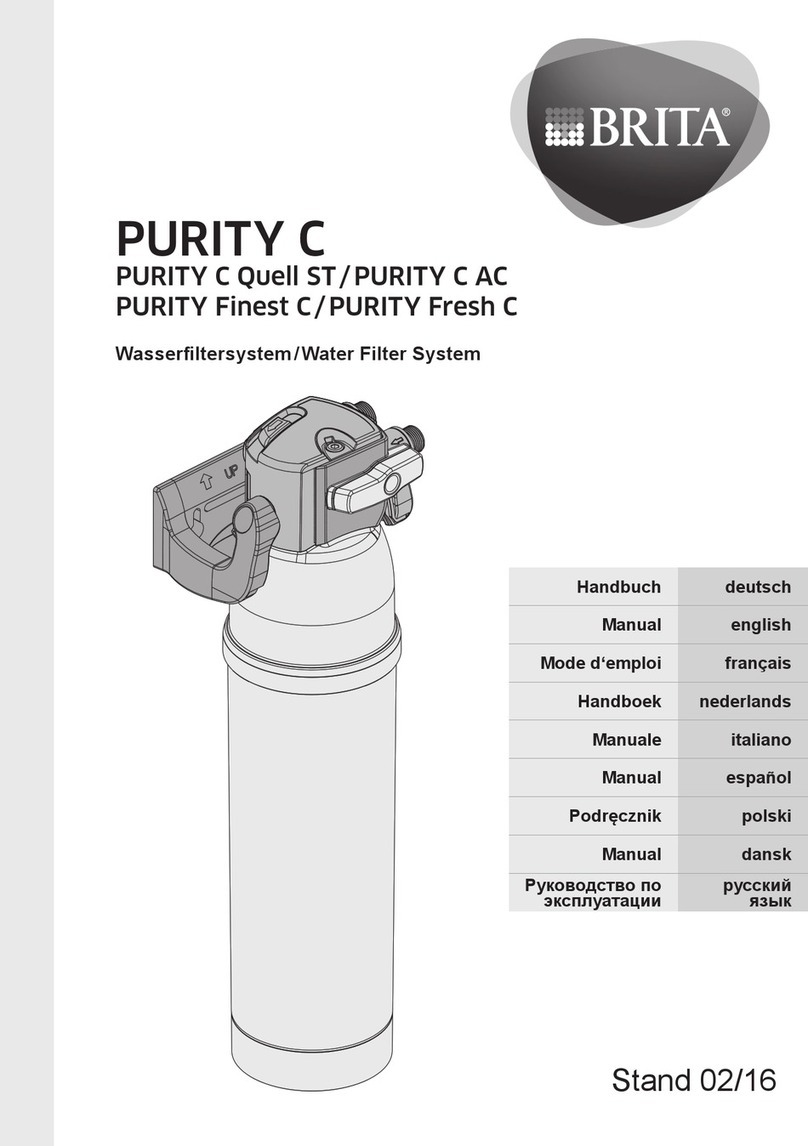

BayFilter 545

Size = 28” (711 mm) diameter

Weight = 250 lbs. (113 kg)

Media Area = 90 ft2(8.4 m2)

Flow Rate = 45 gpm (170 l/min)

Flow Rate per Square Foot = 0.50 gpm/ft2(20 l/min/m2)

Minimum Operational Head = 32” (813 mm)

Recommended Design Head = 34” (864 mm)

Sediment Capture Capacity = 350 lbs (159 kg)

Manifold Diameter = 6” (152 mm)

BayFilter 530*

Size = 28” (711 mm) diameter

Weight = 250 lbs. (113 kg)

Media Area = 90 ft2(8.4 m2)

Flow Rate = 30 gpm (114 l/min)

Flow Rate per Square Foot = 0.33 gpm/ft2(13 l/min/m2)

Minimum Operational Head = 30” (762 mm)

Recommended Design Head = 32” (813 mm)

Sediment Capture Capacity = 350 lbs (159 kg)

Manifold Diameter = 4” (102 mm)

BayFilter 522**

Size = 28” (711 mm) diameter

Weight = 125 lbs. (57 kg)

Media Area = 45 ft2(4.2 m2)

Flow Rate = 22.5 gpm (85 l/min)

Flow Rate per Square Foot = 0.50 gpm/ft2(20 l/min/m2)

Minimum Operational Head = 18” (457 mm)

Recommended Design Head = 20” (508 mm)

Sediment Capture Capacity = 175 lbs (79 kg)

Manifold Diameter = 3” (76 mm) NOTES: The 500 series is for

Total Suspended Solids (TSS) and

Phosphorous and utilizes EMC media.

*BayFilter 530 replaces BFC cartridge.

** BayFilter 522 replaces 545L cartridge.

BayFilter 545

BayFilter 530

BayFilter 522

7

BayFilter 645

Size = 28” (711 mm) diameter

Weight = 250 lbs. (113 kg)

Media Area = 90 ft2(8.4 m2)

Flow Rate = 45 gpm (170 l/min)

Flow Rate per Square Foot = 0.50 gpm/ft2(20 l/min/m2)

Minimum Operational Head = 32” (813 mm)

Recommended Design Head = 34” (864 mm)

Sediment Capture Capacity = 350 lbs (159 kg)

Manifold Diameter = 6” (152 mm)

BayFilter 630

Size = 28” (711 mm) diameter

Weight = 250 lbs. (113 kg)

Media Area = 90 ft2(8.4 m2)

Flow Rate = 30 gpm (114 l/min)

Flow Rate per Square Foot = 0.33 gpm/ft2(13 l/min/m2)

Minimum Operational Head = 30” (762 mm)

Recommended Design Head = 32” (813 mm)

Sediment Capture Capacity = 350 lbs (159 kg)

Manifold Diameter = 4” (102 mm)

BayFilter 622

Size = 28” (711 mm) diameter

Weight = 125 lbs. (57 kg)

Media Area = 45 ft2(4.2 m2)

Flow Rate = 22.5 gpm (85 l/min)

Flow Rate per Square Foot = 0.50 gpm/ft2(20 l/min/m2)

Minimum Operational Head = 18” (457 mm)

Recommended Design Head = 20” (508 mm)

Sediment Capture Capacity = 175 lbs (79 kg)

Manifold Diameter = 3” (76 mm)

NOTES: The 600 series is for enhanced

metals treatment.

BayFilter 645

BayFilter 630

BayFilter 622

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

8

Stormwater runoff enters the manhole or concrete structure

via an inlet pipe and begins to fill the structure. When the

water surface elevation in the vault/manhole reaches the

minimum operating level, water flows through the BayFilter

driven by a hydrostatic head. Within the BayFilter, the water

flows through a proprietary filter media and drains via a

vertical pipe. The vertical pipe is connected to the under

drain system, which conveys filtered water to the outfall.

During a typical storm event, the BayFilter

system has four cycles:

A. BayFilter cartridge fills and releases air

B. Positive head filtration

C. Siphon (negative head) filtration

D. Siphon break and hydrodynamic backwash

The cycle operation of a BayFilter is as follows:

A. BayFilter cartridge fill and air release: The BayFilter vault

and BayFilter cartridges fill when stormwater flow enters

the system. As the vault fills, water enters the BayFilter

cartridge through the inlet plate on the bottom. Air is

purged from the media spiral and filter housing during

this process.

The air release is critical for the proper functioning of the

siphon. The siphon draws flow through the BayFilter

during periods of low water in the vault.

BAYFILTER OPERATION

BayFilter Cutaway

BayFilter Vault

Cartridge Filling

9

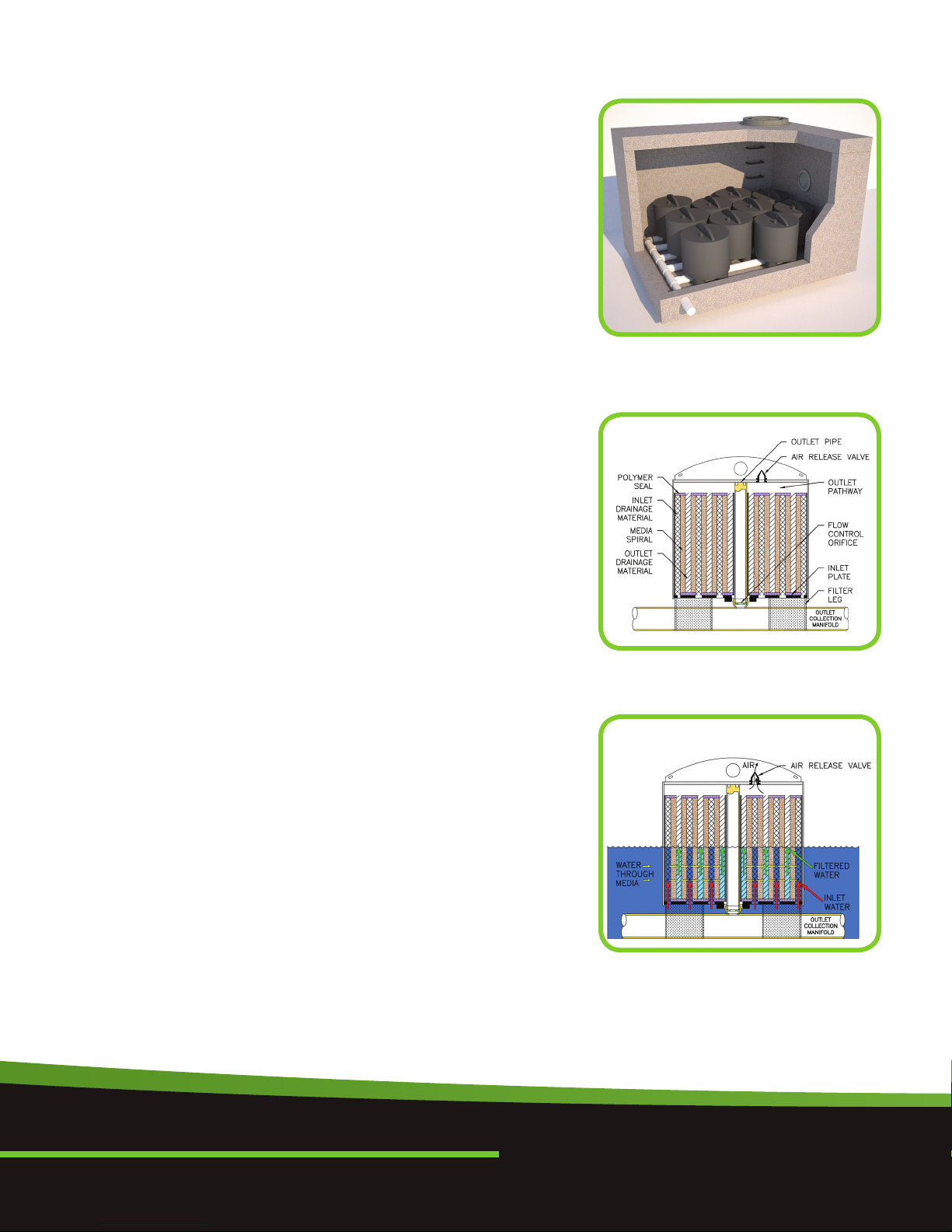

B. Positive Head Filtration: Water enters the Filter from the

bottom of the filter housing and travels upward through

the inlet-flow conduit-spiral. From the inlet spiral,

untreated water flows horizontally through the

engineered media. Treated water exits the engineered

media and flows into the outlet-flow conduit-spiral.

Treated water flows vertically to the top of the cartridge

where it can exit through the outlet pipe—please see

product details (pg.6) for operating head levels. Finally,

filtered water leaves the system via the outlet.

C. Siphon (Negative Head) Filtration: After the water level in

the vault falls below the top of the filter cartridge-

minimum operating head level, a siphon is established

and water will continue to flow through the filter media

until the siphon is broken. During siphon, the water level

in the vault will decrease until it reaches the inlet plate

of the BayFilter.

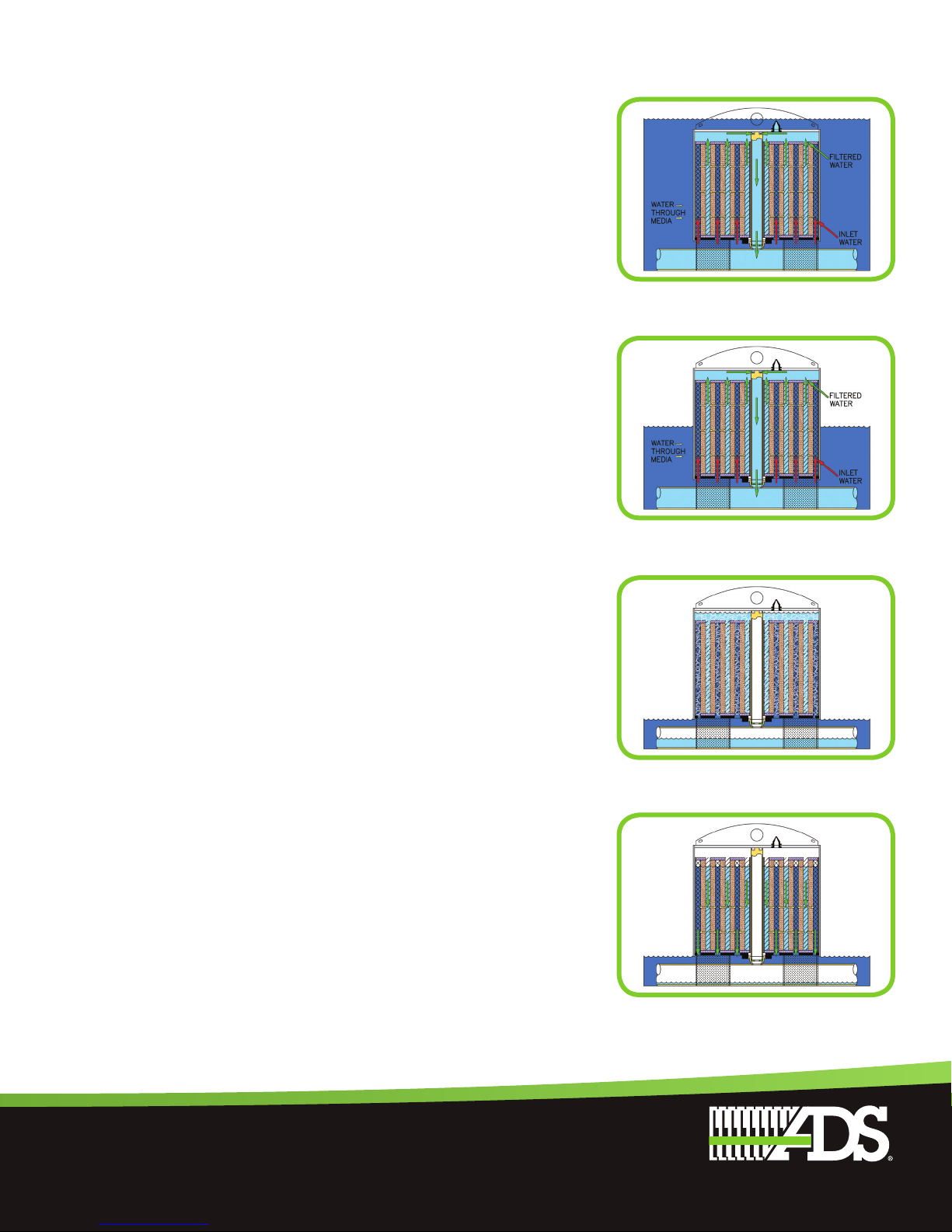

D. Siphon Break and Hydrodynamic Backwash: When

the water level drops below the inlet plate, air enters

the filter and the siphon breaks. Once the siphon breaks,

a gravity-driven backwash occurs with all of the water

flowing from the outlet pathway backwards through the

filter media. This backwash has the effect of dislodging

particles captured in the filtration layers and

re-establishing porosity. Dislodged particles are

transported back in to the filter vault and accumulate

on the filter vault floor.

Each BayFilter has a maximum flow rating. At this flow,

each cartridge can treat the specified total sediment

load before requiring maintenance. BayFilter flow may

also be custom regulated to meet specified design

parameters by modifying the flow control orifice. Please

contact BaySaver for custom design requirements.

Backwash

Siphon Filtration

Siphon Break

Positive Filtration

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

10

The BayFilter cartridge system design is easily

completed in four phases:

A. BayFilter System Configuration

B. BayFilter Site Plan Placement

C. BayFilter System Sizing

D. Final Check

The design process can be iterative until the determined

design parameters are satisfied. Some of the items to

consider when designing a stormwater filtration system:

•Site specific constraints and proposed

BayFilter system location

•BayFilter system configuration—on-line or off-line

•Pretreatment requirements

•Operating head

•Treatment efficiency requirements and local regulations

•Pollutant loading (sediment load)

•Treatment flow rates and hydraulics

•Maintenance intervals

BAYFILTER SYSTEM CONFIGURATION

BayFilter systems can accommodate any treatment

flow requirement. The peak design flow through the

storm drain system will be significantly greater than

the treatment design flow through BayFilter. It is a best

practice to only convey the required treatment flow

through a stormwater filter and this will extend the filter’s

life cycle. Conveying the peak design flow around a

stormwater filter is considered off-line treatment.

Off-Line Design

Schematics of off-line BayFilter systems are shown below.

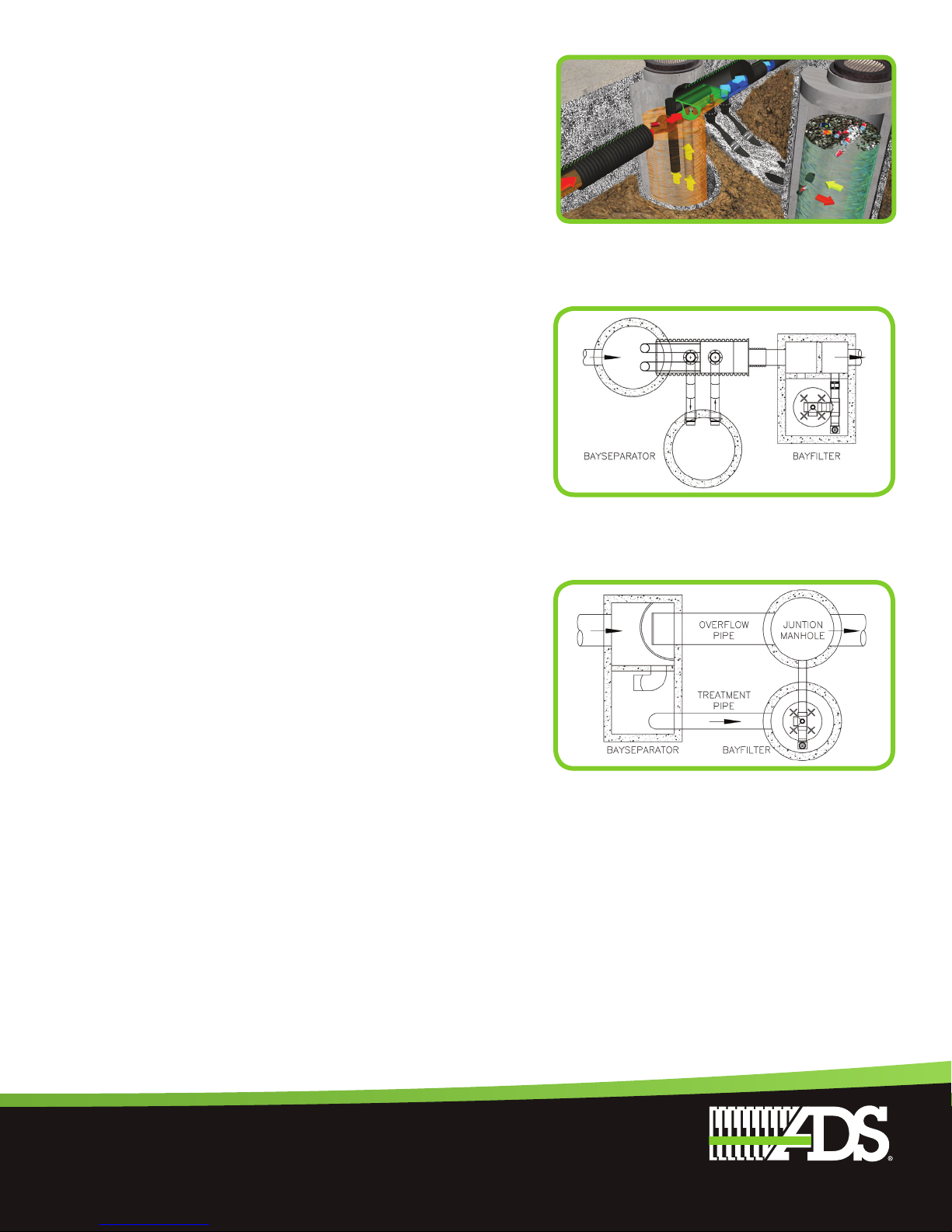

In Figure 1, the bypass structure diverts treatment flows to

the BayFilter system and allows high flows to pass to a

separate outfall. The bypass structure will feature flow

controls designed by an engineer to ensure that the required

treatment flows are sent to the BayFilter. In Figure 2, this

same concept is accomplished within a 3-chamber vault.

In stormwater filter system installations, sediment

will accumulate in the filter cartridge and on the vault

floor. In off-line installations, high intensity flows are

routed away from the vault minimizing the risk of re-

suspending the sediment accumulated on the vault

floor. In online applications it is possible for high

flows to mobilize and release this sediment.

BAYFILTER SYSTEM DESIGN & SIZING

Figure 1: Offline Configuration

External Bypass

Figure 2: Inline Configuration

Internal Bypass

11

Operating Head

Head is required to activate BayFilter flow and establish

siphon flow. The height of individual BayFilter cartridges

will determine the operating head. Please consult

product details for individual operating head levels. The

drainage system and network does not need to provide

the operating head. Filter systems can easily be designed

on sites where the elevation drop of the hydraulic grade

line is less than the required operating head of the filter.

Consult BaySaver Technologies Engineering Department

for verification based on your particular site conditions.

Pretreatment

Regional regulations may require pretreatment of

stormwater flows prior to flow entering filters. Pretreatment

will remove a portion of the influent pollutant load. This

will lessen the pollutant load received by a filter and

potentially increase the maintenance interval duration.

The BaySeparator™ system (Figures 3 & 4) is an ideal

hydrodynamic separator that removes sediments and

floatables from stormwater runoff. Please contact your

ADS representative for additional pre-treatment options.

BAYFILTER SITE PLAN PLACEMENT

Locating a BayFilter system on your site will be determined

by giving consideration to several factors including:

maintenance access, the unit’s footprint, available head,

available depth, and the surface elevation of the receiving

waters. A BayFilter system must be installed in an area that

is accessible to maintenance equipment. The maintenance

of a BayFilter system requires a vacuum truck as well as

the removal and replacement of the filter cartridges. The

manhole covers, and or access hatches of the BayFilter

must be placed in locations that can be easily reached

by such a vehicle. Consult the BaySaver Technologies

Engineering Department for expert assistance.

Traditional BaySeparator

Figure 4: BaySeparator FS Unit

Pre-Treatment Configuration

Figure 3: Traditional BaySeparator

Pre-Treatment Configuration

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

12

BayFilter System Sizing

Each BayFilter system relies on a collection of individual

BayFilter cartridges to achieve the desired removal

efficiency. Accurately determining the required

number of filters is important to efficient operation.

Undersizing a system may lead to shorten service life.

A valuable stormwater treatment system will

be provided when the three design parameters

listed below are given consideration.

•Jurisdiction – specific sizing requirements

•Flow capacity of the system

•Treated sediment load of the system

Each parameter results in a required number of BayFilter

cartridges. After computing the number of filters for each

parameter, determine which requires the most filters, and

this is is the limiting design parameter and the number

of required BayFilter cartridges for your drainage area.

Jurisdiction

Local regulatory requirements play a significant role

in any BayFilter design. Depending on the jurisdiction

in which the project site is located, the engineer may

have to meet minimum treatment flow rates, treatment

volumes or some other criteria such as filter bed area.

Some jurisdictions specify a methodology for calculating

a minimum treatment flow rate for a given site.

Flow Capacity

Regulatory requirements will determine water quality

treatment values. The BayFilter system is simply applied by

the design professional to their computed values. Typically,

the primary treatment value is treatment flow rate (QTRT).

This value tells us the rate at which flow must pass through

a filter system. Other common treatment values are water

quality volume and phosphorous load reduction. Please

contact BaySaver Technologies Engineering Department

when designing to volume or phosphorous requirements.

The minimum number of BayFilter cartridges can be

determined by dividing the treatment flow rate by flow

rate of the BayFilter you have chosen. This calculation

provides the minimum number of BayFilters that will be

necessary to fully treat the water quality flow from the

site. The step-by-step procedure is shown below.

BayFilter

Cartridge

Treatment

Flow Rate

gpm (l/min)

Treatment

Volume

f3(m3)

522 22.5 (85.1) 1250 (35.4)

530 30.0 (113.6) 2500 (70.8)

545 45.0 (170.3) 2500 (70.8)

BayFilter

Cartridge

Treatment

Flow Rate

gpm (l/min)

Treatment

Volume

f3(m3)

622 22.5 (85.1) 1250 (35.4)

630 30.0 (113.6) 2500 (70.8)

645 45.0 (170.3) 2500 (70.8)

BayFilter Series 500

System Sizing Table

BayFilter Series 600

System Sizing Table

13

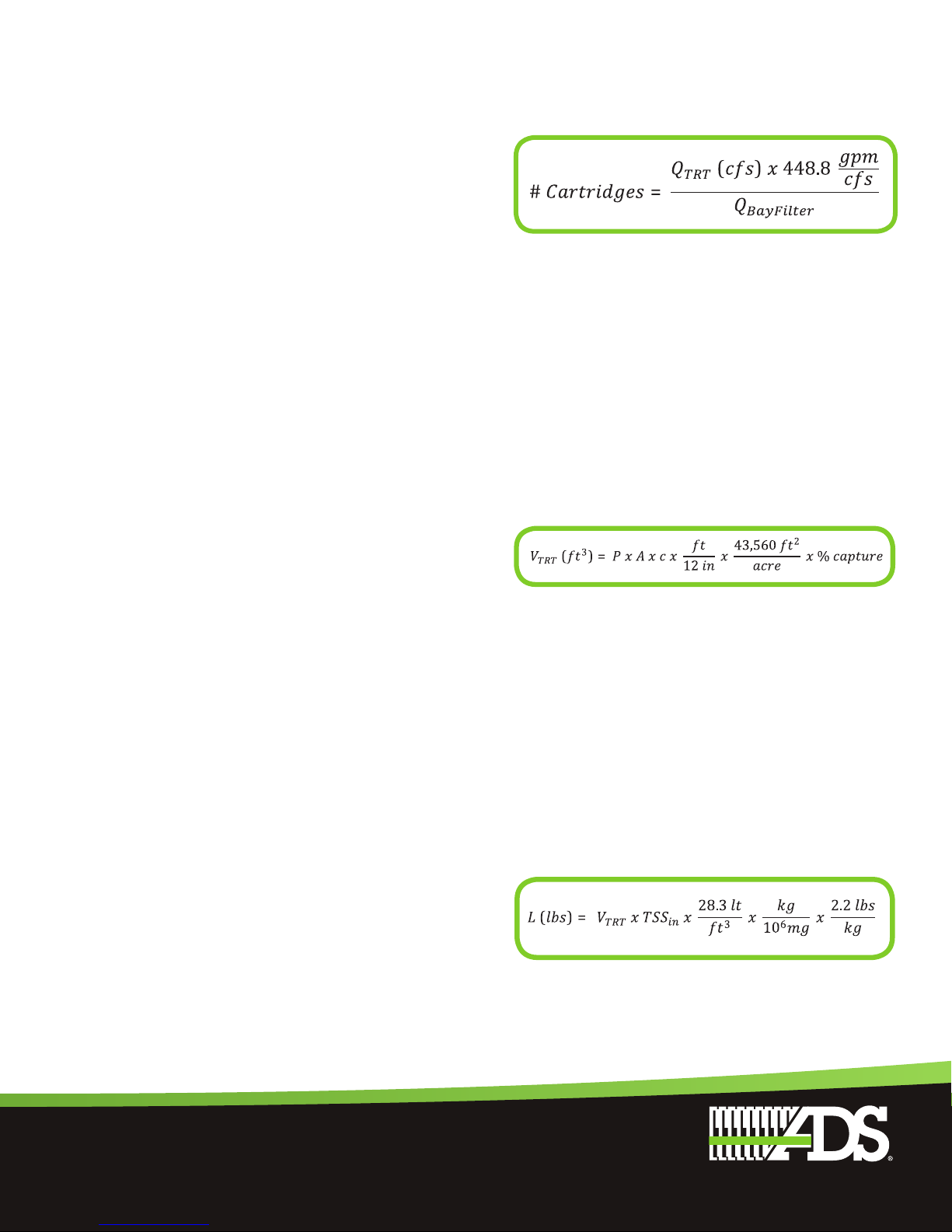

1. Determine the required treatment flow rate (QTRT)

based on locally approved methodologies for

the project site. This may involve the use of the

Rational Method, TR-55 or another locally specified

hydrologic model. If a locally approved methodology

is not specified, BaySaver Technologies recommends

using one of these commonly accepted models.

2. Using the BayFilter cartridge treatment flow rate

(QBayFilter), calculate the minimum numbers of BayFilter

cartridges required to treat that flow using Equation 1.

Refer to the product details for BayFilter flow rates.

The minimum number of BayFilter cartridges is

equal to the maximum treatment flow rate divided by

QBayFilter, rounded up to the next whole number.

Sediment Load Capacity

BayFilter sediment load capacity allows the professional

designer to establish the maintenance interval for the

stormwater system. Establishing a sediment load is a

straight forward computation which may be completed

once the number of BayFilter cartridges required to

treat the flow is known. With the known filter quantity, a

designer will establish the sediment load capacity for the

BayFilter system, and compare this value to the annual

sediment load for the site. The following equations may

be used to compute these values and help determine

BayFilter suitability for a specific site design.

Sediment Load Capacity Calculations

1. Calculate the annual treated runoff volume according

to Equation 2. VTRT is the annual treated runoff

volume, Pis the average annual precipitation (in

inches), Ais the area of the site (in acres), c is the

runoff coefficient of the site (c is dimensionless), and

% Capture is the fraction of the total annual runoff

that is treated by the stormwater quality system. If %

Capture is not otherwise specified, a default value of

0.90 can be used. Please check local regulations.

2. Using the annual treated runoff volume, calculate the

anticipated total system sediment load to BayFilter

according to Equation 3. In Equation 3, Lis the mass

of sediment that BayFilter is exposed to annually

(in pounds), VTRT is the annual treated runoff volume

as calculated in step 1 (in ft3), and TSSIN is the

influent concentration of TSS in the runoff (in mg/L).

The influent TSS concentration (TSSIN) depends

greatly on the site and the surrounding land use.

In the absence of readily available data, BaySaver

Technologies recommends using a minimum event

mean concentration (EMC) TSS value of 60 mg/l.

The impact on the filter cartridge will also be less if

Equation 1

Equation 2

Equation 3

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

14

the filtration system is preceded by pretreatment. In

these cases, the influent TSS to the BayFilter system

need to be reduced to reflect pretreatment sediment

removal. The BaySaver Technologies’ Engineering

Department can assist with these calculations.

3. Once the total annual system sediment load (L) is

calculated, the engineer must ensure that the number

of cartridges specified will be able to remove that

sediment load at the specified design flow rate. Divide

the total system sediment load L by the capacity

of each BayFilter and note the associated BayFilter

flow rate. Round up to the next whole number to get

the minimum number of BayFilters required. This

quantity of BayFilters will need to treat this sediment

load at the required flow rate per BayFilter. The

BaySaver Technologies Engineering Department is

available to assist with the required calculations.

FINAL CHECK

It may be beneficial to perform a Final Check on the

BayFilter design for your site. The BaySaver Engineering

Department is available to assist you with this function.

Standard Details and Notes

Standard details are available on the Website at

www.BaySaver.com or by calling 1.800.229.7283.

BayFilter Configurations

BayFilter Systems include the four typical concrete

structures: manhole, precast vault, box culvert, and cast

in place. BaySaver Technologies can also design BayFilter

systems with Nyloplast structures, and HP Pipe manholes.

BayFilter systems in manholes have a small footprint

and easily fit into site plans. Manhole BayFilter systems

are ideal for applications downstream from water quality

detention structures. Please consult with the BaySaver

Technologies Engineering Department for more details.

When designing access for a BayFilter utilizing manhole

frame and covers a minimum of 30” (762) diameter

should be used, however, it is recommended that a

36” (914) diameter opening is used to provide ample

access for filter replacement and maintenance. In each

BayFilter system, the BayFilters are arranged so that

a maintenance worker can stand on the floor of the

manhole while installing or removing the cartridges.

Example of a manhole

BayFilter system

Example of a precast

vault BayFilter system

15

INSTALLATION

Note: BayFilters are not recommended to be used as

erosion control during site construction operations.

BayFilters should remain offline or uninstalled until site

stabilization has occurred. Please contact your local

ADS or BaySaver representative if you should have any

questions.

1. Contact utility locator to mark any nearby underground

utilities and make sure it is safe to excavate.

2. Reference the site plan and stake out the location of the

BayFilter manhole/vault.

3. Excavate the hole, providing any sheeting and shoring

necessary to comply with all federal, state and local

safety regulations.

4. Level the subgrade to the proper elevation. Verify the

elevation against the manhole/vault dimensions, the

invert elevations, and the site plans. Adjust the base

aggregate, if necessary.

5. Have the soil bearing capacity verified by a licensed

engineer for the required load bearing capacity. On solid

subgrade, set the first section of the BayFilter manhole/

vault.

6. Check the level and elevation of the first section to

ensure it is correct before adding any riser sections.

7. If additional section(s) are required, add a watertight

seal to the first section of the BayFilter manhole/vault.

Set additional section(s) of the manhole/vault, adding a

watertight seal to each joint.

8. Install the outlet pipe in BayFilter manhole/vault.

9. Install the inlet pipe to the BayFilter manhole/vault.

10. Install the trolley system (if applicable).

a. Attach the mounting brackets to the track.

b. Each track is split in sections. The length and

number of sections vary depending on the vault.

It is generally better to start installing longer track

sections first. Hold a section in place and align the

top of the brackets with the ceiling of the vault. Mark

the center of the hole in each bracket and remove the

track.

c. Using a hammer drill and ¼” (6 mm) bit, drill a hole

approximately 3” (76 mm) deep at each mark.

d. Hold the track back in place and realign the brackets

with the holes. Place a plastic spacer block behind

each bracket and using the supplied ¼” (6 mm) x 3¼”

(83 mm) anchor bolts mount the track in place. Only

install one section of track at this stage.

Modular Vault Assembly

Vault End Section

Trolley System

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

16

e. Repeat this procedure on the opposite wall of the

vault directly across from the first section.

f. Bolt the 4 trolleys to the aluminum I-beam as shown

in the attached diagram. Make sure that the wheels

for each trolley are mounted an equal distance from

the top of the I-beam.

g. Lift the I-beam in to place and insert the trolleys in to

the track.

h. Using the supplied couplers, install the second

sections of track via the same procedure. Continue

until the track runs the length of the vault or as

designed.

11. Install the PVC manifold. Glue all PVC joints with the

exception of the BayFilter cartridge coupling. See Parts

List drawing.

12. After the site has stabilized, remove any accumulated

sediment or debris from the vault.

13. Install the Bayfilter Vertical Drain Down Modules (VDDM)

to the manifold system (if applicable).

14. Install a row of flow disks and the BayFilter cartridges.

Place each cartridge so the handle points across the

vault. Make sure the air valve is on the side closer to the

outlet.

15. Place one full set of one Hold Down Bar and two Retainer

Brackets into place. Mark and drill two 5/8” holes for

each bracket. After fully anchoring Retainer Brackets,

place the left end of the Hold Down Bar in position. Slide

right end into bracket and secure with U-Bolt.

16. Repeat steps 14 and 15 for each set of BayFilter

Cartridges and Hold Down Bar until the whole system

is installed. See Parts List drawing for Hold Down Bar

placement.

Tool List

• PVC glue and primer

• Crane/lifting mechanism to lower the cartridges in the

vault (each cartridge weighs 230-350 lbs (104-159))

• Screwdriver or nut driver for Fernco®couplers

• Hammer and soft blow hammer

• Saw (in case PVC Sch 40 piping

length needs to be adjusted)

• Hammer drill

• ¼” (6 mm) and 5/8” (16 mm) concrete drill bit

• ¾” (19 mm) wrench

Filter Tee

Flow Disc

Chain Hoist System

BayFilter Vault Overview

Drain Down Module

Filter Placement

Hold Down Bar

and Bracket

Vault Internal Assembly

17

Pre-Assembled Manifold

In some areas the vaults can be provided with pre-in-

stalled manifold systems. Please contact your local ADS

or BaySaver representatives for additional details.

Inspection and Maintenance

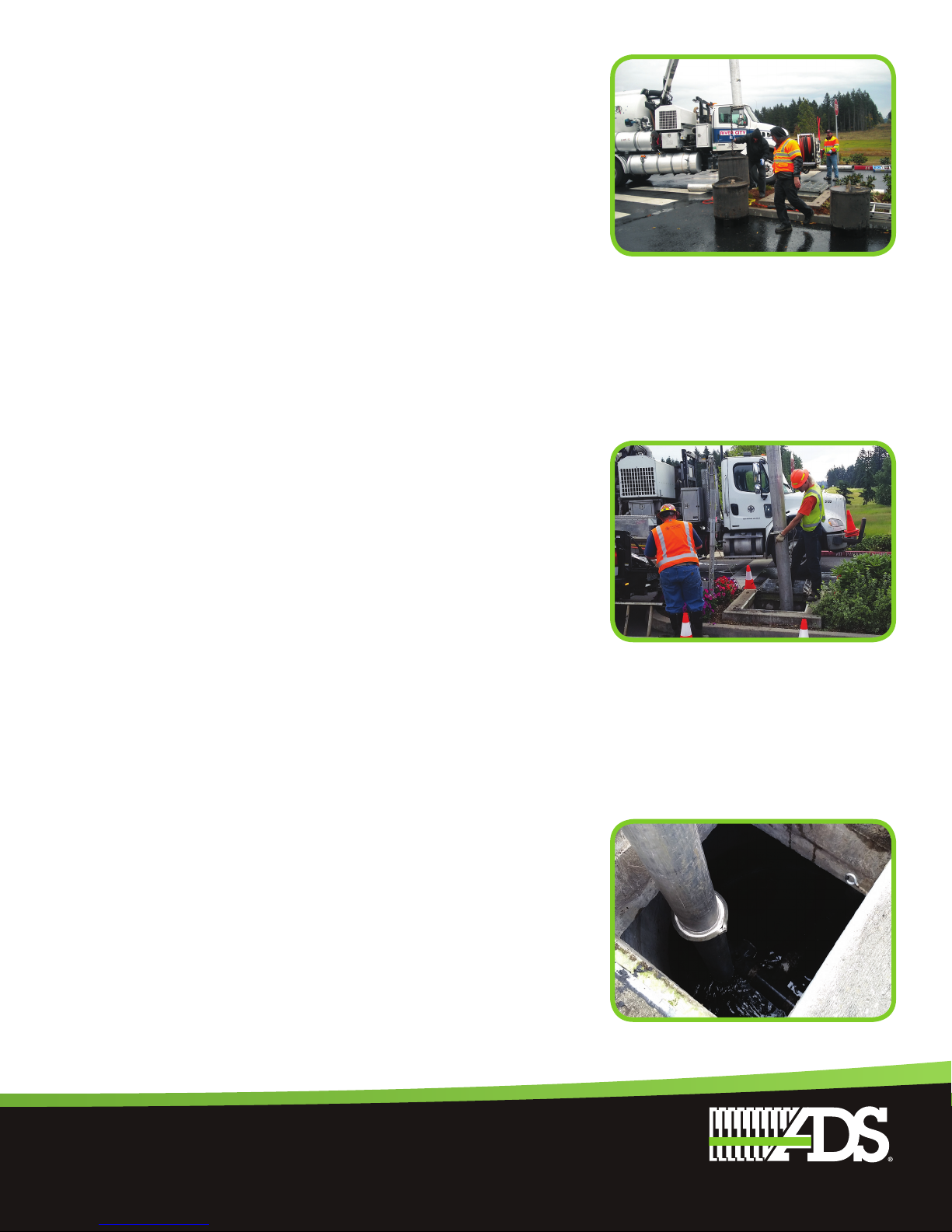

The BayFilter system requires periodic maintenance

to continue operating at the design efficiency. The

maintenance process is comprised of the removal

and replacement of each BayFilter cartridge,

vertical drain down module; and the cleaning of

the vault or manhole with a vacuum truck.

The maintenance cycle of the BayFilter system will be

driven mostly by the actual solids load on the filter. The

system should be periodically monitored to be certain

it is operating correctly. Since stormwater solids loads

can be variable, it is possible that the maintenance cycle

could be more or less than the projected duration.

BayFilter systems in volume-based applications

are designed to treat the WQv in 24 to 48 hours

initially. Late in the operational cycle of the BayFilter,

the flow rate will diminish as a result of occlusion.

When the drain down exceeds the regulated

standard, maintenance should be performed.

When a BayFilter system is first installed, it is recommended

that it be inspected every six (6) months. When the filter

system exhibits flows below design levels the system should

be maintained. Filter cartridge replacement should also

be considered when sediment levels are at or above the

level of the manifold system. Please contact the BaySaver

Technologies Engineering Department for maintenance

cycle estimations or assistance at 1.800.229.7283.

Maintenance Procedures

1. Contact BaySaver Technologies for replacement filter

cartridge pricing and availability at 1-800-229-7283.

2. Remove the manhole covers and open all

access hatches.

3. Before entering the system make sure the air

is safe per OSHA Standards or use a breathing

apparatus. Use low O2, high CO, or other applicable

warning devices per regulatory requirements.

4. Using a vacuum truck remove any liquid and

sediments that can be removed prior to entry.

5. Using a small lift or the boom of the vacuum truck,

remove the used cartridges by lifting them out.

6. Any cartridges that cannot be readily lifted

can be easily slid along the floor to a location

BayFilter System Cleanout

Vactor Truck Maintenance

Jet Vactoring Through Access Hatch

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

18

they can be lifted via a boom lift.

7. When all the cartridges have been removed, it is

not practical to remove the balance of the solids

and water. Loosen the stainless clamps on the

Fernco couplings for the manifold and remove

the drain pipes as well. Carefully cap the manifold

and the Ferncos and rinse the floor, washing away

the balance of any remaining collected solids.

8. Clean the manifold pipes, inspect, and reinstall.

9. Install the exchange cartridgess and close all covers.

10. The used cartridges may be sent back to

BaySaver Technologies for recycling.

BayFilter Availability and Cost

BayFilter systems are available throughout the

United States from BaySaver Technologies. Material,

installation, and maintenance costs vary with location.

For BayFilter pricing in your area, please contact

BaySaver Technologies at 1-800-229-7283.

BayFilter cartridges and outlet components can be

shipped anywhere in the world. Manholes and precast

vaults are also supplied by BaySaver Technologies as

part of a complete stormwater filtration system.

BayFilter Specifications

Products

A. Internal components: all components including

concrete structure(s), PVC manifold piping

and filter cartridges, shall be provided by

BaySaver Technologies 1-800-229-7283).

B. PVC manifold piping: all internal PVC pipe and

fittings shall meet ASTM D1785. Manifold piping

shall be provided to the contractor pre-cut and/or pre-

assembled. Minor field modifications may be necessary.

C. Filter cartridges: external shell of the filter cartridges

shall be substantially constructed of polyethylene

or equivalent material acceptable to the manufacturer.

Filtration media shall be arranged in a spiral layered

fashion to maximize available filtration area. An orifice

flow control (i.e. flow disk) shall be supplied with each

cartridge to restrict the flow rate to a maximum of

45 gpm (170 l/min).

D. Filter media: filter media shall be a proprietary mix

produced by BaySaver Technologies and may consist

of the following materials: zeolite, perlite, and activated

alumina and/or other materials required to meet the

project pollutant removal requirements.

Manifold Tee View of a Cleaned System

Cartridge Hoist Point

19

E. Precast concrete vault: concrete structures shall be

provided according to ASTM C478, C858, and C913.

The materials and structural design of the devices shall

be per ASTM C478 and ACI 318. Precast concrete shall

be provided by BaySaver Technologies.

Performance

A. The stormwater filter system shall be capable of

treating 100% of the required treatment flow at full

sediment load conditions.

B. The stormwater filter system’s cartridges shall have

no moving parts.

C. The stormwater treatment unit shall be designed to

remove a minimum of 80% of suspended solids,

60% of total phosphorus, 50% of turbidity, 40% of total

copper, and 40% of total zinc. All filter designs shall

comply with local regulations.

D. The stormwater filtration system shall not have any

components that leach nitrates, phosphates or metals.

E. The stormwater filtration cartridge shall be equipped

with a hydrodynamic backwash mechanism to extend

the filter’s life and optimize its performance.

F. The stormwater filtration system’s cartridges shall have

a treated sediment capacity for 80% TSS removal

between 150-350 lbs (68-159 kg).

When BayFilter is initially installed, we recommend

that an inspection be performed on the system in the

first six (6) months. After that, the inspection cycle

typically falls into an annual pattern given normal

storm occurrence and actual solids loads.

When BayFilter exhibits flows below design levels,

the system should be inspected and maintained as

soon as practical. If flow monitoring is not available,

BayFilter cartridges should be replaced when sediment

levels are at or above the top of the manifold.

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

20

1-800-821-6710 www.ads-pipe.com

1-800-229-7283 www.baysaver.com

ADS “Terms and Conditions of Sale” are available on the ADS website, www.ads-pipe.com

The ADS logo and the Green Stripe are registered trademarks of Advanced Drainage Systems, Inc.

BayFilterTM is a registered trademark of BaySaver Technologies, Inc.

© 2018 Advanced Drainage Systems, Inc. #10951 01/18 MH

The MosT ADVANCED NaMe iN WaTer MaNageMeNT soluTioNsTM

Table of contents