3

2. IMPORTANT INFORMATION

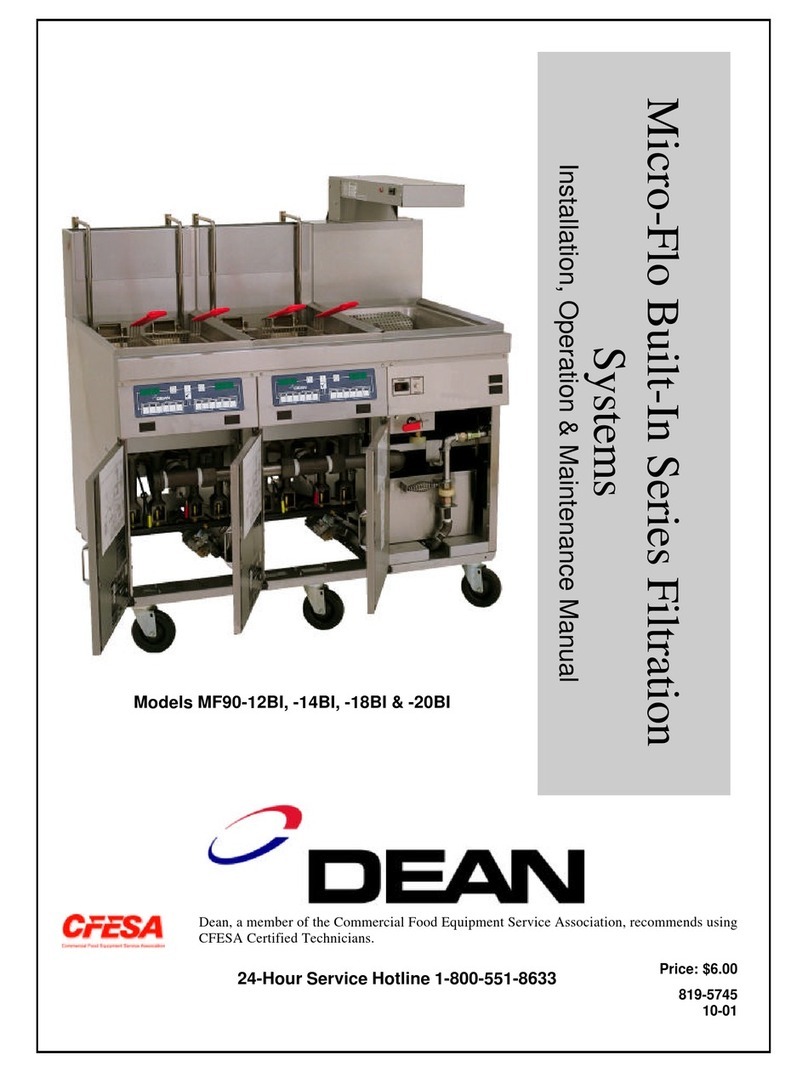

2.1 GENERAL:The MF-90 portable oil

filters may be used with a variety of Dean

fryers, as well as other manufacturers’

equipment.

The used oil may be drained by gravity

(MF90-U/110) from the fryer into the

filter pan, or, on some models, MF90-

AU/110, removed from the fryer by use of

a suction/return hose. It is then pumped

back into the fryer vessel by means of the

suction/return hose and nozzle assembly.

Filtering is accomplished through two

sheets of replaceable filter paper assisted

by a micro pre-coat filter powder.

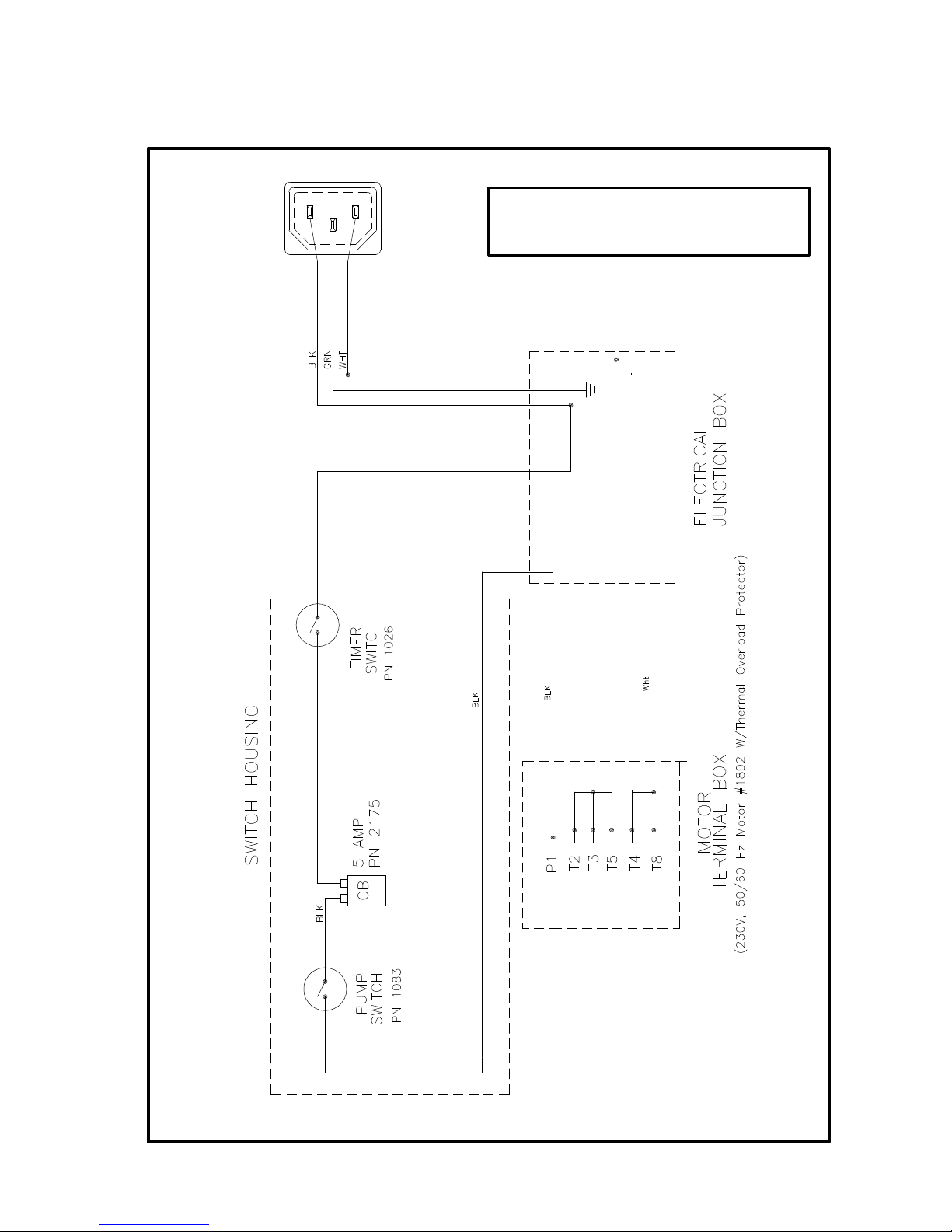

2.2 OPERATING CONTROLS:

Two types of portable filters are available.

The most common is “return only”.

Primary filter control on the MF90-U/110

model is a two-position switch (on/off), or

on units with the optional heater, a three-

position switch (on/off/heater) is used.

The other type is “suction/return”.

Control on the MF90-AU/110 is by a

three-position switch (in/off/out). A pair

of swing-type check valves controls the

direction of oil flow. If any of these units

has an optional pan heater, the heater

switch is also mounted on the panel.

In many cases, a 60-minute timer may also

be activated to start the unit.

2.3 SAFETY FEATURES: On the

larger capacity filters, a 5-amp (230V) or a

7-amp (115V) circuit breaker switches the

power OFF if an overload occurs.

NOTE:If circuit breaker is triggered, depress

the reset button to activate the circuit

after the failure has been detected and

fixed.

2.4 RATING PLATE:Information on

this plate includes the model and serial

numbers as well as electrical requirements.

This data is essential when contacting the

factory about a unit or ordering special

parts.

2.5 PRE-INSTALLATION:

a. STANDARDS: Usage of this filter

unit must be in accordance with all

applicable state and local codes.

b. ELECTRICAL CONNECTIONS:

This unit requires connection to a

230V, 15 amp electrical supply. The

unit is equipped with a 3-wire, 16

AWG power cord. If an extension

cord must be used, it must be a three

conductor, grounded power cord of at

least 16 AWG.

2.6 UNPACKING THE FILTER:

Before unpacking, make certain the

container is upright. Unpack the filter

carefully and remove all accessories from

the carton, being careful not to discard or

misplace any parts, as they will be needed.

Loose parts include a starter kit and

accessories that may have been ordered.

These are packaged inside the filter tank.

The tank top is strapped to the shipping

frame.

After unpacking, immediately check the

equipment for visible signs of shipping

damage. If such damage has occurred,

contact the carrier and file the appropriate

freight claims. Do not contact the factory,

the responsibility of shipping damage is

between the carrier and the dealer or end-

user.

CAUTION

The on-site supervisor is responsible for

ensuring that operators are made aware of the

inherent dangers of operating a hot oil filter

system, particularly aspects of oil filtration,

draining, and cleaning of the filter.