BBT BBT-BC-26CCBH User manual

OWNER’S MANUAL

Assembly & Operating Instructions

MODEL NO. BBT-BC-26CCBH

BBT-BC-26CCDH

BBT-BC-52CCBH

BBT Brush Cutter

2WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

To The Owner

Thank you for purchasing our Brush Cutter. It was carefully engineered to provide excellent performance when

properly operated and maintained.

Please read this entire manual prior to operating the Brush Cutter. It instructs you how to safely and easily set

up, operate and maintain your Brush Cutter. Please be sure that you and any other persons who will operate

the Brush Cutter carefully follow the recommended safety practices at all times. Failure to do so could result in

personal injury or property damage.

All information in this manual is relative to the most recent product information available at the time of printing.

Review this manual frequently to familiarise yourself with the machine, its features and operation. Please be

aware that this Owner’s Manual may cover a range of product specifications for various models. Characteristics

and features discussed and/or illustrated in this manual may not be applicable to all models. We reserve the right

to change product specifications, designs and equipment without notice and without incurring obligation.

All the power testing information used to establish the power rating of the engine equipped on this Brush

Cutter can be found in the engine manufacturer’s manual or website. If you have any problems or questions

concerning the machine, please contact our Customer Support Department.

Throughout this manual, all references to right and left side of the Brush Cutter are observed from the operating

position. The engine manufacturer is responsible for all engine-related issues with regards to performance,

power-rating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s Manual

packed separately with your Brush Cutter for more information.

Customer Support

Please do NOT return the Brush Cutter without first contacting the Customer Support Department at

If you have difficulty assembling this product or have any questions regarding the controls, operation, or

maintenance of this Brush Cutter, please contact our Customer Support Department.

SAVE THESE INSTRUCTIONS

3

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

TABLE OF CONTENTS

Page(s)

To The Owner.........................................................................................................................................................2

Customer Support..................................................................................................................................................2

TABLE OF CONTENTS .............................................................................................................................3

IMPORTANT SAFETY INFORMATION ................................................................................................. 4-5

Additional Information and Potential Changes...................................................................................................4

Key to Symbols.......................................................................................................................................................5

GENERAL SAFETY RULES ................................................................................................................... 6-7

PARTS LOCATION....................................................................................................................................8

ASSEMBLING .................................................................................................................................... 9-10

Installing Plastic Shield ..........................................................................................................................................9

Blade Installation ...................................................................................................................................................9

Installing Bull Horn Handle ................................................................................................................................10

Installing D–Handle .............................................................................................................................................10

RULES OF SAFE OPERATION .......................................................................................................... 11-15

Danger Zone - An Area 15 Metres in Radius......................................................................................................11

Cutting with a Nylon Head..................................................................................................................................12

Cutting with a Blade............................................................................................................................................14

PREPARING FOR OPERATIONS ....................................................................................................... 16-17

Engine Safety Precautions...................................................................................................................................16

Burns and Fires.....................................................................................................................................................16

Fuel & Oil Mixture................................................................................................................................................17

OPERATIONS.........................................................................................................................................18

Engine Starting and Stopping Procedures .........................................................................................................18

Hot Restart ...........................................................................................................................................................18

Emergency Stop ...................................................................................................................................................18

MAINTENANCE CARE...........................................................................................................................19

TROUBLESHOOTING....................................................................................................................... 19-20

SPECIFICATIONS....................................................................................................................................21

WARRANTY & SERVICE ........................................................................................................................22

EXPLODED DIAGRAM & PARTS LIST.............................................................................................. 23-29

YOU MAY ALSO LIKE ...........................................................................................................................30

4WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

IMPORTANT SAFETY INFORMATION

Additional Information and Potential Changes

We reserve the right to discontinue, change, and improve our products at any time without notice or obligation

to the purchaser. The descriptions and sections contained in this manual were in effect at the time of printing.

Equipment described within this manual may be optional. Some illustrations may not be applicable to your

machine.

WARNING: Read and thoroughly understand all instructions in this manual and on the safety decals

before assembling or operating this Brush Cutter. Failure to do so may cause serious injury or death.

Do not allow anyone to operate this Brush Cutter who has not read this manual. As with all power

equipment, a Brush Cutter can be dangerous if assembled or used improperly. Do not operate this

Brush Cutter if you have any questions concerning its safe operation. To get answers to any questions,

call our Customer Support Department.

This SAFETY ALERT SYMBOL identifies important safety messages in this manual. Failure to follow

this important safety information may result in serious injury or death.

DANGER! This Brush Cutter was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the operator

can result in serious injury. This Brush Cutter is capable of amputating hands and feet and throwing

debris. Failure to observe the following safety instructions could result in serious injury or death.

The following signals, words and meanings are intended to explain the levels of risk associated with this product.

DANGER indicates a hazardous situation which, if not avoided, will result in serious injury or

death.

WARNING indicates a hazardous situation which, if not avoided, could result in serious injury

or death.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE is important information about the proper use of your Brush Cutter. Failure to follow

this instruction could result in damage to your Brush Cutter or property.

Because a trimmer/cutter is a high-speed, fast cutting power tool, special safety precaution must

be observed to reduce the risk of personal injury. Read this manual carefully. Be familiar with

the controls and the proper use of the unit. Know how to shut off your Brush Cutter and how to

unhook a harnessed unit quickly

5

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

IMPORTANT SAFETY INFORMATION

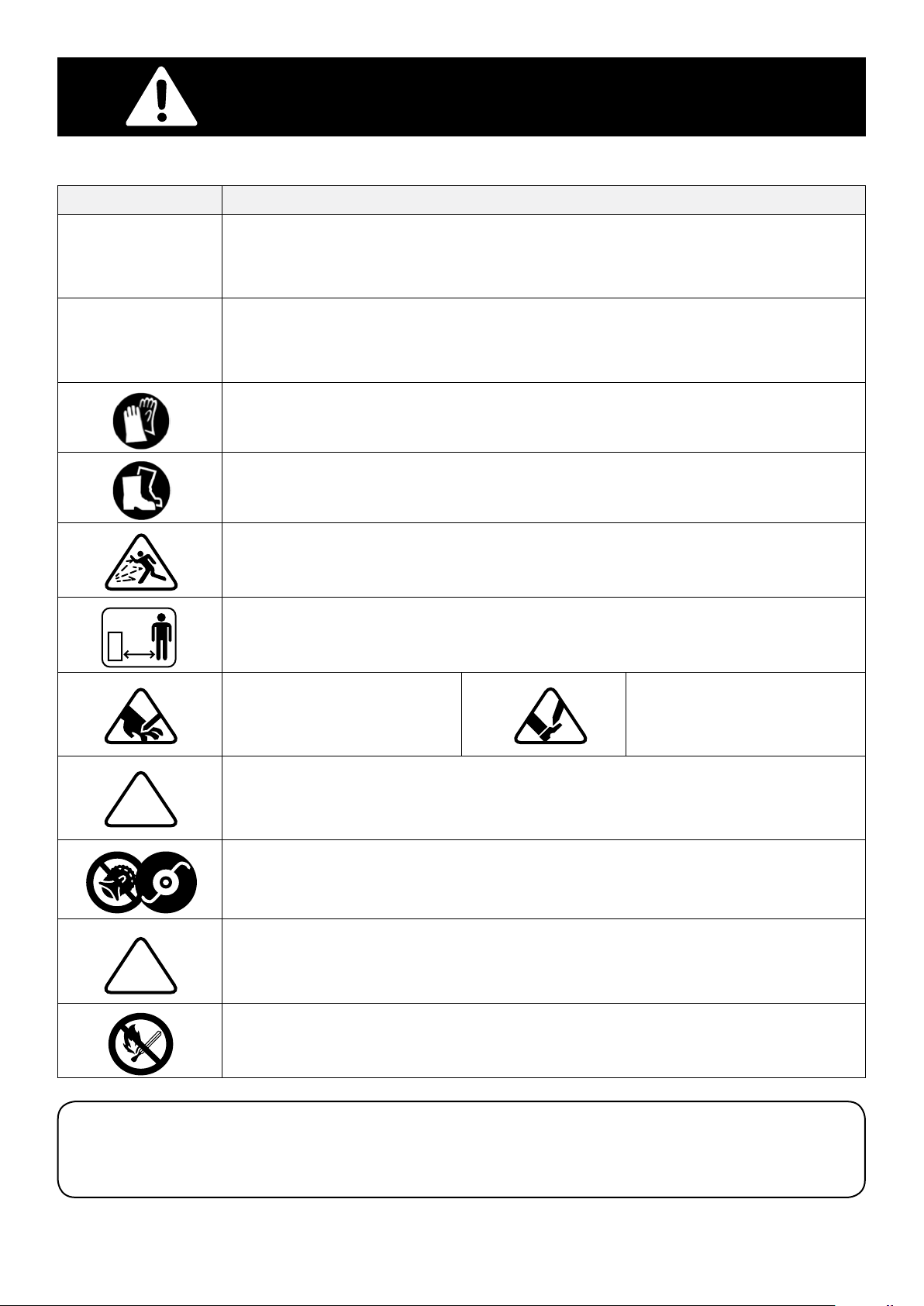

Key to Symbols

Symbol Description

READ THE OWNER’S MANUAL(S)

Read, understand and follow all instructions in the manual(s) before attempting to

assemble and operate.

FACE PROTECTION

Always wear safety goggles or safety glasses with side shields or a face shield when

operating this product as well as ear protection.

WEAR GLOVES

Always wear non-slip, heavy-duty protective gloves when operating this product.

WEAR SAFETY FOOTWEAR

Always wear non-slip steel-toed safety footwear when operating this product.

BEWARE OF FLYING OBJECTS

Danger of eye injury. Wear safety glasses.

BYSTANDERS

Keep bystanders, helpers and children at least 15 metres away.

BEWARE OF SHARP BLADES

Serious injury is possible.

BEWARE OF FALLING

OBJECTS

Serious injury is possible.

TURN OFF ENGINE

Make sure the cutting tool has stopped before cleaning, removing or adjusting

blade.

NEVER MODIFY A TRIMMER OR CUTTER IN ANY WAY

Improper use of any trimmer can cause serious or fatal personal injury.

BEWARE OF HAZARDOUS GASES

The engine exhaust from this product contains chemicals known to cause cancer,

birth defects, or other reproductive harm.

NO FIRE

No fire, no unprotected source of flame, no smoking.

WARNING! Your Responsibility—Restrict the use of this power machine to persons who have read,

understood and will follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

15M

STOP

6WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

GENERAL SAFETY RULES

This machine can cause serious injuries. Read the

instructions carefully for the correct handling,

preparation, maintenance, starting and stopping of

the machine. Be familiar with all controls and the

proper operation of them. Know how to stop the

machine and disengage them quickly.

Keep this manual in a safe place for future and regular

reference and for ordering replacement parts.

Never allow children or anyone unable to fully

understand the directions given in the manual to use

the machine.

• Always wear safety goggles

for eye protection. Dress

properly; do not wear

loose clothing or jewellery

that could become caught

in the moving parts of

this unit. Safe, sturdy,

non-slip footwear should

always be worn. Long hair

should be tied back. It is

recommended that legs and

feet be covered to protect

from flying debris during

operation.

• Inspect the entire machine for loose parts (nuts,

bolts, screws, etc.) or any damage. Repair or replace

as necessary before using the machine.

• DO NOT use any attachment with this power

head other than the ones recommended by our

company, otherwise this could cause serious injury

to the operator or bystander, as well as damage to

the machine.

• Keep the handles free from oil and fuel.

• Always use proper handles and shoulder strap

when cutting.

• DO NOT smoke while mixing fuel or filling the tank.

• DO NOT mix fuel in an enclosed room or near open

flames. Ensure adequate ventilation.

• Always mix and store the fuel in an approved and

properly marked container that is approved by

local codes and ordinances for such usage.

• NEVER remove the fuel tank cap while the engine

is running.

• NEVER start or run the engine inside a closed

room or building. Fumes from the exhaust contain

dangerous carbon monoxide.

• NEVER attempt to make engine adjustments while

the unit is running and strapped to the operator.

Always make engine adjustments with the unit

resting on a flat, clear surface.

• DO NOT use the unit if it is damaged or poorly

adjusted. Never remove the machine’s guard.

This could cause serious injury to the operator or

bystanders as well as damage to the machine.

• Inspect the area to be cut and remove all debris

that could become tangled in the nylon cutting

head. Also remove any objects that the unit may

throw during cutting.

• Keep children away. Onlookers should be kept

at a safe distance from the work area, at least 15

metres.

• NEVER leave the machine unattended.

• DO NOT use this unit for any job other than those

for which it is intended and as described in this

manual.

• DO NOT over reach. Keep proper footing and

balance at all times.

• DO NOT run the unit while standing on a ladder or

on any other unstable footing location.

• Keep hands and feet clear of the nylon cutting

head while unit is in use.

• DO NOT use this type of machine for sweeping

away debris.

• DO NOT use the unit when you are tired, ill or under

the influence of medication, drugs or alcohol.

• Use nylon cutting head which is free of damage.

If a stone or any other object hits the machine,

stop the engine and check the nylon cutting head.

A broken or unbalanced nylon cutting head must

never be used.

Instructions for Changing Accessories

• DO NOT store in a closed area where fuel vapours

can reach an open flame from hot water heaters,

heaters, etc. Store in a locked, well ventilated area

only.

• To ensure safe and proper performance of

your product use only the parts available from

your dealer. The use of any other accessories or

attachments may cause a potential hazard or injury

to the user, damage to the machine and void this

warranty.

• Clean the machine completely, especially the fuel

tank, its surroundings, and the air filter.

• When refuelling, be sure to stop the engine and

confirm that it is cooled down. Never refuel when

the engine is running or hot. When fuel spills, be

sure to wipe it up completely and properly dispose

of those materials before starting the engine.

• Stay clear of other workers or bystanders by at

least 15 metres/50 feet.

• Whenever approaching the operator of the

machine, carefully call for their attention and

confirm that the operator has stopped the engine.

Be careful not to startle or distract the operator,

this can cause an unsafe situation.

• NEVER touch the nylon cutting head whenever the

engine is running. If it is necessary to adjust the

protector or nylon cutting head, be sure to stop

the engine and confirm that the nylon cutting

head has completely stopped running.

7

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

• The engine should be turned off when the machine

is moved between work areas.

• Be careful not to hit the nylon cutting head against

stones or the ground.

• Unreasonable rough operation will shorten the

life of the unit and potentially create an unsafe

environment for yourself and those around you.

• Pay attention to loosening and overheating of

parts. If there is any abnormality of the machine,

stop operation immediately and check the machine

carefully. If necessary, have the machine serviced

by an authorised dealer. Never continue to operate

a machine which may be malfunctioning.

• In start-up or during operation, never touch hot

parts such as the muffler, the high voltage wire or

the spark plug.

• After the engine has stopped, take caution as the

muffler is still hot. Never place the machine in any

area where there are flammable materials (dry

grass, etc.), combustible gasses or combustible

liquids.

• Pay special attention when operating your unit in

the rain or just after the rain as the ground may be

slippery.

• If you slip or fall to the ground, or into a hole,

release the throttle lever immediately.

• Be careful not to drop the machine or hit it against

obstacles.

• Before proceeding to adjust or repair the machine,

be sure to stop the engine and detach the spark

plug cap from the spark plug.

• When the machine is placed in storage for a long

time, drain fuel from the fuel tank and carburettor,

clean the parts, move the machine to a safe place

and confirm that the engine has cooled down.

• Make periodic inspections to ensure safe and

efficient operation.

• Keep the machine away from fire or sparks.

• It is believed that a condition called Raynaud’s

phenomenon, which affects the fingers of certain

individuals may be brought about by exposure

to vibration and cold. Exposure to vibration and

cold may cause tingling and burning sensations

followed by loss of colour and numbness in the

fingers.

• The following precautions are strongly

recommended because the minimum exposure

which might trigger the ailment is unknown.

a. Keep your body warm, especially the head,

neck, feet, ankles, hands and wrists.

b. Maintain good blood circulation by performing

vigorous arm exercises during frequent work

breaks and also by not smoking.

c. Limit the hours of operation. Try to fill each day

with jobs where operating the Brush Cutter

or other hand-held power equipment is not

required.

d. If you experience discomfort, redness and

swelling of the fingers followed by whitening

and loss of feeling, consult your physician

before further exposing yourself to cold and

vibration.

• Always wear ear protection, loud noises for long

periods of time can make hearing debase and may

even cause loss of hearing.

• Total face and head protection must be worn to

prevent damage from falling branches.

• Wear non-slip heavy duty work gloves to improve

your grip on the Brush Cutter handle. Gloves also

reduce the transmission of machine vibration to

your hands.

• The cutter area is still dangerous while the machine

is coasting to a stop.

GENERAL SAFETY RULES

SAFETY MANUAL included with unit

8WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

1. BLADE: Circular blade for grass, weed or brush

cutting applications. Harness, metal shield and Bull

Horn Handles/D-Handles are required for blade

operation.

2. DRIVE SHAFT ASSEMBLY: Contains a specially

designed liner, flexible drive shaft.

3. THROTTLE TRIGGER: Spring loaded to return to

idle when released. When accelerating, press

trigger gradually for best operating technique .Do

not hold trigger whilst starting.

4. IGNITION SWITCH: “Slide switch” mounted on

top of the Throttle Trigger Housing. Move switch

FORWARD to RUN and BACK to STOP.

5. SAFETY LEVER: Before acceleration, compress this.

6. BULL HORN/D-HANDLES: These handles can be

adjusted at your convenience for comfort.

7. HARNESS STRAP: An attachment which hangs

the machine on the operator and is adjustable in

length.

8. AIR CLEANER COVER: Contains a replaceable felt

element.

9. FUEL TANK LID.

10. FUEL TANK: For fuel and contains fuel filter.

11. PURGE BULB: Pushing purge bulb (7 to 10 times

before starting) will remove all air and stale fuel

from fuel system and bring fresh fuel to the

carburettor.

12. CHOKE: The choke control is located on the top of

the filter cover. COLD STARTS: Pull lever up to close

choke for cold starts. Push lever down for RUN

position.

13. DEBRIS SHIELD: Mounted just above the cutting

attachment helps protect operator by deflecting

debris produced during the trimming operation.

Do not operate unit without shield.

14. CUT-OFF KNIFE: Trims nylon filament to the correct

length 17cm, head to end of line. If trimmer is

operated without a cut-off knife the line becomes

too long (more than 17cm) the operating speed

will slow down the engine, and will overheat or

damage the engine.

15. NYLON CUTTER HEAD: Contains replaceable nylon

trimming line.

PARTS LOCATION

9

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

ASSEMBLING

Installing Plastic Shield

Install the safety cover on the shaft with the safety cover bracket and the screws provided.

Tighten the screws after setting the safety cover bracket at the appropriate position.

Blade Installation

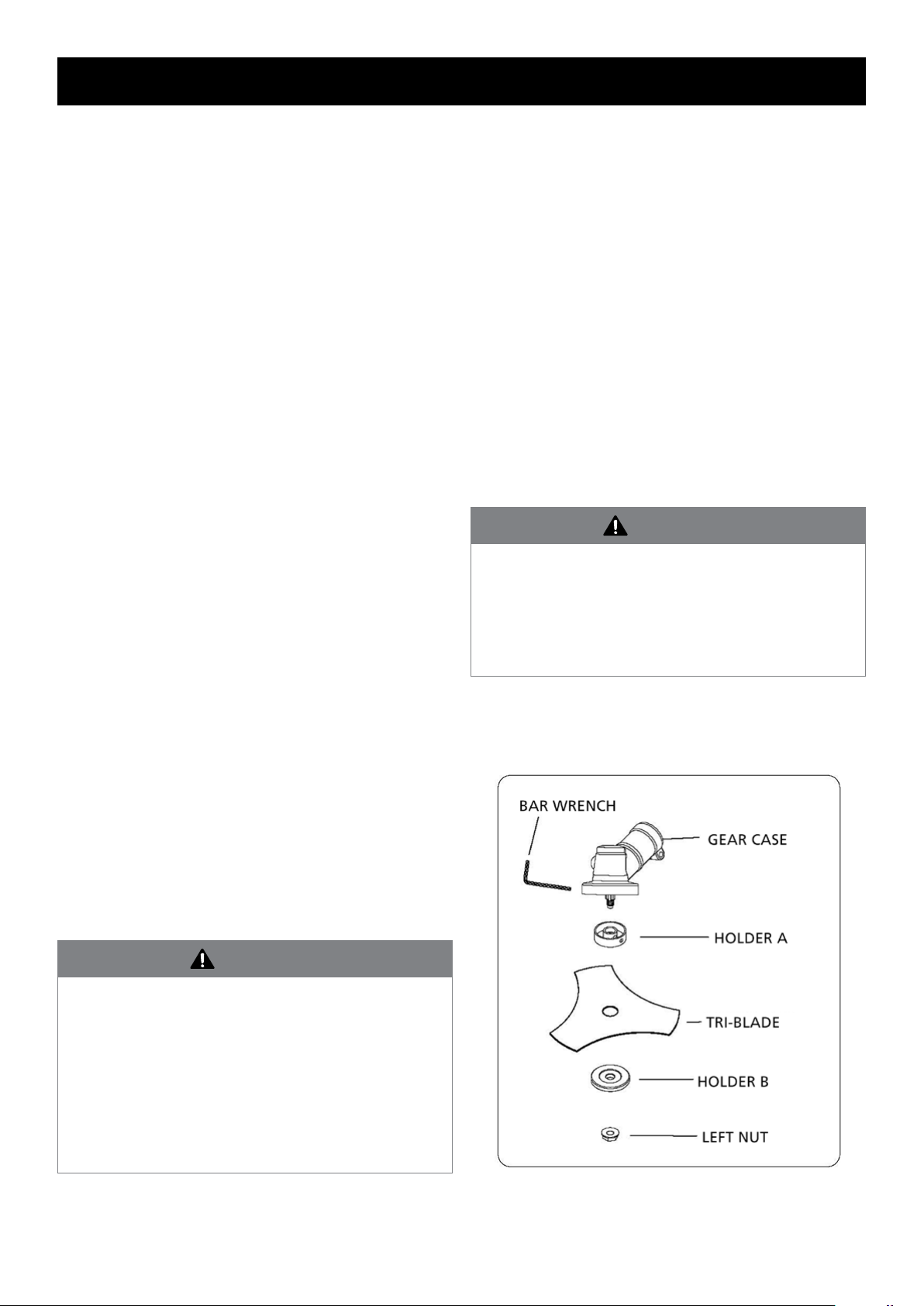

Install holder A, the tri-blade, holder B, in this order,

then clamp with a left hand thread nut.

Align hole of gear case and holder A, and insert S=4mm

bar wrench.

Rotate blade-fastening nut with plug box wrench in

clockwise direction until securely tightened.

EXCESSIVE VIBRATION -

STOP ENGINE IMMEDIATELY

Excessive vibration of blade means that it has not

been properly installed. Stop engine immediately

and check blade.

Blade improperly installed will cause injury.

Use only our company’s original cutting equipment

parts for this unit.

WARNING

INSTALLING NYLON LINE CUTTING HEAD

Align hole in adapter plate with hole in shaft and

install with lock tool.

Thread cutter head onto shaft (turning it

clockwise) until it is tight. Remove locking tool.

WARNING

10 WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

ASSEMBLING

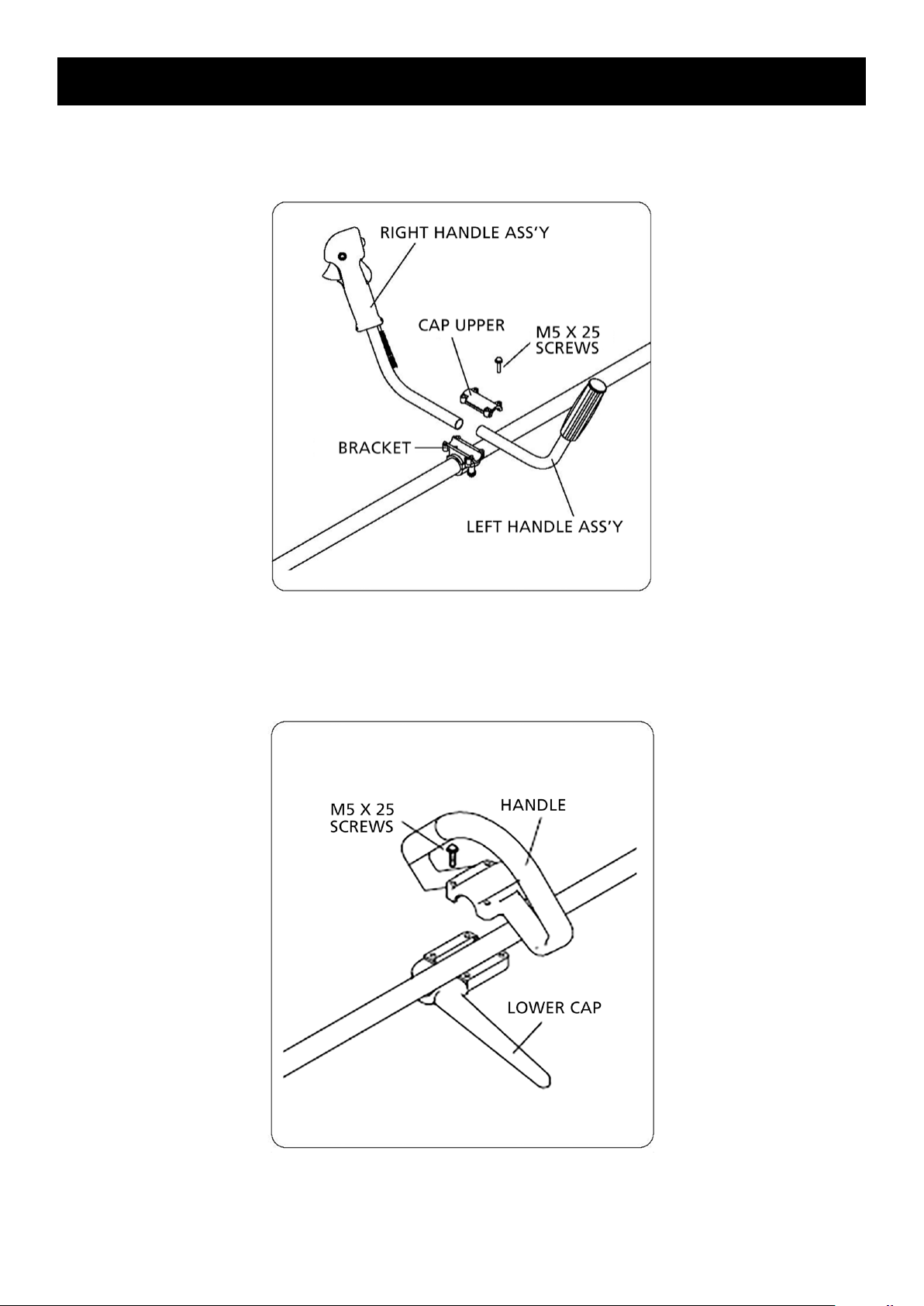

Installing Bull Horn Handle

Install handle in bracket. Position handle in a comfortable operating position and tighten four M5×25 screws.

Installing D–Handle

Install handle in bracket. Position handle in a comfortable operating position and tighten for M5 x 25

screws.

11

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

Read the Owner’s Manual carefully. Be thoroughly

familiar with the controls and proper use of the unit.

NEVER allow anyone to use the unit without proper

instruction. Be sure the operator wears the correct

foot, leg, eye, face and hearing protection.

DO NOT rely on the debris shield on the unit to protect

your eyes from ricocheting or thrown objects. Keep the

area clear of bystanders, children and pets.

NEVER allow children to operate or play with the unit.

DO NOT allow anyone to enter the operating DANGER

ZONE with you. The danger zone is an area 15 metres

in radius (about 16 paces) or 50 feet.

Persons in the RISK ZONE beyond the danger zone are

advised to wear eye protection from flying objects. If

the unit must be used where there are unprotected

people, operate at a low throttle speed to reduce the

risk of thrown objects.

Move the stop switch to “STOP” position when the

engine idles, ensure unit is reliable before cutting.

Only continue to operate the unit when stop switch is

in good working condition, routine checks for this, is if

the cutting attachment stops turning when the engine

idles.

RULES OF SAFE OPERATION

Danger Zone - An Area 15 Metres in Radius

In addition to wearing head, eye, face and ear

protectors, ensure you wear shoes that protect

your feet and improve your footing on slippery

surfaces. Do not wear ties, jewellery, or loose

dangling clothing which could get caught in the

unit.

DO NOT wear open-toed footwear or go bare-

foot or bare-legged. In certain situations, you

must wear total face and head protection. Pay

attention not to kick back and blade thrust.

WARNING

All models of trimmers and Brush Cutters can

throw small stones, metal and other small objects

as well as the material being cut. Read these Rules

of Safe Operation with care.

WARNING

NO PERSON EXCEPT OPERATOR ALLOWED WITHIN 15 METRES RADIUS DANGER ZONE. EYE, EAR, FACE,

FOOT, LEG AND BODY PROTECTION MUST BE WORN BY OPERATOR. PERSONS IN ZONE OR RISK AREA

BEYOND DANGER ZONE SHOULD WEAR EYE PROTECTION AGAINST THROWN OBJECTS. RISK DIMINISHES

WITH DISTANCE FROM DANGER ZONE.

15M

12 WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

Line head rotates in a CLOCKWISE direction. The CUT-

OFF KNIFE will be on the right side of the debris shield.

Cutting with a Nylon Head

RULES OF SAFE OPERATION

For nearly all cutting, it is good to tilt the line head

so that contact is made on the part of the line circle

where the line is moving AWAY from you and the

debris shield. (See appropriate picture). This results in

the debris being thrown AWAY from you.

The proper debris shield must be in place on the

unit when nylon cutting line is used. The cutting

line can flap around if too much line is exposed.

Always use the plastic debris shield with cut-off

knife when using nylon cutting heads.

WARNING

Tilting the head to the wrong side will shoot the

debris TOWARDS you. If the line head is held flat

to the ground so that cutting occurs on the whole

line circle, debris will be THROWN at you, drag

will slow the engine down, and you will use up a

lot of line.

WARNING

Use only quality nylon monofilament line of

2.5mm diameter.

NEVER use wire or wire-reinforced line in place of

nylon trimmer line. Load your nylon line cutting

head only with nylon trimmer line of the proper

diameter.

WARNING

Use extreme caution when operating over bare

spots and gravel, because the line can throw small

rock particles at high speeds.

Debris shields on the unit cannot stop objects

which bounce or ricochet off hard surfaces.

WARNING

13

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

RULES OF SAFE OPERATION

Trimming

This is feeding the trimmer carefully into the material

you wish to cut. Tilt the head slowly to direct debris

away from you. If cutting up to a barrier such a fence,

wall or tree, approach from an angle where any debris

ricocheting off the barrier will fly away from you.

Move the line head slowly until the grass is cut right

to the barrier, but do not jam (overfeed) the line into

the barrier.

If trimming up to a wire mesh or chain linked fence, be

careful to feed only up to the wire. If you go to too far

the line will snap off around the wire.

Trimming can be done to cut through weed stems

one at a time. Place the trimmer line head near the

bottom of the weed, never high up which could cause

the weed to catch the line. Rather than cut the weed

right through, just use the very end of the line to wear

through the stem slowly.

Scalping and Edging

Both of these are done with the line head tilted at a

steep angle. Scalping is removing top growth leaving

the earth bear.

Edging is trimming the grass back where it has spread

over a sidewalk or driveway.

During both edging and scalping, hold the unit at a

steep angle and in a position where the debris, and

any dislodging dirt and stones, will not come back

towards you even if it ricochets off the hard surface.

Although the picture shows how to edge and scalp,

every operator must find for themselves the angles

which suits there body size and cutting situation.

DO NOT to use a steel blade for edging or scalping.

WARNING

DO NOT trim in any area where there are strands

of fencing wire. Wear protective safety clothing.

DO NOT cut where you cannot see what the

cutting device is cutting.

WARNING

14 WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

RULES OF SAFE OPERATION

Use the shoulder harness at all times. Adjust both

harness and harness clamp on the unit so that the

unit hangs a few inches above ground level. The

cutting head and the metal debris shield should

be level in all directions. Harness the unit on the

right side of your body.

WARNING

DO NOT USE A BRUSH CUTTER FOR CUTTING

TREES

WARNING

DO NOT cut with a dull, cracked or damaged

metal blade. Before cutting growth, inspect

for obstructions such as boulders, metal stakes

or strands of wire from broken fences. If an

obstruction cannot be removed, mark its location

so that you can avoid it with the blade. Rocks and

metal will dull or damage a blade. Wires can catch

on the blade head and flap around or be thrown

into the air.

WARNING

Cutting with a Blade

DO NOT TOUCH

THESE TYPES OF OBJECTS WITH BLADE

WARNING

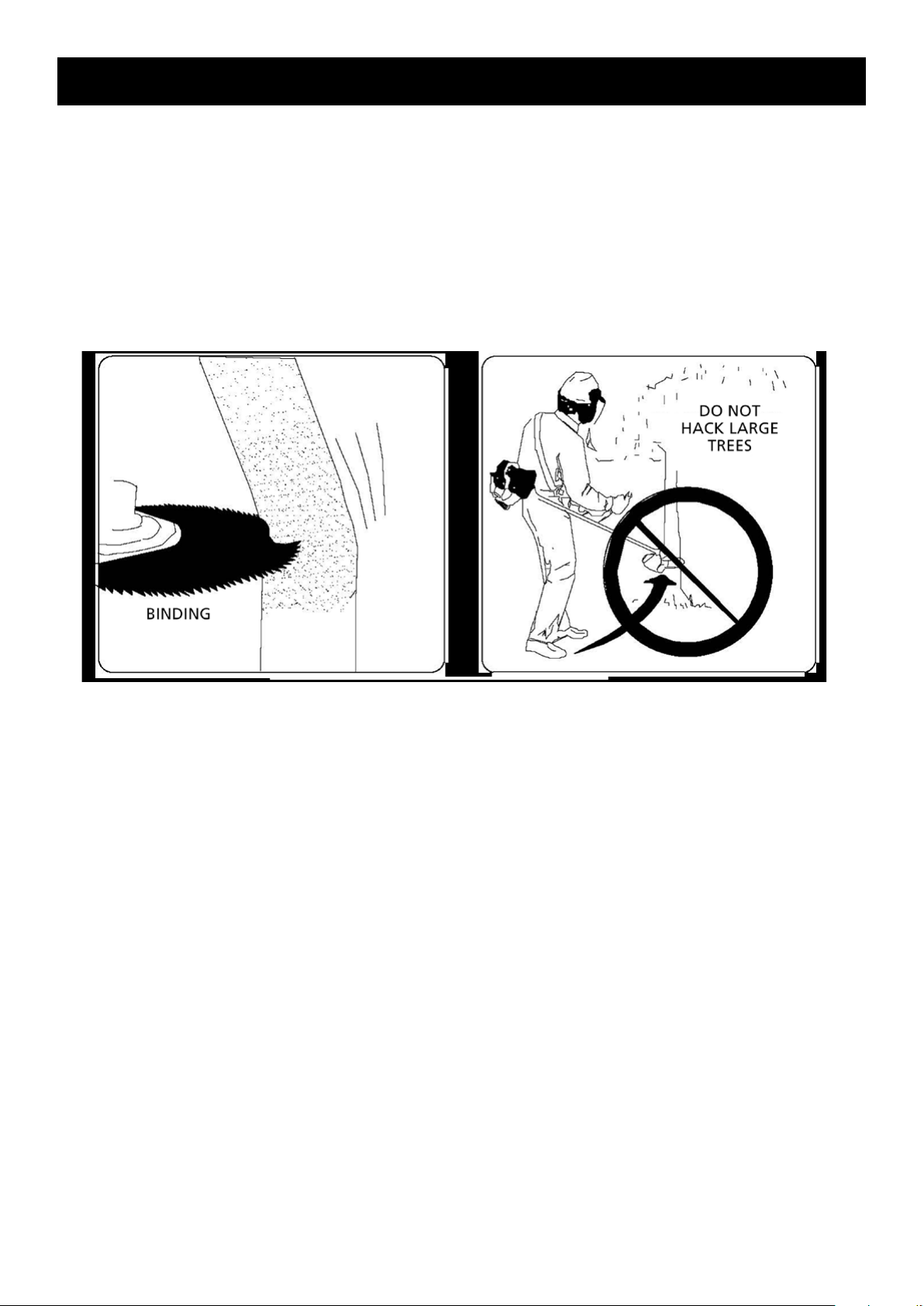

Scything Weeds

This is cutting by swinging the blade in a level arc.

It can quickly clear areas of field grass and weeds.

Scything should not be used to cut large, tough weeds

or woody growths.

Scything can be done in both directions, or just one

way which results in the debris being thrown away

from you.

NOTE: DO NOT use a brush blade to cut trees

which exceed a diameter of 1/2 to 3/4 inches.

NOTE: You will be hit by some debris if you scythe

in both directions.

15

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

RULES OF SAFE OPERATION

Sawing

This must be done with a saw blade when the weeds

are too thick and strong for scything.

If kickback occurs, the blade may be dull, or the

material is to too thick and hard that you should use a

saw blade instead of the brush blade.

Growth up to 75mm in diameter, which is too thick

for scything, may be cut by sawing. Sawing requires

judgement on your part whether to cut on the side

where the blade pulls away from you but throws back

the debris, or on the side where the debris is thrown

away from you but the reaction is to push which could

cause a kickout (blade thrust).

Always cut on the side of the tree which will cause the

tree to fall away from the unit. A kickout may result if

the tree falls toward the unit and pinches the blade.

Do not force the blade to cut. Do not change the angle

of cut after blade is in the wood. Avoid using any

pressure or leverage which could cause the blade to

bend or crack.

16 WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

PREPARING FOR OPERATIONS

Engine Safety Precautions

Warning Carbon Monoxide Poisoning

All engines contain carbon monoxide in their exhaust.

Carbon monoxide is a deadly, colourless, tasteless,

odourless gas which may be present even if you do

not smell or see any engine exhaust. Levels of carbon

monoxide, which can be deadly, can be present for days

in an enclosed area that has poor ventilation. Any level

of carbon monoxide, if inhaled, can cause headaches,

drowsiness, nausea, dizziness, confusion and eventually

death. If you experience any of these symptoms, seek

fresh air and medical attention immediately.

Preventing Carbon Monoxide Poisoning

• Never run engine indoors.

• Carbon monoxide can reach dangerous levels very

quickly.

• Never run engine outdoors where exhaust fumes

may be pulled into a building.

• Never run engine outdoors in a poorly ventilated

area where the exhaust fumes may be trapped and

not easily taken away. (Examples include: in a large

hole or areas where hills surround your working

area.)

• Never run engine in an enclosed or partially

enclosed area. (Examples include: buildings that

are enclosed on one or more sides, under tents,

carports or basements.)

• Always run the engine with the exhaust and

muffler pointed in the direction away from the

operator.

• Never point the exhaust muffler towards anyone.

People should always remain a safe distance

away from the operation of the engine and its

attachments.

Petrol Fires and Handling Fuel Safely

Fuel and fuel vapours are highly flammable. Never use

fuel where a spark or flame may be present. Never use

fuel where a potential source of ignition could occur.

(Examples include: hot water systems, clothes dryer or

electric motors, etc.)

Keep flames and sparks away from engine and fuel

to prevent fires. Fuel fires spread very quickly and are

highly explosive.

Prevention of Petrol Fires

• Never fill your fuel tank with fuel indoors.

(Examples include: garage, shed, house, porch,

etc.)

• Always fill fuel tank outside in a well ventilated

area.

• Never remove the fuel cap or add fuel with the

engine running. Stop engine and allow to cool

before filling.

• Never drain fuel from engine in an enclosed area.

• Always wipe up excess (spilled) fuel from engine

before starting. Clean up spilled fuel immediately.

• Allow spilled fuel to dry, after wiping and before

starting.

• Allow fuel fumes/vapours to escape from the area

before starting engine.

• Test the fuel cap for proper installation before

starting and using engine.

• Always run the engine with fuel cap properly

installed on the engine.

• Replace fuel cap if it allows fuel to spill or leak.

• Never smoke while refilling engine fuel tank.

• Prevent fire and explosion caused by static electric

discharge. Use only non-metal, portable approved

fuel containers.

• Do not store engine with fuel in fuel tank indoors.

Fuel and fuel vapours are highly explosive.

• When storing, screw down fuel cap vent tightly.

• Never pour fuel from engine fuel tank.

• Never siphon fuel by mouth to drain fuel tank.

• Always have an adult fill the fuel tank.

• Never allow an adult or anyone under the influence

of drugs or alcohol to fill engine.

• Never allow children to fill the engine.

Burns and Fires

The muffler, muffler guard and other parts of the

engine become extremely hot during the operation

of the engine. These parts remain extremely hot even

after the engine has stopped.

Prevention of Burns and Fires

• Never remove the muffler guard from the engine.

• Never touch the muffler guard as it is extremely

hot and will cause severe burns.

• Never touch parts of the engine that become hot

after operation.

• Always keep materials and debris away from

muffler guard and other hot parts of the engine

to avoid fires.

Hot gases are a normal by-product of a functioning

catalytic converter. Follow all safety instructions

to prevent burns and fires.

CAUTION

17

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

PREPARING FOR OPERATIONS

The fuel and oil mixture of 25:1 only applies if your unit

is a 2-stroke engine, these include the 26cc, 33cc and

52cc engines.

Fuel used for this model is a mixture of unleaded petrol

and approved engine lubricant. When mixing petrol

with 2-stroke engine oil, use only petrol which contains

NO ETHANOL or METHANOL (types of alcohol). Use

branded 89 octane or higher unleaded petrol known

to be of good quality. This will help avoid possible

damage to engine fuel lines and other engine parts.

Fuel mixed at a rate other than 25:1 may cause damage

to the engine, ensure mixture ratio is correct.

Petrol

Use branded 89 octane or higher unleaded fuel known

to be of good quality.

Storing Fuel

Store fuel only in a clean, safe, approved container.

Check and follow local ordinances on type and location

of storage container.

Fuel and Oil Mixture

Inspect fuel tank making sure that it is clean and filled

with fresh fuel. Use a mixture of 25:1 for 2-stroke only.

Check Points Before Operation

1. Check for loose bolts, nuts and fittings.

2. Check the air filter for dirt. Clean the air filter of all

dirt, etc. before operation.

3. Check that protector is securely in place.

4. Check that fuel is not leaking.

5. Check that blades are not cracked.

OIL – 1 PART

PETROL - 25 PART

• NEVER fill the fuel tank to the very top.

• NEVER add fuel to the tank in a closed non-

ventilated area.

• DO NOT add fuel to this unit close to an open

fire or sparks.

• Be sure to wipe off spilled fuel before

attempting to start engine.

• DO NOT attempt to refuel a hot engine.

WARNING

Fuel & Oil Mixture

The engine exhaust from this product contains

chemicals known to cause cancer, birth defects,

or other reproductive harm.

WARNING

IMPORTANT: Failure to follow proper fuel mix

instructions may cause damage to the engine.

IMPORTANT: 2-stroke fuel may separate. Shake

fuel container thoroughly before each use.

Stored fuel ages. Do not mix more fuel than you

expect to use within a month.

18 WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

1. Move the stop switch to START position.

2. Give a gentle push on the primer pump repeatedly

(7-10 times) until fuel comes into the primer pump.

3. Cold Starts: Pull lever up to close choke.

4. Pull starter handle until engine false fires.

5. To start a cold engine, move the choke lever to

CLOSED (up position).

6. Pull the pull start handle out until you feel

resistance, then pull firmly, allowing the pull start

cord to return gently.

7. Pull the start handle until engine starts.

8. If the choke was engaged while starting the

engine, slowly disengage the choke to the CLOSED

position as the engine begins to fire.

9. Allow engine to warm up for a few minutes before

using.

Starting Warm Engine

• If fuel tank was not run dry, pull starter one to

three times and engine should start.

Do Not Use Choke

• If fuel tank was run dry, after refilling repeat steps

3 to 7 in Starting Cold Engine.

Stopping the Engine

• Move switch to STOP position.

Hot Restart

If the engine is operated at above ambient temperature,

then turned off and allowed to sit for a while, it

may not start again on the first pull and the starting

procedure may need to be restarted.

Emergency Stop

To stop the engine in an emergency, simply flick the

switch on the handle into the OFF position. Although

under regular conditions, you should fully release the

throttle and wait until engine slows down to idle speed

before stopping the engine, as stopping the engine at

full revs can be damaging.

OPERATIONS

Any level of carbon monoxide, if inhaled, can

cause headaches, drowsiness, nausea, dizziness,

confusion and eventually death.

Avoid any areas or actions that expose you to

carbon monoxide.

WARNING

NOTE: Do not allow the starter grip to snap back

against the engine. Return it gently to prevent

damage to the starter.

Engine Starting and Stopping Procedures

Starting Cold Engine

STOP

19

WWW.BBTA.COM.AUBBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

MAINTENANCE CARE

Air Filter

• Accumulated dust in the air filter will reduce engine

efficiency. Increase fuel consumption and allow

abrasive particles to pass into the engine. Remove

the air filter as often as necessary to maintain in a

clean condition.

• Light surface dust can readily be removed by

tapping the filter. Heavy deposits should be

washed out in suitable solvent.

• Remove filter cover by loosening air filter cover

knob.

Adjusting Carburettor

Fuel Filter

• Fuel tank is fitted with a filter.

• Filter is situated at the free end of fuel pipe and

can be picked out through fuel port with a piece

of hooked wire or something similar.

• Check the fuel filter periodically. Do not allow dust

to enter into fuel tank. A clogged filter will cause

difficulty in starting engine or abnormalities in the

engines performance.

• When filter is dirty, replace the filter.

• When the inside of the fuel tank is dirty, it can be

cleaned by rinsing the tank out with petrol.

Check Spark Plug

• Do not attempt to remove the plug from a hot

engine as this could cause damage to the threads.

NOTE: Do not adjust carburettor unless necessary.

Improper adjustment may cause engine damage

and void warranty.

TROUBLESHOOTING

Transport and Handling

• Secure the power unit during transport to prevent

loss of fuel, damage or injury.

• The engine should be turned off when the unit is

moved between work areas.

• After the engine has stopped, the muffler will still

be hot. Never touch hot parts such as the muffler.

• Confirm that the fuel is not leaking from the tank.

Extended Storage

• Inspect, clean and repair unit if necessary.

• Remove all fuel from tank.

• Start engine - this will consume all fuel in fuel line

and carburettor.

• Remove spark plug and pour one teaspoon of clean

motor oil into spark plug hole of cylinder. Replace

spark plug.

• Store in clean, dry, dust free area.

• Clean or replace the plug if fouled with heavy oily deposits.

• Replace the plug if the centre electrode is worn rounded at the end.

• Spark gap 0.6-0.7mm (.023”.028”)

• Fastening torque =145-155kg.cm(125-135in.lb)

FAILURES, such as difficulty in starting engine,

irregularity in functions and abnormality in

performance can normally be prevented if careful

attention is paid to all operating instructions and

maintenance procedures. Should the engine not

function properly, check the following:

• That the fuel system is in good condition and fuel

is flowing to the engine.

• The ignition system is in good condition and the

spark plug sparks correctly.

• Compression of the engine is adequate.

Failure To Start

• Dispose of fuel in tank.

• Ensure that fuel is fresh and clean.

• Check fuel filter to make sure it is clean. (Replace

filter if necessary).

• Make sure air filter elements are clean.

• Install new, properly gapped spark plug.

• When there is serious trouble with the unit, do not

try to repair it yourself.

20 WWW.BBTA.COM.AU BBT-BC-26CCBH, BBT-BC-26CCDH, BBT-BC-52CCBH

1. Failure to Start

CHECK PROBABLE CAUSES ACTION

Cylinder

Compress

Pressure

Normal

Spark Plug

Spark normal

Fuel System abnormality There is no fuel in tank

Fuel filter obstruction

Add fuel in tank

Clean fuel filter

Fuel System

abnormality Fuel

Fuel is too dirty

There is water in fuel

There is too much fuel in

cylinder

Mixture ratio is incorrect

Replace fuel

Replace fuel

Tear down spark plug and dry it

Mixture proportion

Fuel System

Normal

High Voltage

Wire Spark

Normal

Spark plug

Spark plug fouled with oily

deposits

Spark plug insulation damage

Spark plug gap is too large or

small

Clean the oily deposits

Replace spark plug

Adjust spark plug gap 0.6-0.7mm

High Voltage

Wire Spark Abnormality

High voltage wire breach or

break off

Coil looseness

Replace or tighten

Tighten

Fuel

System

Normal

Ignition

System

Normal

Compress is shortage

Piston ring attrite

Piston ring is broken

Piston ring cementation

Spark plug looseness

Conjoint surface of the cylinder

and crankcase leak

Replace with new

Replace

Eliminate

Tighten

Eliminate

Compress Normal

High voltage wire and spark

plug contact bad

Stop switch failure or short

circuit

Tighten the spark plug cap

Repair or replace

TROUBLESHOOTING

2. Low Output

CHECK PROBABLE CAUSES ACTION

Flameout when speedup

The smoke is thin

Fuel filter obstruct, fall short of fuel

Muffler fouled with oily deposits

Clean fuel filter, adjust carburettor

Clean the oily deposits

Compression shortage Piston, piston ring, cylinder attrite Replace piston, piston ring

Engine leak Conjoint surface of the cylinder and crankcase

leak

Repair

Rocket cover leak The seal is bad Replace seal

Engine overheats burning, room fouled with

oily deposits

Avoid using for long periods of time, high speed

and heavy load, clean the oily deposits

3. Engine Running Unstable

CHECK PROBABLE CAUSES ACTION

There is a knock sound in engine

Piston, piston ring, cylinder attrite

Piston pin, piston attrite

Bearing of crankshaft attrite

Replace piston, piston ring

Replace piston pin, piston

Replace bearing

There is a metal knock sound

Engine overheats

Burning, room fouled with oily deposits

Fuel brand is unfit

Avoid using for long periods of time or high

speed and heavy load

Clean the oily deposits

Replace require branded octane

Engine ignition break off There is water in fuel

Spark plug gap is wrong

Coil gap is wrong

Replace fuel

Adjust spark gap 0.6-0.7mm

Adjust coil gap 0.3-0.4mm

4. The Engine Suddenly Stopped

PROBABLE CAUSES ACTION

Fuel is empty

Spark plug fouled with oily deposits and short circuit

High voltage wire disconnected off

Add fuel

Clean the oily deposits

Connect

This manual suits for next models

2

Table of contents

Other BBT Brush Cutter manuals