Look for this Symbol to point out important safety precautions.

It means ATTENTION! Become Alert! Your safety is involved.

RULES FOR SAFE OPERATIONS 81.200.004

CAUTION: Vehicle braking and stability may be aected with the

addition of an accessory or an attachment. Be aware of changing

conditions on slopes.

Remember, any power equipment can cause injury if operated improperly or if the user does not understand

how to operate the equipment.

Exercise caution at all times when using power equipment.

1. Read this owners manual carefully for operating and service instructions before attempting to assemble or

operate this equipment this equipment. Be thoroughly familiar with the proper use of this equipment.

2. Read the vehicle owners manual and vehicle safety rules and know how to operate the vehicle before

using this equipment.

3. Never allow children to operate the tractor or plug aerator attachment, and do not allow adults to operate

without proper instructions.

4. This aerator attachment has sharp knife points. Always handle with care and wear substantial foot wear

when operating this aerator.

5. Do not allow anyone to ride or sit on plug aerator attachment frame or on towing vehicle.

6. Keep the area of operation clear of all persons, particularly small children and also pets.

7. Always begin with the transmission in first (low) gear and engine at low speed and gradually increase

speed as conditions permit.

8. The vehicle braking and stability may be aected with the attachment of this equipment. Be aware of

changing conditions on slopes. STAY OFF STEEP SLOPES.

9. Always operate up and down a slope, never across the face of slope.

10. This equipment should be operated at reduced speed on rough terrain, along creeks and ditches and on

hillsides, to prevent tipping and loss of control. Do not drive too close to a creek or a ditch.

11. Do not this equipment on a highway or any other public thoroughfare.

12. Follow the maintenance instructions as outlined in this owner’s manual.

CARTON CONTENTS

Ref# Description

1Tray

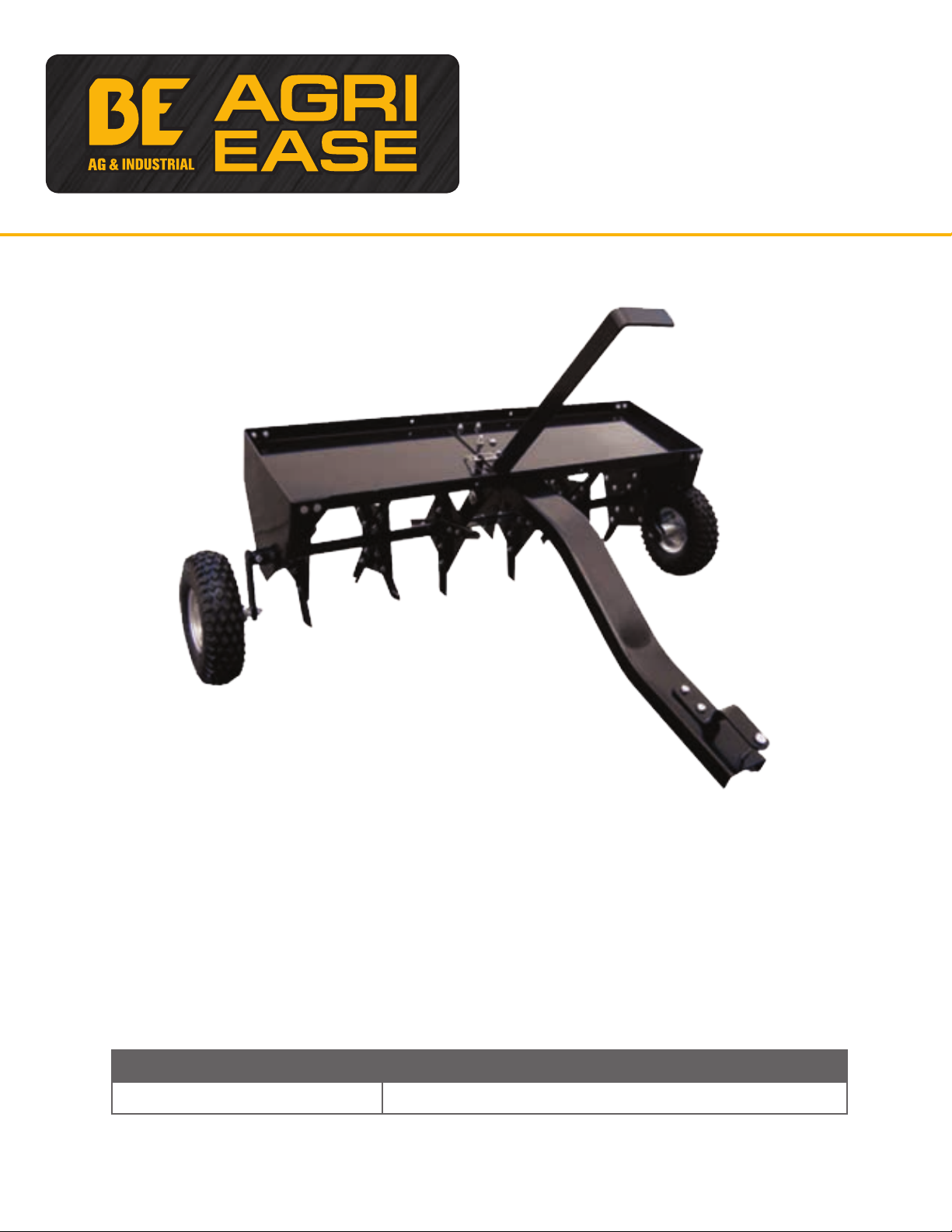

2 Middle Brace

3 End Plate (2)

4 Lift Handle

5 Tongue

6 Shaft

7 Hitch Bracket

8 Wheels (2)

26 Single Spool (2)

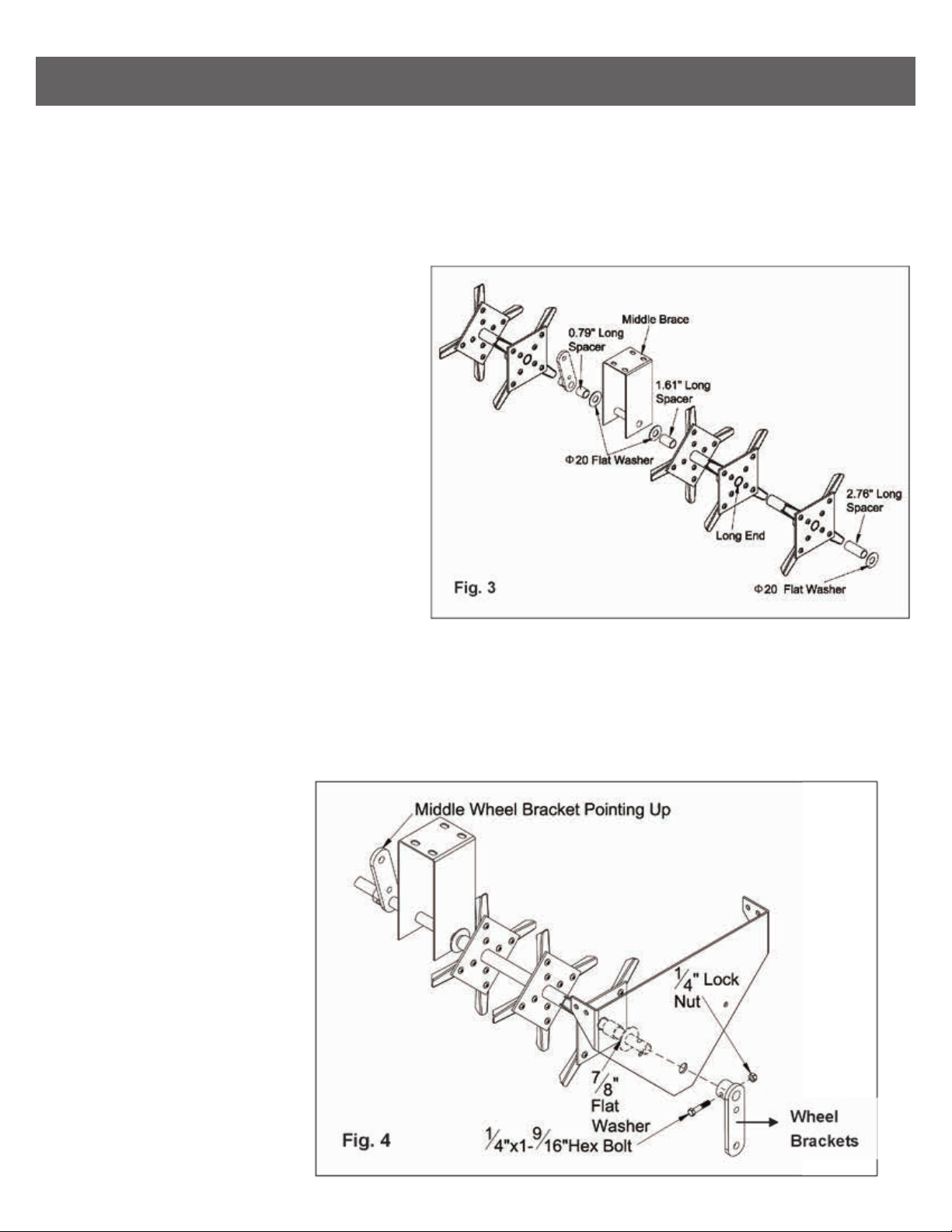

9 Wheel Bracket (3)

10 Double Spool (2)