BE Power Equipment COMMERCIAL HW255E1CNG User manual

User Manual

NATURAL GAS

HOT WATER WASHER

85.610.594

COMMERCIAL

SERIES

HW255E1CNG

HW255E3CNG

HW2775E1CNG

HW2775E3CNG

2

TABLE OF CONTENTS

Introduction & Product Info

3 Introduction & Production info

Important Safety Warnings

4 Important Safety Warnings & Symbols

Product Specifications

7 Specifications Chart

Before Starting The Unit

8 Pre-Operation Safety & Inspection Procedures

9 Combustion Air Supply

Start-Up & Shutdown Operations

10 Starting the Unit

10 Shutting down the Unit

Safety Components

11 Saftey Components Specifications

Maintenance

12 Maintenance Chart

Storage & Winterizing

13 Storing the Unit

13 Winterizing the Unit

Parts Breakdown

14 5 HP units Breakdown

15 5 HP Phase units Parts Reference List

16 7 HP units Breakdown

17 7 HP Phase units Parts Reference List

Electrical Box Assembly

18 5 HP Electrical Box Assembly Breakdown

19 5 HP Electrical Box Assembly Parts

Reference List

20 7.5 HP Electrical Box Assembly Breakdown

21 7.5 HP Electrical Box Assembly Parts

Reference List

Wiring Diagrams

22 5 HP Wiring Diagram

23 7.5 HP Wiring Diagram

Coil Servicing

24 Coil Maintence & Servicing

Warranty

25 Unit & Coil Warranty

Maintenance Notes

26 Notes

3

INTRODUCTION & PRODUCT INFO

Using the Operator’s Manual

Thank you for purchasing our hot water pressure washer! This operating manual is an important part of the

unit. It should be read thoroughly before initial use, and referred to often to make sure adequate safety and

service concerns are being addressed.

Reading the owner’s manual thoroughly will help avoid any personal injury or damage to your pump, engine,

and other components. By knowing how best to operate this machine you will be better positioned to show

others who may also operate the unit.

You can refer back to the manual at any time to help troubleshoot any specific operating functions, so store

it with the machine at all times.

Product Registration

Please register your product online to get the maximum benefit from your warranty. Use the QR code below

or register online at: bepowerequipment.com/product-registration

It is recommended that you record the product identification numbers in this manual. These numbers are

important to have on hand if you need to contact technical support (1-866-850-6662). The model and serial

number can be found on the box and on decal on the machine.

ATTENTION: Read through the complete manual

prior to the initial use of your pressure washer.

PRODUCT SPECIFICATIONS

MODEL GPM PSI HP PHASE MOTOR VOLT PUMP UNIT

WEIGHT SHIPPING DIMS

HW255E1CNG 3.5 2500 5 1 BALDOR 240V COMET 598lbs 51” x 35” x 57”

MODEL GPM PSI HP PHASE MOTOR VOLT PUMP UNIT DIMS SHIPPING DIMS

HW255E3CNG 3.5 2500 5 3 BALDOR 240V COMET 568lbs 51” x 35” x 57”

MODEL GPM PSI HP PHASE MOTOR VOLT PUMP UNIT DIMS SHIPPING DIMS

HW277E1CNG 4.6 2700 7.5 1 BALDOR 240V COMET 675lbs 51” x 35” x 57”

MODEL GPM PSI HP PHASE MOTOR VOLT PUMP UNIT DIMS SHIPPING DIMS

HW277E3CNG 4.6 2700 7.5 3 BALDOR 240V COMET 628lbs 51” x 35” x 57”

PRODUCT IDENTIFICATION

Model Number:

Serial Number:

Date of Purchase:

Dealer Name:

4

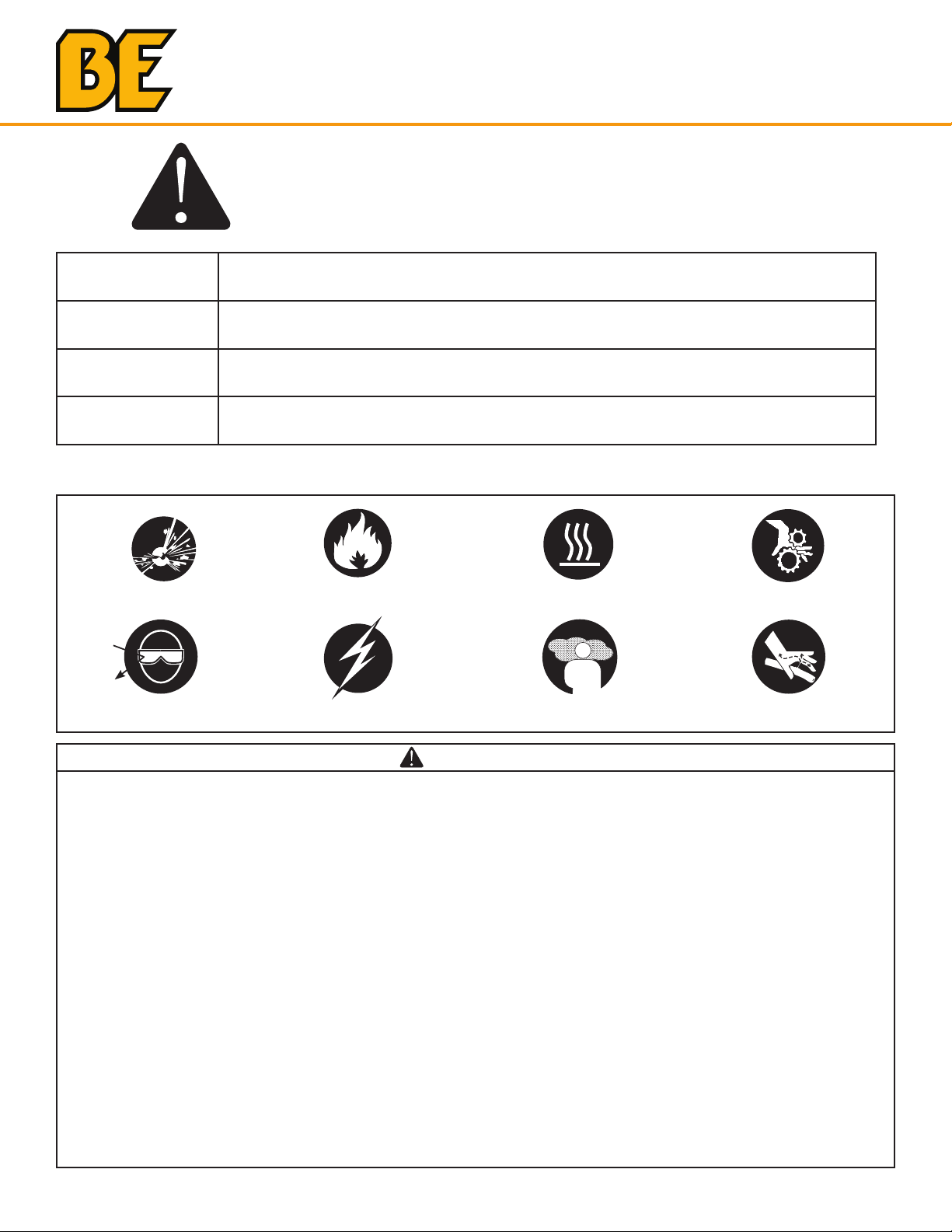

IMPORTANT SAFETY WARNINGS

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

explosion fire

toxic fumes

hot surface

flying objects injection

moving parts

electric shock

DANGER This is indicates a hazard which, if not avoided, will result in serious injury or

death.

WARNING This indicates a hazard which, if not avoided, will result in a severe injury or

property damage.

CAUTION This indicates a hazard which, if not avoided, might result in a minor or

moderate injury.

NOTICE This indicates a situation that could result in equipment damage or damage

to other property. Ensure all safety messages are observed and adhered to.

Hazard Symbols and Meanings

DANGER

• Always operate the pressure washer in a well-ventilated area free of flammable vapors, combustible dust, gases, or

other combustible materials.

• Do not store the pressure washer near an open flame or any equipment such as a stove, furnace, water heater, etc.,

which utilizes a pilot light or sparking device.

• Do not use this pressure washer to spray flammable material.

• Do not smoke while filling burner fuel tank.

• Never fill the fuel tanks while the pressure washer is running or hot. Allow unit to cool for two minutes.

• Always refuel slowly to avoid the possibility of spilled fuel which may cause a risk of fire.

• Always leave room for fuel to expand in the gas tank. Do not overfill.

• Engine Fuel Tank: If using a Gasoline Engine, refuel with gasoline only. Do not use diesel or kerosene.

• Burner Fuel Tank (Black): When refueling the Burner Fuel Tank, use No. 1 or No. 2 fuel oil/diesel or kerosene. Do not

use gasoline.

• Do not operate the unit if gasoline or diesel fuel is spilled. Wipe the pressure washer clean and move it away from the

spill. Avoid creating any ignition until the gasoline or diesel fuel has evaporated.

• When the battery is being activated, hydrogen and oxygen gases in the battery are extremely explosive. Keep open

sparks and flames away from the battery at all times, especially when charging.

• Be certain to disconnect the battery ground terminal before servicing. When disconnecting the cable from the

battery, start with the negative terminal. When connecting them, start with the positive cable.

• When charging the battery, remove the battery vent plugs.

• Use only a voltmeter or hydrometer to check a battery charge.

• DO NOT jump start the battery unless both batteries are of equal voltage and amperage.

5

IMPORTANT SAFETY WARNINGS

WARNING

Serious injury or death may occur from a fire caused by a muer spark.

Serious injury or death may occur if system safety’s are not properly maintained.

• A spark arrester must be added to the muer of this engine when using on land covered with any

flammable agricultural crop (hay and grain), and if they are used in or near brush or forested areas. The

arrester must be maintained in eective working order by the operator of the equipment. In the state

of California, the above is required by law. (Section 4442 and 4443 of the California Public Resources

Code.) Other states/provinces may have similar laws. Federal laws apply on Federal lands.

• This pressure washer has a Safety Relief Valve . This should never be altered, modified, removed or

made inoperative. If the device fails, replace immediately with genuine manufacturer replacement part.

WARNING

Serious injury or death may occur from inhaling engine/burner exhaust or dangerous

vapors. The engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

• Never operate this pressure washer in an enclosed area. Always ensure there is adequate ventilation

(fresh outside air) for breathing and combustion. This will prevent the buildup of dangerous carbon

monoxide gases. Beware of poorly ventilated areas, or areas with exhaust fans which can cause poor

air exchange. This unit should only be used outdoors to ensure ventilation is never an issue.

• Follow all safety instructions provided with the materials you are spraying. Use of a respirator may be

required when working with some materials. Do not use this pressure washer to dispense hazardous

detergents.

WARNING

Serious injury or death could occur from high pressure spray penetrating the skin.

• Keep clear of nozzle and spray! Never put your hand, fingers or body directly over the spray nozzle.

• Do not direct discharge stream at self, other persons, or pets.

• This product is to be used only by trained operators.

• Always keep operating area clear of other people.

• Do not allow children to operate this unit or be in the vicinity while you operate it.

• Seek emergency medical care if spray seems to have penetrated the skin. Do not treat as a simple cut!

• High pressure hoses and fuel lines should be inspected daily for signs of wear. If evidence of failure

exists, promptly replace all suspect hoses and fuel lines to prevent the possibility of injury from the

high pressure spray. If a hose or fitting is leaking, do not place your hand on the leak.

• Never operate the gun with the trigger held in the open position. To prevent accidental discharge, the

trigger gun should be securely locked when not in use.

• Before removing the spray nozzle or servicing the unit, always shut the unit o and pull the trigger of

the gun to release trapped pressure (even after you shut o the unit, there is high pressure water left in

the pump, hose and gun until you release it by pulling the trigger the gun).

WARNING

Serious injury or death may occur from contact with electricity.

• Do not direct spray on or into electrical installations of any kind! This includes electrical outlets, light

bulbs, fuse boxes, transformers, and the unit itself.

• Do not allow metal components of the pressure washer to come in contact with live electrical

components.

6

IMPORTANT SAFETY WARNINGS

WARNING

Serious injury may occur from touching the gasoline engine, muer, or heat exchanger. These

areas can remain hot for some time after the pressure washer is shutdown.

• Never allow any part of your body to contact the gasoline engine, muer, or heat exchanger.

WARNING

Serious injury may occur to the operator from moving parts on the pressure washer.

• Before making any adjustments, be certain the engine is turned o and the ignition cable(s) is removed

from the spark plug(s). Turning the machinery over by hand during adjustment or cleaning might start the

engine and machinery with it.

• Do not operate the unit without all protective covers in place.

WARNING

Serious injury may occur from a pressure washer malfunction or exploding accessories if

incorrect system components, attachments, or accessories are used.

Serious injury or death may occur if attempting to start the pressure washer when the

pumping system is frozen.

• Never make adjustments to the factory set pressures.

• Never exceed manufacturers maximum allowable pressure rating of attachments.

• Do not allow any hoses to make contact with heat exchanger to prevent the possibility of bursting. Avoid

dragging the hoses over abrasive surfaces such as cement.

• Use only manufacturer recommended repair parts for your pressure washer.

• In freezing temperatures, the unit must always be warm enough to ensure there is no ice formation in

the pump. Do not start the pressure washer if it has been transported in an open or under heated vehicle

without first allowing the pump to thaw.

WARNING

Serious injury or death may occur from detergents contacting the skin.

Serious injury can occur from loose debris being propelled at a high speed from the spray gun.

Injury may occur if the operator loses their balance caused by the thrust of water traveling

through the spray nozzle.

• Never use any solvents or highly corrosive detergents or acid type cleaners with this pressure washer.

• Protective equipment such as rubber gloves and respirators are advisable, especially when using cleaning

detergents.

• Keep all detergents out of the reach of children!

• Always wear protective goggles when operating the unit to shield the eyes from flying debris and

detergents.

• Do not direct spray toward fragile materials such as glass.

• Stay alert: watch what you are doing. Do not operate the unit when fatigued or under the influence of

alcohol or drugs.

• Never squeeze the trigger unless securely braced.

• Do not overreach or stand on unstable support.

• Wet surfaces can be slippery. Wear protective foot gear and keep good footing/balance at all times.

• Never pull the trigger of the gun while on a ladder, roof, or other unstable surface.

• Always hold on firmly to the gun/lance assembly when starting and operating the unit. Failure to do so

can cause the lance to fall and whip dangerously.

• Do not leave pressurized unit unattended. Shut o the pressure washer and release trapped pressure

before leaving.

• Do not operate the unit if you see any fuel, oil, or water leaking from the machine. DO NOT resume

operation until the unit has been inspected and repaired by a qualified technician.

• Do not transport the unit by pulling on hoses or cords.

WARNING

If you smell gas, shut o the gas supply to the appliance, extinguish any open flame, and test all joints with

a soap solution. If the odor persists, call your gas supplier immediately.

7

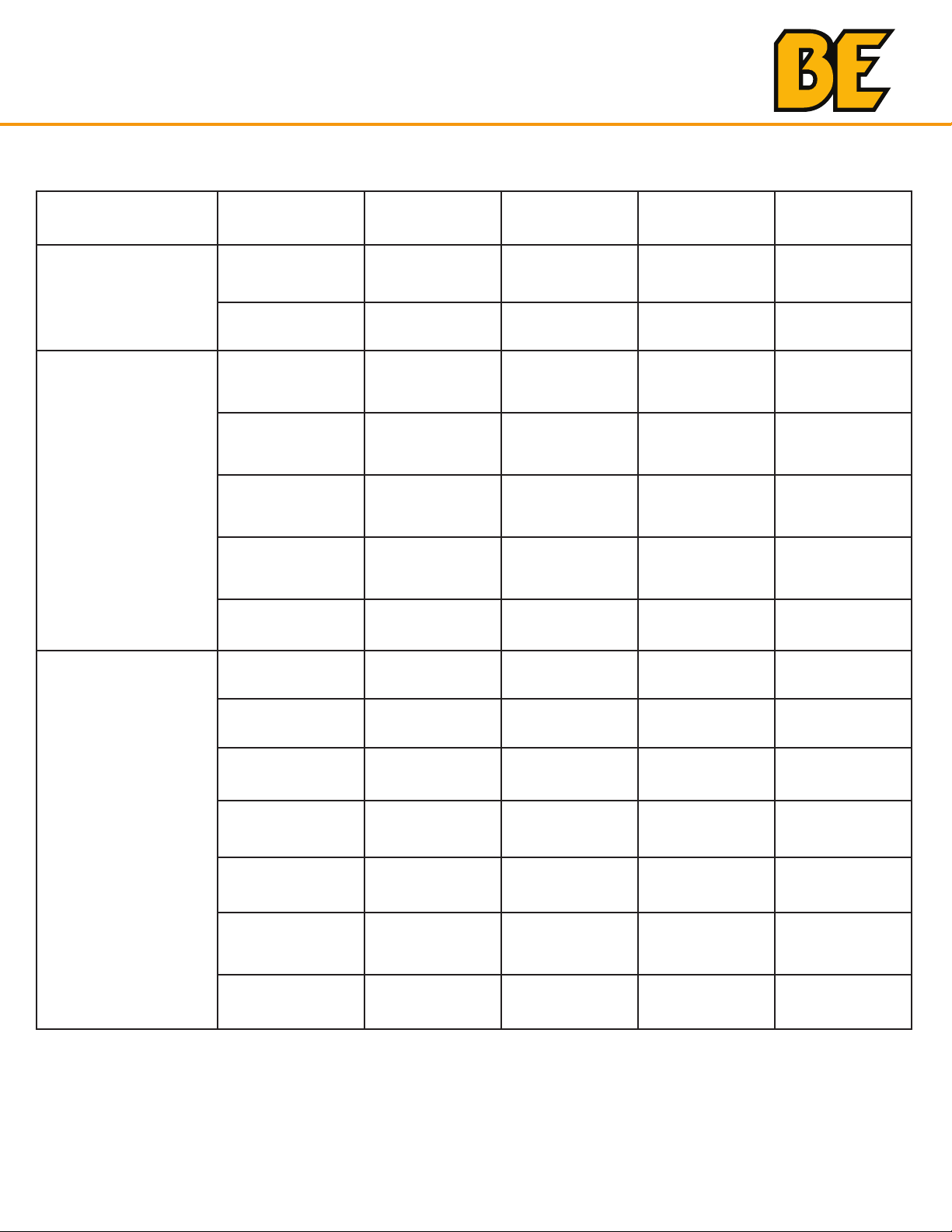

UNIT SPECIFICATIONS

MODEL HW255E1CNG HW255E3CNG HW2775E1CNG HW2775E3CNG

HEATER

PSI & GPM 2500 @3.5 GPM 2500 @3.5 GPM 2700 @4.6

GPM

2700 @4.6

GPM

BTU’s 345,500 345,500 345,500 345,500

SPECIFICATIONS

INPUT

PRESSURE

NG

7 INCHES 7 INCHES 7 INCHES 7 INCHES

MANIFOLD

PRESSURE

NG

2.6 INCHES 2.6 INCHES 2.6 INCHES 2.6 INCHES

INPUT

PRESSURE

PROPANE

14 INCHES 14 INCHES 14 INCHES 14 INCHES

MANIFOLD

PRESSURE

PROPANE

10 INCHES 10 INCHES 10 INCHES 10 INCHES

ORIFICE SIZE #53NG

or #65LP

#53NG

or #65LP

#53NG

or #65LP

#53NG

or #65LP

SAFETY

COMPONENTS

Thermostat YES YES YES YES

Flow Switch YES YES YES YES

High Temp

Limit Protector YES YES YES YES

High Pressure

Relief Valve YES YES YES YES

Dimensions

(LxWxH) in. 43”x20”x42” 43”x20”x42” 43”x20”x42” 43”x20”x42”

DRAFT HOOD

SIZE

(diameter)

9” 9” 9” 9”

Weight

(pounds) 598 568 675 628

8

Whenunpackingtheunitifyoufinddamage

duetoshippingcontactyourdealerorBEPower

Equipmentimmediately

ELECTRICALSUPPLY

Arrangewithanelectriciantoinstallaproperly

groundedthreewirereceptacle

Toprotectthereceptaclefromsplashestherecom-

mendedheightabovethegroundlevelisaminimum

offourfeetMakesurethesupplyvoltageiscorrect

Thevoltageisshownontheratingplateoftheunit

orsee“SpecificationsFeaturesandOptions”sheet

inthismanual

INCOMINGWATERSUPPLY

Connectagardenhosetothewaterinletoftheunit

Thewatersupplymustbeabletodeliverfromto

gallonsperminuteataminimumpressureof

psiSeethe“SpecificationsFeaturesandOptions”

sheetinthismanual

OUTGOING(HIGHPRESSURE)WATER

Tothewateroutletfittingconnectthehighpres-

surehosetriggergunextensionandnozzle(The

nozzleislocatedinaplasticbagwiththismanual)

PUMP-OIL

Beforeoperatingthepumpchecktoseethatthe

oilislevelwiththedotonthesightgaugewhichis

locatedattherearofthepumpTheoillevelcan

alsobecheckedusingthedipstickwhichisattached

totheoilfillercapEnsurethattheventholeinthe

capdipstickisclearofdirtWhenoilisrequired

useornon-detergentheavydutyoil

ENGINE-OIL

RefertotheEngineManual

FUELSUPPLY

Forstationaryinstallationshavethegaspiping

installedbyalicensedgasfitterThismustbedone

inaccordancewiththegascodes

BforNaturalGas

BforPropaneGas

Forportablemachinesconnectthesupplyhose

andregulatorintothePOLfittinginthevalveon

thesupplytankRememberthatthisfittinghasa

lefthandthreadOpenthetankvalveandcheck

forleaksinthepropaneconnectionswithasoap

solutionDepressthepilotvalveforapproximately

aminutetopurgethelinesofairWaitminutes

toallowanyescapedpropanetodissipatebefore

lightingthepilot

DETERGENTSUPPLY

Onlyusechemicalswithaphbetweenand

ForstrongerchemicalsuseaDownStream

injectionsystemContactyourdealerforadditional

information

PROTECTFROMFREEZING

Whentransportingorstoringyourpressurewasher

attemperaturesbelowfreezingmakesurethatthe

unithasbeenproperlywinterized(SeeWinterizing

YourPressureWasher)

Evenanovernightfrostcansplitacoilorcracka

pump

BEFORE STARTING THE UNIT

WARNING

DONOTCHANGETHEACPLUGONTHEUNIT

TOADIFFERENTTYPE

DONOTCUTOFFTHEGROUNDPINORTHE

OPERATORWILLBEEXPOSEDTOSEVERE

SHOCKKEEPELECTRICALCORDSAND

CONNECTIONSDRYATALLTIMES

CAUTION

Propanegasinheavierthanairandcancollectin

lowhollowareasinanexplosivemixtureEnsure

thattheareaswhereyouoperatethismachine

areopentobreezesetc

9

COMBUSTION AIR SUPPLY

The 5004N/P heater is comprised with an

Atmospheric burner and requires air for

combustion and ventilation.

The appliance installer will know how and

where to place a supply air duct. Take care

that this opening will not promote drafts

which could blow out the pilot light.

Keep the area around the machine clear so

this air can get to the burner.

APPLIANCE IN CONFINED SPACE

The confined space shall have two per-

manent openings: one near the top of the

enclosure and one near the bottom of the

enclosure. Each opening shall have a free

area of not less than one (1) square inch

per 4000 BTU’s per hour of the total input

of all appliances within the enclosure. The

openings shall have free access to the room

interior which should have adequate infiltra-

tion from the outside.

OUT DOOR ROOF STACK SPACING RE-

QUIREMENTS

Must Conform to local standards. Below

drawing is a Guide.

PRE-OPERATING INSTRUCTIONS

10

STARTING & SHUTTING DOWN

THE PRESSURE WASHER

STARTING THE MACHINE

1) Turn gas supply valve “ON”

2) Turn control valve “ON”

START UP

1) Make sure that switches are “OFF”

2) Connect electrical supply

3) Connect machine to water supply

4) Connect high pressure hose gun and

wand to outlet of pressure washer

5) Grasp gun firmly and turn “pump” switch

“ON”

6) When spray is constant turn on “burner”

switch “ON” then turn thermostat to de-

sired temperature

SHUTDOWN

1) Turn “burner” switch o

2) Pump cold water through spray gun for

two minutes

3) Shut o “pump” and activate spray gun

to release pressure in the line

4) Shut o gas supply valve if machine is to

be left for long periods of time

CHANGING PRESSURE

The variable Unloader Valve is already set

to full pressure. Do not adjust the Unloader

past the maximum pressure, as this will not

increase the performance, and the excessive

shut-o pressure will damage the Washer.

CLEANING CHEMICALS

For chemical application, a chemical injec-

tor is required. Open the valve at the lance.

To change concentration, adjust metering

valve toward open or close. Use only chem-

icals with a pH between 7.0 and 10.0. For

stronger chemical, use a Downstream Injec-

tion System. (Contact dealer for details.)

CAUTION

The force of the water leaving the nozzle

causes a kick-back or recoil at the trigger

gun.

CAUTION

Afteryouusechemicaladditivesthoroughly

FLUSHthesystemwithcleanwater

WARNING

Neverrunthewasherwithoutwater

11

FLOWSWITCH

Theflowswitchpreventstheburnerfrombeing

turnedonifthereisinsufficientwaterProper

waterflowcausesthemagneticcoretobe

pushedupclosingthereedcontactThiscon-

tactisinterlockedwiththegascontrolvalve

UNLOADERVALVE

TheUnloaderValveallowsallofthewater

deliveredbythepumptoreturntothepump

suctionsideIfthetriggergunisclosedor

“OFF”theUnloaderValvegoesintothe

“bypassmode”andthepumprunswithout

pressureHoweverthepumpmaybeseverely

damagedduetoexcessiveoverheatingifleft

runninginthe“bypassmode”or“gun-off”

situationformorethanminutes

SAFETYRELIEFVALVE

TheReliefValvepreventsthemachinefrom

beingsubjectedtoabnormallyhighpressures

Ifthissituationoccursthevalvewillblowoff

relievingthepressureinthecoilThisvalvemay

alsooperateiftheunloaderisadjustedtoo

high

PRESSURESWITCH

ThePressureSwitchensuresthatthereis

pressureandthereforethereiswaterflowat

theheadofthepumpThiscontroldoesnot

operateatlessthanpsiThereforeifthe

pumpison“bypassmode”theburnerwillnot

operateAlsoiftheUnloaderisturnedback

lessthanpsiinthesteammodetheburner

willnotoperateTheeffectofthisswitchis

verysimilartothatoftheflowswitch

THERMOSTAT

Thebuilt-inthermostatstopstheunitfrom

overheatingMaximumtemperatureoftheunit

is°F(°C)Abovethistemperaturethe

burnerstopsautomatically

HIGHLIMITSWITCH

TheHighLimitSwitchisathermostatwhich

operatesatahighertemperaturethanthe

built-inthermostatabout°F(°C)This

switchisnotadjustableandwillonlyoperate

whenothercontrolsfailtokeepthewater

temperaturewithinthenormaloperatingrange

Unliketheotherburnercontrolswitchesthis

switchcutsthepowertothewholegasvalve

notjustthegassolenoid

COMBINATIONAUTOMATICGASVALVE

Thegasvalveincorporatesamanualshut-off

valveagasregulatorthepilotcontrolanda

timedautomaticshut-offThefunctionsofthe

manualshut-offandregulatoraresimpleThe

manualshut-offclosesthegasinletsothat

nogascanentertheburnerTheregulator

regulatestheflowofgastokeepitatconstant

pressureThepilotcontrolisapilotcontrol

valveandthermocouplesensorThepilot

valvecanbeopenedtolightthepilotburner

Whenlittheburnerflameisdirectedtoa

thermocouplesensorThesensorheatsupfrom

theflameandallowsthepilotvalvetostay

openpermittingautomaticoperationofthe

burnerIfthepilotgoesoutthethermocouple

willcooldownandthecontrolwillshut-offthe

gassupplyThepilotmustthenbemanually

relit

SAFETY COMPONENTS

12

MAINTENANCE SCHEDULE

PROCEDURE DAILY 3 MONTHS 6 MONTHS 9 MONTHS 12 MONTHS

Check engine oil level

(ONLYusethetypeandgradeofoil

specifiedforthispump)

X

Change engine oil***** X X X X

Check water pump oil level X

Change water pump oil ** X X X X

Oil leak inspection X

Fuel leak inspection X

Water leak inspection X

Hose inspection X

Water inlet screen inspection X

Check fuel filter X X X X

Replace fuel filter X

Inspect belts X X X X

Replace high pressure nozzle*** X X X X

Inspect fuel pump filter* X

Replace fuel nozzle* X

Check burner air adjustment X X X X

Check burner electrodes* X

Test water pressure* X X X X

Test fuel pressure* X X X X

Test water temperature* X X X X

Descale coil**** X

Power Cord/Outlet Socket inspection

(replace worn or damaged parts

immediately) X

* Must be performed by an authorized service technician.

** The pump oil must be changed after the first 50 hours of operation and then every

250 hours or 3 months, whichever comes first.

*** High pressure nozzle should be replaced whenever pressure drops to less than 85%.

**** Scale build-up will vary with mineral content in the water and amount of usage.

Descaling can range from weekly to yearly maintenance.

***** The engine oil must be changed after the first 8 hours of operation and then every

50 hours or 3 months, whichever comes first.

13

CAUTION

Be certain the hoses and spray gun are not

attached to the pump during application

of pump saver or use of the blowout tool.

Having a hose attached greatly reduces

the amount of water/debris removed from

the pump and coil.

STORAGE & WINTERIZING

When storing the unit for winter, it is

important to ensure it is stored in the right

environment. Ensure the storage area stays

above freezing during cold weather, and try

to limit the amount of dust gathered on the

unit via a cover.

STORINGWITHAFLOATBOX

•Shutoffthewatersupplyanddisconnect

hose

•RemovecoverfromFloatBox

•Runthepressurecleaneruntilthelevelofthe

waterintheFloatBoxisjustabovetheoutlet

screen

•Turnoffthecleaner

•FilltheFloatBoxtoaboutwith

windshieldwasherorantifreeze

•Turnonthecleanerandopengununtilliquid

comesoutofnozzle“foamy”or“soapy”

•PutguninOFFpositionforfivesecondsto

allowantifreezeintobypassline

•Shutoffmotor-unitisnowwinterized

STORINGWITHOUTAFLOATBOX

•Shutoffthewatersupplyanddisconnect

hose

•Youneedashort(”)lengthofhosewitha

malegardenhosefittingononeend

•Connecttheshorthosetotheinletofthe

machine

•Puttheotherendofthehoseintoa

containerofwindshieldwasherorantifreeze

•TurnonCleanerandopengununtilliquid

comesoutofnozzle“foamy”or“soapy”

•PutguninOFFpositionforsecondstoget

antifreezeintobypasslineShutoffmotor

Theunitisnowwinterized

• BE “Pump Saver” Solution

(P/N: 85.490.046). This is an anti-freeze

solution that is used before storing the

unit. It coats to inside of the pump to

ensure that any residual water doesn’t

freeze. To use BE Pump Saver, follow

the instructions written on the bottle.

Water freezing in the pump will damage

seals and other internal parts. Freezing

damage is not covered by warranty.

• BE “Pump & Coil Blowout Tool”

(P/N: 59.400.000). This tool utilizes

compressed air to forcefully remove

any water left in the pump. One end of

the tool attaches to an air compressor,

while the other attaches to the inlet

of your water pump via an adapter.

Follow the instructions on the back of

the packaging to use the Pump and Coil

Blowout Tool.

STORAGE & WINTERIZING

CAUTION

Ifyourhoseislongerthanfeetthefloat

boxmayemptybeforetheliquidfromthe

nozzlegetsfoamyIfthishappensrefillthe

floatboxwithantifreezeintobypassline

14

UNIT BREAKDOWN

1

2

10

3

4

6

89

7

5

HW255E1CNG

HW2775E1CNG

11

12

13

14

15

16

17

18

19

20

25

26

27

28

21

22

23

24

15

PARTS REFERENCE LIST

ITEM PART NUMBER DESCRIPTION QT Y.

1 HEX- BURNERRING 1

2 HEX- BURNERRING 1

3 HEC-B GASVALVEELECTRONICIGNITION-PILOTRELIGHT 1

4 HES ELECTRONICIGNITIONMODULE 1

5 QASSY PILOTBURNERASSEMBLY 1

6 H- VELECTRONICIGNITIONGASVALVE 1

7 SH IGNITIONMODULE 1

8 RUB-T RELIEFVALVE 1

9 PUST FLOWSWITCH 1

10 85.300.097 CHEMICAL INJECTOR 1

11 T44110 HI LIMIT 1

12 24606 BOTTOM PAN 1

13 70.001.005 230V, 5HP MOTOR (HW255E1CNG) 1

14 70.001.075 230V, 7.5HP MOTOR (HW2775E1CNG) 1

15 24601 BASE 1

16 85.300.037 UNLOADER 1

17 85.149.017B COMET FWS23530E, TRIPLEX, 3000 PSI 5HP PUMP (HW255E1CNG) 1

18 85.0149.033B COMET FWS2, TRIPLEX, 3000 PSI 7.5HP PUMP (HW2775E1CNG) 1

19 85.300.056 WATER INLET ASSEMBLY 1

20 FIA59LD36A CONNECTOR HOSE 1

21 40362 DRAFT HOOD 1

22 40168 HEATING COIL 1

23 246115 S.S. COIL SKIN 1

24 24609 COIL CAP 1

25 85.210.045BEP 5 HP QUICK CONNECT SPRAY NOZZLE 45 1

26 85.210.055BEP 7.5 HP QUICK CONNECT SPRAY NOZZLE 55 1

27 85.238.251 50FT 6000 PSI 3/8” RUBBER HOSE 1

28 85.205.064 36” GUN AND WAND ASSEMBLY 1

HW255E1CNG

HW2775E1CNG

16

10

HW255E3CNG

HW2775E3CNG

11

12

13

14

15

16

17

18

19

20

21

22

23

24

UNIT BREAKDOWN

1

2

3

4

6

89

7

5

25

26

27

28

17

ITEM PART NUMBER DESCRIPTION QT Y.

1 HEX- BURNERRING 1

2 HEX- BURNERRING 1

3 HEC-B GASVALVEELECTRONICIGNITION-PILOTRELIGHT 1

4 HES ELECTRONICIGNITIONMODULE 1

5 QASSY PILOTBURNERASSEMBLY 1

6 H- VELECTRONICIGNITIONGASVALVE 1

7 SH IGNITIONMODULE 1

8 RUB-T RELIEFVALVE 1

9 PUST FLOWSWITCH 1

10 85.300.097 CHEMICAL INJECTOR 1

11 T44110 HI LIMIT 1

12 24606 BOTTOM PAN 1

13 70.003.005 230V/460V, 5HP MOTOR (HW255E3CNG) 1

14 70.003.075HE 230V/460V, 7.5HP MOTOR (HW2775E3CNG) 1

15 24601 BASE 1

16 85.300.037 UNLOADER 1

17 85.149.017B COMET FWS23530E, TRIPLEX, 3000 PSI 5HP PUMP (HW255E3CNG) 1

18 85.0149.033B COMET FWS2, TRIPLEX, 3000 PSI 7.5HP PUMP (HW2775E3CNG) 1

19 85.300.056 WATER INLET ASSEMBLY 1

20 FIA59LD36A CONNECTOR HOSE 1

21 40362 DRAFT HOOD 1

22 40168 HEATING COIL 1

23 246115 S.S. COIL SKIN 1

24 24609 COIL CAP 1

25 85.210.045BEP 5 HP QUICK CONNECT SPRAY NOZZLE 45 1

26 85.210.055BEP 7.5 HP QUICK CONNECT SPRAY NOZZLE 55 1

27 85.238.251 50FT 6000 PSI 3/8” RUBBER HOSE 1

28 85.205.064 36” GUN AND WAND ASSEMBLY 1

HW255E3CNG

HW2775E3CNG

PARTS REFERENCE LIST

18

ELECTRICAL BOX ASSEMBLY BREAKDOWN

HW255E1CNG

HW2775E1CNG

1

2

3

4

5

OVERLOAD RELAY

(REFER TO CHART ON PAGE 19) 7

CONTACTOR

(REFER TO CHART ON PAGE 19)

6

8

19

PARTS REFERENCE LIST

ITEM PART NUMBER DESCRIPTION QT Y.

1 ELCA ROTARY SWITCH PUMP/BURNER 1

2 EL SHOCKSAFE FUSEHOLDER 1/4x1.25 1

3 ELGGC5 1/2 AMP GLASS FUSE 1

4 ELTR86 OFF-120 DEGREES THERMOSTAT 1

5 ELCT1S30 CT1S30 OFF DELAY TIMER SSAC 1

6 ELMH50AG 600/24V 50A TRANSFORMER 1

7 EL6M30A2SQ 600V 30A 2POLE FUSE HOLDER 1

8 ELATDR1/2 TIME DELAY FUSE 600V 1/2A 1

HW255E1CNG

HW2775E1CNG

ELECTRICAL CONTACTOR AND OVERLOAD PARTS LIST

PART NO. PHASE MOTOR (HP) VOLTAGE (V) CONTACTOR

PART NO.

OVERLOAD

PART NO.

HW255E1CNG 15 230 ELCI-32 ELT9E1/23-28

HW2775E1CNG 7.5 230 EL42CF35AJ ELT9E1/28-40

20

ELECTRICAL BOX ASSEMBLY BREAKDOWN

HW255E3CNG

HW2775E3CNG

1

2

3

4

5

6

7

8

10

9

CONTACTOR

(REFER TO CHART ON PAGE 21)

OVERLOAD RELAY

(REFER TO CHART ON PAGE 21)

This manual suits for next models

3

Other BE Power Equipment Washer manuals

Popular Washer manuals by other brands

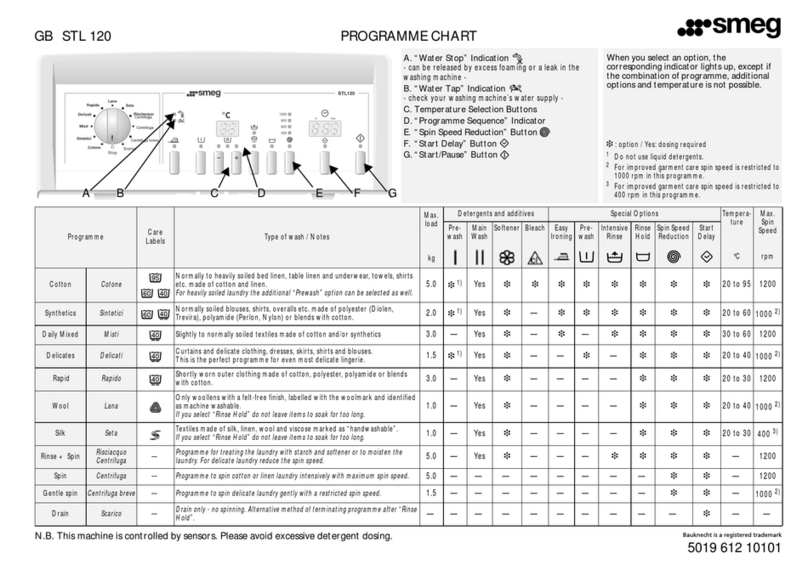

Smeg

Smeg STL120 user manual

Whirlpool

Whirlpool Gold GSW9550KQ0 Use and care guide

VOX electronics

VOX electronics WM1275-YTQD operating instructions

Panasonic

Panasonic NA-127VB4 Operating instructions & installation instructions

Frigidaire

Frigidaire FLCF09GGFWTU user manual

Electrolux

Electrolux ews 1042 edu user manual