BE Power Equipment WHIRL-A-WAY User manual

pressure washer surface cleaner

USER MANUAL

WHIRL-A-WAY

85.403.003

85.403.007

85.403.008

85.403.009

85.403.010

85.403.011

Introduction

3Owners Responsibility

3Product Identication

Product Specification and Safety

4Product Specication

4Safety

Operating Instructions

5Intended Use

5Pre-Operation

5Operation

Parts Diagram

685.403.003 / 85.403.007 / 85.403.011

Parts List

785.403.003 / 85.403.007 / 85.403.011

Parts Diagram

885.403.008

Parts List

985.403.008

Parts Diagram

10 85.403.009 / 85.403.010

Parts List

11 85.403.009 / 85.403.010

Trouble Shooting and Parts List

12 Trouble Shooting

12 Parts list

Nozzle Maintenance

13 Nozzle Maintenance

Nozzle Chart and Warranty

14 Nozzle Chart

14 Warranty

TABLE OF CONTENTS

3

Congratulations on your purchase of a BE Power Equipment Whirl-A-Way Surface

Cleaner.

Reading this manual will help get you the best results for set-up, operation, maintenance

and avoid personal injury or damage to your machine. By knowing how best to operate

this machine, you will be better positioned to show others who may also operate the unit.

All the information in this manual is based on the latest product information available at

the time of printing. BE Power Equipment reserves the right to make changes at any time

without notice or incurring any obligation.

Owner/Operator Responsibility

The owner/operator must have a thorough understanding of the operation, maintenance

and dangers associated with using this machine. It must be understood that it is ultimately

up to the owner/operator to safely use this machine as outlined in this manual.

This manual is considered a part of the machine and needs to be kept in a safe location. If

the machine is resold or given to someone else, this manual needs to be included.

Record Identification Numbers

It is recommended that you record the product identification numbers in this manual.

These numbers are important to have on hand if you need to contact technical support

(1-866-850-6662). The model and serial number can be found on the box and on decal on

the machine.

PRODUCT IDENTIFICATION

Model Number:

Date of Purchase:

Dealer Name:

INTRODUCTION

4

PRODUCT SPECIFICATIONS

The pressure washer being used MUST be compatible with the below specifications to

ensure proper operation.

• 3/8" Quick Connect hose coupler

• 4,000 Maximum PSI / 5,000 PSI for 85.403.008 Model

• 1,500 Minimum PSI

• 5.0 Maximum GPM

• 3.0 Minimum GPM

• Up to 200°F/82°C water temperature

• (Changing nozzles will alter the min and maxes, see NOZZLE CHART)

SAFETY

• ALWAYS review and know all the warnings and safety alerts for the pressure washer

that you are using that can be found in the pressure washer manual.

• ALWAYS be aware of where the Whirl-A-Way is being used or pointed. High-pressure

spray can cause injury or damage.

• If this type of injury occurs, DO NOT TREAT AS A SIMPLE CUT. SEEK

EMERGENCY MEDICAL ATTENTION IMMEDIATELY. If you are using

cleaning detergents, be prepared to tell the physician exactly what kind.

• Spray guns can have signicant kickback. ALWAYS brace yourself and have rm

footing when operating.

• NEVER attempt to repair high-pressure components if damaged. Always replace parts.

• ALWAYS use on at surfaces.

• WARNING: Hitting any raised obstacle with the surface cleaner can cause damage.

If performance changes, or if it begins to vibrate aer impact, immediately turn o the

pressure washer. Inspect for damages and make repairs.

• ALWAYS ensure all component connections and ttings are securely fastened. High-

pressure water can turn loose ttings or spray nozzles into projectiles causing injury or

damage.

• CAUTION: If stones or debris collect in the whirl-a-way they can be cleared by tilting

it in safe direction to ush away the debris.

• ONLY use cold water pressure washers. Hot water pressure washers will cause failures

and will void warranty.

• ALWAYS be aware of surfaces that will become wet and may become slippery.

• ALWAYS wear appropriate personal safety equipment. Eye protection is especially

important.

• NEVER use without wearing foot protection.

• ALWAYS have a secure grip of the gun and stable footing.

• NEVER modify the Whirl-A-Way in any manner.

• NEVER reach under the Whirl-A-Way while it is operating.

• ALWAYS test in a safe location when rst using.

PRODUCT SPECIFICATIONS AND SAFETY

5

Pre-Operation Instructions

1. Remove Whirl-A-Way from packaging. Ensure there is no damage and that

rotary arm freely spins by hand.

2. Connect Whirl-A-Way to the end of the high-pressure hose. e high-pressure

hose will need to have 3/8” quick connect coupler to attach to the 3/8” quick

connect plug on the Whirl-A-Way.

3. Prepare your pressure washer for start-up as per its start-up procedure found its

manual.

4. Once water is connected to the pressure washer, squeeze the trigger of the spray

wand to ensure that water ows through the whirl-a-way.

5. Level the Whirl-A-Way onto a at surface.

6. Start the pressure washer as instructed in its manual.

Operating Instructions

1. Walk slowly behind the Whirl-A-Way moving it in a rhythmic side-to-side

motion.

2. If striping or swirling occurs then slow your pace.

3. If striping or swirling continues then it is likely the nozzles are clogged or

damaged. If they are damage you will see visible deformation of the nozzle from

impact. If there is no damage, then they need to be cleaned. See the Nozzle

Maintenance section for details.

4. When done working, always ush with clean water. Detach from your pressure

washer and drain out any water to prevent possible freezing damage. Store in a

manner so not to deform the bristle skirt.

Intended Use

1. e Whirl-A-Way is designed to rapidly clean large, at surfaces such as concrete

oors.

2. It is not intended to clean rough or uneven surfaces such as stairs. Uneven surfaces

can cause damage.

3. e pressure washer must be rated to make the Whirl-A-Way operate properly. For

the standard nozzles that come with the Whirl-A-Way the pressure washer must

have the following.

• 3/8” Quick-connect coupler on the end of the high-pressure hose

• 1,500 - 4,000 PSI rating / 5,000 for 85.403.008 Model

• 3.0 - 5.0 GPM rating

OPERATING INSTRUCTIONS

6

PARTS DIAGRAM

5.

13.

4.

7.

2.

3.

10.

9.

11.

12.

16.

8.

1.

6.

85.403.003

85.403.007

85.403.011

PARTS LIST

14.

15.

7

85.403.003

85.403.007

85.403.011

NO#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PART #

85.792.003

85.790.004

85.792.004

85.238.059

AC7501

85.300.105

85.792.008K

85.602.005

85.792.010

85.792.009

85.792.011

85.225.025

85.791.020

85.419.102

85.419.103

DESCRIPTION

Bracket, Mounting Head 16"

Rotary Head, 16"

Mounting Blocks

Hose, 62" x 3/8"

Easy Pull Gun

Plug, 3/8" MNPT

Handle

Hand Grip

Brush, 16"

Cover, Polypropylene 16"

Rotary Arm, 16"

Nozzle, 25 Deg. 025

Sleeve For DC5090 WAW Gun

Cotter Pin Set, 2-1/4"

Cotter Pin Set, 2-5/8"

NO#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

NO#

16

PART #

85.792.003

85.790.004

85.792.004

85.238.059

AC7501

85.300.105

85.792.002K

85.602.005

85.792.006

85.792.005

85.792.007

85.225.025

85.791.020

85.419.102

85.419.103

PART #

85.793.016

DESCRIPTION

Bracket, Mounting Head 20"

Rotary Head, 20"

Mounting Blocks

Hose, 62" x 3/8"

Easy Pull Gun

Plug, 3/8" MNPT

Handle

Hand Grip

Brush, 20"

Cover, Polypropylene 20"

Rotary Arm, 20"

Nozzle, 25 Deg. 025

Sleeve For DC5090 WAW Gun

Cotter Pin Set, 2-1/4"

Cotter Pin Set, 2-5/8"

See 85.403.007 for parts 1-13.

DESCRIPTION

Castor Kit

PARTS LIST

8

85.403.008

5.

13.

4.

7.

2.

3.

10.

9.

11.

12.

14.

8.6.

15.

PARTS DIAGRAM PARTS LIST

9

85.403.008

NO#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PART #

85.792.003

85.790.004

85.792.004

85.238.046

85.202.133

85.300.105

85.792.050K

85.660.035

85.792.006

85.792.005

85.792.007

85.225.025

85.300.102S

85.211.007

85.792.051

DESCRIPTION

Bracket, Mounting Head 20”

Rotary Head, 20”

Mounting Blocks

Hose, 46” x 3/8”

Italian design linear spray gun

Plug, 3/8” MNPT

Handle

Hand Grip

Brush, 20”

Cover, Polypropylene 20”

Rotary Arm, 20”

Nozzle, 25 Deg. 025

Quick Connect plug

Inline lter

Handle hardware kit

Includes nozzle cleaning tool

(sold separately with other models)

Part # 85.211.008

PARTS LIST

10

85.403.009

85.403.010

5.

4.

7.

2.

3.

11.

10.

9.

12.

13.

1.

6.

8.

PARTS DIAGRAM PARTS LIST

14.

15.

11

85.403.009/85.403.015

85.403.010

NO#

1

2

3

4

5

6

7

8

9

10

11

12

12

13

14

15

PART #

85.791.002

85.790.004

85.792.019

85.238.059

AC7501

85.300.105S

85.792.018K

85.602.005

85.792.013

85.790.029

85.792.012

85.792.017

85.791.010S

85.225.020

85.419.102

85.419.103

DESCRIPTION

Bracket, Mounting Head 20"

Rotary Head, 20"

Mounting Blocks

Hose, 62" x 3/8"

Spray Gun

Plug, 3/8" MNPT

Handle

Hand Grip

Brush Skirt, 20"

Castor Wheel

Cover, Stainless Steel 20"

Rotary Arm, 20" SS WAW, 2 Arm

Rotary Arm, 20" SS WAW, 3 Arm

Nozzle, 25 Deg. 020

Cotter Pin Set, 2-1/4"

Cotter Pin Set, 2-5/8"

NO#

1

2

3

4

5

6

7

8

9

10

11

12

12

13

14

15

PART #

85.791.002

85.790.004

85.792.019

85.238.059

AC7501

85.300.105S

85.792.018K

85.602.005

85.792.015

85.790.029

85.792.014

85.792.016

85.791.033

85.225.020

85.419.102

85.419.103

DESCRIPTION

Bracket, Mounting Head 24"

Rotary Head, 24"

Mounting Blocks

Hose, 62" x 3/8"

Spray Gun

Plug, 3/8" MNPT

Handle

Hand Grip

Brush Skirt, 24"

Castor Wheel

Cover, Stainless Steel 24"

Rotary Arm, 24" SS WAW, 2 Arm

Rotary Arm, 24" SS WAW, 3 Arm

Nozzle, 25 Deg. 020

Cotter Pin Set, 2-1/4"

Cotter Pin Set, 2-5/8"

PARTS LIST

12

Rotary Head Repair Parts

A repair kit for this Whirl-a-Way’s rotary head, is available.

If you encounter problems with the rotary head aer the 1 year warranty

has expired, this repair kit (part #85.790.010) allows you to replace the inner

components very quickly.

e rotary head has a snap ring on the bottom holding all the bearings inside.

By removing the snap ring and washer, you can tap o the outer shell with a

hammer while the output sha is held in a vice. e rotary head repair kit can

then be used to replace the worn items inside the rotary head shell.

NO#

1

2

3

4

PART #

85.790.010

85.790.001

85.790.002

85.790.011

DESCRIPTION

Rotary Head Rebuild Kit

Inlet Valve

Inlet Valve Viton O-Ring

Outlet Sha

Troubleshooting

Problem Cause Solution

Rotary arm not spin-

ning

• 1 or more plugged nozzles

• Nozzles not aligned with arm

• Damaged nozzle or rotary arm

• Clean or replace nozzles

• Realign nozzles

• Replace damaged part(s)

Low pressure or slow

spinning

• Inline lter in the plug is

clogged • Clean or replace

Leaking water from

weep hole • Damaged or worn seals • Replace rotary head

Leaking water from

QC plug • Damaged or missing o-ring in coupler • Replace o-ring

Unit vibrating while

in use

• One or more plugged nozzles

• Uneven nozzle wear

• Damaged nozzle or rotary arm

• Miss matched nozzles

• Clean nozzles

• Replace damaged part(s)

• Replace nozzles

TROUBLESHOOTING / PARTS LIST NOZZLE MAINTENANCE

13

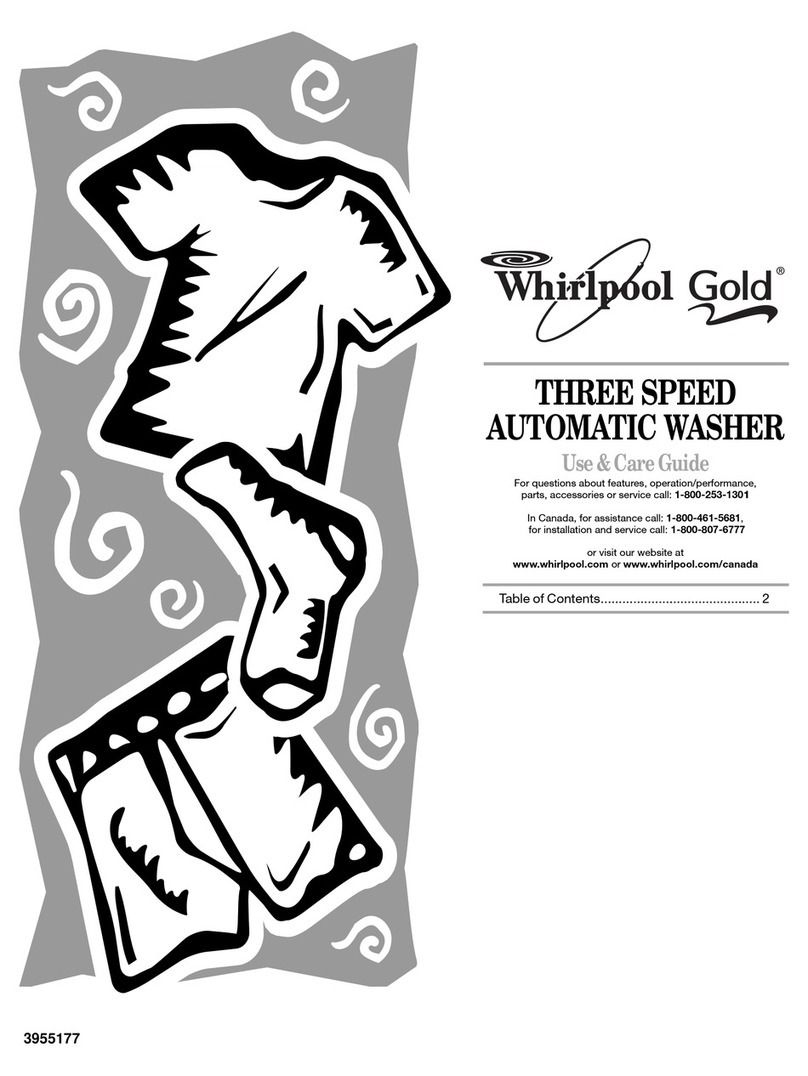

Nozzle Maintenance

e Whirl-A-Way comes with 25° nozzles that have an orice size of 020. ey are

installed and aligned properly during production. To conrm proper alignment, inspect

the nozzles. e indent line of the nozzle has to be in line with the rotary arm. If they are

out of alignment the resulting spray angle will result in striping with the possibility of the

rotary arm not spinning at all.

If there are any performance issues, including vibration, pulsing, or stripping, then it is very

likely the nozzles are damaged or clogged.

Always turn o the pressure washer and detach the Whirl-A-Way when performing any

inspection or maintenance.

1. If the nozzle struck any hard object it can be damaged. If the metal nozzle is

deformed it will need to be replaced.

2. If there is no damage, then it is likely the nozzle is clogged.

3. To clean, remove the nozzles. Use CAUTION when removing the nozzles as

trapped pressure may be suddenly released.

4. Use the included cleaning tool (or a ne metal wire) to remove any debris or

foreign material that has built up in the nozzle.

5. Use water to back ush the nozzle. (Run the water through the nozzle in the

opposite direction the water would normally spray out).

6. Use Teon tape or paste on the threads to prevent leaks when reinstalling.

7. Install nozzles back on. Ensure the indent on the nozzles are in line with the

rotary arm.

8. Reconnect your pressure washer and start.

9. Always ush the Whirl-A-Way with clean water aer use, especially if soaps or

detergents were used.

10. When not in use, make sure water has been drained from the Whirl-A-Way to

prevent freezing damage.

Nozzle Cleaning Tool

NOZZLE MAINTENANCE

Part # 85.211.008

14

Warranty

is surface cleaning unit has a 1-Year warranty on all components except for

the nylon brush ring. is includes the rotary head, spray gun, hose, the nylon

brush ring, and plastic cover.

is warranty covers manufacturer defects only and does not extend

to any damage caused by the user. It also does not extend to any wear and tear

caused by regular use of the product.

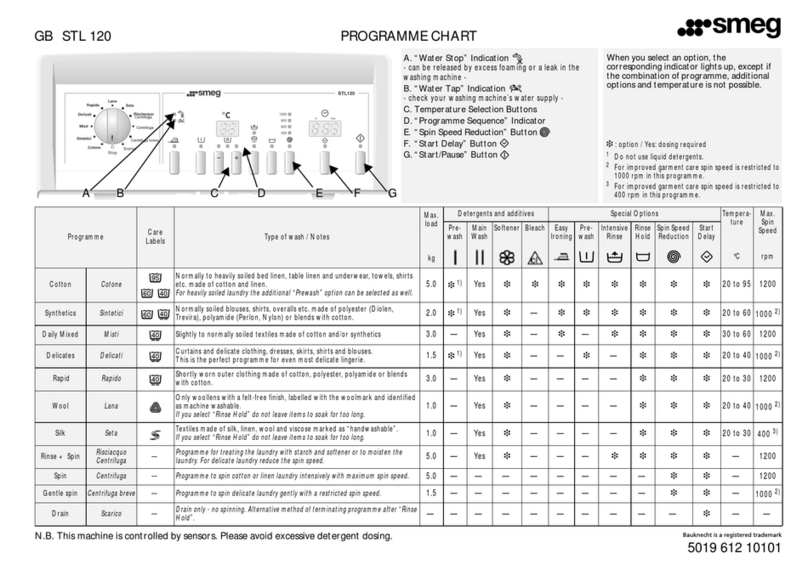

Nozzle Chart

is Whirl-A-Way comes equipped with 020 nozzles. ese can be swapped out with

larger nozzles to increase the PSI and GPM capacities as per the cart below.

Orifice Size MIN PSI/GPM MAX PSI/GPM

015 1,500 PSI / 2.0 GPM 4,000 PSI / 3.0 GPM

020 1,500 PSI / 2.5 GPM 4,000 PSI / 4.0 GPM

025 1,500 PSI / 3.0 GPM 4,000 PSI / 5.0 GPM

030 1,500 PSI / 3.5 GPM 4,000 PSI / 6.0 GPM

035 1,500 PSI / 4.5 GPM 4,000 PSI / 7.0 GPM

040 1,500 PSI / 5.0 GPM 4,000 PSI / 8.0 GPM

If the minimum requirements are not observed, then the Whirl-A-Way will spin poorly, if

it at all.

If the maximum requirements are not observed, then there will be risk of damage or injury.

NOZZLE CHART / WARRANTY NOTES

15

NOTES

nettoyeur de surface

nettoyeur haute pression

WHIRL-A-WAY

85.403.003

85.403.007

85.403.008

85.403.009

85.403.010

85.403.011

GUIDE DE L’UTILISATEUR

Introduction

19 Responsabilité des propriétaires

19 Identication du produit

Spécification et sécurité du produit

20 Spécication du produit

20 Sécurité

Mode d’emploi

21 Utilisation prévue

21 Pré-opération

21 Fonctionnement

Schéma des pièces

22 85.403.003 / 85.403.007 / 85.403.011

Liste des pièces

23 85.403.003 / 85.403.007 / 85.403.011

Schéma des pièces

24 85.403.008

Liste des pièces

25 85.403.008

Schéma des pièces

26 85.403.009 / 85.403.010

Liste des pièces

27 85.403.009 / 85.403.010

Dépannage et liste des pièces

28 Dépannage

28 Liste des pièces

Entretien des buses

29 Entretien des buses

Tableau des buses et garantie

30 Tableau des buses

30 Garantie

TABLE DES MATIÈRES

19

INTRODUCTION

Félicitations pour votre achat d’un nettoyeur de surface Whirl-A-Way BE Power

Equipment.

Lire ce manuel vous aidera à le configurer adéquatement, fonctionnement, entretien

afin d’éviter des blessures ou dommage à votre appareil. En sachant comment utiliser au

mieux cet appareil, vous serez mieux placé pour montrer aux autres comment l’utiliser

adéquatement

Toutes les informations dans ce manuel sont bases sur les dernières informations

disponibles au moment de l’impression. BE Power Equipment se réserve le droit de faire

des changements à tout moment sans préavis ou contracter une obligation.

Responsabilité du Propriétaire/ Opérateur

Le propriétaire/ opérateur doit avoir une compréhension approfondie du fonctionnement,

entretien et dangers associé à l’utilisation de cet appareil. Il faut comprendre qu’il

appartient en fin de compte au propriétaire/ opérateur d’utiliser cet appareil en toute

sécurité comme indiqué dans ce manuel.

Ce manuel est considéré comme une pièce de l’appareil et doit être conserver dans un

endroit sur. Si cet appareil est revendu ou donné à quelqu’un d’autre, ce manuel doit être

inclus.

Enregistrer les Numéros d’Identification

Il est recommandé d’enregistrer les numéros d’identification du produit dans ce manuel.

Ce numéros sont importants d’avoir en mains si vous avez besoin de contacter le support

technique (1-866-850-6662). Le numéro de modèle et série peut être trouvé sur la boîte et

sur le décalque de l’appareil.

IDENTIFICATION DU PRODUIT

Numéro de Modèle:

Date d’Achat:

Nom du Détaillant:

20

SPÉCIFICATIONS PRODUIT

La laveuse à pression utilise DOIT être compatible avec les spécifications ci-bas afin d’assurer une

utilisation adéquate.

• 3/8" Raccord de boyau à connection rapide

• 4,000 Maximum lb/po2 / 5,000 PSI for 85.403.008

• 1,500 Minimum lb/po2

• 5.0 Maximum GPM

• 3.0 Minimum GPM

• Up to 200°F/82°C water temperature

• (Changer les buses modiera le min et max, voir TABLEAU DE BUSES)

SÉCURITÉ

• TOUJOURS passer en revue et connaître tous les avertissements et alertes de sécurité de la

laveuse à pression que vous utilisez qui se trouvant dans le manuel .

• TOUJOURS être conscient de l’endroit où le Whirl-A-Way est utilise ou pointe. Une

pulvérisation à haute pression peut causer blessures ou dommages.

• Si ce genre de blessure survient, NE PAS TRAITER COMME UNE SIMPLE COUPURE.

ALLEZ CHERCHER DES SOINS MÉDICAUX D’URGENCE IMMÉDIATEMENT. Si

vous utilisez des détergents de nettoyage, soyez prêt à mentionner exactement lequel au médecin.

• Les pistolets peuvent avoir des rebonds important. Préparez-vous TOUJOURS et ayez une base

ferme lors de l’utilisation.

• Ne JAMAIS tenter de réparer des composantes haute pression si endommagées. Toujours les

remplacées.

• TOUJOURS utiliser sur des surfaces planes.

• ATTENTION: Heurter un obstacle avec le nettoyeur de surface peut causer des dommages. Si la

performance change, ou si elle commence à vibrer suite à un impact, arrêter immédiatement la

laveuse. Vérier les dommages et réparer.

• TOUJOURS s’assurer que toutes les connections et raccords des composantes sont solidement

xés. L’eau à haute pression peut desserer les raccords ou buses et ainsi devenir des projectiles

causant blessures ou dommages.

• AVERTISSEMENT: Si des pierres ou débris s’accumulent dans le whirl-a-way ils peuvent être

dégagés en l’inclinant dans une direction sécuritaire an de libérer les débris.

• Utiliser SEULEMENT des laveuse à eau froide. Les laveuses à pression à eau chaude

provoquera des échecs et annulera la garantie.

• Soyez TOUJOURS conscient que les surfaces deviendront mouillées et pourront être glissantes.

• TOUJOURS porter un attirail sécuritaire approprié. La protection des yeux est spécialement

importante.

• JAMAIS Utiliser sans protection pour les pieds.

• TOUJOURS avoir une prise sûre de pistolet et une assise stable.

• Ne JAMAIS modier le Whirl-A-Way d’aucune manière.

• Ne JAMAIS mettre la main sous le Whirl-A-Way lorsqu’il est en marche.

• TOUJOURS tester dans un endroit sécuritaire lors de la première utilisation.

SPÉCIFICATIONS PRODUIT ET SÉCURITÉ

This manual suits for next models

6

Table of contents

Languages:

Other BE Power Equipment Washer manuals

Popular Washer manuals by other brands

Smeg

Smeg STL120 user manual

Whirlpool

Whirlpool Gold GSW9550KQ0 Use and care guide

VOX electronics

VOX electronics WM1275-YTQD operating instructions

Panasonic

Panasonic NA-127VB4 Operating instructions & installation instructions

Frigidaire

Frigidaire FLCF09GGFWTU user manual

Electrolux

Electrolux ews 1042 edu user manual