Beachside Lighting MB4 12V User manual

MB4 12V

04/2019

LAMP TYPES:

• 12V MR16 GU5.3 bi-pin base; Max. 10W LED, 50W halogen

• LED Module; Max. 12W

800-405-6732

www.BeachsideLighting.com

CSA Listing pending

WARNING — Risk of Electric Shock. Install all luminaires 10 feet (3.05 m) or more from a

pool, spa, or fountain. This xture must be installed in accordance with the National Electric

Code and/or local codes. Failure to do so

may result in serious personal injury or death. Wir-

ing must be done by a licensed electri

cian.

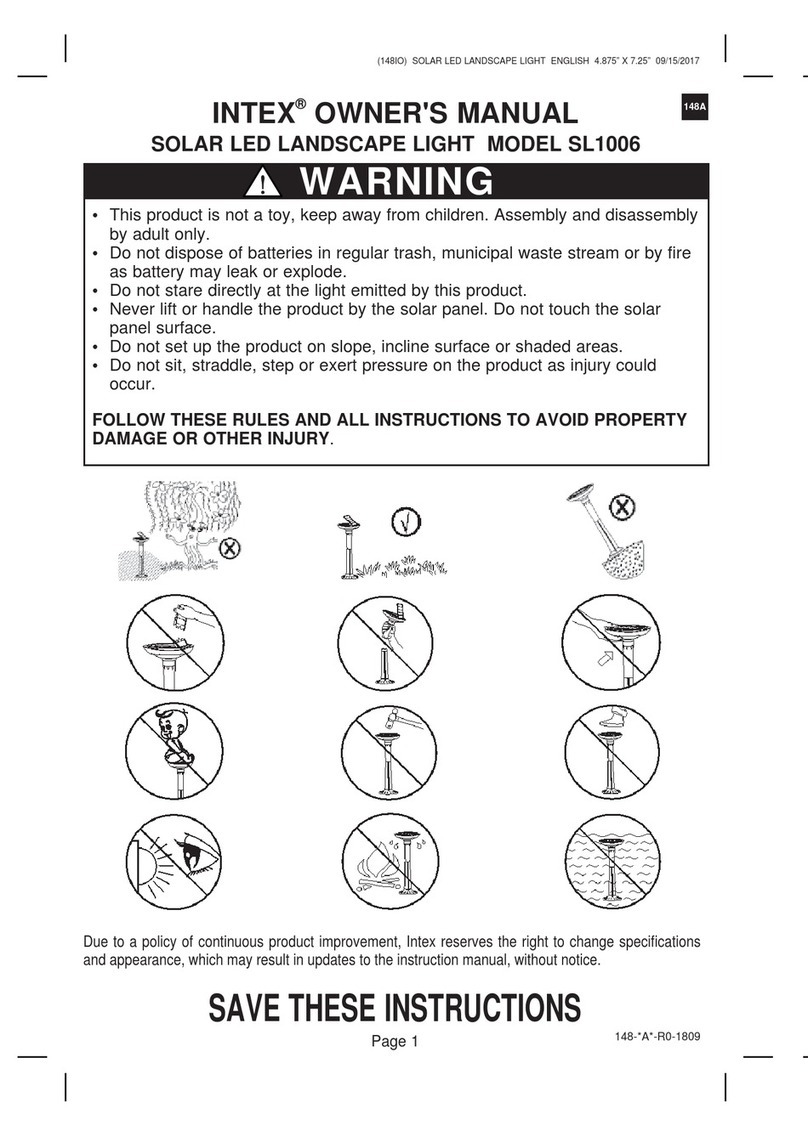

INSTRUCTIONS PERTAINING TO A RISK OF FIRE OR INJURY TO PERSONS

IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

Lighted lamp is HOT!

WARNING – To reduce the risk of FIRE OR INJURY TO PERSONS:

• Turn off/unplug and allow to cool before replacing lamp.

• Lamp gets HOT quickly! Contact only switch/plug when turning on.

• Do not touch hot lens or faceplate.

• Keep lamp away from materials that may burn.

• Do not touch the lamp at any time. Use a soft cloth. Oil from skin may damage lamp.

• Do not operate the luminaire fitting with a missing or damaged faceplate or lens.

For luminaires equipped with halogen lamps:

This is a low-voltage xture for use with maximum 25A, 15V power units only. A remote

transformer is required. Do not overload the transformer by installing or relamping with high-

er wattage lamps that together exceed the capacity of the transformer. The unit low-voltage

cable shall: a) be protected by routing in close proximity to the luminaire or tting, or next to a

building structure such as a house or deck; b) not be buried except for a maximum 6 inches

(15.2 cm) in order to connect to the main low-voltage cable; and c) have the length cut o

so that it is connected to a connector within 6 inches (15.2 cm) from a building structure, a

luminaire, or tting. Contact Beachside Lighting for low voltage cable and direct burial wire

for use as main secondary wiring.

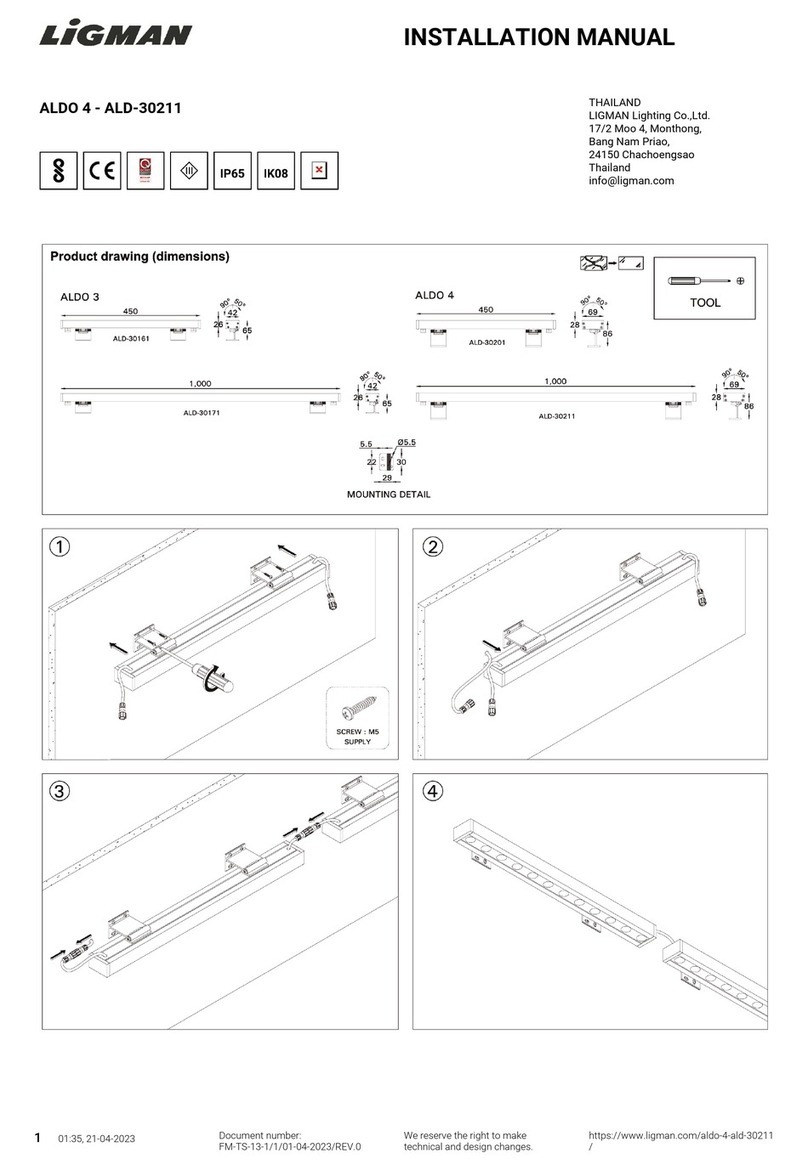

necessary for power supply wires, using the

Mounting Collar for positioning. Conduit

should stick up above top of concrete 1/4”.

(Figure 1)

6. Fill hole with concrete. Double-check

conduit location with Mounting Collar.

7. Once concrete is set, place Mounting

Collar over conduit and mark locations for

the three mounting holes.

8. Use a 5/8” masonry bit to drill a minimum

2-1/2” deep hole at each marked location

and tap in the supplied lag shields.

9. Secure the Mounting Collar with supplied

3/8” lag screws using a 9/16” socket

wrench.

10. Pull supply wires and verify they are not

energized.

11. Feed the wire leads from the xture through

the top of the BSB Cover, apply threadlock

to the Base threads, and screw the Cover

tightly onto the 1/2” threads in the bottom

of the xture.

12. Use silicone-lled wire nuts to join xture

leads to supply wires. Use silicone or

electrical tape around wire nuts to ensure

proper connection.

13. Slide the xture with the Cover attached

straight down over the Mounting Collar.

14. If the xture is equipped with the Half

Shield, orient the xture so the light shines

in the desired direction. Alternately tighten

the three set screws in the Cover with a

1/8” hex wrench.

INSTALLATION on BRASS SURFACE BOX (BSB)

1. For mounting to concrete, skip to Step 5.

2. When mounting to a wooden surface, use the Mounting Collar to mark locations of the

three mounting screws and hole(s) for the supply wiring.

3. Drill holes for wires as needed and drill pilot holes at the marked screw locations using

a 15/64” drill bit.

4. Secure the Mounting Collar with supplied 3/8” lag screws using a 9/16” socket/wrench.

Proceed to Step 10.

5. Dig a hole at desired location at least 12” diameter x 12” deep and run conduit as

BSB COVER

LAMP OR LED

MODULE

LAMP HOUSING

LAG SHIELDS

BASE

Apply thread-locking

agent (by others) to

male threads.

SET SCREW (x3)

MOUNTING

COLLAR

SET SCREW (x3)

CONDUIT

CONCRETE

MOUNTING COLLAR

TOP VIEW

CONDUIT GUIDES

3/8" HOLES FOR

LAG SCREWS

UNION

LAG SCREWS

LOWER SHAFT

SET SCREW (x3)

Figure 1

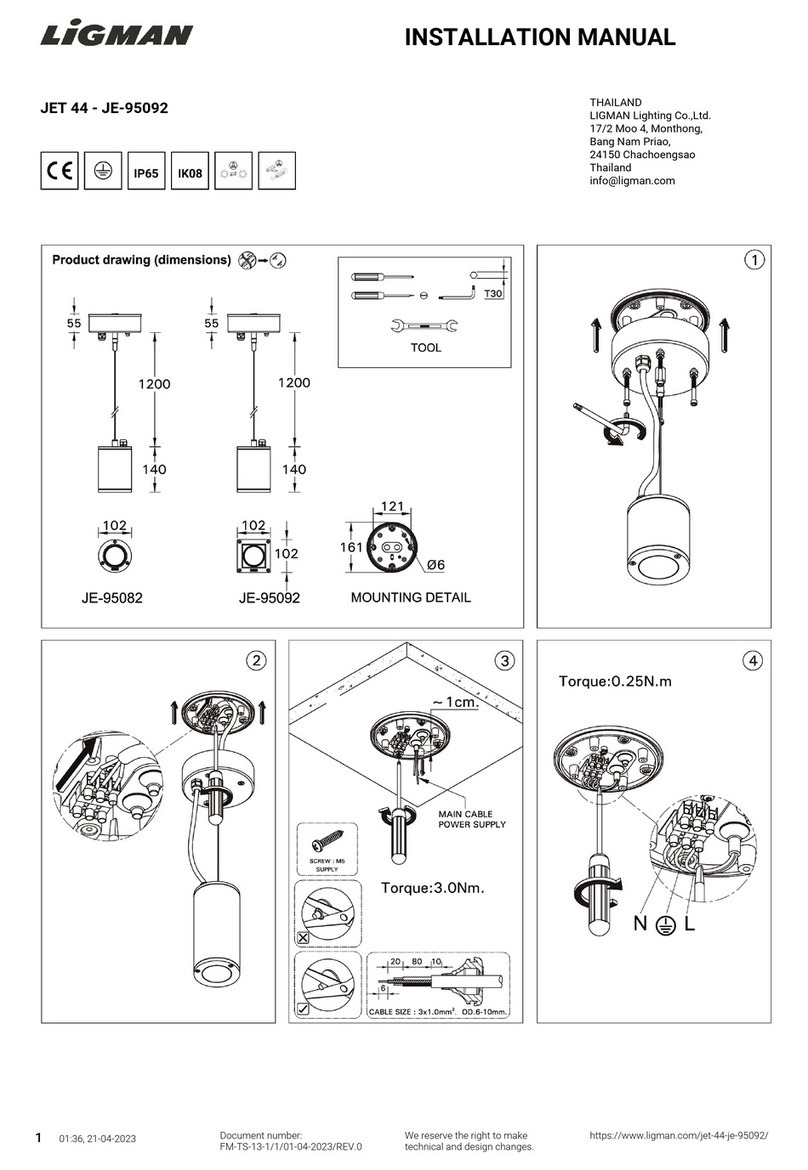

INSTALLATION on JUNCTION BOX (JB)

1. Dig a hole at desired location at least 12” diameter x 12” deep and run conduit as

necessary for power supply wires. Position the Junction Box (JB) so that the bottom of

its Cover will be above grade after the concrete is poured. (Figure 2)

2. Plug unused holes and ensure all ttings are watertight.

3. Fill hole with concrete, making sure JB is level and that its Cover will be above grade.

4. Once concrete is set, remove Cover using a 5/32” hex wrench and pull the supply wires.

Verify they are not energized.

5. Feed the wire leads from the xture through the top of the JB Cover and gasket, apply

threadlock to the Base threads, and screw the Cover tightly onto the 1/2” threads in the

bottom of the xture.

6. Use silicone-lled wire nuts to join xture leads to supply wires. Use silicone or electrical

tape around wire nuts to ensure proper connection.

7. Push the connections into the JB and reattach the Cover/xture assembly.

8. If the xture is equipped with the Half Shield, it can be aimed by loosening the three set

screws at the base of the Shaft (or Lamp Housing if not equipped with a lower Shaft) with

a 3/32” hex wrench. Aim the xture as desired and alternately retighten the set screws.

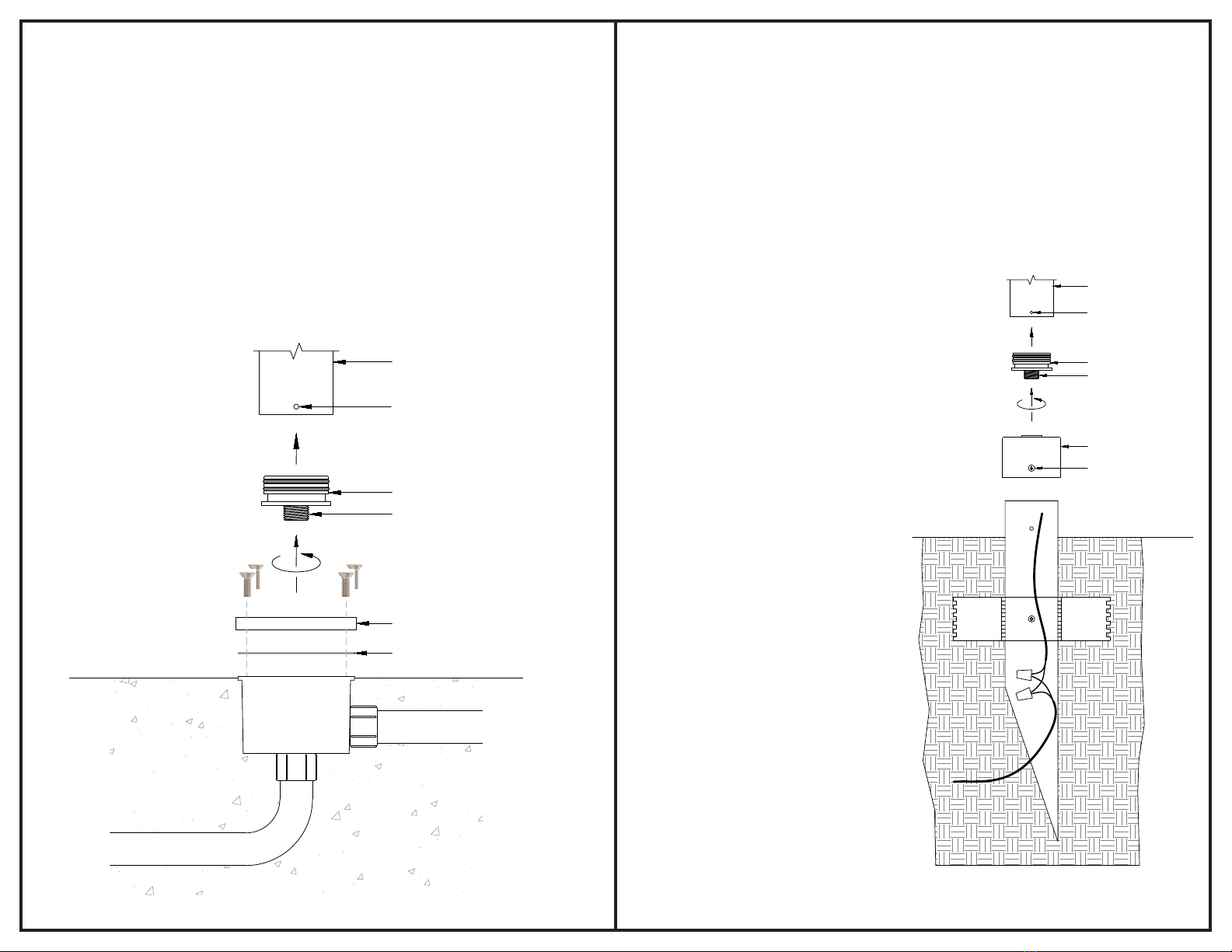

INSTALLATION on GROUND SPIKE (GS2BC)

1. Dig a hole at desired location roughly 10” diameter x 18” deep and route the supply wires

coming from the power source to the hole, entering it near the bottom. (Figure 3)

2. Remove the Brass Cap from the Ground Spike by removing the screw from the side of

the Cap.

3. Feed the supply wire into the bottom of the Spike and out through the top while placing

the Spike into the hole.

4. Rell the hole while keeping the Spike vertical. Position the Spike so that the bottom of

its Cap will be at grade when the hole is completely lled.

5. Feed the wire leads from the xture

through the top of the Cap, apply

threadlock to the Base threads, and

screw the Cap tightly onto the 1/2”

threads in the bottom of the xture.

6. Use silicone-lled wire nuts to join

xture leads to supply wires. Use

silicone or electrical tape around wire

nuts to ensure proper connection.

7. Feed the wires and connectors into

the top of the Spike while replacing

the Cap/xture assembly onto the

Spike. Align the hole and fasten

the Cap to the Spike with the screw

removed in Step 2.

8. If the xture is equipped with the Half

Shield, it can be aimed by loosening

the three set screws at the base of

the Lamp Housing with a 3/32” hex

wrench. Aim the xture as desired

and alternately retighten the set

screws.

Mounting on ground spike is only recommended for the 9” version of the MB4. Taller versions

require use of the BSB or JB mounting accessories.

LAMP HOUSING

BASE

SET SCREW (x3)

SCREW

BRASS CAP

Apply thread-locking

agent (by others) to

male threads.

LOWER SHAFT

CONDUIT

CONCRETE

JUNCTION

BOX

BASE

Apply thread-locking

agent (by others) to

male threads.

JB COVER

GASKET

SET SCREW (x3)

Figure 2 Figure 3

LAMPING – Integrated LED Module

1. Make sure the power to the xture is o.

2. With the xture still attached, remove the Cap or Cover from the Ground Spike, Junction

Box, or BSB.

3. Disconnect the xture leads from the supply wires.

4. Loosen the three set screws at the bottom of the Lamp Housing with a 3/32” hex wrench

and slide it straight up to remove, exposing the LED Module.

5. If the xture is equipped with a Lower Shaft, loosen the three set screws at its bottom

with a 3/32” hex wrench and slide it up o the Base, pulling the wires up through the red

silicone plug inside the Base. (Figure 1)

6. Unscrew the LED Module 4-5 revolutions to remove it.

7. Carefully press the red silicone plug out the bottom of the Base from the top with a

narrow, blunt object and save to be reinserted later.

8. Feed the lead wires from the new LED Module through the Base (or Union and Lower

Shaft, if equipped, then the Base) and screw the Module down until it bottoms out.

9. Replace the Lamp Housing (and Lower Shaft, if equipped) and alternately tighten the

set screws.

10. Feed the leads through the silicone plug. Carefully slide the plug up the wires and

reinsert the plug back into the Base.

11. Follow the nal three Steps in the appropriate “Installation” section of these instructions

to complete the operation.

This xture has a long-life LED Module that should not need replacement for years. However,

if a Module fails or technology improves and a new one is desired, replacements are available

from Beachside Lighting (808-263-5717). Once received:

LAMPING – MR16

1. Make sure the power to the xture is o.

2. To access the lamp compartment, loosen the three set screws at the bottom of the Lamp

Housing with a 3/32” hex wrench and slide it straight up to remove, exposing the Lamp.

(Figure 1)

3. Grasp the Lamp at its base and pull straight up to remove from socket.

4. Holding the new Lamp at its base, align its pins with the holes in the socket and push

straight down.

5. Reinstall the Lamp Housing. Apply a grease appropriate for use on silicone o-rings to

the o-rings if necessary.

6. Alternately tighten all three set screws.

Popular Landscape Lighting manuals by other brands

LIGMAN

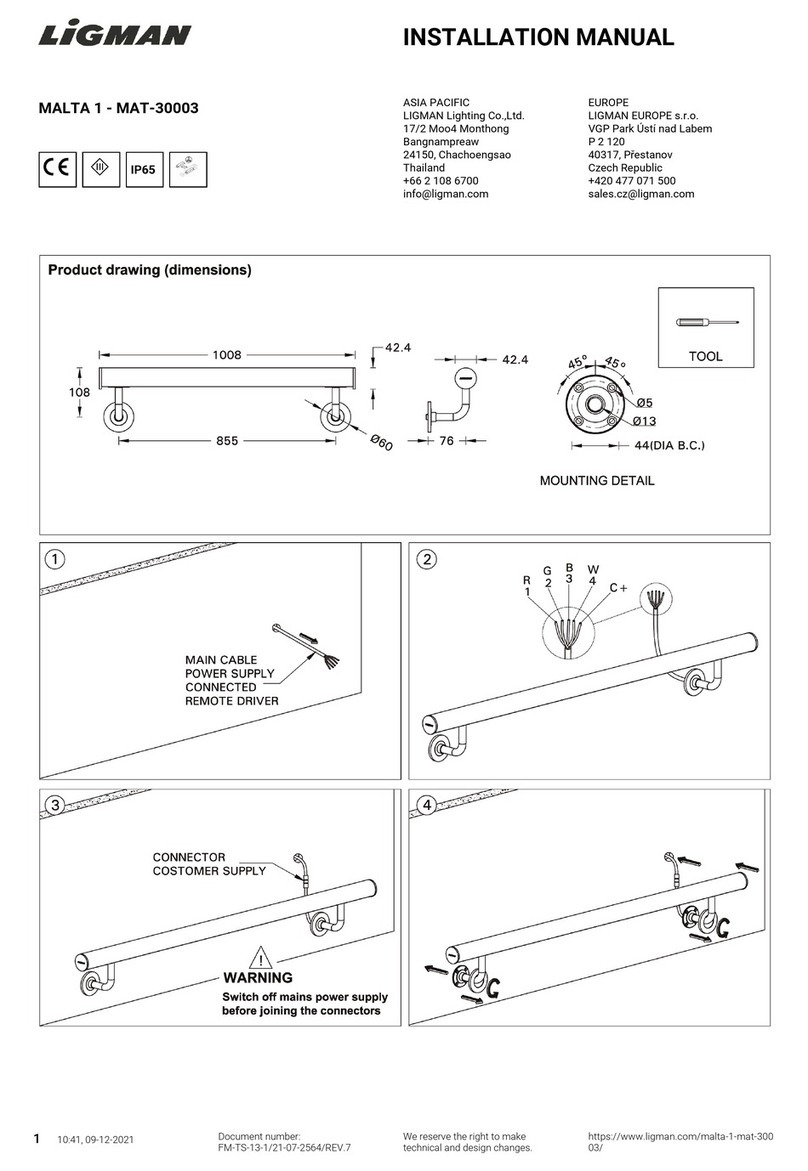

LIGMAN MALTA 1 installation manual

Saxby Lighting

Saxby Lighting Islay 68784 Instruction leaflet

LIGMAN

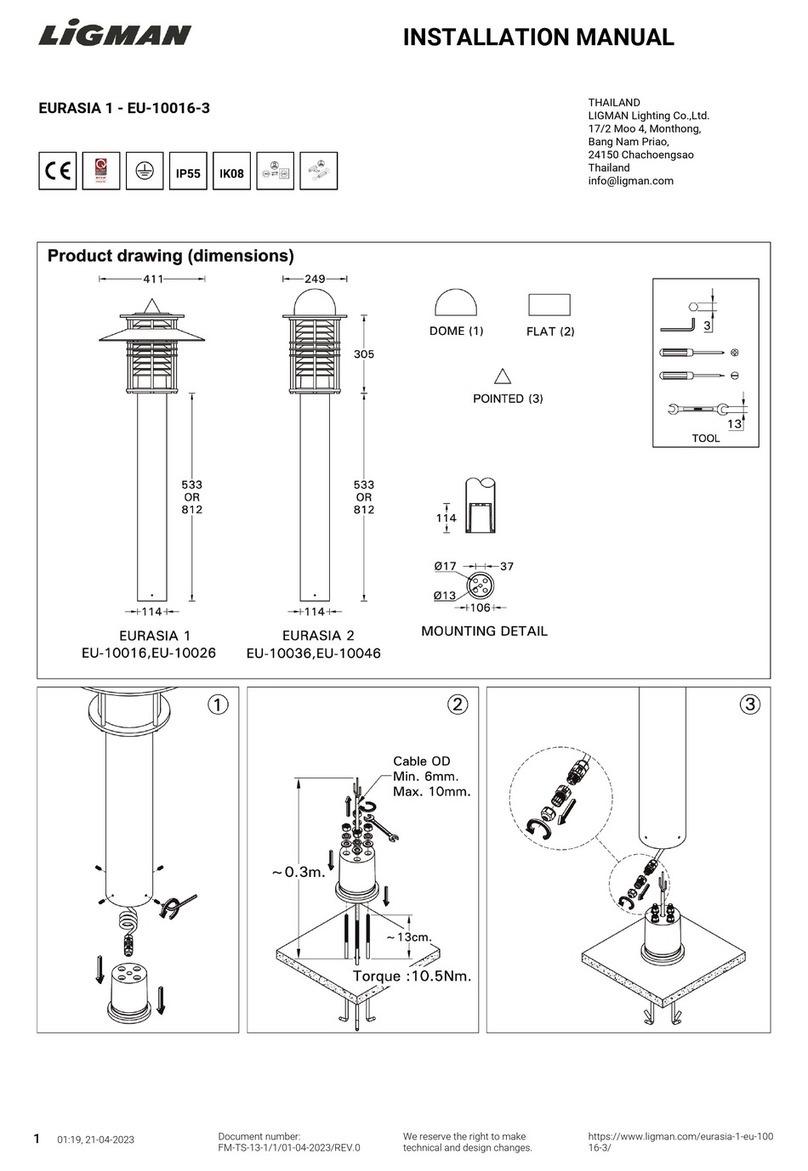

LIGMAN EU-10016-3 installation manual

LIGMAN

LIGMAN KI-60475 installation manual

Cooper Lighting

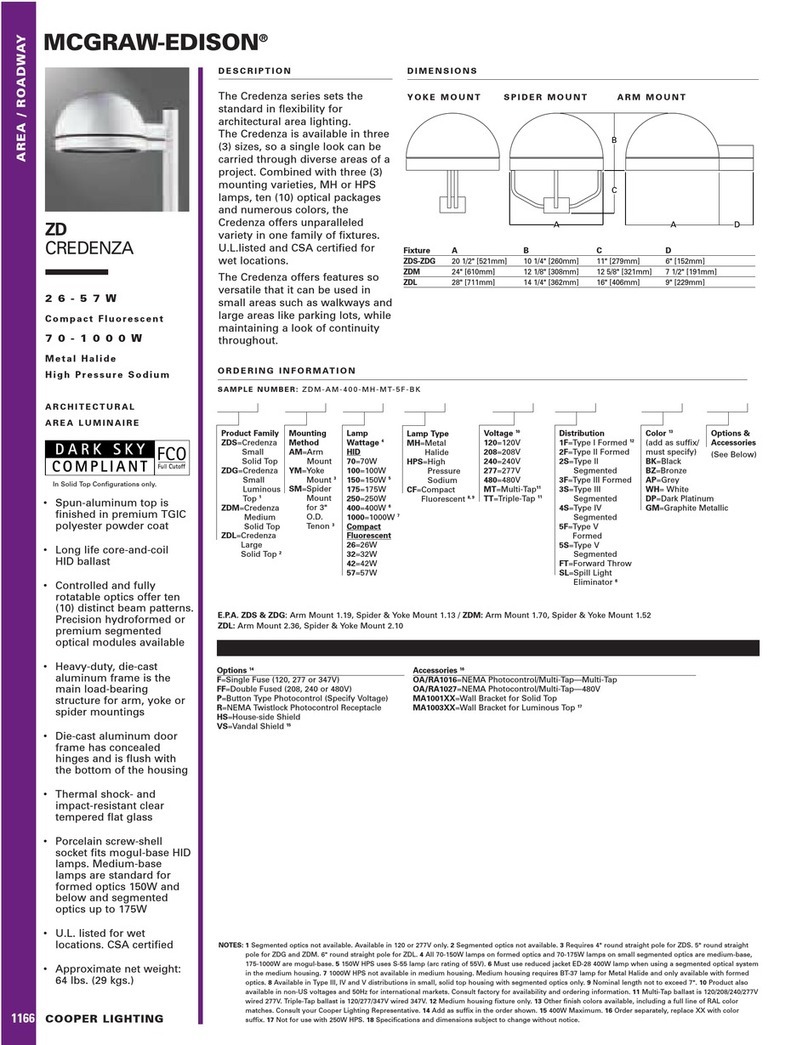

Cooper Lighting McGraw-Edison ZD Credenza specification

Cooper Lighting

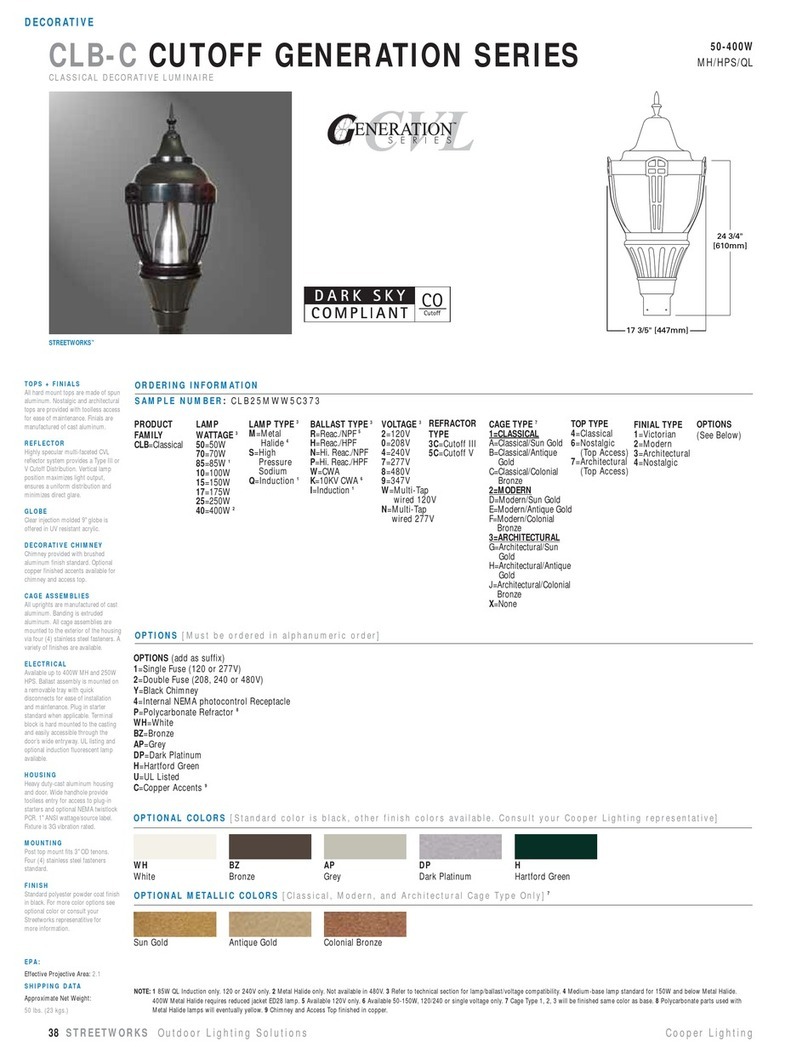

Cooper Lighting Generation CLB25MWW5C373 Specification sheet

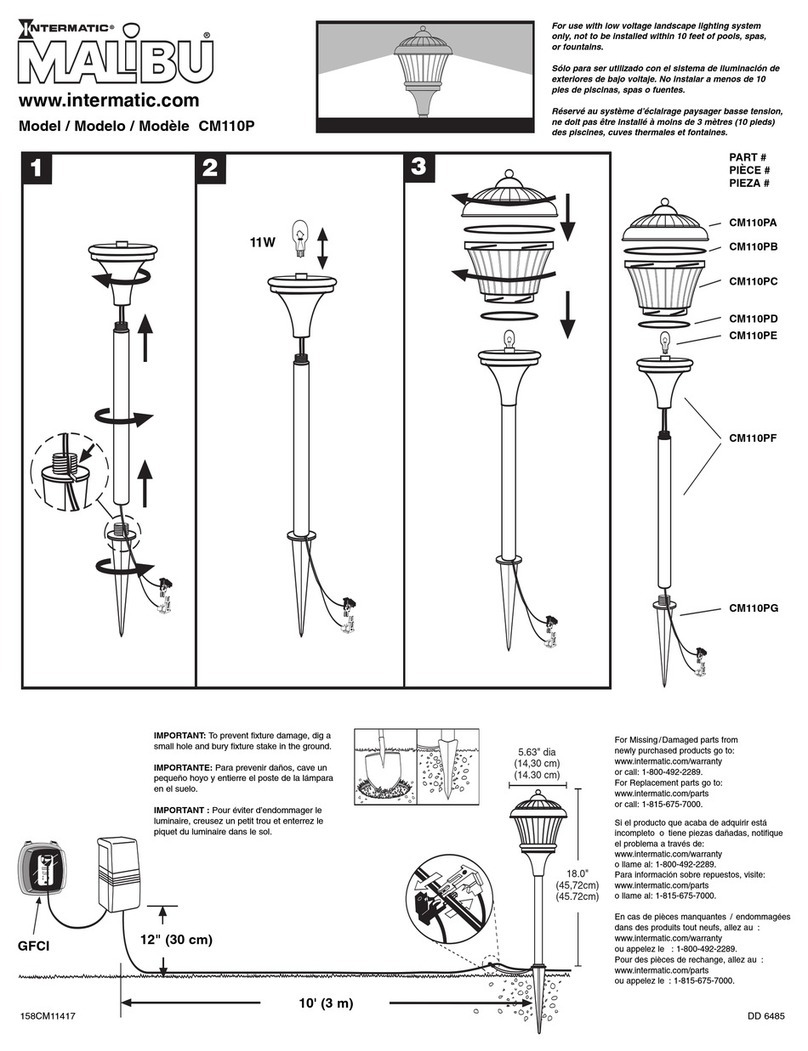

Malibu Boats

Malibu Boats CM110P instructions

AMP Lighting

AMP Lighting OrchardPro APL-3018-B-BZ Installation & maintenance guide

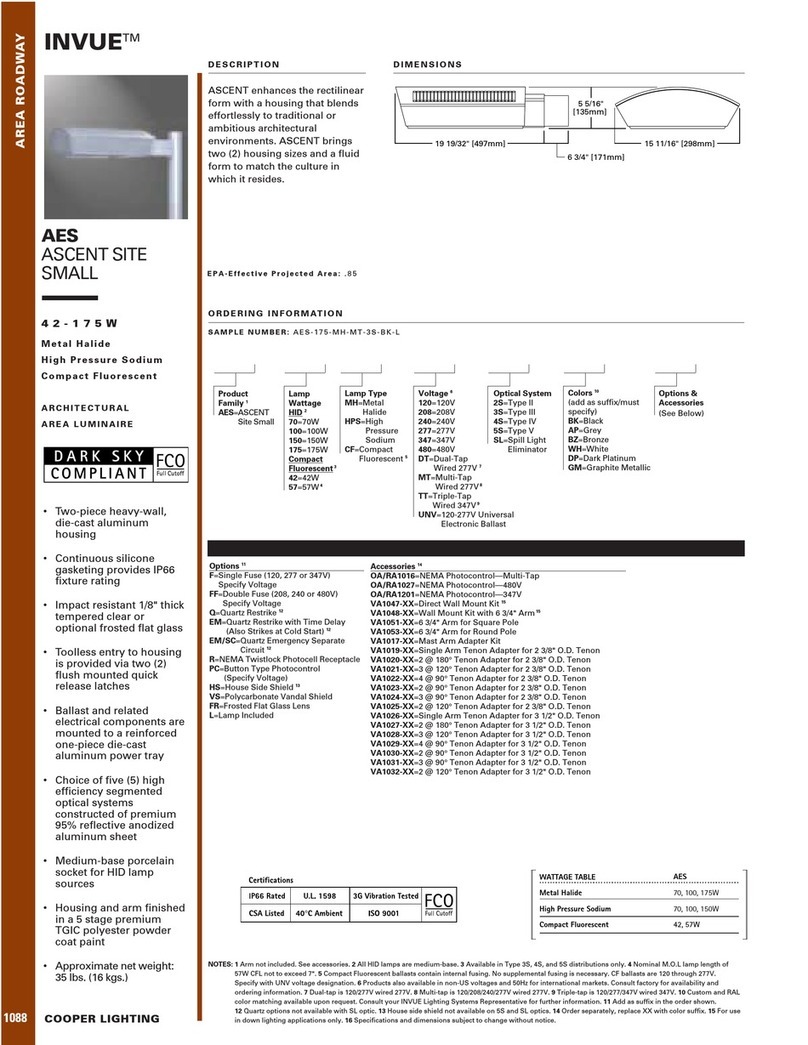

Cooper Lighting

Cooper Lighting Invue 42 - 175W Specification sheet

ABBA

ABBA SPB12 installation guide

Techmar

Techmar Garden Lights GILVUS + manual

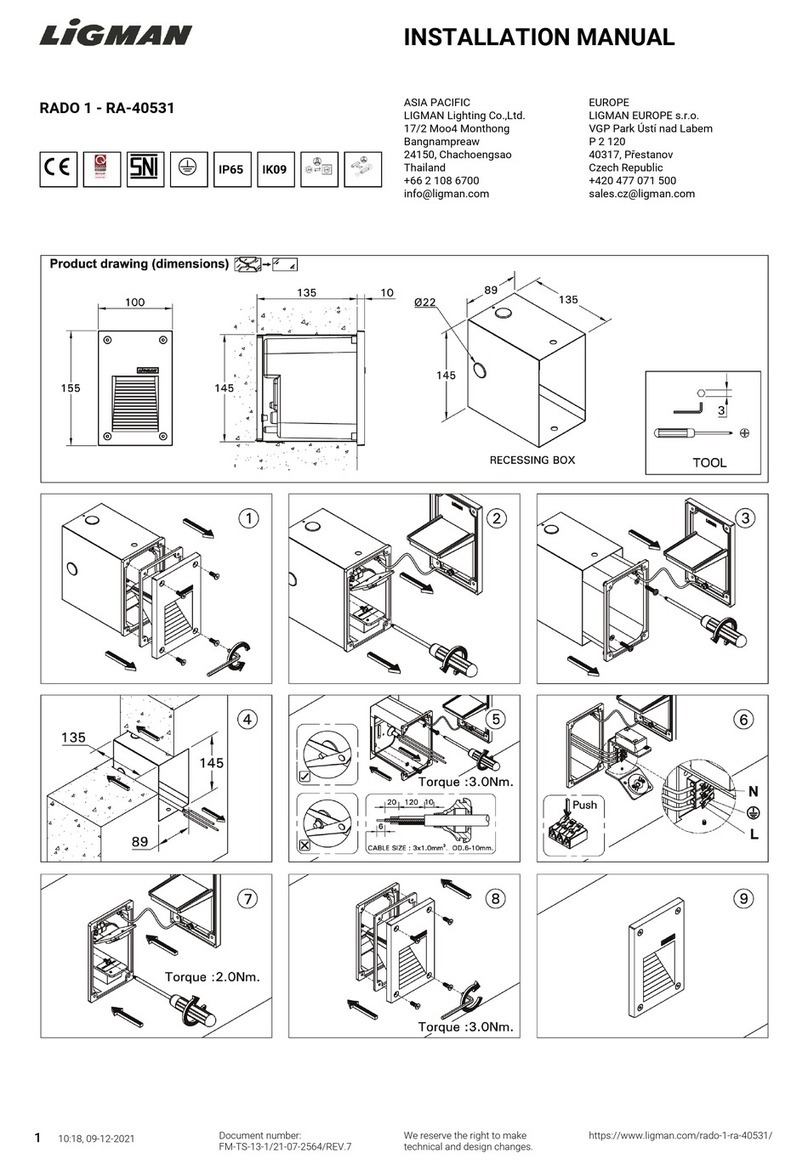

LIGMAN

LIGMAN RADO 1 installation manual