Bearon Aquatics F250 User manual

☐ F250 - .25HP Single Propeller Aerator

☐ F500 - .5HP Single Propeller Aerator

☐ F750DP - .75HP Dual Propeller Aerator

☐ F1000DP - 1HP Dual Propeller Aerator

☐ F1500TP - 1.5HP Tri-Propeller Aerator

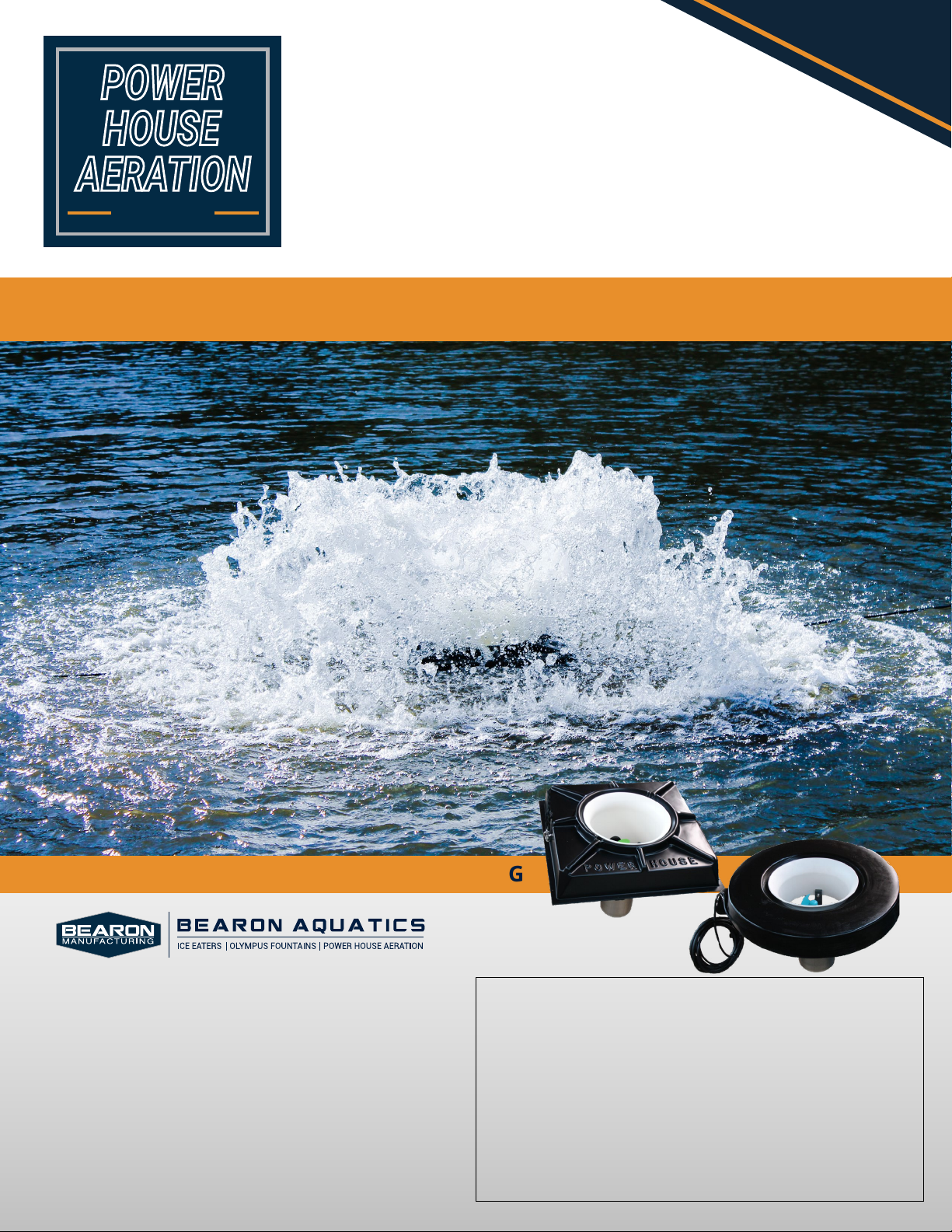

AERATION

BEARON AQUATICS

POWER

HOUSE

OWNER’S MANUAL | SURFACE AERATORS

PLEASE READ ENTIRELY BEFORE OPERATING

2

Safety Instructions page 3

SpecicationSheet page4

Installation & Operation page 5

Maintenance&Troubleshooting page6

Parts & Accessories page 7

Warranty Information page 8

CONTENTS

WARNING: This product contains lead, a chemical known to the State of California to cause cancer and birth defects,

or other reproductive harm.

Service Center

Paperwork

www.bearonaquatics.

com/service

Product

Registration

www.bearonaquatics.

com/resources/warranty-

registration/

Search for

Distributor or

Service Center

www.bearonaquatics.

com/search-for-a-

distributor/

3

CAUTION SHOULD BE USED WHEN DEALING WITH ANY ELECTRICAL EQUIPMENT WITH

MOVING PARTS.

NEVER LIFT OR DRAG THE UNIT BY THE POWER CORD. USE PROVIDED MOORING LINE TO MOVE

THE UNIT AS NECESSARY.

THIS MOTOR IS PROVIDED WITH A GROUND WIRE OR GROUNDING TYPE PLUG FOR

YOUR PROTECTION.

THE GROUND WIRE MUST BE SECURELY ATTACHED TO PROPER ELECTRICAL GROUND OR THE

GROUNDING TYPE PLUG MUST BE USED ONLY WITH A PROPERLY GROUNDED RECEPTACLE. IN

ADDITION, YOU SHALL USE GROUND FAULT INTERRUPTER PROTECTION IN ACCORDANCE WITH

THE NATIONAL ELECTRIC CODE.

DO NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE GROUND PRONG FROM A

GROUNDING TYPE PLUG.

ANY REWORK OR DAMAGE TO THIS CORD MAY CREATE SHOCK HAZARD AND WILL VOID

THE WARRANTY.

A QUALIFIED ELECTRICAN MUST BE CONSULTED TO INSURE A SAFE INSTALLATION.

UNDER NO CIRCUMSTANCES SHOULD ANYONE ENTER THE WATER WITH THE ELECTRICAL

EQUIPMENT CONNECTED AND/OR IN OPERATION. IT IS NEVER RECOMMENDED TO ENTER THE

WATER WITH THE EQUIPMENT IN OPERATION.

ALWAYS DISCONNECT THE ICE EATER FROM THE POWER SOURCE BEFORE ANY SERVICING OR

CLEANING OR MOVING OF THE UNIT BY UNPLUGGING OR BY REMOVING FUSE OR DEACTIVATING

CIRCUIT BREAKER.

WHEN USING OUR ICE EATER AND OUR THERMOSTAT TOGETHER, UNIT WILL START

AUTOMATICALLY BY AIR TEMPERATURE.

ALWAYS DISCONNECT THE ICE EATER FROM POWER SOURCE BEFORE ANY SERVICING OR

CLEANING OR MOVING OF THE UNIT BY UNPLUGGING OR BY MOVING FUSE OR DEACTIVATING

CIRCUIT BREAKER.

DO NOT REMOVE END COVER PLATE. REMOVAL OF PLATE WILL VOID WARRANTY. ALL REPAIRS

MUST BE MADE AT FACTORY OR AN AUTHORIZED SERVICE STATION.

RECOMMENDED COMMERCIAL GRADE BREAKER. USE DEDICATED CIRCUIT PER UNIT.

WARNING WARNING WARNING WARNING WARNING WARNING WARNING WARNING

WARNING WARNING WARNING WARNING WARNING WARNING WARNING WARNING

10233 SOUTH DOLFIELD RD • OWINGS MILLS, MD 21117

410.654.9700 • AQUATICSINFO@BEARONMFG.COM • WWW.BEARONAQUATICS.COM

BEARON AQUATICS

POWER HOUSE AERATIONOLYMPUS FOUNTAINSICE EATERS

4

COMPLETE PACKAGE

• (1) Assembled Motor (with shroud).

• (1) UV Resistant Float.

• (2) 25’ Long 3/8” thick Hollow Braided

Polypropylene Mooring Lines.

• (1) SJTOW Rated 3-Wire, 14 Gauge

Power Cable with Potted Quick

Disconnect.

QUICK FACTS

• Able to Operate in Water as Shallow

as 36” (92cm).

• Total Component Listed to meet UL,

CE, & CSA Standards for Safety in

Water.

ULListingNo.E481181

MetListingNo.E112360

• Energyecientwithexcellent

Gallons per Minute (GPM)/kW Rates.

• HighOxygenTransferatan

aordableprice.

• SacricialAluminumAnodeand

Electrolysis Kit are available for

corrosion protection and use in

salt-water applications.

• Industrial Strength Design.

• 3-Year Warranty.

WARNING

Discontinue use and remove

fromwaterwhenwaterisbelow

freezing tempteratures (32F/0C).

Donotruntheunitoutofwater.

Ground Fault Circuit Interrupter

(GFCI) or Residual Current Device

(RCD) protected circuit required.

MOTOR ASSEMBLY

• .25Hp; 300GPM; 2.6amps (115V).

• .5Hp; 884GPM; 6amps (115V).

• .75Hp Dual Propeller; 1050GPM;

7amps (115V).

• 1Hp Dual Propeller; 1150GPM;

8.2amps (115V).

• 1.5Hp Tri-Propeller; 1300GPM;

5amps (230V).

• Single Phase motors; 3-Phase on

1Hp motors available upon request.

• Units available in 115V or 230V.

• 50/60 Hz.

• 1,650 Rotations per Minute (RPM).

• Oil Cooled, Continuous Duty Rated.

• Two Long Life Bearings.

• Thermal Overload Protection.

• Fully Utilized Heavy Duty Carbon

Ceramic Mechanical Seal.

• Series 300 Austenitic Stainless

Housing with Magnesium Bronze

End-Bell.

POWER CABLE

• SJTOW UL & CSA Approved

Underwater Rated Cable, 3 Wire.

• 115V available in 50’, 100’, and 150’

with Quick Disconnect Power Cord.

• 230V available in 50’, 100,’ 150’,

200’, 250’, 300’, 350’, 400’ with Quick

Disconnect Power Cord.

• Potted Quick Disconnect on 14

Gauge Cord.

FLOAT

• U.V. Resistant High Density

Thermoplastic.

• Single Piece Float with Closed Cell

Foam Filling.

• Series 300 Stainless Steel Hardware.

• (2) 25’ long 3/8” thick hollow braided

polypropylene ropes.

Aswaterowsthroughthebottomoftheshroudandfouradditionalholes,thepropellermixesandforcesthewaterabovethe

surface.Thehighpumpingvolumedegassesthewaterofnitrogen,carbondioxide,andhydrogensuldewhileraisingdissolved

oxygenlevels.Degassinggetsridofnutrientswhichcausealgaeandweeds,resultinginclearerwateranddecreasedodor.

Movingwatermixesandagitatesthewater,spreadingoxygenatedwaterthroughoutthebodyofwater.

POPULAR ACCESSORIES

115V TIMER

• Portable Outdoor 24 Hour Timer

available for both 115V and 230V.

• Outdoor grade plastic.

• Timer: 24-hour with 23-1/2 hour

maximumontime.(2)“ON”&(2)

“OFF”trippers–standard.

• Dial will accept up to 12 sets of

trippers.

• Electrical Rating: 15 A (1800 W),

Resistive or Tungsten.

• Agency Approval: CSA/C-US.

• Outdoor grade cord with ground

plug, 3 wire, 22 inches.

• 1 Year Manufacturer’s Warranty.

230V TIMER

• Electromechanical Time Switch.

• Type 3R Plastic Enclosure.

• Provides direct 24-Hour control of

most loads.

• Control electrical loads up to 40

Amps.

• 1to12ON/OFFoperationseachday.

• MinimumON/OFFtimesof1hour.

• Manual override.

• Equippedwith(1)ONand(1)OFF

tripper.

• 1 Year Manufacturer’s Warranty.

FLOAT CAGE

• 24”Wx24”Lx16”H.

Fits F500, F750DP, F1000DP &

F1500TP.

• Protect your investment by

preventing foreign objects from

entering the shroud.

• Choiceof1/2”or1″gridplastic

coated, hot rolled metal screen that

covers the bottom 5 sides of the

oat.

SURFACE AERATORS

5

SideViewofSurfaceAeratorshown

withMooringLinesata45°angle

INSTALLATION

1. Immediately after delivery, inspect the aerator shipment

for any visible damages. Report any damage to your

dealer.

2. The surface aerator is completely assembled within the

housing. You will not need additional hardware.

3. Installtheaeratorintheoatbyfollowingthesesimple

instructions:

• Turn the aerator upside down with the propeller end

facingdownwardandplaceonaatsurface.

• Passpowercordthroughthetopsideoftheoat

(sidewith“PowerHouse”printedonit).

• Slideoat,PowerHousenamesidedown,over

the shroud. Twist to align slots in the throat of the

oatwiththepowercordandmountingbolts.

• Make sure cord is free and does not loop above the

level of the propeller hub.

• Ifyouareinstallingoptionaloatcage-connect

thescreentothebottomlipoftheoatusingthe

(16) small white clamps. The sides of the screen will

need to be connected by using pliers to close the

metal rings.

4. Turn unit to an upright position with the propeller

facing up.

5. Fasten one mooring line to a secure place such as a fence

post or large cinder block.

6. Drop unit into water and secure the other rope directly

acrossfromtherst.Adjustyourfasteningpointsto

position the unit where desired.

7. Make certain that there is adequate water depth

(atlowestwaterlevel)sothattheunitoatsfreely.

Keep unit away from heavy grass or debris.

8. Make sure all hands, feet, cords, lines, etc. are clear of the

unit before connecting to power supply.

OPERATION

1. Once your Power House Surface Aerator unit is properly

installed and secured, the surface aerator is ready for

immediate use.

2. Your surface aerator is designed for continuous

operation. It can be cycled by the use of a timer, photocell

ordissolvedoxygenmeter.Thiscanhelptogreatlyreduce

the amount of energy consumed by the aerator, while still

circulating the water.

Contact your local electrician for assistance.

3. Operating equipment should be observed on a regular

basis for any reduction or variation in the aerator’s

performance.

4. Plug the electrical cord into properly grounded GFCI

(Ground Fault Circuit Interrupter) or RCD (Residual

Current Device) protected circuit. Plug the electrical cord

into a receptacle that matches the unit operating voltage

or connect to an appropriate power source. GFI required

for each unit. (Recommended that an electrician verify

your power supply.)

WARNING:Whenanextensioncordisused,itmustbe

sized as follows:

Up to 100ft. - Use #12/3 wire cord

Up to 200ft. - Use #10/3 wire cord

5. Unit will start immediately and can twist slightly upon

starting. Make certain that all lines are clear and secure.

Water should be forced well above the top lip of the white

shroud and should look thick.

WARNING: Do not run out of water. Unit must be

submerged.Keephandsclear.

6. Routinely inspect the propeller and shaft for any damage

from foreign objects.

7. Ifusinginsaltwater,routinelyinspectthesacrical

anode. Replace parts as necessary.

8. Whentheunitisusedforowgenerationinacircular

tank or pond, the water will gradually circulate and will

continueforsometimeaftertheunitisturnedo.

9. Smallshcanbesuckedthroughtheunitundercertain

operating conditions. Make sure that you have reviewed

your stock and any possible damage before you start the

unit.

10. FreezingTemperaturescancauseoattocrackorsplit.

WARNING: Discontinue use and remove from water

whenwaterisbelowfreezingtemperatures(32°F/0°C)

INSTALLATION & OPERATION INSTRUCTIONS

10233 SOUTH DOLFIELD RD • OWINGS MILLS, MD 21117

410.654.9700 • AQUATICSINFO@BEARONMFG.COM • WWW.BEARONAQUATICS.COM

BEARON AQUATICS

POWER HOUSE AERATIONOLYMPUS FOUNTAINSICE EATERS

This manual suits for next models

4

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions