Table of contents

EP9521-0020 3Version: 1.2

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

2 EtherCAT Box - Introduction ....................................................................................................................8

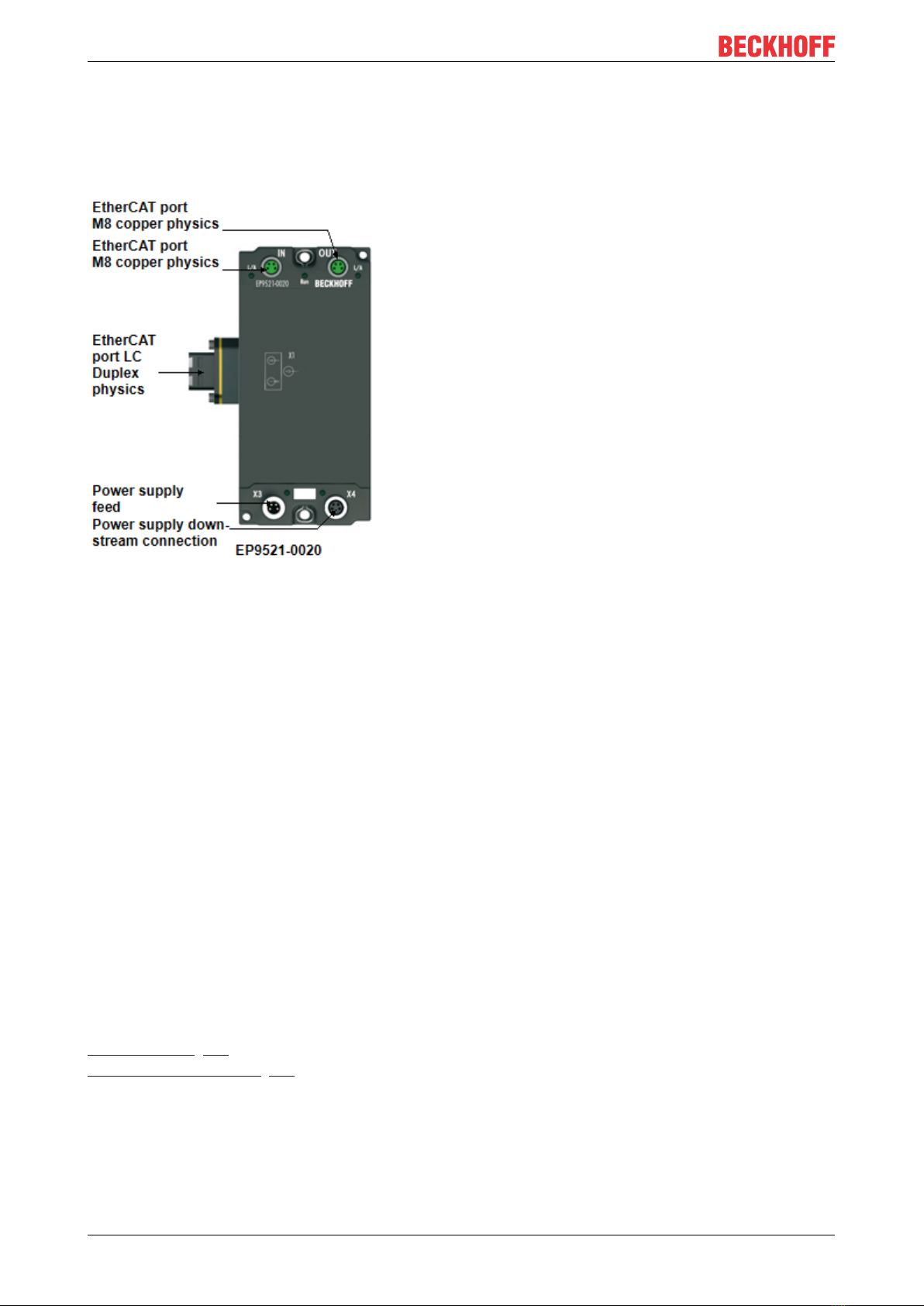

3 Product overview.....................................................................................................................................10

3.1 Introduction......................................................................................................................................10

3.2 Technical Data.................................................................................................................................11

3.2.1 Additional checks............................................................................................................. 11

3.3 Scope of supply ...............................................................................................................................11

4 Mounting and connection.......................................................................................................................13

4.1 Mounting..........................................................................................................................................13

4.1.1 Dimensions ...................................................................................................................... 13

4.1.2 Fixing ............................................................................................................................... 14

4.1.3 Functional earth (FE) ....................................................................................................... 14

4.1.4 Tightening torques for plug connectors ........................................................................... 14

4.2 Connection ......................................................................................................................................15

4.2.1 EtherCAT ......................................................................................................................... 15

4.2.2 Optical fiber cables .......................................................................................................... 17

4.2.3 Supply voltages ............................................................................................................... 20

4.3 UL Requirements.............................................................................................................................22

5 Commissioning/Configuration ...............................................................................................................23

5.1 Integration in TwinCAT ....................................................................................................................23

5.2 Application notes .............................................................................................................................24

5.3 Restoring the delivery state .............................................................................................................28

5.4 Diagnostic LEDs ..............................................................................................................................29

6 Appendix ..................................................................................................................................................30

6.1 General operating conditions...........................................................................................................30

6.2 Accessories .....................................................................................................................................31

6.3 Version identification of EtherCAT devices .....................................................................................32

6.3.1 Beckhoff Identification Code (BIC)................................................................................... 36

6.4 Support and Service ........................................................................................................................38