Table of contents

EPP9022-0060 3Version: 1.3

Table of contents

1 Foreword....................................................................................................................................................5

1.1 Notes on the documentation .............................................................................................................5

1.2 Safety instructions.............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

2 Product group: EtherCATPBox modules..............................................................................................8

3 Product overview ......................................................................................................................................9

3.1 Introduction .......................................................................................................................................9

3.2 Technical data.................................................................................................................................10

3.3 Scope of supply...............................................................................................................................12

3.4 Process image ................................................................................................................................13

4 Mounting and connections.....................................................................................................................18

4.1 Mounting .........................................................................................................................................18

4.1.1 Dimensions ......................................................................................................................18

4.1.2 Fixing................................................................................................................................ 19

4.1.3 Functional earth (FE) ....................................................................................................... 19

4.2 Connections ....................................................................................................................................20

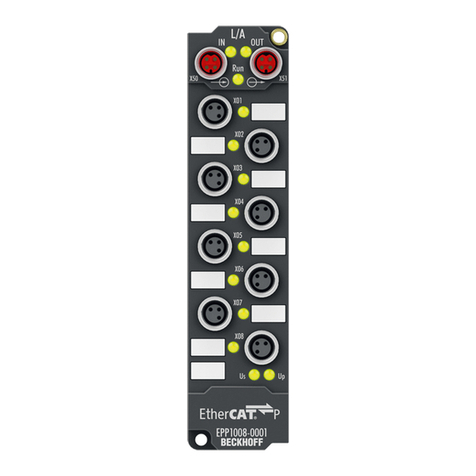

4.2.1 Overview ..........................................................................................................................20

4.2.2 EtherCATP ......................................................................................................................21

4.2.3 Voltage measurement output ........................................................................................... 25

4.3 UL Requirements ............................................................................................................................26

4.4 Disposal ..........................................................................................................................................27

5 Commissioning and configuration........................................................................................................28

5.1 Integrating into a TwinCAT project..................................................................................................28

5.2 Measured values.............................................................................................................................29

5.2.1 Representation................................................................................................................. 29

5.2.2 Filter .................................................................................................................................30

5.3 Warning and error messages..........................................................................................................31

5.3.1 Set the threshold values................................................................................................... 32

5.3.2 Disabling messages ......................................................................................................... 33

5.4 LEDs ...............................................................................................................................................34

5.4.1 LED filter ..........................................................................................................................35

5.5 Restoring the delivery state.............................................................................................................36

5.6 Decommissioning............................................................................................................................37

6 CoE parameters.......................................................................................................................................38

6.1 Introduction .....................................................................................................................................38

6.1.1 Accessing CoE parameters with TwinCAT ...................................................................... 38

6.1.2 Data format of CoE parameters ....................................................................................... 38

6.2 Object overview...............................................................................................................................39

6.3 Object description ...........................................................................................................................40

6.3.1 Objects to be parameterized during commissioning ........................................................ 40

6.3.2 Profile-specific objects ..................................................................................................... 42

6.3.3 Standard objects .............................................................................................................. 44

7 Appendix..................................................................................................................................................46