Table of contents

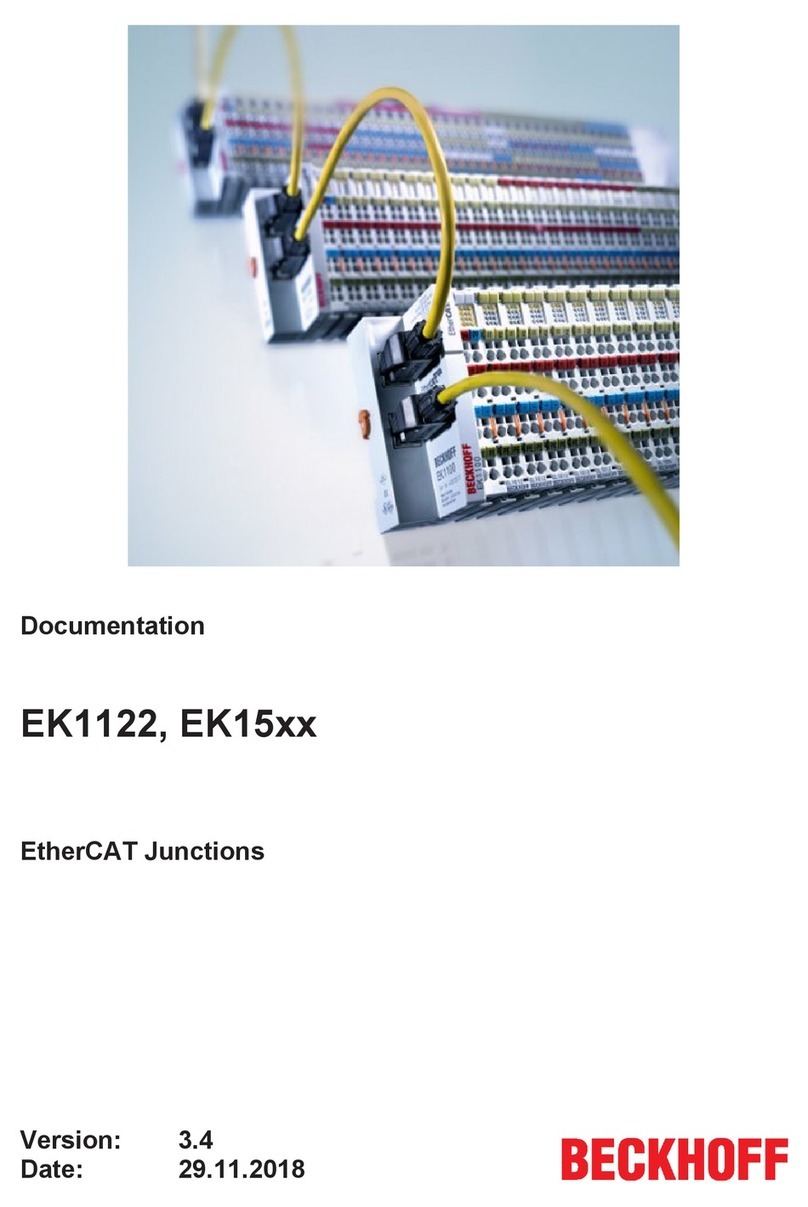

EK112x, EK15xx 3Version: 3.6

Table of contents

1 Foreword....................................................................................................................................................5

1.1 Overview EtherCAT Junctions ..........................................................................................................5

1.2 Notes on the documentation .............................................................................................................6

1.3 Safety instructions.............................................................................................................................7

1.4 Guide through documentation...........................................................................................................8

1.5 Documentation issue status ..............................................................................................................9

1.6 Version identification of EtherCAT devices .....................................................................................10

1.6.1 General notes on marking................................................................................................10

1.6.2 Version identification of EK Couplers...............................................................................11

1.6.3 Beckhoff Identification Code (BIC) ................................................................................... 12

1.6.4 Electronic access to the BIC (eBIC).................................................................................14

2 Product overview ....................................................................................................................................16

2.1 Junction with RJ45 connection........................................................................................................16

2.1.1 EK1122, EK1122-0080 .................................................................................................... 16

2.1.2 EK1121-0010 ...................................................................................................................22

2.2 Junctions with M8 connection .........................................................................................................26

2.2.1 EK1122-0008 ...................................................................................................................26

2.3 Junctions with fiber optic connection...............................................................................................28

2.3.1 EK1521 ............................................................................................................................28

2.3.2 EK1521-0010 ...................................................................................................................30

2.4 Junctions with POF connection.......................................................................................................32

2.4.1 EK1561 ............................................................................................................................32

3 Commissioning/application notes.........................................................................................................34

3.1 Application notes RJ45 junction ......................................................................................................34

3.1.1 EK1121-0010 - Settings and port assignment ................................................................. 34

3.1.2 EK1122 - Settings and port assignment........................................................................... 35

3.2 Application notes M8 junction .........................................................................................................36

3.2.1 EK1122-0008 - Settings and port assignment ................................................................. 36

3.3 Application notes fiber optic junction...............................................................................................37

3.3.1 Principles of fiber-optic technology .................................................................................. 38

3.3.2 EK1521-00x0 - Settings and port assignment.................................................................. 43

3.3.3 Notes on suitable optical fiber cables............................................................................... 44

3.3.4 Application with EK1521 and EK1521-0010 .................................................................... 45

3.4 Application notes POF junction .......................................................................................................47

3.4.1 EK1561 - Settings and port assignment........................................................................... 47

3.4.2 Notes regarding suitable POF cables .............................................................................. 48

3.4.3 Application with EK1561 .................................................................................................. 49

3.5 Notes regarding assembly of POF cables with the connector set ZS1090-0008............................51

4 Error handling and diagnostics .............................................................................................................55

4.1 Diagnostic LEDs EK1121-0010, EK1122, EK1122-0008................................................................55

4.2 Diagnostic LEDs EK1521, EK1521-0010........................................................................................56

4.3 Diagnostic LEDs EK1561................................................................................................................57

5 Mounting and wiring ...............................................................................................................................58