BECSys 2 User manual

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08ev: D08

Operator's Manual

Page 1

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

TABLE OF CONTENTS

Firmware Version......................................................1

Environmental Conditions.........................................2

Electrical Specifications............................................2

Warnings....................................................................3

Section A: Programming the Controller...................4

A – 1: The Program Menu........................................4

A – 1.1: Entering the Program Menu................4

A – 1.2: Selecting Language.............................4

A – 1.3: pH High Alarm Point..........................4

A – 1.4: pH Low Alarm Point...........................4

A – 1.5: ORP High Alarm Point.......................4

A – 1.6: ORP Low Alarm Point........................4

A – 1.7: ORP/ppm............................................4

A – 1.8: Exiting the Menu ................................4

Section B: Normal Operation ...................................5

B – 1: Displaying the Set points...........................5

B – 2: Modifying the Set Points ...........................5

B – 2.1: Modifying the pH Set Point................5

B – 2.2: Modifying the ORP Set Point .............5

B – 2.3: Modifying the ppm Set Point..............5

B – 2.4: Modifying the Booster Trigger Point..5

B – 2.5: Modifying the Booster End Point .......5

B – 3: Single Point Calibration.............................5

B – 3.1: Single Point Calibration - pH..............5

B – 3.2: Single Point Calibration - ppm............5

B – 3.3: Probe Error..........................................6

B – 4: Alarms........................................................6

B – 4.1: pH High/Low alarms...........................6

B – 4.2: ORP High/Low alarms........................6

B – 4.4: No Flow alarm ....................................6

B – 4.5: (x) min Feed Delay .............................6

B – 4.6: Cl/Br Lockout .....................................6

B – 4.7: pH FAILSAFE ALM..........................6

B – 4.8: Cl/Br FAILSAFE................................6

B – 4.9: Booster FAILSAFE ............................6

B – 5: Resetting a Failsafe Alarm.........................6

Section C: Maintenance............................................7

C – 1: Potentiometric Sensors (pH and ORP).......7

C – 1.1: Electrode Cleaning:.............................7

C – 1.2: Long-Term Storage:............................7

Section D: Feed Charts.............................................8

D – 1: Spa Feed Charts.........................................8

D – 2: Pool Feed Charts........................................9

Section E: Installation Diagrams ............................10

E – 1: Pressure Filter Installation........................10

E – 2: Vacuum Filter Installation........................10

Section F: Warranty................................................11

Firmware Version

This manual was written for firmware v1.20. If you received newer firmware but did not receive a copy of the manual

covering that version of firmware, please contact your distributor.

Page 2

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

Environmental Conditions

The BECSys2 is housed in a NEMA 4X (IP65) enclosure. It should not be used in explosive environments. The

BECSys2 should be mounted so that adequate ventilation is provided around the enclosure, preventing general

environmental specifications from being exceeded (see table below).

Environmental Specifications

Specification Rating

Storage Temperature -30 to 60 Deg C

Ambient Operating Temperature -18 to 40 Deg C

Ambient Humidity 95% non condensing maximum humidity

Electrical Specifications

The BECSys2 may be ordered in either a 115VAC model or a 230VAC model. Following are the electrical specifications

for each model:

115VAC Model:

Voltage: 115VAC 60Hz

Phase: Single

Current: 9.25 Amps Full Load

(0.25 Amps – Controller)

(9 Amps – Relay Outputs, 3A X 3)

230VAC Model:

Voltage: 230VAC 50Hz

Phase: Single

Current: 9.125 Amps Full Load

(0.125 Amps – Controller)

(9 Amps – Relay Outputs, 3A X 3)

Page 3

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08Rev: D08

WarningsWarnings

Pay particular attention to the following warnings encountered while utilizing your

BECSys2 Water Chemistry Controller:

Warning: Various other warnings maybe found

throughout the manual text.

Page 4

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

Section A: Programming the Controller

A – 1: The Program Menu

A – 1.1: Entering the Program Menu

To enter the program menu, press and hold both the

Cal and Up keys for 3 seconds. When the LCD

screen clears, release the keys and “Program” should

appear on the display. Press the Up key to enter the

menu and press the Down key to exit. Use the Up

or Down Arrows to scroll to the setting you wish to

change. Press the Cal key to select the setting, then

use the Up or Down Arrows to modify the value.

Press the Cal key again to enter the new value and

return to the menu. To exit the program menu,

scroll to the “Exit menu” option and depress the Cal

key.

NOTE: After two minutes of no programming

activity, the Time-Out feature will

automatically exit the programming

menu.

A – 1.2: Selecting Language

The BECSys2 can be programmed to display in

three different languages. Once you have entered

the program menu the screen will display

Language ENG, signifying that the display is

currently set to English. Pressing the Cal key will

display a question mark (?) before the language.

Use the up and down buttons to select between

ENG (English), ESP (Spanish), and FRA (French),

and press the Cal key to select the language you

would like to use for the display.

A – 1.3: pH High Alarm Point

Pressing the down arrow displays pH High

followed by the current pH high alarm point. To

change this setting, press the Cal key, use the up or

down arrows to input the value you would like,

then press the Cal key again to save the new value.

A – 1.4: pH Low Alarm Point

Pressing the down arrow displays pH Low

followed by the current pH low alarm point. To

change this setting, press the Cal key, use the up or

down arrows to input the value you would like,

then press the Cal key again to save the new value.

A – 1.5: ORP High Alarm Point

Pressing the down arrow displays ORP High

followed by the current ORP high alarm point. To

change this setting, press the Cal key, use the up or

down arrows to input the value you would like,

then press the Cal key again to save the new value.

A – 1.6: ORP Low Alarm Point

Pressing the down arrow displays ORP Low

followed by the current ORP low alarm point. To

change this setting, press the Cal key, use the up or

down arrows to input the value you would like,

then press the Cal key again to save the new value.

A – 1.7: ORP/ppm

Pressing the down arrow displays ORP/ppm

selection. This option selects whether to use an

ORP set point or a ppm set point for the main

Cl/Br feed control. It is set to ORP by default.

To change this setting, press the Cal key, use the

up and down arrows to change between ORP and

ppm, then press the Cal key again to save the new

value. This option is only available if configured

to allow ppm control.

A – 1.8: Exiting the Menu

Pressing the down arrow displays Exit menu.

Pressing the Cal key exits the programming menu.

Page 5

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

Section B: Normal Operation

B – 1: Displaying the Set points

To display the Set Points, press the Set point key

briefly. The set points will be displayed for three

seconds.

B – 2: Modifying the Set Points

To modify the set points press the Set Point key for

three seconds. The display will change to pH SetPt

followed by the current pH Set Point.

B – 2.1: Modifying the pH Set Point

To change this setting, use the Up or Down

Arrows to input the new value, then press the Set

point key again to save it. To skip entering a new

value, press the Set Point key.

B – 2.2: Modifying the ORP Set Point

If the system is configured to control using an

ORP set point, the screen will display ORP SetPt

followed by the current ORP Set point. To

change this setting, use the Up or Down Arrows

to input the new value, then press the Set point

key again to save it. To skip entering a new value,

press the Set Point key.

B – 2.3: Modifying the ppm Set Point

If the system is configured to control using a ppm

set point, the screen will display ppm SetPt and the

current ppm set point on the LED bar graph will

be flashing. To change this setting, use the UP or

Down Arrows to adjust this value shown on the

LED bar graph and press the Set point key again

to save the new value. To skip entering a new

value, press the Set Point key.

B – 2.4: Modifying the Booster Trigger Point

If relay 3 is configured for Cl/Br Booster control,

the screen will display boostr trig followed by the

current trigger point. To change this setting, use

the Up or Down Arrows to input the new value,

then press the Set point key again to save it. To

skip entering a new value, press the Set Point key.

NOTE: This menu is only shown if you have

the Cl/Br Booster feed is enabled.

B – 2.5: Modifying the Booster End Point

If relay 3 is configured for Cl/Br Booster control,

the screen will display booster end followed by the

current end set point. To change this setting, use

the Up or Down Arrows to input the new value,

then press the Set point key again to save it. To

skip entering a new value, press the Set Point key.

NOTE: This menu is only shown if you have

the Cl/Br Booster feed is enabled.

B – 3: Single Point Calibration

To enter the calibration menu, press and hold the Cal

key for three seconds. After the display clears,

release the Cal key.

B – 3.1: Single Point Calibration - pH

The display should now read Cal pH followed by

the current pH reading. Use the arrow keys to

adjust the displayed value to match your test kit

reading, and then press the Cal key to save it. To

skip entering a new value, press the Cal key.

B – 3.2: Single Point Calibration - ppm

If ppm is available on your unit, the display should

read Cal ppm and the ppm LED's will be flashing.

Use the arrow keys to adjust the LED bar graph to

match your test kit reading, and then press the Cal

key to save it. To skip entering a new value, press

the Cal key.

Page 6

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

B – 3.3: Probe Error

If during a single point calibration you receive the

error message “Probe Error!” replace the probe.

B – 4: Alarms

During normal operation, the following alarms may

be displayed. Some alarms will not be available

depending on the system's configuration.

B – 4.1: pH High/Low alarms

This is displayed when the pH input has risen

above/fallen below the pH high/low alarm point.

These alarms will also trigger the Cl/Br Lockout

alarm.

B – 4.2: ORP High/Low alarms

This is displayed when the ORP input has risen

above/fallen below the ORP high/low alarm

point.

B – 4.4: No Flow alarm

Displayed when the flow input indicates the flow

has stopped. This alarm disables all chemical

feeds.

B – 4.5: (x) min Feed Delay

When flow is disrupted and then restored, the

controller will delay restarting feeds for a

programmed duration in order to prevent

operating feeds based on readings from stagnant

water. (x) = the number of minutes remaining

before feeds are allowed to start (e.g. 5 min Feed

Delay).

B – 4.6: Cl/Br Lockout

This is triggered whenever there is a pH high or

low alarm. This message indicates that the Cl/Br

feed (relay 2) and the optional Cl/Br Booster (relay

3) are disabled in order to prevent the Cl/Br feeds

from driving the pH even further out of range.

B – 4.7: pH FAILSAFE ALM

This is displayed when the active pH feed (feed up

or feed down) attempted to feed continuously for

the selected failsafe duration. The active pH feed

is disabled until one of the following conditions

occurs:

1) The pH input reaches the programmed set

point.

2) Disruption of flow

3) User manually resets the failsafe.

B – 4.8: Cl/Br FAILSAFE

This is displayed when the Cl/Br feed attempted

to feed continuously for the selected failsafe

duration. The Cl/Br feed is disabled until one of

the following conditions occurs:

1) The ORP/ppm input reaches the

programmed set point.

2) Disruption of flow

3) User manually resets the failsafe.

B – 4.9: Booster FAILSAFE

This is displayed when the optional Cl/Br Booster

feed attempted to feed continuously for the

selected failsafe duration. The Cl/Br Booster feed

is disabled until one of the following conditions

occurs:

1) The ORP input reaches the Cl/Br Booster set

point.

2) Disruption of flow

3) User manually resets the failsafe.

B – 5: Resetting a Failsafe Alarm

To reset a failsafe alarm, press and hold the Up and

down arrow keys momentarily.

Page 7

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08Rev: D08

Section C: MaintenanceSection C: Maintenance

The BECSys2 requires no maintenance other than a

periodic calibration check and sensor cleaning.

C – 1: Potentiometric Sensors (pH and ORP)

C – 1.1: Electrode Cleaning:

Slow response time and large offsets may indicate the

electrode has become coated. The nature of the

coating will dictate the type of cleaning technique

that should be used.

Soft coatings, like bacterial films, are best removed

using a squirt bottle or the water jet from a faucet.

If this is not successful, then gently wipe with a

soft wet cloth.

For a more severe coating, first try a strong

detergent (something similar to Dawn liquid

detergent) and warm water, using a soft brush (like

a toothbrush). Isopropyl alcohol on a Q-tip is

another good choice. Rinse the measuring end in

distilled water before reinstallation.

Greasy and oily coatings are best removed with a

detergent solution or a solvent that will not attack

the sensor body. Methanol and isopropyl alcohol

are good choices for solvents. Acetone, MEK,

THF, or trichloroethane will irreparably harm the

electrode.

Hard coatings, like calcium or lime scale, are best

removed with a solvent appropriate for the

particular coating. A 5% solution of hydrochloric

acid (HCl) would be a good choice for calcium

scale. If unsure of the proper solvent to remove a

hard mineral coating, then alternate between a 5%

hydrochloric acid and a 4% sodium hydroxide

(NaOH) for 10 minutes each. After treating the

electrode with these strong acids or bases, rinse the

electrode with water and soak it in a pH 4 buffer

for at least 1/2 hour.

The platinum tip of an ORP sensor can be cleaned

with an abrasive as a last resort. Gently scour the

platinum with a 600 grit wet emery cloth, or

preferably, a 1-3 micron alumina polishing powder.

C – 1.2: Long-Term Storage:

Save the wetting cap that came with the sensor for

long-term storage. After removing the sensor

from the flow-cell, clean it as in routine

maintenance, and then store it in the wetting cap

using a pH 4 buffer saturated with potassium

chloride (KCl). The potassium chloride will

prevent electrolyte from leaching out of the

sensors reference cell. The wetting cap only needs

to be half full. If a number of sites are going to be

serviced, for example, at the end of a season, then

it might be a good idea to carry a pint of 4.0/KCl

storage solution.

Warning: You may lightly blot the water

On a pH sensor tip on a paper towel, but never

vigorously rub or wipe the pH bulb because this

may scratch the delicate outer layer on the pH

g

lass im

p

airin

g

its res

p

onse.

Page 8

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

Section D: Feed Charts

Use the charts on the following pages to determine the correct amount of chemical to add to spa or pool water to

achieve desired conditions. Choose which chart to use by the chemical indicated and the number of gallons to be

treated.

D – 1: Spa Feed Charts

Quantity of Muriatic Acid Needed to Lower Total Alkalinity

Gallons in Spa

Desired

Decrease

In ppm 100 150 250 500 750 1000

10 1.25 ts 2.00 ts 1.00 tb 2.00 tb 3.00 tp 0.25 cp

20 2.50 ts 4.00 ts 2.00 tb 0.25 cp 0.33 cp 0.50 cp

30 1.25 tb 2.00 tb 3.00 tb 0.33 cp 0.67 cp 0.75 cp

40 5.00 ts 2.50 tb 0.25 cp 0.50 cp 0.75 cp 1.00 cp

50 2.00 tb 3.00 tb 5.00 tb 0.67 cp 1.00 cp 1.33 cp

60 2.50 tb 0.25 cp 0.33 cp 0.75 cp 1.00 cp 1.50 cp

70 3.00 tb 0.25 cp 0.50 cp 1.00 cp 1.33 cp 1.75 cp

80 3.50 tb 0.33 cp 0.50 cp 1.00 cp 1.50 cp 2.00 cp

90 0.25 cp 0.33 cp 0.67 cp 1.00 cp 1.67 cp 2.33 cp

100 0.25 cp 0.50 cp 0.67 cp 1.33 cp 2.00 cp 2.50 cp

ts = teaspoon tb = tablespoon cp = one cup (8 fl oz)

Quantity of Sodium Bisulfate Needed to Lower Total Alkalinity

Gallons in Spa

Desired

Decrease

In ppm 100 150 250 500 750 1000

10 1.50 ts 2.50 ts 1.00 tb 2.50 tb 0.25 cp 0.33 cp

20 1.00 tb 1.50 tb 2.50 tb 0.33 cp 0.50 cp 0.67 cp

30 1.50 tb 2.50 tb 0.25 cp 0.50 cp 0.75 cp 1.00 cp

40 2.00 tb 3.00 tb 0.33 cp 0.67 cp 1.00 cp 1.25 cp

50 2.50 tb 0.25 cp 0.50 cp 0.75 cp 1.25 cp 1.50 cp

60 3.00 tb 4.50 tb 0.50 cp 1.00 cp 1.50 cp 2.00 cp

70 0.25 cp 0.33 cp 0.50 cp 1.00 cp 1.67 cp 2.25 cp

80 0.25 cp 0.33 cp 0.67 cp 1.25 cp 2.00 cp 2.50 cp

90 0.33 cp 0.50 cp 0.75 cp 1.50 cp 2.25 cp 3.00 cp

100 0.33 cp 0.50 cp 0.75 cp 1.67 cp 2.50 cp 3.25 cp

ts = teaspoon tb = tablespoon cp = one cup (8 fl oz)

Quantity of Bicarbonate of Soda Needed to Raise Total Alkalinity

Gallons in Spa

Desired

Increase

In ppm 100 150 250 500 750 1000

10 1.25 ts 2.00 ts 4.00 ts 2.50 tb 0.25 cp 0.33 cp

20 1.00 tb 1.50 tb 2.50 tb 5.00 tb 0.50 cp 0.50 cp

30 1.50 tb 2.00 tb 3.50 tb 0.50 cp 0.67 cp 1.00 cp

40 2.00 tb 3.00 tb 0.33 cp 0.50 cp 1.00 cp 1.00 cp

50 2.50 tb 3.50 tb 6.00 tb 0.75 cp 1.00 cp 1.50 cp

60 3.00 tb 0.25 tb 0.50 cp 1.00 cp 1.33 cp 1.75 cp

70 3.50 tp 0.35 cp 0.50 cp 1.00 cp 1.50 cp 2.00 cp

80 0.25 cp 0.33 cp 0.50 cp 1.25 cp 1.75 cp 2.50 cp

90 0.33 cp 0.50 cp 0.67 cp 1.33 cp 2.05 cp 2.75 cp

100 0.33 cp 0.50 cp 0.75 cp 1.50 cp 2.25 cp 3.00 cp

ts = teaspoon tb = tablespoon cp = one cup (8 fl oz)

Quantity of Calcium Chloride Needed to Increase Calcium Hardness

Gallons in Spa

Desired

Increase

In ppm 100 150 250 500 750 1000

10 1.25 ts 2.00 ts 1.00 tb 2.00 tb 3.00 tb 0.25 cp

20 2.50 ts 4.00 ts 2.00 tb 0.25 cp 0.33 cp 0.50 cp

30 1.25 tb 2.00 tb 3.00 tb 0.33 cp 0.67 cp 0.75 cp

40 4.00 ts 2.50 tb 0.25 cp 0.50 cp 0.75 cp 1.00 cp

50 2.00 tb 3.00 tb 5.00 tb 0.67 cp 1.00 cp 1.33 cp

60 2.50 tb 0.25 cp 0.33 cp 0.75 cp 1.00 cp 1.50 cp

70 3.00 tp 0.25 cp 0.50 cp 1.00 cp 1.33 cp 1.75 cp

80 3.50 tp 0.25 cp 0.50 cp 1.00 cp 1.50 cp 2.00 cp

90 0.25 cp 0.33 cp 0.33 cp 1.00 cp 1.67 cp 2.33 cp

100 0.25 cp 0.50 cp 0.67 cp 1.33 cp 2.00 cp 2.50 cp

ts = teaspoon tb = tablespoon cp = one cup (8 fl oz)

Quantity of Chlorine Compound Needed to Increase 1 ppm

Gallons in Spa

Percent

Chlorine In

Product 100 150 250 500 750 1000

5 0.50 tb 2.00 ts 1.25 tb 2.50 tb 0.25 cp 0.33 cp

10 0.25 tb 1.00 ts 2.00 ts 1.25 tb 2.00 tb 2.50 tb

12 0.25 tb 1.00 ts 0.50 tb 1.00 tb 1.50 tb 2.00 tb

30 0.25 tb 0.33 ts 0.75 ts 1.25 ts 2.00 ts 2.50 ts

40 0.167 ts 0.25 ts 0.500 ts 1.00 ts 1.50 ts 2.00 ts

50 0.167 ts 0.25 ts 0.375 ts 0.75 ts 1.25 ts 1.50 ts

60 0.167 tb 0.200 ts 0.375 ts 0.50 ts 1.00 ts 1.25 ts

65 0.100 ts 0.167 ts 0.250 ts 0.50 ts 0.75 ts 1.00 ts

ts = teaspoon tb = tablespoon cp = one cup (8 fl oz)

Page 9

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

D – 2: Pool Feed Charts

Quantity of Muriatic Acid Needed to Lower Total Alkalinity

Gallons in PoolDesired Decrease

In ppm 10,000 25,000 50,000 75,000 100,000 200,000 500,000 750,000 1,000,000

10 1.30 pt 1.62 qt 3.25 qt 1.22 gl 1.62 gl 3.25 gl 8.13 gl 12.20 gl 16.25 gl

20 1.30 pt 3.25 qt 1.62 gl 2.43 gl 3.25 gl 7.50 gl 16.20 gl 24.30 gl 32.50 gl

30 1.95 qt 1.22 gl 2.44 gl 3.86 gl 4.98 gl 9.76 gl 24.40 gl 36.60 gl 48.80 gl

40 2.80 qt 1.63 gl 3.25 gl 4.87 gl 6.50 gl 13.00 gl 32.50 gl 48.80 gl 65.00 gl

50 3.25 qt 2.03 gl 4.07 gl 6.10 gl 8.14 gl 16.28 gl 40.70 gl 61.00 gl 81.40 gl

60 3.90 qt 2.44 gl 4.88 gl 7.32 gl 9.76 gl 19.52 gl 48.80 gl 73.20 gl 97.80 gl

70 1.14 gl 2.84 gl 5.69 gl 8.54 gl 11.38 gl 22.76 gl 56.90 gl 85.45 gl 113.80 gl

80 1.30 gl 3.25 gl 6.50 gl 9.75 gl 13.00 gl 26.00 gl 65.00 gl 97.50 gl 138.00 gl

90 1.48 gl 3.66 gl 7.31 gl 10.96 gl 14.82 gl 29.24 gl 73.10 gl 109.60 gl 146.20 gl

100 1.63 gl 4.06 gl 8.12 gl 12.18 gl 16.24 gl 32.48 gl 81.20 gl 121.80 gl 162.40 gl

120 1.96 gl 4.88 gl 9.76 gl 14.64 gl 19.52 gl 39.00 gl 97.80 gl 148.40 gl 196.20 gl

150 2.44 gl 6.09 gl 12.18 gl 18.27 gl 24.40 gl 48.80 gl 121.80 gl 182.70 gl 244.00 gl

200 3.25 gl 8.12 gl 18.24 gl 24.36 gl 32.50 gl 65.00 gl 162.40 gl 243.80 gl 325.00 gl

pt = one pt (16 fl oz) qt = one quart (32 fl oz) gl = one gallon (128 fl oz)

Quantity of Bicarbonate of Soda Needed to Raise Total Alkalinity

Gallons in PoolDesired Increase

In ppm 10,000 25,000 50,000 75,000 100,000 200,000 500,000 750,000 1,000,000

10 1.50 lb 3.75 lb 7.50 lb 11.25 lb 15.00 lb 30.00 lb 75.00 lb 112.50 lb 150.00 lb

20 3.00 lb 7.50 lb 15.00 lb 22.50 lb 30.00 lb 60.00 lb 150.00 lb 225.00 lb 300.00 lb

30 4.50 lb 11.25 lb 22.50 lb 33.75 lb 45.00 lb 90.00 lb 225.00 lb 337.50 lb 450.00 lb

40 6.00 lb 15.00 lb 30.00 lb 45.00 lb 60.00 lb 120.00 lb 300.00 lb 450.00 lb 600.00 lb

50 7.50 lb 18.75 lb 37.50 lb 56.25 lb 75.00 lb 150.00 lb 375.00 lb 562.50 lb 750.00 lb

60 9.00 lb 22.50 lb 45.00 lb 67.50 lb 90.00 lb 180.00 lb 450.00 lb 675.00 lb 900.00 lb

70 10.50 lb 26.25 lb 52.50 lb 78.75 lb 105.00 lb 210.00 lb 525.00 lb 787.50 lb 1050.00 lb

80 12.00 lb 30.00 lb 60.00 lb 90.00 lb 120.00 lb 240.00 lb 600.00 lb 900.00 lb 1200.00 lb

90 13.50 lb 33.75 lb 67.50 lb 101.25 lb 135.00 lb 270.00 lb 675.00 lb 1012.50 lb 1350.00 lb

100 15.00 lb 37.50 lb 75.00 lb 112.50 lb 150.00 lb 300.00 lb 750.00 lb 1125.00 lb 1500.00 lb

lb =pounds of dry chemical

Quantity of Calcium Chloride Needed to Increase Calcium Hardness

Gallons in Pool

10,000 25,000 50,000 75,000 100,000 200,000 500,000 750,000 1,000,000

Desired Increase

In ppm lb oz lb oz lb oz lb oz lb oz lb lb oz lb oz lb

10 1 4 3 2 6 4 9 6 12 8 25 62 8 93 12 125

20 2 8 6 4 12 8 18 12 25 0 50 125 0 197 8 250

30 3 12 9 6 18 12 28 2 37 8 75 187 8 281 4 375

40 5 0 12 8 25 0 37 8 50 0 100 250 0 375 0 500

50 6 4 15 10 31 4 46 14 62 8 125 312 8 468 12 625

60 7 8 18 12 37 8 56 4 75 0 150 375 0 562 8 750

70 8 12 21 14 43 12 65 10 87 8 175 437 8 658 4 875

80 10 0 25 0 50 0 75 0 100 0 200 500 0 750 0 1,000

90 11 4 28 2 56 4 84 6 112 8 225 562 8 843 12 1,125

100 12 8 31 4 62 8 93 12 125 0 250 625 0 937 8 1,250

150 18 12 46 14 93 12 104 10 187 8 375 937 8 1,406 4 1,875

200 25 0 62 8 125 0 187 8 250 0 500 1,250 0 1,875 0 2,500

Quantity of Chlorine Compound Needed to Increase 1 ppm

Gallons in PoolPercent Chlorine

In Product 10,000 25,000 50,000 75,000 100,000 200,000 500,000 750,000 1,000,000

5 3.2 cp 2 qt 1 gl 1.5 gl 2 gl 4 gl 10 gl 15 gl 20 gl

10 1.6 cp 1 qt 2 qt 3 qt 1 gl 2 gl 5 gl 7.5 gl 10 gl

12 1.33 cp 1.67 pt 1.517 qt 2.276 pt 3.33 qt 1.665 gl 4.163 gl 6.245 gl 8.326 gl

30 0.278 lb 0.665 lb 1.390 lb 2.085 lb 2.780 lb 5.580 lb 13.900 lb 20.850 lb 27.800 lb

40 0.209 lb 0.521 lb 1.043 lb 1.565 lb 2.086 lb 4.172lb 10.430 lb 15.645 lb 20.860 lb

50 0.167 lb 0.417 lb 0.834 lb 1.251 lb 1.668 lb 3.336lb 8.340lb 12.511 lb 16.680 lb

60 0.139 lb 0.348 lb 0.695 lb 1.043 lb 1.390 lb 2.780lb 6.950 lb 10.425 lb 13.900 lb

65 0.128 lb 0.321 lb 0.642 lb 0.963 lb 1.284 lb 2.568lb 6.420 lb 9.630lb 12.840 lb

70 0.119 lb 0.298 lb 0.596 lb 0.894 lb 1.192 lb 2.384lb 5.960lb 8.940 lb 11.920 lb

75 0.111 lb 0.278 lb 0.556 lb 0.834 lb 1.112 lb 2.224 lb 5.560 lb 8.340 lb 11.120 lb

80 0.104 lb 0.261 lb 0.521 lb 0.782 lb 1.042 lb 2.064 lb 5.210 lb 7.815 lb 10.420 lb

85 0.096 lb 0.417 lb 0.491 lb 0.737 lb 0.982 lb 1.964 lb 4.910 lb 7.365 lb 9.829 lb

90 0.093 lb 0.232 lb 0.463 lb 0.695 lb 0.926 lb 1.852 lb 4.630 lb 6.945 lb 9.260 lb

100 0.083 lb 0.209 lb 0.417 lb 0.626 lb 0.634 lb 1..668 lb 4.170 lb 6.225lb 8.340 lb

cp = one cup (8 fl oz) pt = one pt (16 fl oz) qt = one quart (32 fl oz)

gl = one gallon (128 fl oz) lb =pounds of dry chemical

Page 10

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08ev: D08

Section E: Installation DiagramsSection E: Installation Diagrams

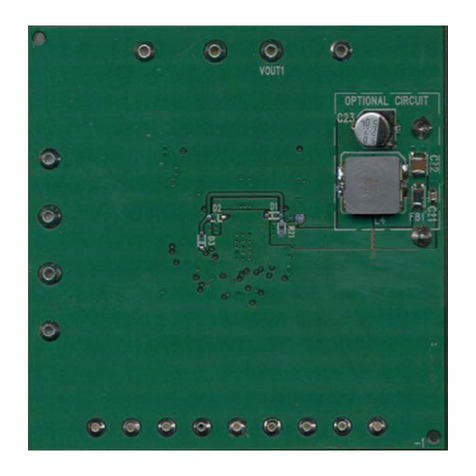

E – 1: Pressure Filter Installation

E – 2: Vacuum Filter Installation

Page 11

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08

Section F: Warranty

LIMITED WARRANTY

BECS warrants the controller electronics and flow cell against any defect in workmanship or

materials for a period of two years from the date of shipment. BECS warrants the pH and ORP

sensors against any defect in workmanship or materials for a period of one year from the date of

shipment. In the event of a component failure due to any defect in workmanship or materials,

BECS will repair, or if repair is not possible, replace the defective part or parts of the BECSys

controller.

BECS will have the sole right to determine whether to repair or replace a product. BECS will not be

responsible for any expense associated with installation of repaired or replacement parts.

LIMITATIONS AND EXCLUSIONS

This is a LIMITED WARRANTY. BECS makes NO WARRANTIES other than those contained

herein. The LIMITED WARRANTY replaces and is in lieu of any WARRANTIES of

MERCHANTABILITY or of FITNESS FOR A PARTICULAR PURPOSE which are expressly

DISCLAIMED. All GENERAL, SPECIAL, INDIRECT, INCIDENTAL AND/OR

CONSEQUENTIAL DAMAGES ARE EXCLUDED AND DISCLAIMED.

This Limited Warranty is governed by Missouri Law and all disputes related to or arising from this

transaction or Limited Warranty shall be resolved in Circuit Court of St. Louis County, Missouri.

Any claims under this Limited Warranty must be brought within ONE YEAR after the cause of

action accrued.

Document Part Number: 8620009-D08

April 2008

9487 Dielman Rock Island Industrial Dr. St. Louis, MO 63132 Tel:(314) 567-0088

Operator's Manual Rev: D08Rev: D08

has been designing and manufacturing the industry’s

most reliable water chemistry controller for over 15 years. Our 24,000 ft2facility in

Saint Louis, Missouri is home to an exceptional design team, and all manufacturing is

performed onsite at this facility where we can personally assure the quality of our

products. The BECS commitment to excellence drives the most innovative new

products and unparalleled customer service.

has been designing and manufacturing the industry’s

most reliable water chemistry controller for over 15 years. Our 24,000 ft2facility in

Saint Louis, Missouri is home to an exceptional design team, and all manufacturing is

performed onsite at this facility where we can personally assure the quality of our

products. The BECS commitment to excellence drives the most innovative new

products and unparalleled customer service.

B

EC

S

TECHNOLOGY Inc.

Table of contents

Popular Controllers manuals by other brands

ProMinent

ProMinent DULCOMETER Assembly and operating instructions

TECOMAT FOXTROT

TECOMAT FOXTROT CP-1005 Basic documentation

Keithley

Keithley S46 instruction manual

Samson

Samson 45-1 Mounting and operating instructions

Superior Electric

Superior Electric STABILINE WHR22 Series instructions

Linear Technology

Linear Technology LTM4650EY-1 Demo Manual

Linear Technology

Linear Technology LTM4650-1 Demo Manual

Linear Technology

Linear Technology LT3507 Demo Manual

Sturtevant Richmont

Sturtevant Richmont Global 400mp user manual

TIANJIN BAILI ERTONG MACHINERY

TIANJIN BAILI ERTONG MACHINERY IMT Series Operation manual

SIYI

SIYI AK28 HD user manual

Metal Work

Metal Work ONE Use and maintenance