Becx Machines HS150HR User manual

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Hedge Cutter

HS150HR

User-Manual

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 2 of 37

Manufacturer Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

Tel +31 (0) 13 2070760

Email: info@becxmachines.com

Website: http://www.becxmachines.com

© Copyright 2020

Nothing in this publication may be reproduced and/or made public in any form by print, photocopy,

microfilm, recording tape, electronically or by any other means without prior written permission

from Becx Machines B.V.

Becx Machines B.V. reserves the right to modify parts of the system, including the contents of this

manual, at any moment, without prior or direct notification to the buyer.

Although Becx Machines B.V. has taken the greatest care to make sure that individual parts have

been described correctly and in full where necessary, it accepts no liability for damage as a result of

inaccuracies or incompleteness of this manual.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 3 of 37

Preface

The Becx hedge trimmer has been specially developed to cut hedges safely and efficiently.

Each cutting head is equipped with a double row of cutter blades, enabling extra fine cutting.

Combined with the five-sided protection, this prevents danger from flailing branches. The hedge

trimmer is designed in such a way that it will continue to function in the most demanding situations

and will continue to work for a long time. Each cutter head is therefore equipped with its own

hydraulic motor. The shafts and the bearings are of an extra heavy-duty construction.

•Read this manual carefully before you start to use the hedge

trimmer. Always follow the safety instructions set out in chapter 2.

•One copy of this manual must be kept with hedge trimmer and must

be available to the user. All important servicing sessions and any

comments must be recorded and retained by the servicing company.

•The user is responsible for selecting a suitable tool carrier for the

hedge trimmer and for ensuring that the hedge trimmer is properly

attached and connected.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 4 of 37

Table of contents

PREFACE ...................................................................................................................................... 3

TABLE OF CONTENTS .................................................................................................................... 4

CERTIFICATE OF CONFORMITY (IIA) (COPY) ................................................................................... 5

1) TECHNICAL DATA................................................................................................................ 7

2) SAFETY............................................................................................................................... 8

2.1 GENERAL...................................................................................................................................... 8

2.2 IN USE ......................................................................................................................................... 8

2.3 OPERATING PERSONNEL.................................................................................................................. 9

2.4 CAUTION SYMBOLS ON MACHINE ................................................................................................... 10

3) COMPONENT DESCRIPTION .................................................................................................... 11

3.1 MECHANICAL COMPONENTS.......................................................................................................... 12

3.2 HYDRAULIC COMPONENTS ............................................................................................................ 14

3.3 HYDRAULIC SCHEME..................................................................................................................... 15

4) OPERATION............................................................................................................................ 16

4.1 ASSEMBLY AND ADJUSTMENT OF THE HEDGE TRIMMER ...................................................................... 16

4.2 CARRYING OUT TRIMMING OPERATIONS .......................................................................................... 18

4.3 STORAGE.................................................................................................................................... 22

5) MAINTENANCE....................................................................................................................... 23

5.1 REPLACING AND/OR SHARPENING THE CUTTER BLADES....................................................................... 24

5.2 TORQUE +ORDER OF TIGHTENING CUTTING UNITS ............................................................................ 29

5.3 TORQUE +ORDER OF TIGHTENING BLADES ....................................................................................... 31

6) FAILURE ANALYSES................................................................................................................. 32

7) REMOVAL............................................................................................................................... 33

8) LOGBOOK............................................................................................................................... 34

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 5 of 37

Certificate of conformity (IIa) (copy)

We:

Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

declare entirely under our sole responsibility, that this product:

Description : Becx Hedge Trimmer.

Type : HS150 HR

Serial number :

to which this declaration applies, complies with the provisions of the Directives:

Machinery Directive 2006/42/EG

Complies with the following standards:

NEN-EN-12100 Safety of machinery. Basic definitions, general design principles.

NEN-EN 4413 Hysraulics –Safety requirements for hydraulic and

pneumatic systems and their components: Hydraulics

NEN-ISO 4254-1 Agricultural machinery - Safety - Part 1: General requirements

Director; Erwin Hommen

The Netherlands, Moergestel,

Date:

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 6 of 37

List of symbols

This manual uses the following symbols for all actions and situations where the safety of the operator or

technician is at stake and where it is necessary to act with caution:

Warning!

Explanation.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 7 of 37

1) Technical data

Description

Value

Unit

General

Noise pressure

See tool carrier

dB(A)

Vibration level in normal use

n.a.

Cutting capacity

35

mm

Needed power

14

Kw

Dimensions and weights

Width

1590

mm

Length

1170

mm

Height

500

m

Own weight

199

kg

Attachment information

Standard attachment tube

80*80

mm

Available mounting width

488

mm

Force on attachment point (see Figure 8)

1980

N

Hanging moment (see Figure 8)

187

Nm

Connection data

Maximum operating pressure

210

bar

Maximum revolutions

2000

RPM

Maximum Oil flow (at 2000 rev/min)

45

L/min

Pressure line attachment: with rapid flat seal attachment

1/2”

Return line connection: with rapid flat seal attachment

1/2”

Drain line connection: with rapid flat seal attachment

3/8”

Maximum pressure on drain line

non-pressurized

bar

Hydraulic oil filtering requirements

10

Microns

Oil for the drive

HV-46 or equivalent

Grease specs

NLGI 2

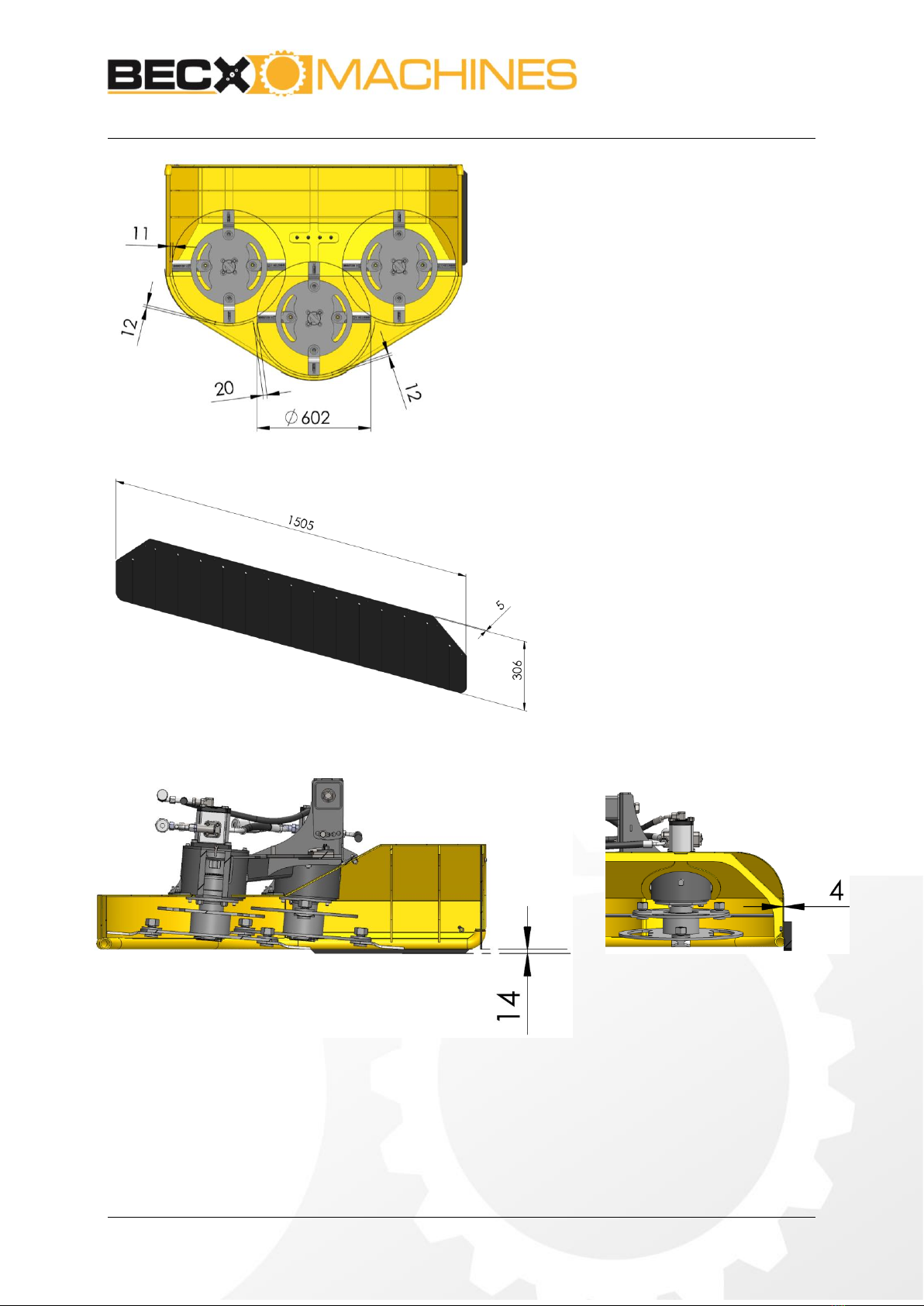

Figure 1: Dimensions

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 8 of 37

2) Safety

2.1 General

•No modifications must be made to the hedge trimmer.

•Only cutting blades that comply with the supplier's specifications must be

installed.

•You are at risk of being cut by the sharp knife edges when you work on the

cutter blades.

•The user is responsible for making sure that the correct tool carrier and lifting

arm are used (see chapter 0:1) Technical data). The following are

important points in this regard:

•The maximum pressure and number of revolutions (oil flow) must not be

exceeded. Excess pressure and excess revving can damage the machine and

cause injury.

•The lifting arm and tool carrier must be strong and stable enough to absorb

the forces and moments exerted by the hedge trimmer safely and under all

circumstances.

2.2 In use

•Consult the tool carrier manual for the noise rating. Because this is

considerably louder than the hedge trimmer itself, the noise load of the tool

carrier determines the rating.

•The machinery must only be used for the activities for which it is designed.

•The trimmer is not suitable for trimming with ground contact. The design of

the hedge trimmer means that there is too great a risk that the cutter blades

will touch the ground and/or obstacles.

•The hedgecutter is build for cutting hedges and groundcover plantation and

must not be used for any other purposes such as cutting grass or road-sides.

•Persons or animals who are present in or who approach the danger zone must

be stopped immediately and the hedge trimmer must be switched off (see

4.2). This also applies to situations where the hedge trimmer is switched on

after maintenance to make sure it operates correctly.

•If passers-by disrupt the trimming work too much, the operator can consider

temporarily cordoning off the site.

•The work-place should be secured when the operator’s sight is diminished by

a high or dense hedge.

•If the hedge trimmer starts to make a different sound and/or starts to vibrate,

work must stop immediately and the hedge trimmer has to be switched off

(see 4.2). Work can only continue after the source of the noise has been

identified and resolved.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 9 of 37

•If no trimming work is being done, always switch off the hedge trimmer. This

includes when you are driving to the work site. The risk of coming into contact

with passers-by is greater at these times than during trimming. There is no

hedge present to act as a protective shield in these situations and it is more

difficult for bystanders and passers-by to judge the route you are taking.

Objects that are flung out can travel a greater distance when there is no

hedge to stop them.

•Always complete inspection and maintenance jobs.

•The machinery must not be used for any other purposes during inspection and

maintenance.

•The hydraulic feed to the hedge trimmer must be disconnected during

inspection, maintenance or cleaning to prevent accidental operation.

•Always comply with local work regulations and safety rules.

•If the machinery is used in the dark, use sufficient lighting (approx. 50 lux at

the work site).

•Trimming operations must stop immediately if there is any possibility that

people and animals could enter the danger zone. (see 4.2)

•Switch machinery on and off at a low revolution speed to prevent damage.

Depending on the tool carrier used, this means that the machine is running

stationary or at minimum flow.

2.3 Operating personnel

•Operating personnel must be over 18.

•Only persons who have received permission from the owner are allowed to

operate the system.

•Persons must only carry out jobs for which they are trained. This applies to

both maintenance work and normal operations.

•Personnel who operate equipment must be familiar with all possible

situations that could arise.

•The owner or person in charge must be told if personnel operating machinery

identify faults or hazards or do not agree with safety measures.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 10 of 37

2.4 Caution symbols on machine

1.

Cutt-off danger

2.

Read manual before operation.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 11 of 37

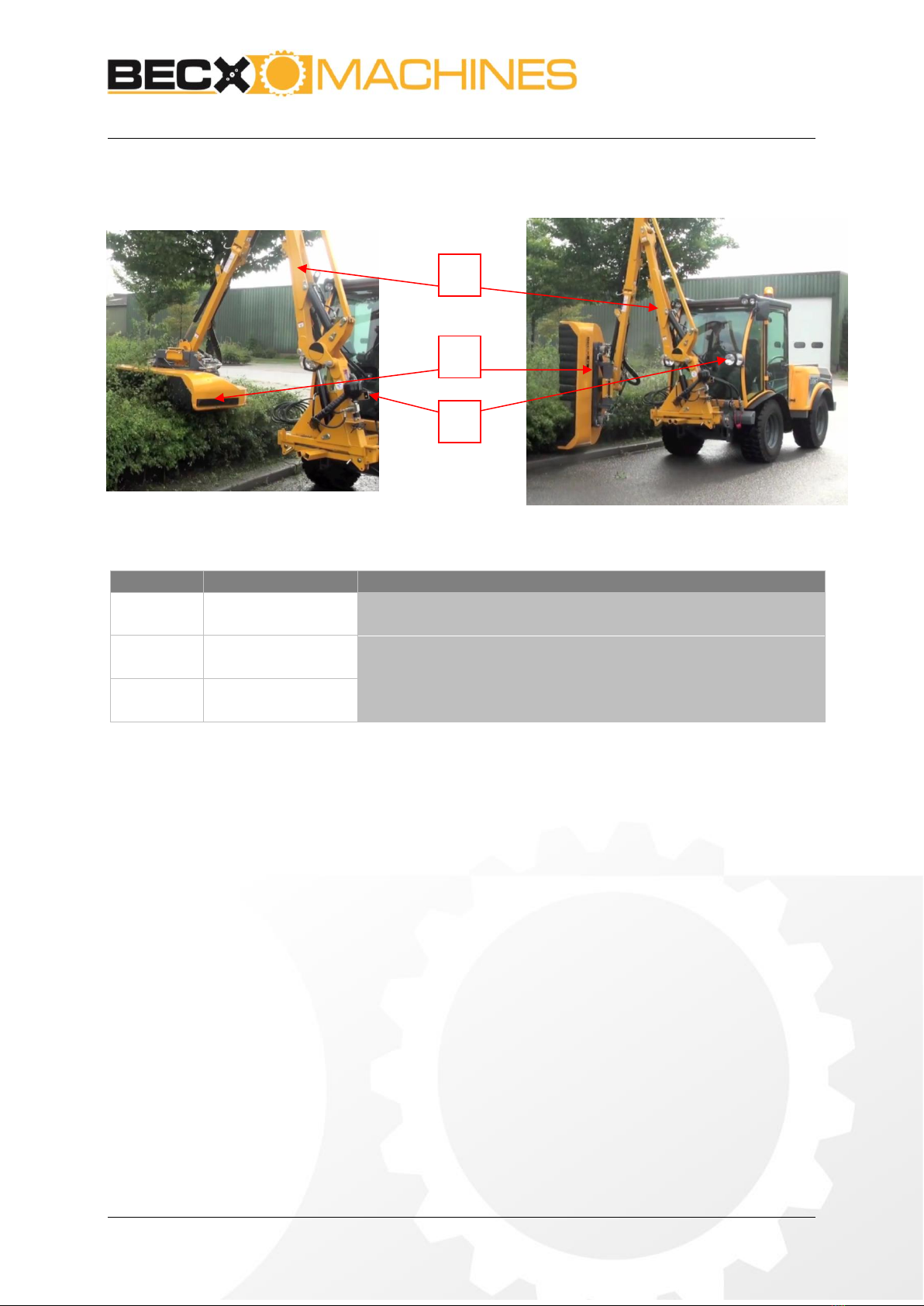

3) Component description

Figure 2: General photo

Figure

Part

Explanation

1

Lifting arm

•The lifting arm is not supplied. The user is responsible for

using a lifting arm that is suitable for the hedge trimmer.

2

Hedge trimmer

•The hedge trimmer can be used horizontally, vertically and

at all intermediate angles.

3

Tool carrier

•The tool carrier is not supplied. The user is responsible for

using a tool carrier that is suitable for the hedge trimmer.

1

2

3

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 12 of 37

3.1 Mechanical components

Figure 3: General overview of the mechanical components

Figure

Part

Explanation

1

Attachment tube

•The hedge trimmer must be attached to the lifting arm on

the tool carrier by means of the attachment tube.

2

Angle adjustment

•Once the hedge cutter has been attached to the lifting arm it

can be adjusted to the correct angle. (see paragraph 0)

3

Inlet side

•During trimming, the branches to be cut will enter on the

inlet side, which is protected with Vulkollan flaps next to the

cutting heads.

4

Cutting head (3*)

•Each cutting head carries four cutter blades. The lower two

cutting blades cut the branches and twigs off the hedge. The

upper two cutting blades slice the cut branches into small

chips.

5

Protective deck

•The protective deck is made of high-quality steel and

prevents cut material from being hurled out.

4

5

3

1

2

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 13 of 37

Figure 4: Dimensions protective body

Figure 5: Dimensions protective material front side (Material: PUR SH 90 A)

Figure 6: Dimensions blade swing and protective body

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 14 of 37

3.2 Hydraulic components

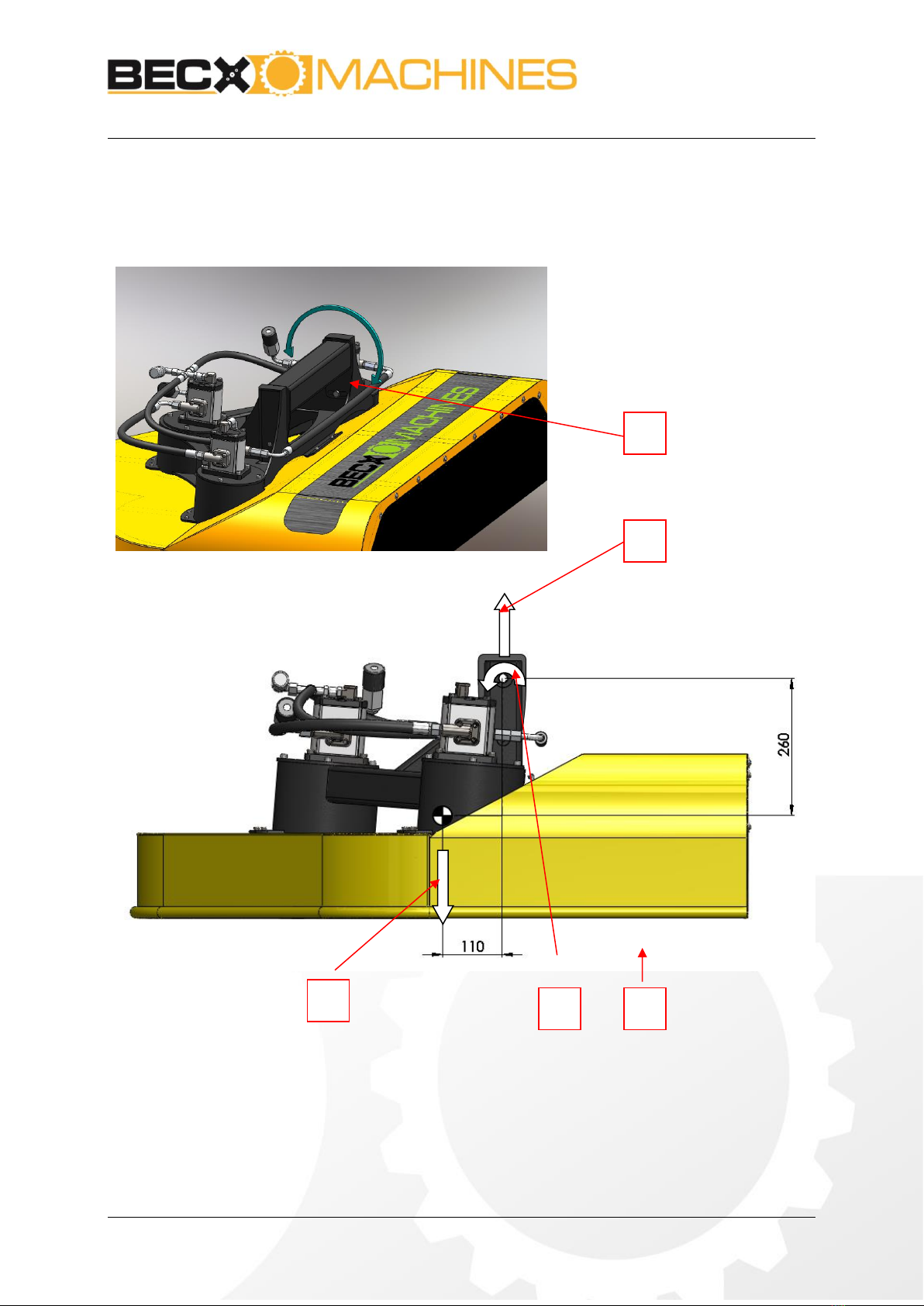

Figure 7: Overview hydraulic components

Figure

Part

Explanation

1

Drain line

connection with

rapid attachment

•The drain oil from the motors is returned to the hydraulic

aggregate on the tool carrier through a separate drain line.

2

Feeder line

connection with

rapid attachment

•The hydraulic oil is fed in from the hydraulic aggregate.

3

Discharge line

connection with

rapid attachment

•The hydraulic oil is returned to the hydraulic aggregate.

4

Hydraulic motor

(3*)

•Each hydraulic motor has connections for a feeder line, a

return line and a drainage line. The three motors are

arranged in series so that the hedge trimmer is connected

with one feeder line, one return line and one drain line.

•The direction of rotation is protected by means of a non-

return valve.

1

2

3

4

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 15 of 37

3.3 Hydraulic scheme

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 16 of 37

4) Operation

4.1 Assembly and adjustment of the hedge trimmer

Figure 8: adjusting trimmer

2

4

1

3

5

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 17 of 37

Nr.

What to do

Action

Result

1

Select the correct

tool carrier and

lifting arm

•make sure that the tool carrier and lifting

arm are sufficiently strong and stable for

the hedge trimmer (chapter 0:1)

Technical data) (figure 8:3), the load

when lifting (Figure :2)) and the exerted

moment of the lifting (figure 8:4).

•Make sure that the maximum pressure

and number of revolutions (oil flow) are

not exceeded.

•Make sure that the correct rapid

attachment connections are installed for

the feed line, return line and drain line.

•Make sure that the correct clasp is used.

Ignoring the stated

values can result in

damage to

equipment and

injury to persons.

2

Adjust the hedge

trimmer in the

horizontal position.

•Depending of the deflection of the lifting

arm, the bottom (figure 8:5) ) of the hedge

trimmer will not be completely horizontal.

•Adjust the angle setting (figure 8:1) so

that the deck is suspended horizontally

when lifted upwards.

Trimming will work

best if the base of

the protective deck

runs parallel to the

level of the cutting

plane.

3

Connect the hoses

•Connect the rapid attachment

connections for the feed line, return line

and drain line (see: figure 7).

4

Adjust the hydraulic

system

•Adjust the setting of the hydraulic

aggregate so that the maximum pressure

and number of revolutions cannot be

exceeded.

•This will depend on the type of tool carrier

that is used. Please refer to the manual of

the tool carrier.

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 18 of 37

4.2 Carrying out trimming operations

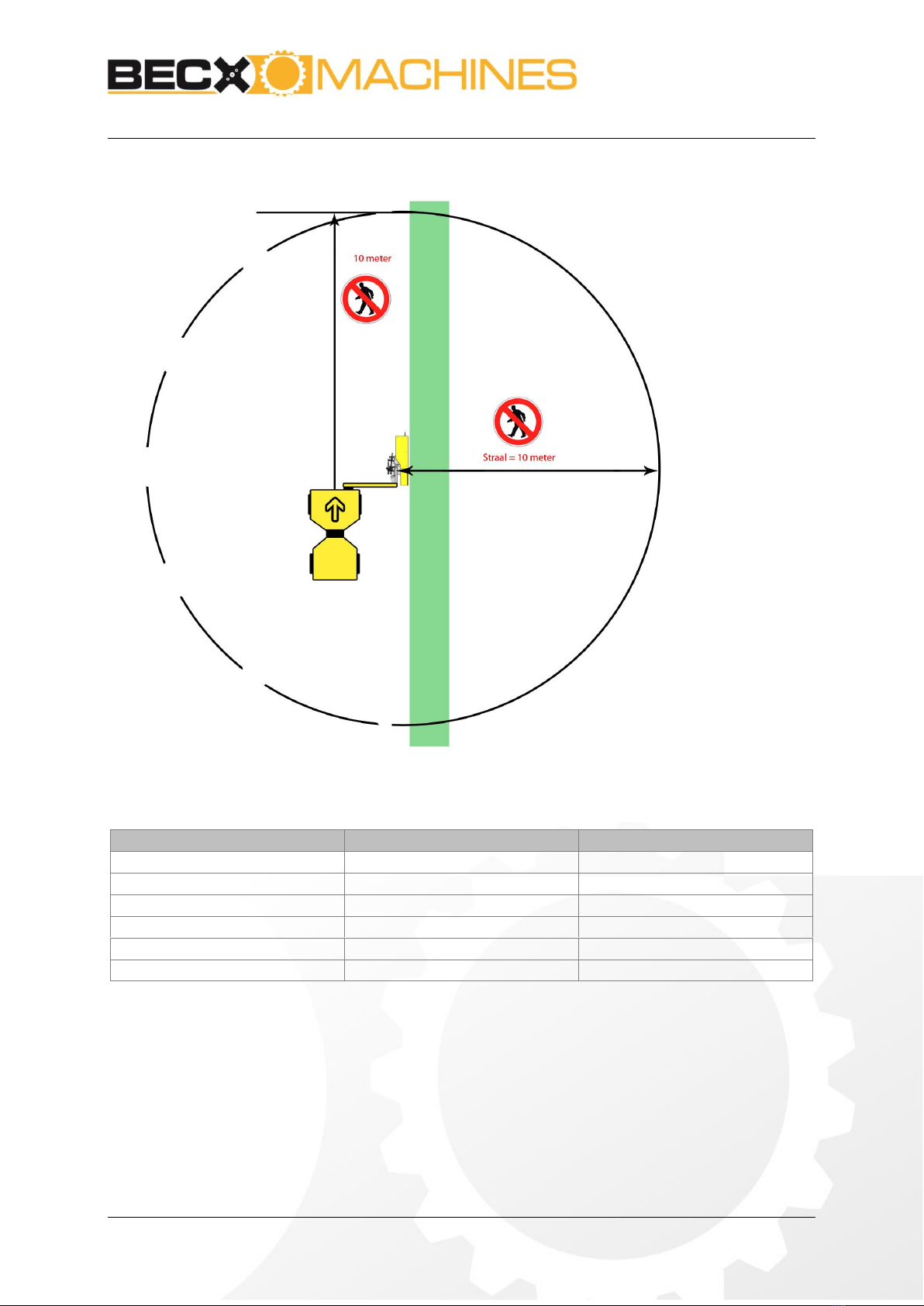

Figure 9: overview of danger zone to 1 meter trim height

Trim height

Danger radius

Safe frontal distance

0-1 m

5 m

10 m

1,1-1,2 m

6 m

11 m

1,2-1,3 m

7 m

12 m

1,3-1,4 m

8 m

13 m

1,4-1,5 m

9 m

14 m

>1,5 m

10 m

15 m

Table 1: Table trim heights - safe distance

vanaf

vanaf

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 19 of 37

Figure 10: overview of danger zone to 1 meter trim height in vertical position

Trim height

Danger radius

Safe frontal distance

0-1 m

10 m

10 m

1,1-1,2 m

11 m

11 m

1,2-1,3 m

12 m

12 m

1,3-1,4 m

13 m

13 m

1,4-1,5 m

14 m

14 m

>1,5 m

15 m

15 m

Table 2: Table trim heights - safe distance vertical position

vanaf

Hedge Trimmer

Type: HS150HR

Version: 04

Feb. 2020

Page 20 of 37

No.

What to do

Action

Result

1

Check the machinery

•check the following points:

•check the cutter blades:

•The cutter blades must not be ground

back too far and must be in balance (

see Chapter 5)

•Check the cutter blades for damage

and cracks before starting, after 4

hours of operation or immediately if

the cutter blades have come into

contact with materials that are

different from what they are

intended to cut.

•Visually check at least on a daily basis

whether the locking plates and locking

nuts of the cutter blades are in place.

•Check whether the direction of rotation

corresponds to the arrow on the deck.

•Check the number of revolutions of the

cutter blades.

•Check whether the cutter blades run

free of vibrations.

•If a defect is identified in one of the above

points, this must first be remedied before

it is allowed to put the hedge trimmer

back into operation.

Carrying on with

loose locking nuts,

cracked cutter

blades or with a

poorly running or

excessively fast

system can result in

damage to the

machinery and/or

injury to the

operator or passers-

by.

2

Check the site where

the work will take

place.

•Check the hedge to be trimmed and the

surroundings for the following points:

•Are there any obstacles which can be

damaged by the hedge trimmer or which

could cause damage to the hedge

trimmer?

•Are there any loose items such as dirt or

loose metal wires?

•Check if there is people or animals in the

danger zone are

•If there are lots of people passing by the

work-place should be secured.

•If the sight of the operator is severly

hindered (for instance by high or dense

hedge) the work-place should be secured.

•Operator needs to always be sure there

are no people on the other side of a high

dense hedge when cutting it.

Bear this in mind

when carrying out

the trimming

operation.

Remove any loose

items in order to

prevent damage to

the hedge trimmer.

3

Drive to the site

where the work will

take place.

•Always switch off the hedge trimmer if

you are not doing any trimming.

•There is a greater risk of a bystander

entering the danger zone without being

Table of contents

Other Becx Machines Trimmer manuals