Becx Machines HS75HR User manual

Hedge trimmer

Type: HS130HR

Version: 04

July 2019

Hedge trimmer

HS75HR

User manual

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 2 of 35

Manufacturer Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

Tel: +31 (0) 13 2070760

www.becxmachines.com

© Copyright 2019

Nothing in this publication may be replicated and/or published in print, photocopy, microfilm, sound

recording, electronically or otherwise without the prior explicit written permission from Becx

Machines B.V.

Becx Machines B.V. retains the right to change parts of the system and the contents of this manual at

any time without prior notification giving or immediate notice to the customer.

Becx Machines B.V. takes the greatest care to guarantee an accurate, and where necessary, complete

description of all parts. Nevertheless, it cannot be held liable for damage due to inaccuracies and/or

deficiencies in this manual.

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 3 of 35

Foreword

The Becx hedge trimmer is specially developed to trim in a safe and efficient manner.

Each blade head is provided with a double row of blades such that extra fine trimming is possible.

Combined with the five-sided guards, the risk of sprigs flying away is prevented. The hedge trimmer

is constructed so that it continues to work and has a long lifespan even under the most demanding

circumstances. Each blade head has its own hydraulic motor. The axles and the bearings are heavy

duty.

Please read this manual carefully before you use the hedge trimmer.

Always observe the safety requirements as set out in Section 2.

A copy of this manual must be kept with the hedge trimmer and be

available to the user. All important maintenance work and relevant

notes must be recorded by the maintenance company.

It is the user’s responsibility to select a suitable tool holder for the

hedge trimmer and ensure that it is correctly attached and

connected to the arm.

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 4 of 35

Table of contents

FOREWORD.................................................................................................................................. 3

TABLE OF CONTENTS .................................................................................................................... 4

DECLARATION OF CONFORMITY (IIA) (COPY)................................................................................. 5

OVERVIEW OF SYMBOLS............................................................................................................... 6

1) TECHNICAL DETAILS.................................................................................................................. 7

2) SAFETY..................................................................................................................................... 8

2.1 GENERAL .............................................................................................................................. 8

2.2 DURING USE.......................................................................................................................... 8

2.3 OPERATING PERSONNEL: .......................................................................................................... 9

2.4 WARNING SYMBOLS ON THE MACHINE....................................................................................... 10

3) DESCRIPTION OF COMPONENTS.............................................................................................. 11

3.1 MECHANICAL COMPONENTS.................................................................................................... 12

3.2HYDRAULIC COMPONENTS ...................................................................................................... 14

3.3 HYDRAULIC DIAGRAM ............................................................................................................ 15

4) OPERATION............................................................................................................................ 16

4.1 ASSEMBLY AND ADJUSTMENT OF THE HEDGE TRIMMER................................................................... 16

4.2 CARRYING OUT THE TRIMMING WORK........................................................................................ 18

4.3 STORAGE ............................................................................................................................. 21

5) MAINTENANCE................................................................................................................. 22

5.1 REPLACING AND/OR SHARPENING THE BLADES............................................................................. 24

5.2 TIGHTENING TORQUES ........................................................................................................... 29

6) MALFUNCTION ANALYSIS ................................................................................................. 30

7) DISPOSAL ......................................................................................................................... 31

8) LOGBOOK......................................................................................................................... 32

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 5 of 35

Declaration of conformity (IIa) (copy)

We:

Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

declare entirely under our own responsibility that the product:

Description :Becx Hedge trimmer

Type : HS75HR

Serial number :…….....................

with respect to this declaration, conforms to the provisions of the Directives:

Machinery directive 2006/42/EC

In accordance with the following standards:

NEN-EN-12100 Safety of machinery. Basic concepts, general principles for design.

NEN-EN ISO 4413 Hydraulic fluid power - General rules and safety requirements for

systems and their components

NEN-ISO 4254-1 Agricultural machinery - Safety - Part 1: General requirements

Director, Erwin Hommen

The Netherlands, Moergestel,

Date: .........................

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 6 of 35

Overview of symbols

All actions and situations risking the safety of the operator and/or technician and where actions must be

carried out carefully will refer to the following symbols in this user manual:

Take note!

Explanation.

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 7 of 35

1) Technical details

Description

Value

Unit

General

Sound pressure

See tool holder

dB(A)

Vibration level during normal use

N/A

Cutting capacity

20

mm

Required output

10

Kw

Physical data

Width

847

mm

Length

1200

mm

Height

390

m

Unladen weight (see Figure 8:4)

90

kg

Attachment details

Standard fixing sleeve

80*80

mm

Available installation width

mm

Fixing sleeve with modification piece (optional)

70*70

mm

The force on the attachment point (see Figure 8:1)

N

Suspension torque (see Figure 8:2)

Nm

Connection details

Maximum operating pressure

180

bar

Maximum revolutions

3000

-/min

Maximum oil flow (at 3,000 RPMs)

28

L/min

Pressure line connection: flat-face quick-release coupling

1/2”

Return line connection: flat-face quick-release coupling

1/2”

Leak line connection: flat-face quick-release coupling

3/8”

Maximum pressure on the leak line

no pressure

bar

Requirements for filtering hydraulic oil

10

micron

Oil for the drive

HV-46 or equivalent

Grease for lubricating blade heads

NLGI 2

Figure 1: dimensions

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 8 of 35

2) Safety

2.1 General

The hedge trimmer may not be modified.

Only blades conforming to the supplier’s specifications may be mounted.

If individuals carry out work near the blades, they risk being cut by the

trimming side.

It is the user’s responsibility to ensure that the correct tool holder and support

arm is used (see Section 0:1) Technical details). To this end, the following

points are important:

The maximum pressure and rotational speed (oil flow) must not be

exceeded. Exceeding these limits may damage the installation and injure

bystanders.

The support arm and tool holder must be sufficiently strong and stable

enough to bear the forces and torques caused by the hedge trimmer in all

circumstances.

2.2 During use

Consult the tool holder manual for the resulting sound load. As this is

significantly higher than the sound produced by the hedge trimmer, the sound

load from the tool holder is leading.

The installation may only be used for the work activities it is designed for.

The trimmer is not suited for work activities at ground level. There is a high

risk that the blades come into contact with the ground and/or obstacles due

to the construction of the hedge trimmer.

If people or animals approach or enter the safety zone, the hedge trimmer

and the work activities must be stopped immediately (see 4.2). This also

applies to situations where the hedge trimmer will be switched on for testing

after maintenance, etc.

If passers by constantly interrupt the work activities too much, consideration

should be given to fencing off the work area.

If the hedge trimmer begins to make a different sound and/or starts to

vibrate, the work and the hedge trimmer must be immediately stopped (see

4.2). The work must not restart until the cause is found and resolved.

If not trimming, the hedge trimmer must always be turned off. Thus, this also

includes the times when driving to the work area. At these times, there is

higher risk of coming into contact with bystanders during the trimming. In

these situations, the hedge does not act as protection and the driving route is

more difficult to estimate for bystanders or passers by. If there is no hedge,

parts can fly away unhindered over a large distance.

Inspection and maintenance work must be carried out.

During inspection and maintenance, the installation must not be used for

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 9 of 35

other purposes.

During inspection, maintenance, or cleaning, the hydraulic feed to the hedge

trimmer must be disconnected to prevent it being accidentally switched on.

The local work and safety regulations must be observed.

If the installation is to be used in the dark, sufficient lighting must be used

(approx. 50 lux on the place of operation).

Trimming work must be stopped immediately when people or animals

approach or enter the safety zone. (see 4.2)

To prevent damage to the installation, the device must be gradually switched

off using the lowest RPMs. Depending on the tool holder used, this is idling

speed or the minimal flow.

2.3 Operating personnel:

Operating personnel must be older than 18 years of age.

Only individuals authorized by the owner may work on or with the installation.

Operators may only perform work activities that they are trained for. This

applies to both the maintenance work and normal usage.

The operating personnel must be acquainted with all situations that can

occur.

If the operating personnel discover faults or risks or do not agree with the

safety measures, this must be reported to the owner or person in charge.

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 10 of 35

2.4 Warning symbols on the machine

1.

Cutting danger

2.

Read the manual before you use the machine!

3.

See safety zone (4.2)

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 11 of 35

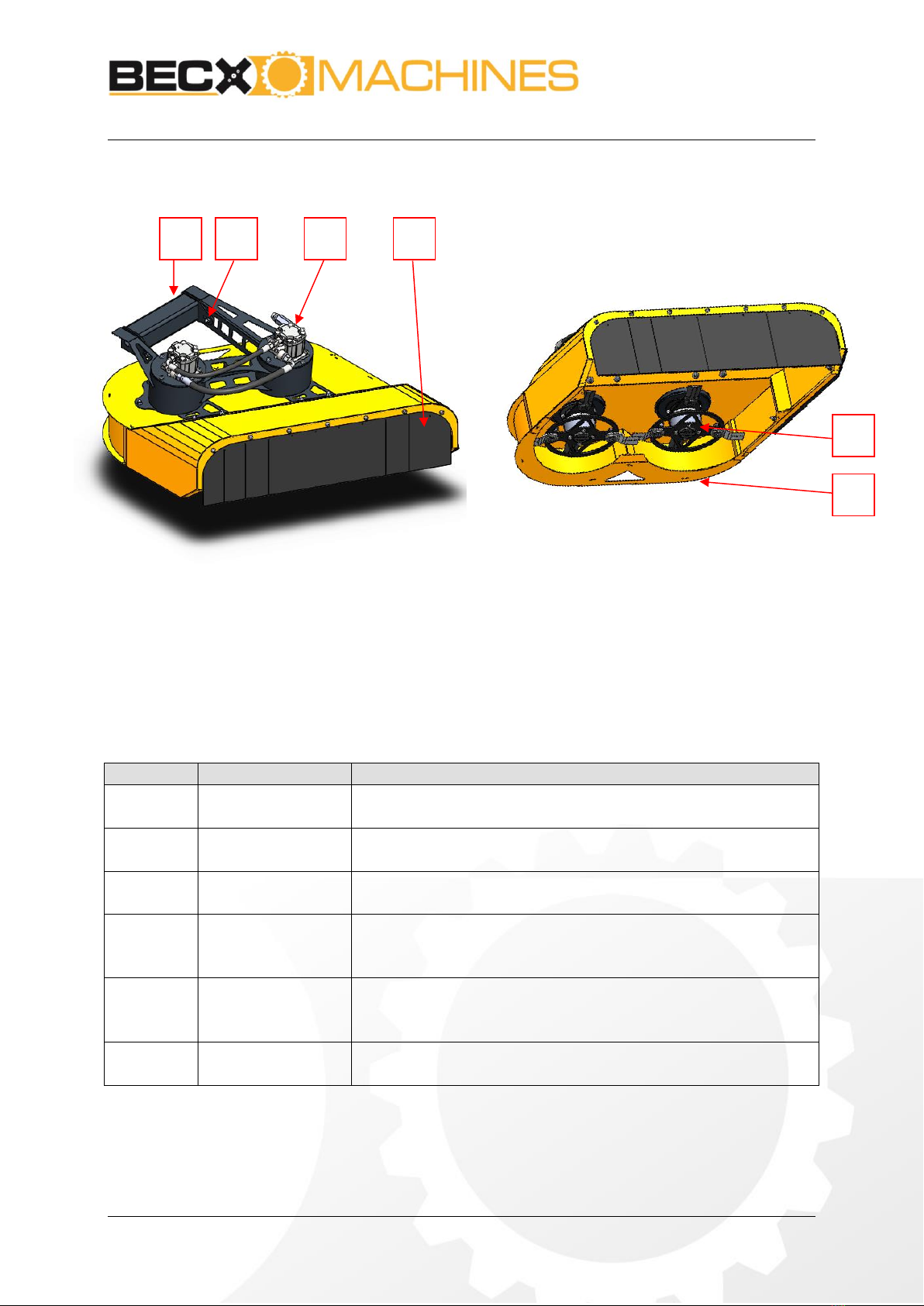

3) Description of components

Figure 2: Overview photo

Figure

element

explanation

1

Support arm

The support arm is not part of the delivery. It is the user’s

responsibility to ensure that a suitable support arm is used

for the hedge trimmer.

2

Hedge trimmer

The hedge trimmer can be used horizontally, vertically, and in

all intermediate angles.

3

Tool holder

The tool holder is not part of the delivery. It is the user’s

responsibility to ensure that a suitable tool holder is used for

the hedge trimmer.

1

2

3

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 12 of 35

3.1 Mechanical components

Figure 3: Overview of mechanical components

Figure

element

explanation

1

Fixing sleeve

The hedge trimmer is attached to the arm of the tool holder

using the fixing sleeve.

2

Angle inclination

Once the hedge trimmer is fastened to the arm, the correct

angle can be set. (see paragraph 4.1)

3

Hydraulic motor

(3*)

Each blade head is driven by its own hydraulic motor.

4

Inlet side

During trimming, the twigs to be cut enter the inlet side

through the protective flaps of the PUR SH 90 A near the

blade heads.

5

Blade head (3*)

Each blade head has four blades. The two blades on the

lower layer cut the hedge twigs. The two blades on the upper

layer shred the sprigs into small pieces.

6

Protective cover

The protective cover is made of high-quality steel and

prevents cut material from flying away.

4

3

1

2

6

5

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 13 of 35

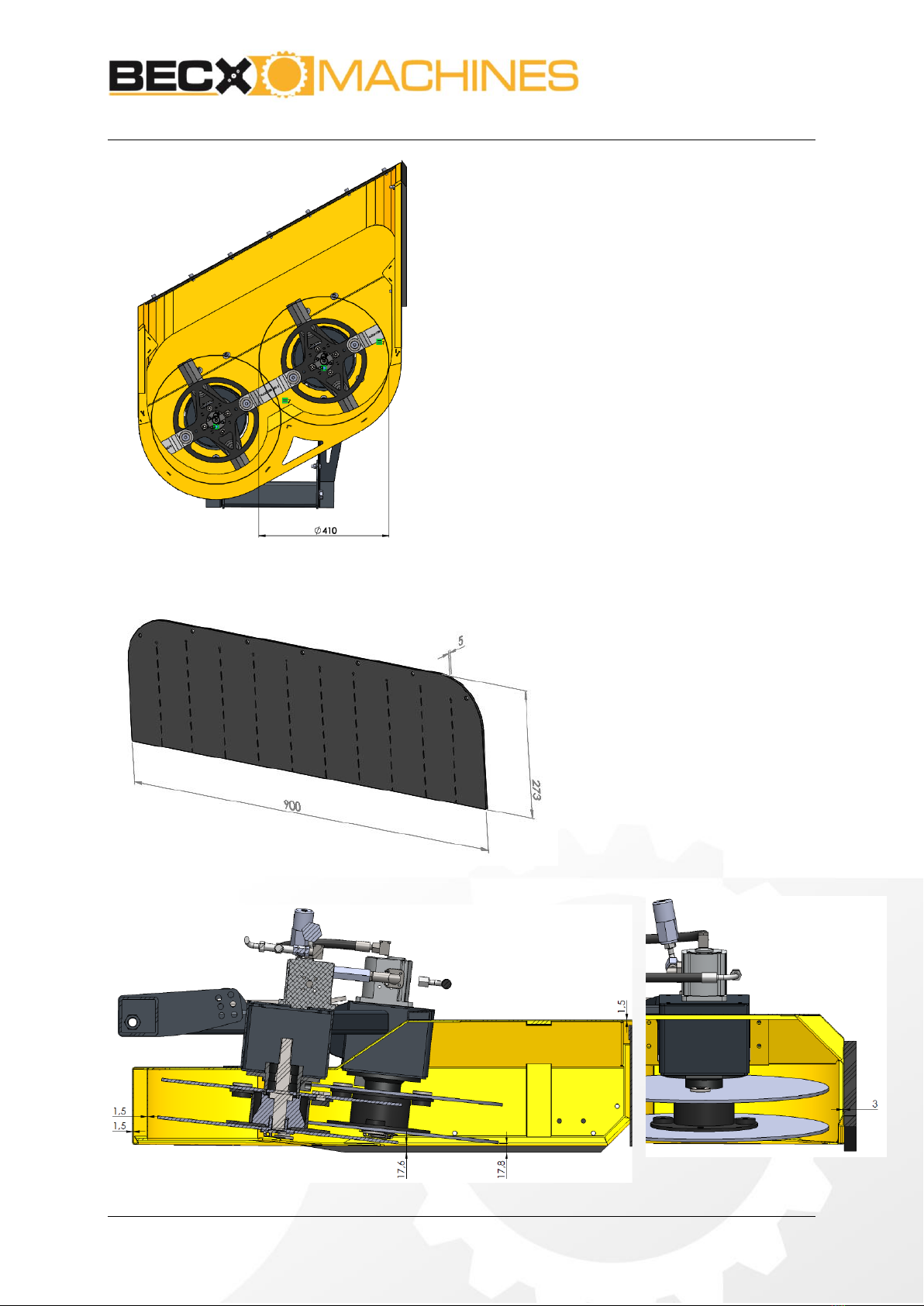

Figure 4: Dimension sketch of blade path

Figure 5: Dimension sketch of cover-seal front side (Material: PUR SH 90 A)

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 14 of 35

Figure 6: Dimension sketch of blades in relation to the cover

3.2 Hydraulic components

Figure 7: Overview of hydraulic components

Figure 7

element

explanation

1

Hydraulic motor

(3*)

Each hydraulic motor has a connection for a supply line, a

return line, and a leak line. The three motors are linked in

series such that the hedge trimmer can be connected with

one supply line, outlet line, and leak line.

The rotation direction is safeguarded with a built-in non-

return valve.

2

Leak line quick-

release coupling

A separate leak line on the tool holder returns the leaked oil

from the motors to the hydraulic generator.

3

Supply line quick-

release coupling

The hydraulic oil is supplied by the hydraulic generator.

4

Outlet line quick-

release coupling

The hydraulic oil is returned to the hydraulic generator.

4

3

1

2

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 15 of 35

3.3 Hydraulic diagram

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 16 of 35

4) Operation

4.1 Assembly and adjustment of the hedge trimmer

Figure 8: adjusting the hedge trimmer horizontally

No.

What to do

Action

Result

1

Select the correct tool

holder and support

arm.

ensure that the tool holder and support arm

are sufficiently strong and stable enough for

the hedge trimmer (see Figure 8 and Section

0:1) Technical details for the unladen weight,

the load in the nesting place (Figure 8.1), and

the resulting torque in the nesting place

(Figure 8Figure 8:2).

Ensure that the maximum pressure and

rotational speed (oil flow) cannot be

exceeded.

Ensure the correct quick-release couplings

are attached for the supply, return, and leak

lines.

Ensure that the correct coupling is attached.

Not respecting the

specified limits

may damage the

installation and

injure bystanders.

1

2

3

4

5

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 17 of 35

2

Adjust the hedge

trimmer horizontally

Depending on the curvature of the support

arm, the underside of the hedge trimmer

(see Figure 8Figure 8:5) will not hang

completely horizontally.

Adjust the angle setting (see Figure 8Figure

8:3) so that the cover hangs horizontally

when it is tilted up.

The optimal

trimming result is

achieved when the

underside of the

protective cover is

parallel to the

cutting surface.

3

Connect the hoses

Connect the quick-release couplings for the

supply, return, and leak lines (see Figure 7).

4

Adjust the oil supply.

Adjust the generator for the tool holder so

that the maximum pressure and rotational

speed cannot be exceeded.

This depends on the type of tool holder

used. See the tool holder manual.

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 18 of 35

4.2 Carrying out the trimming work

Figure 9: overview of safety zone up to one-meter cutting height in horizontal position

Cutting height

safety radius

Safety distance at the front

0-1 m

5 m

10 m

1.1-1.2 m

6 m

11 m

1.2-1.3 m

7 m

12 m

1.3-1.4 m

8 m

13 m

1.4-1.5 m

9 m

14 m

> 1.5 m

10 m

15 m

Table 1: Cutting height –safety distance in horizontal position

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 19 of 35

Figure 10: overview of safety zone up to one-meter cutting height in vertical position

Cutting height

safety radius

Safety distance at the front

0-1 m

10 m

10 m

1.1-1.2 m

11 m

11 m

1.2-1.3 m

12 m

12 m

1.3-1.4 m

13 m

13 m

1.4-1.5 m

14 m

14 m

> 1.5 m

15 m

15 m

Table 2: Table cutting height –safety distance in vertical position

Hedge trimmer

Type: HS75HR

Version: 01

July 2019

Page 20 of 35

No.

What to do

Action

Result

1

Check the

installation

check the following points:

check the blades:

The blades must not be worn away too much and

must be in balance (see 0).

Check the blades for damage and cracks before

starting work, after four hours of trimming, or

immediately after the blades come into contact with

materials other than that intended.

At a minimum, each day, visually check that the locking

plate and locking nuts of the blade head are present.

Check that the rotation direction of the blades matches

the arrow on the housing.

Check the rotational speed of the blades.

Check that the blades work without vibrating.

If one of the above checks discovers a deficiency, it must

first be rectified before the hedge trimmer can be used.

Continuing to

work with loose

locking nuts,

cracked blades, or

with an

installation that

runs poorly or too

quickly may cause

damage to the

installation

and/or injure the

operator or

bystanders.

2

Check the work

area.

Check the hedge to be trimmed and the surrounding area

on the following points:

Are obstacles present that could be damaged by the

hedge trimmer or that could cause damage to the hedge

trimmer?

Are there any loose elements, such as litter, loose iron

wire, and so on?

Ensure that there are no people or animals within the

safety zone.

If lots of passers by would cause the work to be stopped

often, the work area must be fenced off.

The work area must be fenced off when the hedge is tall

and so dense that it blocks the overview of the other

side.

At all times, measures must be in place to prevent

anyone being present on the other side of a non-

transparent hedge.

Take this into

account when

trimming.

Remove loose

items to prevent

damage to the

hedge trimmer.

3

Drive to the

work area

Always switch off the hedge trimmer when it is not being

used to trim.

The chance that a bystander enters the danger zone

unnoticed is greater during the trimming.

If there is no hedge, parts can fly away unhindered over a

large distance.

Table of contents

Other Becx Machines Trimmer manuals

Popular Trimmer manuals by other brands

Sinbo

Sinbo SHC 4375 instruction manual

Makita

Makita DUR141 instruction manual

KRESS

KRESS Commercial KC100 Series instruction manual

GARDEO PRO

GARDEO PRO GTHT26RH-BAG Original instructions

Andis

Andis Pivot Pro Trimmer PMT-1 Specification sheet

FRANCK PROVOST

FRANCK PROVOST THE BARB' XPERT FPH-004 instruction manual