Bedford W713B Series User manual

W713B Series

Intelligent Controller

for Water Pump

User Manual

GUANGZHOU BEDFORD ELECTRIC EQUIPMENT CO.,LTD.

V1.0.0

Preface

Thanks for choosing our product W713B, we will supply you with considerate

service as well as ever.

W713B series products are not only the integrated intelligent controller designed

for water pump, but also the intelligent controller designed for the central

air-conditioning water circulation system to realize the differential constant pressure

control.

W713B intelligent controller has superior performance and rich use function,

can meet the requirement of water supply and drainage on various occasions and

improve the quality of water supply system. The product adopts the control method of

one pump and one variable frequency controller, which can effectively extend the

motor service life; the controller system supports max.6 pumps linkage work, meet

the customers’ operating requirements.

With high quality, multi-functional, low noise and strong commonality etc.

characteristics, W713B multi-function energy-saving controller is suitable to

full-automatic operation.

Suitable for various constant pressure/constant differential pressure/constant

temperature/constant differential temperature water supply applications.

After parameters were set correctly, the system can operate automatically with

constant pressure/constant differential pressure/constant temperature/constant

differential temperature according to the water consumption without manual

operation;

Alternate running automatically in the multiple pump system, prolong the

using life of pumps.

Restart automatically when power recovery

Stop running automatically when no water consumption;

Alarm automatically when faults occurred;

Suitable for various pressure signals input.

Contents

1. SAFETY PRECAUTIONS .....................................................................1

2. PRODUCT INTRODUCTION ..............................................................2

2.1 Features ......................................................................................................2

2.2 Model Specification .................................................................................. 2

2.3 Selection Guide ......................................................................................... 3

2.4 Check the Following Point ........................................................................3

2.5 External Dimension ................................................................................... 4

3. ENVIRONMENTAL REQUIREMENT .............................................. 4

4. WIRING ...................................................................................................5

4.1 Main Circuit Terminals Wiring ................................................................. 5

4.2 Control Circuits Terminals Wiring ............................................................5

4.3 Control Terminals Overall Connect .......................................................... 7

4.4 Wiring Main Circuits .................................................................................7

4.4.1 Wiring of Main Circuits ...................................................................7

4.4.2 Circuit Breaker ............................................................................... 7

4.4.3 AC Reactor (Optional) ................................................................... 8

4.4.4 Input EMC Filter (Optional) ............................................................8

4.4.5 Output EMC Filter (Optional) .........................................................8

4.4.6 Output Reactor ...............................................................................8

4.4.7 Ground Wiring ................................................................................8

5. OPERATION ...........................................................................................8

5.1 Keypad Description ...................................................................................8

5.2 Operation Procedure ..................................................................................9

5.2.1 Add Prefix Characters Display Content for Easy Understanding ..9

5.2.2 Power-on Initialization ...........................................................................9

5.2.3 Parameter Setting ..................................................................................9

6. INSTRUCTIONS OF PARAMETERS GROUP ............................... 11

7. QUICK DEBUG of PARAMETER SETTING ..................................28

8. APPLICATION GUIDANCE .............................................................. 33

8.1 Application of Constant Pressure Water Supply .....................................33

8.1.1 Single Pump Water Supply and Parameter Setting ....................33

8.1.1.1 System Wiring ...........................................................................33

8.1.1.2 System Debugging Procedure ................................................. 34

8.1.1.3 Relevant Parameter Setting ..................................................... 34

8.1.2 Multi-pump Control ...................................................................... 35

8.1.2.1 Typical System Wiring .............................................................. 35

8.1.2.2 Relevant Parameter Setting ..................................................... 36

8.2 Application of Constant Differential Pressure Water Supply ................. 39

8.2.1 Differential Pressure Control System Introduction. .....................39

8.2.2 Typical System Wiring ................................................................. 40

8.2.3 System Debugging Procedure .................................................... 41

8.2.4 Relevant Parameter Setting ........................................................ 41

8.3 Application of Constant Temperature Water Supply .............................. 44

8.3.1 Single Pump Water Supply and Parameter Setting ....................44

8.3.1.1 System Wiring ...........................................................................44

8.3.1.2 System Debugging Procedure ................................................. 44

8.3.1.3 Relevant Parameter Setting ..................................................... 45

8.3.2 Multi-pump Control ...................................................................... 45

8.3.2.1 Typical System Wiring .............................................................. 45

8.3.2.2 Relevant Parameter Setting ..................................................... 46

8.4 Application of Constant Differential Temperature Water Supply.......... 49

8.4.1 Differential Temperature Control System Introduction. ...............49

8.4.2 Typical System Wiring ................................................................. 50

8.4.3 System Debugging Procedure .................................................... 51

8.4.4 Relevant Parameter Setting ........................................................ 51

8.5 Manual/Auto Control Wiring and Setting ...............................................54

8.5.1 System Wiring ..............................................................................54

8.5.2 Operation ..................................................................................... 55

8.5.3 Relevant Parameter Setting ........................................................ 55

8.6 Electric Contact Gauge Water Supply .....................................................55

8.6.1 System Wiring ..............................................................................55

8.6.2 Relevant Parameter Setting ........................................................ 56

8.6.3 Relevant Parameter Setting ........................................................ 56

8.7 Application of One VFD Drive Two Pump .............................................56

8.7.1 Relevant Parameter Setting ........................................................ 56

8.7.2 System Debugging Procedure .................................................... 58

8.7.3 Relevant Parameter Setting ........................................................ 58

8.8 Application Summary ..............................................................................60

9. FAULT AND TROUBLE SHOOTING ...............................................60

9.1 System Running Fault and Trouble Shooting ......................................... 60

9.2 Water Supply Running Fault and Trouble Shooting ...............................61

9.3 Controller Running Fault and Trouble Shooting .................................... 62

9. COMMUNICATION PROTOCOL ....................................................63

W713B Series Intelligent Controller for Water Pump User Manual

1

1. SAFETY PRECAUTIONS

W713B is a new power electronic product, please read the operation manual

carefully before using to keep your safety and make sure proper operation.

In this manual, the safety precautions were sorted to “WARNING” and

“CAUTION”.

WARNING: Wrong using may result in death or serious personal injury.

CAUTION: Wrong using may result in the damage of controller or system.

WARNING

Please don’t dismantle, change the product, or may cause electric shock, fire hazard and

personal injury;

Please don’t open the cover during the running of controller;

Please don’t put wire, bar of metal, filaments etc. into the controller so as not to cause a

short circuit or get an electric shock;

Please don’t splash water or other liquid over the controller.

CAUTION

Please don’t make withstand voltage testing for the controller;

Never connect AC power to output UVW terminals;

If the internal components of the controller were influenced or damaged by static, please do

not to touch;

The motor, controller and power specifications should be matching, otherwise it could cause

abnormal operation even burn out the device;

If the controller appears serious vibration, noise, heat or peculiar smell in the first operation,

please cut off the power immediately and contact suppliers or service center later;

Please don’t install the controller in the environment with direct sunlight, rain, frost or snow

in case of deformation or damage.

Warm reminder:

For convenience, the controller has set default with a nonzero AI1 feedback lost

detecting value, if here hasn’t pressure signal feedback into the terminal AI1, the

controller will be starting up failure and displaying “E022”, just take follows:

◊ If the controller worked as a master, please connect a transducer to the

controller and then press the key;

◊ If it worked as an auxiliary, it should be setting as AI1 feedback lost detecting

value (b02.08) 0 and then pressing the key to reset error warning.

W713B Series Intelligent Controller for Water Pump User Manual

2

2. PRODUCT INTRODUCTION

2.1 Features

Input & Output

◆Input Voltage Range: 220V/380V±15%

◆Input Frequency Range: 47~63Hz

◆Output Voltage Range: 0~rated input voltage

◆Output Frequency Range: 0~50/60Hz

I/O Features

◆Digital Switch Input: 4 input

◆Analog Signal Input: AI1: 0~10V or 0/4~20mA input; AI2: 0~10V or 0/4~20mA input

◆Relay Output: Two pair of switch output

Function Characteristics

◆Multi-Pumps Control Function: Max.6 pump linkage water supply

◆Sleep Function: Sleep down when have no water consumption, to earn a better energy

saving

◆Freeze-Proofing Function: Suitable to low temperature area, prevent pump from

freezing

◆Anti-clogging Function: Take precaution against pipe clogging and clean the pipe dirt

◆Power On Restart: Running automatically when power on

◆Master Fault Shift Automatically: Keep on working when the master break down

◆Alternate Running: Balance every pump’s running time, prolong service life of the

whole unit machine

◆Control Mode: Constant pressure, constant differential pressure, constant temperature,

constant differential temperature, manual

◆Linkage Mode: Synchronize, master-slave, big-small pump combination, one duty one

standby, one VFD drives two pump (in conjunction with control electric cabinet).

◆Terminal Control Mode: Electronic contact gauge control, manual/auto control,

terminal run/stop, automatic water level control, one VFD drives two pump fault input.

◆Various of Water Supply Fault Alarm Function: High-pressure, low-pressure, low-level,

transducer error etc.

◆Many Fault Protection Function: Over-current, over-voltage, low-voltage, phase-failure,

over-Load etc.

◆Scalability: Can be connected to our company touch screen(HMI)

2.2 Model Specification

W713B-4 010

Power Symbol 010: 10HP/7.5kW

Voltage Class 2: 220VAC 4: 380VAC

Series Number of Intelligent Controller for Water Pump

W713B Series Intelligent Controller for Water Pump User Manual

3

2.3 Selection Guide

Table2.3.1 W713B list

Model No.

Rated Input

Voltage (V)

Rated Input

Current (A)

Rated Output

Current (A)

Motor Power

(kW)

W713B-2001

1AC: 220V

-15%~+15%

7.1

4.5

0.75

W713B-2002

11.1

7.0

1.5

W713B-2003

15.8

10.0

2.2

W713B-2001

3AC: 220V

-15%~+15%

7.1

4.5

0.75

W713B-2002

11.1

7.0

1.5

W713B-2003

15.8

10.0

2.2

W713B-2004

17.6

13.0

3.0

W713B-2005

23.0

17.0

3.7

W713B-2007

32.0

25.0

5.5

W713B-2010

40.0

32.0

7.5

W713B-4001

3AC: 380V

-15%~+15%

3.4

2.1

0.75

W713B-4002

5.0

3.8

1.5

W713B-4003

5.8

5.1

2.2

W713B-4004

13.5

9.5

4.0

W713B-4005

19.5

14.0

5.5

W713B-4007

25.0

18.5

7.5

W713B-4010

32.0

25.0

11.0

W713B-4015

40.0

32.0

15.0

W713B-4020

47.0

38.0

18.5

2.4 Check the Following Point

Inspect the nameplate and ensure it meets the order type and specification;

Inspect the entire exterior of the controller to ensure there are no scratches or

other damage caused by the transportation;

Ensure the guarantee odd number matches the controller;

If you have found any problem mentioned above, please contact the supplier.

W713B Series Intelligent Controller for Water Pump User Manual

4

2.5 External Dimension

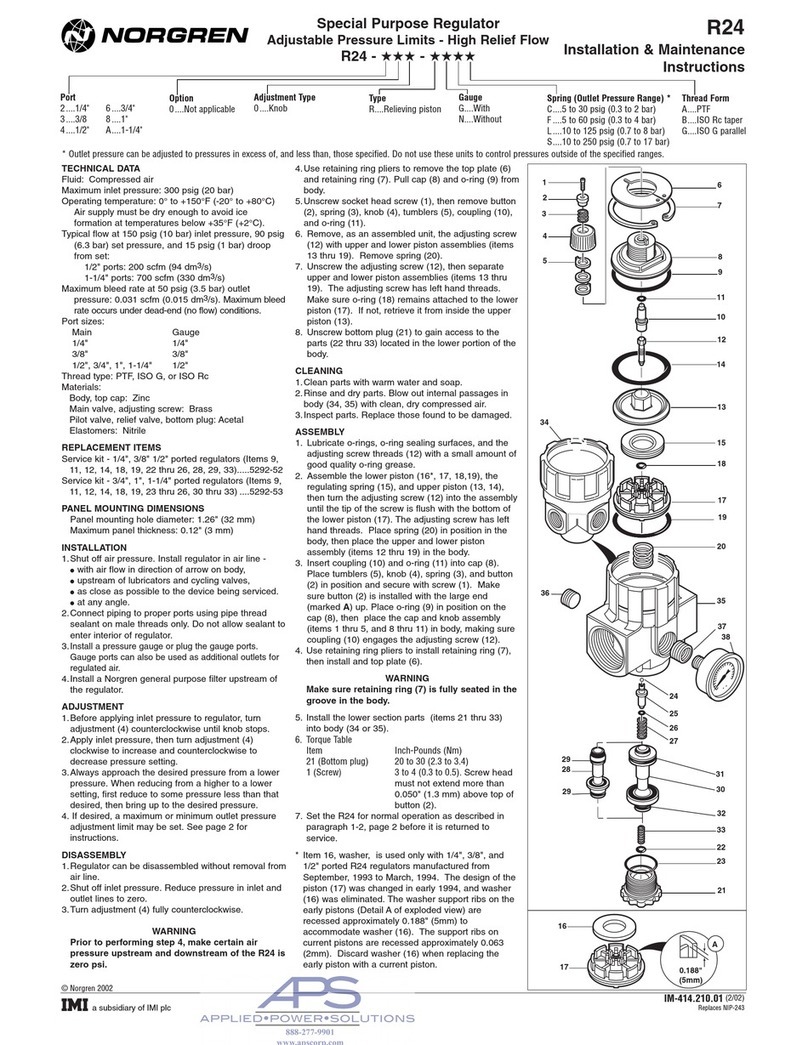

Figure2.5.1 Dimension

Model

(kW)

External Dimension

H (mm)

W (mm)

D (mm)

220V: 0.75~2.2 (380V: 0.75~3.0)

170

190

110

220V: 3.0~3.7 (380V: 4.0~7.5)

205

235

120

220V: 5.5~7.5 (380V: 11.0~18.5)

220

290

150

3. ENVIRONMENTAL REQUIREMENT

1. Environment temperature range: -10℃~40℃, controller will be derated at 4% on

every 1℃if ambient temperature exceeds 40℃, the maximum temperature is less

than 50℃.

2. Prevent rain drops, moist environment, oil fog, salt erosion, corrosive gas, etc..

3. Prevent direct sunlight, keep away from radiation source.

4. Prevent violent vibration or sudden impact.

5. Lower than 1000m installation altitude, if exceeds 1000m, inverter will be derated

at 1% on every 100m.

CAUTION

When moving the controller please lift by its base and don’t lift by the panel. Otherwise may

cause the main unit fall off which may result in personal injury.

Install the controller on the fireproofing material (such as metal) to prevent fire.

When power off, should not install the controller until the power indicator light was

extinguished, which can ensure the device has been discharged completely.

Disconnect all power line before opening front cover of unit. Wait at least 5 minute until DC

Bus capacitors discharge.

W713B Series Intelligent Controller for Water Pump User Manual

5

4. WIRING

4.1 Main Circuit Terminals Wiring

PE

R/L

S/N

T

U

V

W

PE

Figure 4.1.1 The main circuit terminals

2. Main circuit terminal’s function as following:

Terminal Symbol

Function Description

L, N

Terminals of single phase AC input

R, S, T

Terminals of 3 phase AC input

U, V, W

Motor wiring terminal

PE

Terminals of ground

In order to keep safety and prevent electric shock and fire, “PE” must be

grounded with ground resistance. Furthermore, reliable grounding is the simplest,

most effective and minimum cost solution for EMC problems, so it enjoys priority in

all EMC methods.

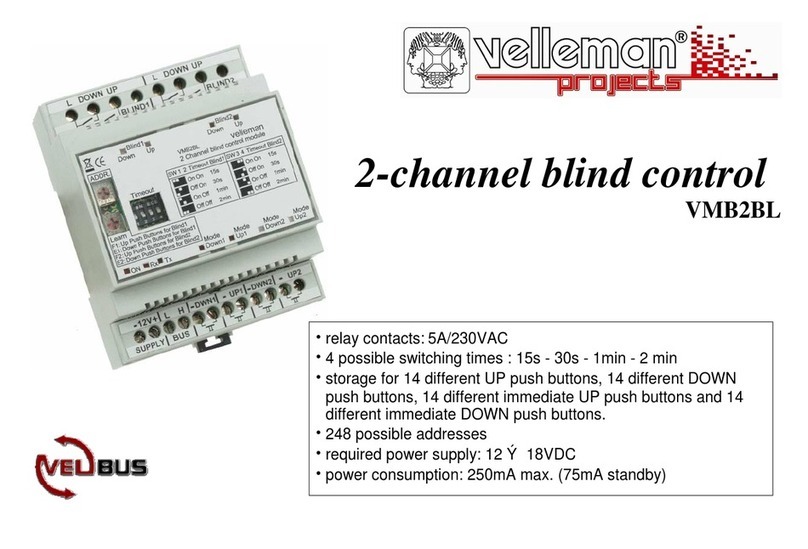

4.2 Control Circuits Terminals Wiring

Figure 4.2.1 Control circuits terminals wiring

Manual/Auto Switchover Function (Constant Speed/Constant Pressure

(Constant Differential Pressure/Constant Temperature/Constant Differential

Temperature) Switchover Function):

(1) Terminal (Terminal in priority, panel keypad control manual/auto switchover

invalid)

When b05.02 = 2, S2 disconnected with COM, and constant pressure/constant

differential pressure/constant temperature/constant differential temperature water

W713B Series Intelligent Controller for Water Pump User Manual

6

supply is provided. The set pressure/differential pressure/temperature/differential

temperature under the primary interface can be adjusted by pressing or

key. S2 connected with COM, operate and supply water at constant speed, and the

constant speed operation frequency under the primary interface can be adjusted by

pressing or key.

(2) Panel Keypad (Manual/Auto Switchover can be realized by pressing the panel

button when the inverter is stopped)

In the stop state, press the and key at the same time in the primary

display interface to realize the manual/automatic switchover.

The functions of the control terminal are described below:

Type

Terminal

symbol

Terminal Name

Function Description

Power

Source

P5V-VCM

10mA output terminal

(Load is less than 1kΩ)

Providing 10mA current (Load is less than 1kΩ),

used for external resistance type remote pressure

gauge

+24V-GND

24V power source

Providing 24V power source, used for pressure

transmitter, the max.output current

Analog

Input

+24V-AI1

Analog input terminal 1

Reception of 0/4mA~20mA pressure transmitter,

Plug in jumper cap on control panel P1.

+24V-AI2

Analog input terminal 2

Digital

Input

S1-COM

Digital Input 1

ON-OFF signal input, optical coupling with +24V

and COM

Input voltage range: 9V~30V

Input impedance: 2.4kΩ

S2-COM

Digital Input 2

S3-COM

Digital Input 3

S4-COM

Digital Input 4

Relay

Output

T/A-T/B

NC terminal

The relay switch contact signal, which can be

either alarm or valve switch signals.Max.capacity

of contact: AC 250V- 3A or DC 30V-1A.

T/A-T/C

NO terminal

P/A-P/C

NO terminal

Commu-

nication

485A+

First pair RS485

communication

terminal

485 communication interface and internal

communication interface, please use twisted pair

or shield wire

485A-

485B+

Second pair RS485

communication

terminal

485 communication interface and external

communication interface, please use twisted pair

or shield wire

485B-

Remarks

P1

The AI1 and AI2 input

type selector switch

Plug in the short circuit cap as current signal,

otherwise voltage signal

P2

485B communication

terminal resistance

selection

Plug the short circuit cap to connect the

terminal resistance and otherwise.

Note that plug the short- circuit caps on

the first and tail two when multiple

pumps are online. that for multi-pump, only

open toggle switch of the first pump and last

pump.

P3

485A communication

terminal resistance

selection

W713B Series Intelligent Controller for Water Pump User Manual

7

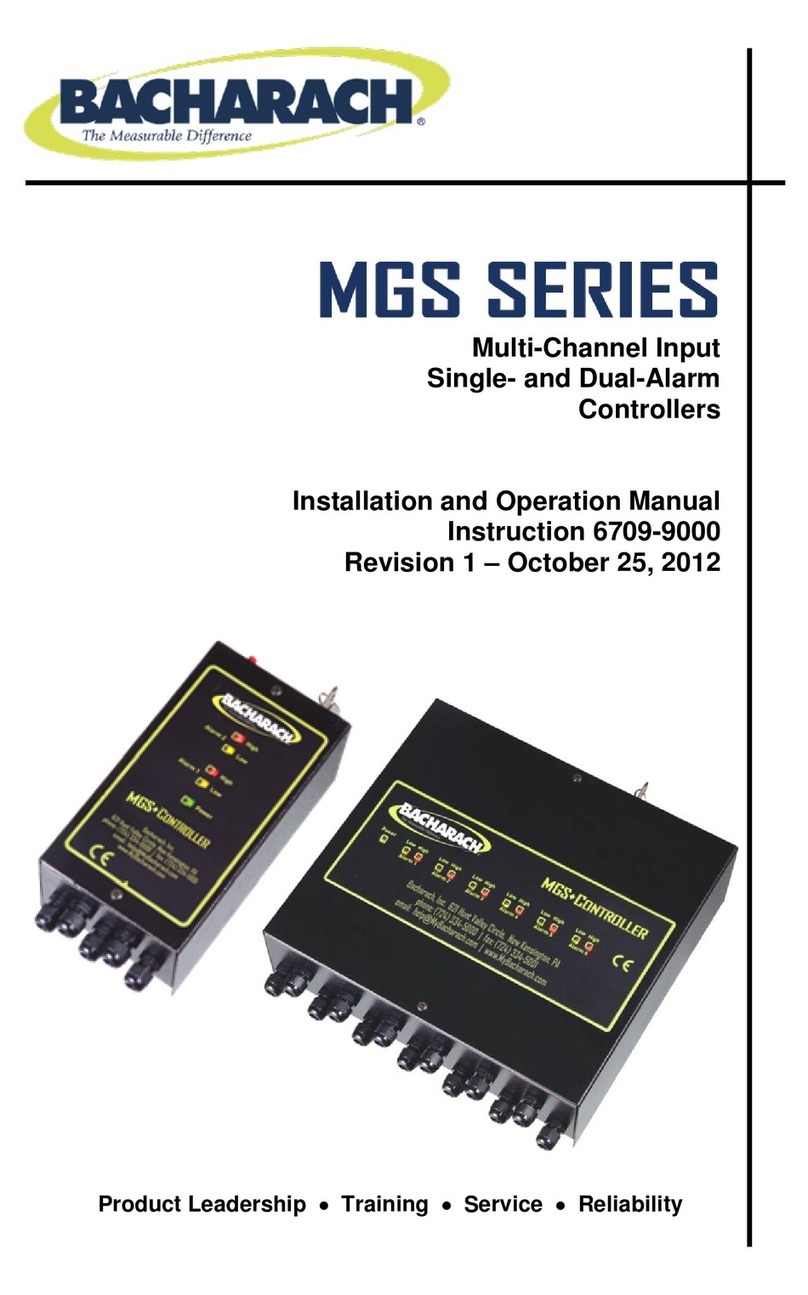

4.3 Control Terminals Overall Connect

Figure 4.3.1 Wiring diagram

4.4 Wiring Main Circuits

4.4.1 Wiring of Main Circuits

Figure4.4.1 High-performance main circuit wiring

4.4.2 Circuit Breaker

It is necessary to connect a suitable circuit breaker between 3 phase AC power

supply and W713B series intelligent constant water supply controller. The capacity of

breaker is 1.5~2 times to the rated current of controller.

W713B Series Intelligent Controller for Water Pump User Manual

8

4.4.3 AC Reactor (Optional)

In order to prevent the rectifier damage resulted from the large current, AC

reactor should be installed at the input side. It can also prevent rectifier from sudden

variation of power voltage or harmonic generated by phase-control load.

4.4.4 Input EMC Filter (Optional)

EMC filter can minimize the interference of the surrounding device which may

be disturbed by the cables when the controller is working.

4.4.5 Output EMC Filter (Optional)

EMC filter should be installed to minimize the leak current caused by the cable

and minimize the radio noise caused by the cables between the controller and motor.

4.4.6 Output Reactor

When the distance between the W713B controller and motor is more than 50m,

the controller may be tripped by over-current protection frequently because of the

large leak current resulted from the parasitic capacitance with ground. So as to avoid

the damage of motor insulation, the output reactor should be installed.

4.4.7 Ground Wiring

In order to keep safety and prevent electric shock and fire, “PE” must be

grounded with ground resistance. Furthermore, reliable grounding is the simplest,

most effective and minimum cost solution for EMC problems, so it enjoys priority in

all EMC methods.

5. OPERATION

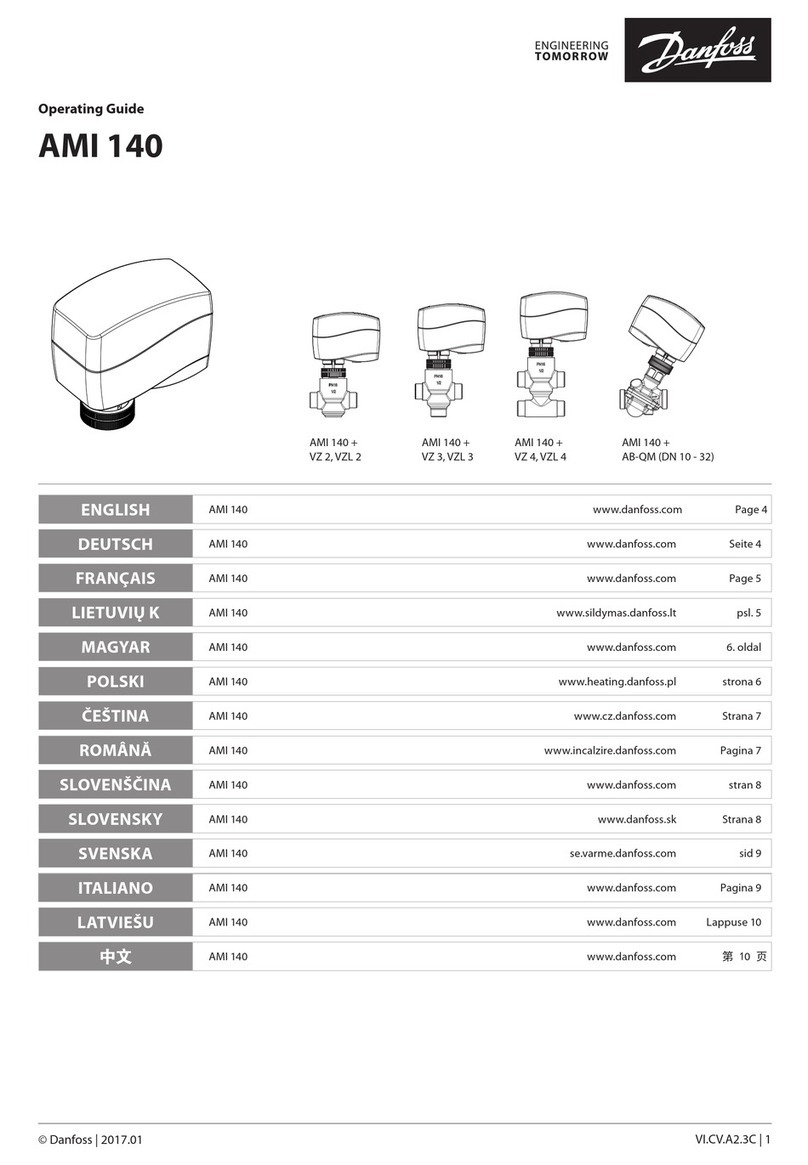

5.1 Keypad Description

Figure5.1.1 Keypad schematic diagram

W713B Series Intelligent Controller for Water Pump User Manual

9

5.2 Operation Procedure

5.2.1 Add Prefix Characters Display Content for Easy Understanding

H: Operating Frequency

P: The Actual Pressure of Pump Outlet

/The Actual Differential Pressure (Outlet Pressure -Inlet Pressure)

/The Actual Temperature of Pump Outlet

/The Actual Differential Temperature (Outlet Temperature - Inlet Temperature)

L: The Setting Pressure of Pump Outlet

/The Setting Differential Pressure (Outlet Pressure -Inlet Pressure)

T: The Setting Temperature of Pump Outlet

/The Setting Differential Temperature (Outlet Temperature -Inlet Temperature)

A: Output current

d: DC Bus Voltage

: The Setting Pressure of Pump Outlet and Actual Pressure of

Pump Outlet

/The Setting Differential Pressure and Actual Differential Pressure

/The Setting Temperature of Pump Outlet and Actual Temperature Pressure of

Pump Outlet

/The Setting Differential Temperature and Actual Differential Temperature

: The Output Current and The Actual Pressure of Pump Outlet

/The Output Current and Actual Differential Pressure

/The Output Current and Actual Temperature of Pump Outlet

/The Output Current and Actual Differential Temperature

5.2.2 Power-on Initialization

Firstly the system initializes during the controller power-on, and LED displays

“713b”. After the initialization is completed, the controller is on stand-by status.

5.2.3 Parameter Setting

Three levels of menu are: 1. Function code group (first-level); 2. Function code

(second-level); 3. Function code setting value (third-level)

▲At the primary interface, press will switch over display running/stop

status monitoring parameters;

W713B Series Intelligent Controller for Water Pump User Manual

10

▲At the primary interface, press will enter the first-level menu then press

will return to the primary interface;

▲At the first-level menu, press will enter the second-level menu. In

second-level menu can also press and return to first-level menu or

enter third-level menu;

▲At third-level menu, press or can return to the second-level menu,

difference is: pressing will save the parameters into the controller and

return to the second-level menu with shifting to the next function code

automatically; while pressing will directly return to the second-level

menu without saving the parameters, and keep staying at the current function

code.

Example 1: Change factory pressure setting 3.0 bar to 2.5 bar

Method 1: Enter parameter setting

Operation flow chart:

Figure 5.2.1 Operation flow chart

W713B Series Intelligent Controller for Water Pump User Manual

11

Method 2: Direct setting at the primary interface

Press or at primary interface, the system will switch-over to display

setting pressure, press or again, the setting pressure increase/decrease,

mean while the system trace the setting pressure.

6. INSTRUCTIONS OF PARAMETERS GROUP

“○”:stands for the inverter is in stop or running status,the parameter can be

changed;

“◎”:stands for the inverter is in running status,the parameter can not be

changed;

“●”:Stand for the parameter can not be changed.

Function

Code

Name

Setting

Range

Factory

Setting

Description

R/W

Address

br-00 Group Application Function

b00.00

Function

Debugging

Password

0~65535

65535

Decide by b06.09, default is 65535

—

—

b00.01

Pressure Setting

b01.01

~b01.00-1.0

3.0bar

Set Pressure/Set Differential Pressure/Set

Temperature/Set Differential Temperature

According to mode (b01.18) selection and

automatically adjust factory setting according

to the responding mode.

○

0xB001

Differential

pressure setting

0.0

~b01.00-1.0

0.5bar

Temperature

Setting

-15.0

~b01.20-10

30.0℃

Differential

Temperature

5.0℃

b00.02

Setting

Motor Rotating

Direction

0~1

0

0: Forward;

1: Reverse

◎

0xB002

b00.03

Freeze-proofing

0~1

0

Used in cold areas. 0: Invalid; 1: Valid

◎

0xB003

b00.04

Anti-clogging

0~1

0

It is only suitable for single pump system

to remove water pump rust blockage and

pipeline blockage. 0: Invalid; 1: Valid

◎

0xB004

b00.05

Anti-clogging

Rotating Cycle

1.0~300.0

20.0s

Set the forward/reverse rotating direction

cycle and corresponding output frequency

(should not be higher than the rated

frequency of the pump) of anti-clogging.

○

0xB005

b00.06

Anti-clogging

Output

Frequency

0.00~b05.05

15.00Hz

○

0xB006

b00.07

Shortcut Key

Setting

0x100

~0x651

0x100

◎

0xB007

W713B Series Intelligent Controller for Water Pump User Manual

12

Function

Code

Name

Setting

Range

Factory

Setting

Description

R/W

Address

b00.08

Constant Speed

Operating

Frequency

Setting Value

b05.07

~b05.06

50.00Hz

When the constant speed operating frequency

needs to be set to a greater value, the upper

operating limit b05.06 shall be modified first,

and then the value shall be modified

○

0xB008

b00.09

Manual

Frequency

Source

Selection

0~3

0

0: Keyboard (b00.08); 1: AI1;

2: AI2; 3: Communications control

◎

0xB009

br-01 Group Application Function

b01.00

High Water

Pressure Alarm

Value

b01.01+1.0

~b01.05

8.0bar

When actual pressure on the outlet side is

higher than this preset value, the inverter

halts, alarms and displays “HP”.

Constant Pressure Mode: When actual

pressure on the outlet side is lower than this

preset value, “HP” would be automatically

cleared,When actual pressure on the outlet

side is lower than the difference value

between this preset value and bias value

(b04.03), pump would restart automatically.

Constant Differential Pressure Mode:

When actual pressure on the outlet side is

lower than the difference value between this

preset value and 1.5 Bar, “HP” would be

automatically cleared and pump would restart

automatically.

○

0xB100

b01.01

Low Water

Pressure Alarm

Value

0.0~b01.00

0.5bar

Outlet side Low Water Pressure Alarm Preset

Value

○

0xB101

b01.02

Low Pressure

Running Time

0.0~3600.0

20.0s

When the “Constant Pressure” or

“Constant Differential Pressure” Control

Modes are in operation, the actual pressure

on the outlet side is lower than the low water

pressure alarm value (b01.01) for a low

pressure running time (b01.02), the inverter

halts, alarms and displays “LP”;

When the “Constant Temperature” or

“Constant Differential Temperature”

Control Modes are in operation, the actual

temperature on the outlet side is lower than

the low temperature alarm value (b01.29) for

a low temperature running time (b01.02), the

inverter halts, alarms and displays “LT”.

○

0xB102

Low

Temperature

Running Time

W713B Series Intelligent Controller for Water Pump User Manual

13

Function

Code

Name

Setting

Range

Factory

Setting

Description

R/W

Address

b01.03

Minimum

Freeze-proofing

Frequency

1.00~b05.07

5.00Hz

Be valid when b00.03 was set to 1, when

sleep, running with the setting frequency in

case of freezing. This value should be lower

than the lower limited frequency (b05.07).

○

0xB103

b01.04

Anti-clogging

FWD./REV.

Dead Time

0.0~3600.0

1.0s

When anti-clogging is valid, b01.04 set the

FWD./REV. transition time

○

0xB104

b01.05

Maximum

Transducer

Setting Range

0.0~100.0

10.0bar

For “Constant Pressure” or “Constant

Differential Pressure” Control Mode. If the

rated max. range of transducer is 16.0bar,

b01.05 should be set to 16.0;

Set the control range of “Constant

Temperature” or “Constant Differential

Temperature” in parameters b01.07 and

b01.09 (water outlet), b01.12 and b01.14

(water inlet).

○

0xB105

b01.06

AI1 Lower

Limit

0.00~b01.08

1.00V

Lower limit (b01.06, b01.11) use to

transducer zero setting

Corresponding Setting of Lower Limit

(b01.07, b01.12) use to transducer

minimum setting

Higher limit (b01.08, b01.13) use to

accordant display and transducer: when

display smaller than the actual, decrease

higher limit; when display greater than the

actual, increase higher limit

Corresponding Setting of Higher Limit

(b01.09, b01.14) use to transducer

maximum setting

When analog input is interfered, prolong

filtering time so as to increase the ability of

anti-interference, but decrease the

sensitivity.

Corresponding relationship of transducer

parameter setting of “Constant Pressure”

and “Constant Differential Pressure”

control mode:

○

0xB106

b01.07

Corresponding

Setting of AI1

Lower Limit

-100.0~200.0

0.0%

○

0xB107

AI1

Temperature

Lower Limit

0.0℃

b01.08

AI1 Higher

Limit

b01.06

~10.00

5.00V

○

0xB108

b01.09

Corresponding

Setting of AI1

Higher Limit

-100.0~200.0

100.0%

○

0xB109

AI1

Temperature

Higher Limit

100.0℃

b01.10

AI1 Filtering

Time

0.00~10.00

0.10s

○

0xB10A

b01.11

AI2 Lower

Limit

0.00~b01.13

1.00V

○

0xB10B

b01.12

Corresponding

Setting of AI2

Lower Limit

-100.0~200.0

0.0%

○

0xB10C

AI2

Temperature

Lower Limit

0.0℃

b01.13

AI2

Hi

gh

er

b01.11

5.00V

○

0xB10D

W713B Series Intelligent Controller for Water Pump User Manual

14

Function

Code

Name

Setting

Range

Factory

Setting

Description

R/W

Address

Corresponding relationship of transducer

parameter setting of “Constant

Temperature” and “Constant differential

Temperature” control mode:

Li

m

i

t

~10.00

b01.14

Co

rre

spond

i

ng

S

e

tt

i

ng of AI2

Hi

gh

er Li

m

i

t

-100.0~200.0

100.0%

○

0xB10E

AI2

Te

mp

er

atu

re

Hi

gh

er Li

m

i

t

100.0℃

b01.15

AI2

Fil

t

eri

ng

Ti

m

e

0.00~10.00

0.10s

○

0xB10F

b01.16

Restart After

Power-on

0~1

1

0: Invalid;

1: Valid

◎

0xB110

0

1

0

b01.17

Linkage Mode

0~4

1

0: Synchronous; 1: Master-slave;

2: Big-small pump combination;

3: One duty one standby;

4: One VFD drive two pumps (It needs to be

used with One VFD drive two pumps boxes)

Note: when b01.17 was set to 4, the

following parameters will be set

automatically. b01.09 is 0 (Independent Start

and Stop Forbidden), b05.02 is 5 (One VFD

drives two pump fault input), b05.12 is 1 (S4

terminal control), b06.03 is 10 (Relay 1 used

for variable frequency pump control), b06.10

is 11 (Relay 2 used for power frequency

pump control).

◎

0xB111

b01.18

Control Mode

0~3

0

0: Constant Pressure;

1: Constant Differential Pressure;

2: Constant Temperature;

4: Constant Differential Temperature

◎

0xB112

b01.19

Independent

Start and Stop

Control

0~1

0

Only be enabled when b05.02 =2 and

b01.17≠4

0: Invalid (Start and stop is controlled by the

system after being put into the system)

1: Valid (Start and stop is controlled by the

inverter, which can be started and stopped by

the panel or S4 terminal)

◎

0xB113

b01.20

One VFD drive

two pumps mode

0~1

1

0: Fixed variable frequency pump

1: Rotate variable frequency pump

When enabled, the alternate mode is

◎

0xB114

W713B Series Intelligent Controller for Water Pump User Manual

15

Function

Code

Name

Setting

Range

Factory

Setting

Description

R/W

Address

determined by b05.11, and the alternate time

is set by b05.10.

Note: After the alternate time reaches, when

the sleep function is enabled, the system will

automatically complete the alternate while

sleeping. When the sleep function is not

enabled, the system will complete the

alternating at the lower limit of output

frequency.

b01.21

Add Power

Frequency Pump

Pressure Bias

0.0~b00.01

0.5bar

Bias Value of Setting Pressure /Setting

Differential Pressure /Setting Temperature

/Setting Differential Temperature subtract

Feedback Pressure /Feedback Differential

Pressure /Feedback Temperature /Feedback

Differential Temperature

○

0xB115

Add Power

Frequency Pump

Differential

Pressure Bias

0.5bar

Add Power

Frequency Pump

Temperature

Bias

5℃

Add Power

Frequency Pump

Differential

Temperature

Bias

5℃

b01.22

Add Power

Frequency Pump

Delay Time

0.0~3600.0

10.0s

When Variable Frequency Pump reach Upper

Limit Frequency, if the difference value of

Setting Pressure /Setting Differential Pressure

/Setting Temperature /Setting Differential

Temperature subtract Feedback Pressure

/Feedback Differential

Pressure /Feedback Temperature /Feedback

Differential Temperature is higher than or

equals to b01.21, after b01.22 delay time,

Power Frequency Pump would be in

operation.

○

0xB116

b01.23

Subtract Power

Frequency Pump

Pressure Bias

0.0~b00.01

0.5bar

Bias Value of Feedback Pressure /Feedback

Differential Pressure/Feedback Temperature

/Feedback Differential Temperature subtract

Setting Pressure /Setting Differential Pressure

/Setting Temperature /Setting Differential

○

0xB117

Subtract Power

Frequency Pump

Differential

Pressure Bias

0.5bar

This manual suits for next models

16

Table of contents

Other Bedford Controllers manuals