Samwontech NOVA541 User manual

Other Samwontech Controllers manuals

Samwontech

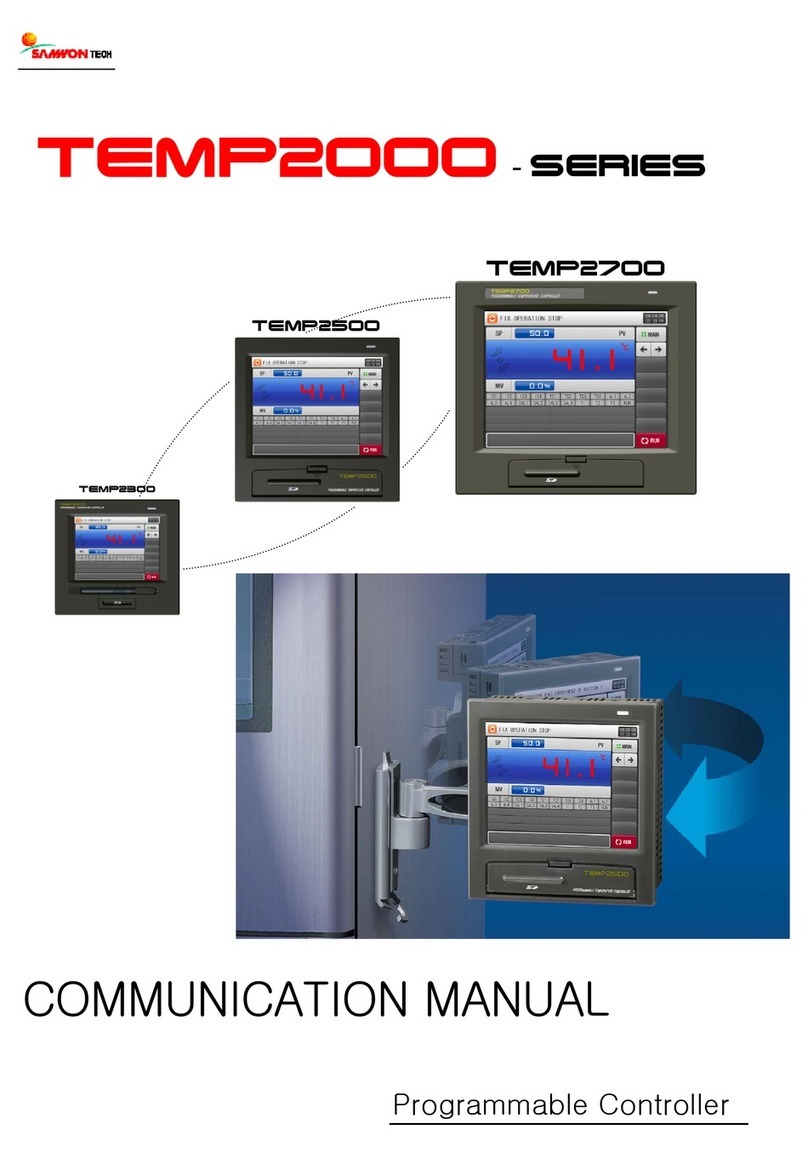

Samwontech TEMP2000 Series Use and care manual

Samwontech

Samwontech TEMI1000 Series User manual

Samwontech

Samwontech TEMI2000 Series User manual

Samwontech

Samwontech TEMI 300 User manual

Samwontech

Samwontech TEMI2000 Series Use and care manual

Samwontech

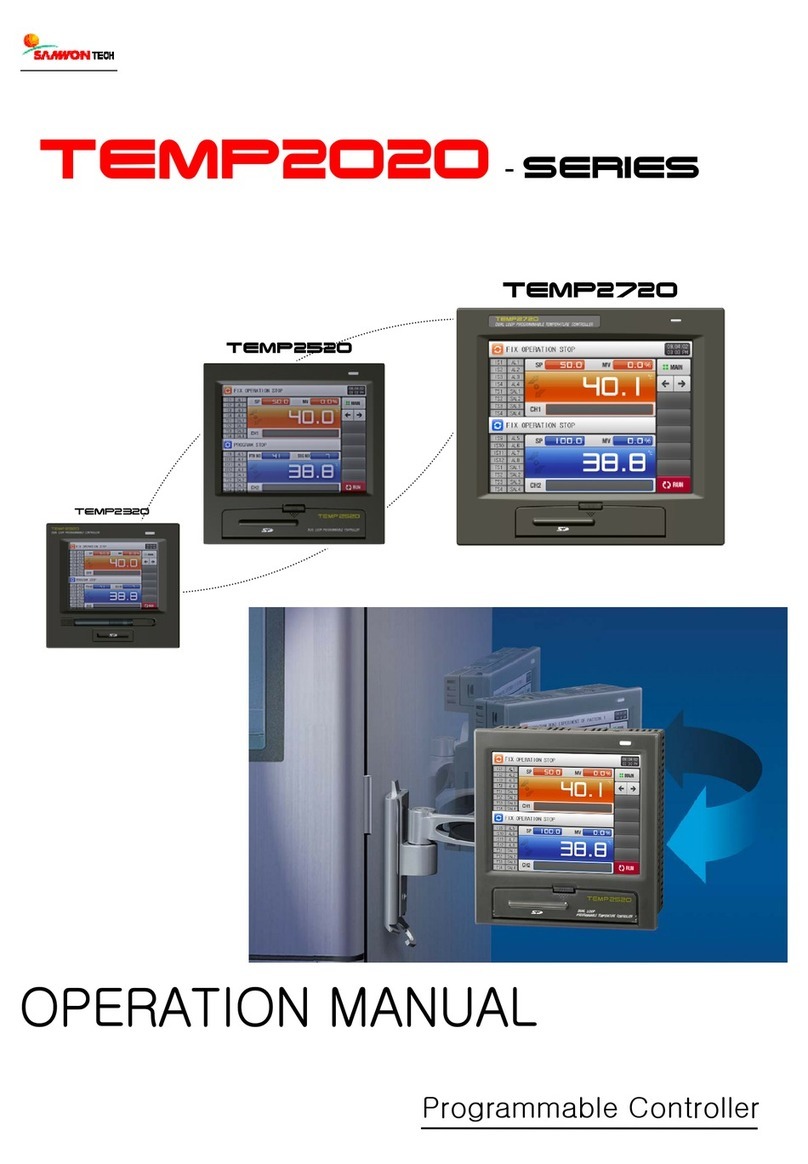

Samwontech TEMP2020M Series Quick start guide

Samwontech

Samwontech TEMP2000 Series User manual

Samwontech

Samwontech TEMI770 User manual

Samwontech

Samwontech Temp 2000 M User manual

Samwontech

Samwontech TEMP2020 series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions