Beha-Amprobe ULD-400-EUR User manual

ULD-400-EUR

Ultrasonic Leak Detector

ULD-410-EUR

ULD-420-EUR

CZK

ULD-400-EUR

Ultrasonic Leak Detector

ULD-410-EUR

ULD-420-EUR

User Manual

10/2019, 6012571 A

©2019 Beha-amprobe.

All rights reserved.

English

Limited Warranty and Limitation of Liability

Your Beha-Amprobe product will be free from defects in material and workmanship for

two years from the date of purchase unless local laws require otherwise. This warranty does

not cover fuses, disposable batteries or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or handling. Resellers are not authorized

to extend any other warranty on the behalf of Beha-Amprobe. To obtain service during the

warranty period, return the product with proof of purchase to an authorized Beha-Amprobe

Service Center or to an Beha-Amprobe dealer or distributor. See Repair Section for details. THIS

WARRANTY IS YOUR ONLY REMEDY. ALL OTHER WARRANTIES - WHETHER EXPRESS, IMPLIED

OR STATUTORY - INCLUDING IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE

OR MERCHANTABILITY, ARE HEREBY DISCLAIMED. MANUFACTURER SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY. Since some states or countries do not allow the exclusion or

limitation of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

Repair

All Beha-Amprobe tools returned for warranty or non-warranty repair or for calibration

should be accompanied by the following: your name, company’s name, address, telephone

number, and proof of purchase. Additionally, please include a brief description of the

problem or the service requested and include the test leads with the product. Non-warranty

repair or replacement charges should be remitted in the form of a check, a money order,

credit card with expiration date, or a purchase order made payable to Beha-Amprobe.

In-warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During

the warranty period, any defective test tool can be returned to your Beha-Amprobe distributor

for an exchange for the same or like product. Please check the “Where to Buy” section on

beha-amprobe.com for a list of distributors near you. Additionally, in the United States and

Canada, in-warranty repair and replacement units can also be sent to an Amprobe Service

Center (see address below).

Non-warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Beha-Amprobe distributor for a

nominal charge. Please check the “Where to Buy” section on beha-amprobe.com for a list of

distributors near you.

Beha-Amprobe

Division and reg. trademark of Fluke Corp. (USA)

Germany*

In den Engematten 14

79286 Glottertal

Germany

Phone: +49 (0) 7684 8009 - 0

beha-amprobe.de

United Kingdom

52 Hurricane Way

Norwich, Norfolk

NR6 6JB United Kingdom

Phone: +44 (0) 1603 25 6662

beha-amprobe.com

The Netherlands - Headquarters**

Science Park Eindhoven 5110

5692 EC Son

The Netherlands

Phone: +31 (0) 40 267 51 00

beha-amprobe.com

*(Correspondence only – no repair or replacement available from this address. European

customers please contact your distributor.)

**single contact address in EEA Fluke Europe BV

1

ULD-400-EUR Ultrasonic Leak Detector

CONTENTS

1. PRECAUTIONS AND SAFETY MEASURES ............................................................. 2

2. INTRODUCTION ..................................................................................................... 3

3. KIT COMPONENTS................................................................................................. 4

3.1 Kit Components ............................................................................................................4

3.2 ULD-400-RE Receiver .....................................................................................................5

3.3 ULD-400-TE Transmitter ................................................................................................6

3.4 Accessories ....................................................................................................................7

4. MAIN APPLICATIONS ............................................................................................ 8

4.1 Using the ULD-400-RE Ultrasonic Leak Detector Receiver ..........................................8

4.2 Using the ULD-400-TE Ultrasonic Leak Detector Transmitter .....................................10

5. MAINTENANCE...................................................................................................... 11

5.1 Changing the Receiver Batteries ..................................................................................11

5.2 Changing the Transmitter Batteries .............................................................................12

5.3 Cleaning .........................................................................................................................12

6. SPECIFICATIONS .................................................................................................... 13

2

1. PRECAUTIONS AND SAFETY MEASURES

SYMBOLS

�Caution! Refer to the explanation in this manual.

Consult user documentation.

Battery.

Complies with European Directives.

Conforms to relevant South Korean EMC Standards.

Electromagnetic Compatibility:

Korea (KCC): Class A Equipment (Industrial Broadcasting & Communication Equipment) [1]

[1] This product meets requirements for industrial (Class A) electromagnetic wave

equipment and the seller or user should take notice of it. This equipment is intended for

use in business environments and is not to be used in homes.

Conforms to relevant Australian standards.

This product complies with the WEEE Directive marking requirements. The affixed

label indicates that you must not discard this electrical/electronic product in

domestic household waste. Product Category: With reference to the equipment

types in the WEEE Directive Annex I, this product is classed as category 9

“Monitoring and Control Instrumentation” product. Do not dispose of this product

as unsorted municipal waste.

Safety information

The product complies with:

• IEC 61326-1

CENELEC Directives

The instrument conforms to CENELEC Electromagnetic compatibility directive 2014/30/EU.

�WARNINGS AND PRECAUTIONS

• Not for use on explosive gases.

• Use extreme care when using near pressurized air/gas.

• Use extreme care when using near rotation equipment.

• Use extreme care when using near electrical equipment.

• Use only 4 x AA batteries for the ULD-400-RE Receiver and only 2 x AAA size batteries

for the ULD-400-TE Transmitter, properly installed in the battery compartment, to

power the Product (see Section 5: Maintenance).

• Remove the batteries if the Product is not used for an extended period of time, or if

stored in temperatures above 50 °C (122 °F). If the batteries are not removed, battery

leakage can damage the Product.

• Follow all battery care from the battery manufacturer.

3

Ultrasonic sound, or ultrasound, is a sound wave with frequencies above 20 kHz, higher

than the upper audible limit of human hearing. Ultrasound can be generated when

turbulence created by air or gas is forced through a small orifice. Leaking air or gas is

generally considered to be viscous flow, and as the flow velocity increases, the frequency

of the ultrasound emitted becomes higher. Vibrating, moving objects or electric discharge

will also create an ultrasonic wave, which is very directional in nature and can be used to

pinpoint the exact location of a leak, vibration or discharge.

The ULD-400-RE Receiver detects ultrasounds within 20 kHz to 90 kHz frequency, then

amplifies and converts these ultrasonic sounds to frequencies and levels that the human

ear can hear through headphones and show it on the LCD screen. The 20 kHz to 90 kHz

frequency range is the optimal range for detecting a variety of leakage events in assets such

as HVAC systems and pneumatic lines. A change in the ultrasound produced by an asset may

be indicative that an asset is beginning to fail.

0

20kHz

20Hz 200

MHz

20MHz

Infrasound Acoustic Sound Ultrasound

Figure 2: Sound range spectrum

2. INTRODUCTION

4

3.1 Kit Components

Your shipping box should include:

ULD-410-EUR ULD-420-EUR

ULD-400-RE Receiver 1 1

ULD-400-TE Transmitter - 1

Headphones 1 1

Earbuds (for use with hard hat) 1 1

PB-1 Power Parabola 1 1

TEA-1 Flexible Tubing Adapter 1 1

TE-1 Tubular Extension 1 1

CC-ULD-400-EUR Hard Carrying Case 1 1

AA Batteries (Receiver) 4 4

AAA Batteries (Transmitter) - 2

Manual 1 1

Note: Batteries are not pre-installed in the Receiver or Transmitter.

3. KIT COMPONENTS

5

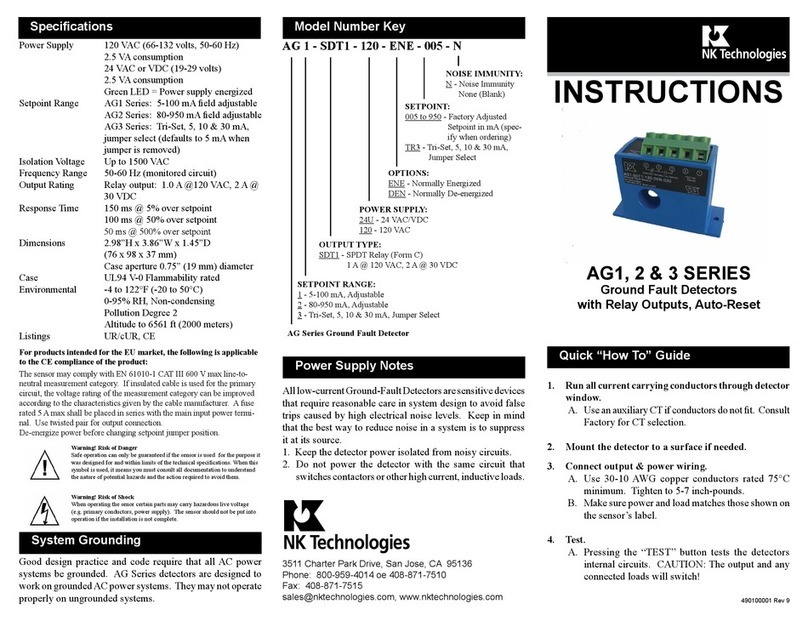

3.2 ULD-400-RE Receiver

Sound

volume

Microphone

sensor

Sensitivity

“+/-” button

Headphone

Volume "+/-"

button

On/Off button

Signal strength

indication

Sensitivity

level

Signal

filter

Auto Filter

button

Headphone

jack

Battery

status

Figure 3.2: ULD-400-RE Receiver

3. KIT COMPONENTS

6

3. KIT COMPONENTS

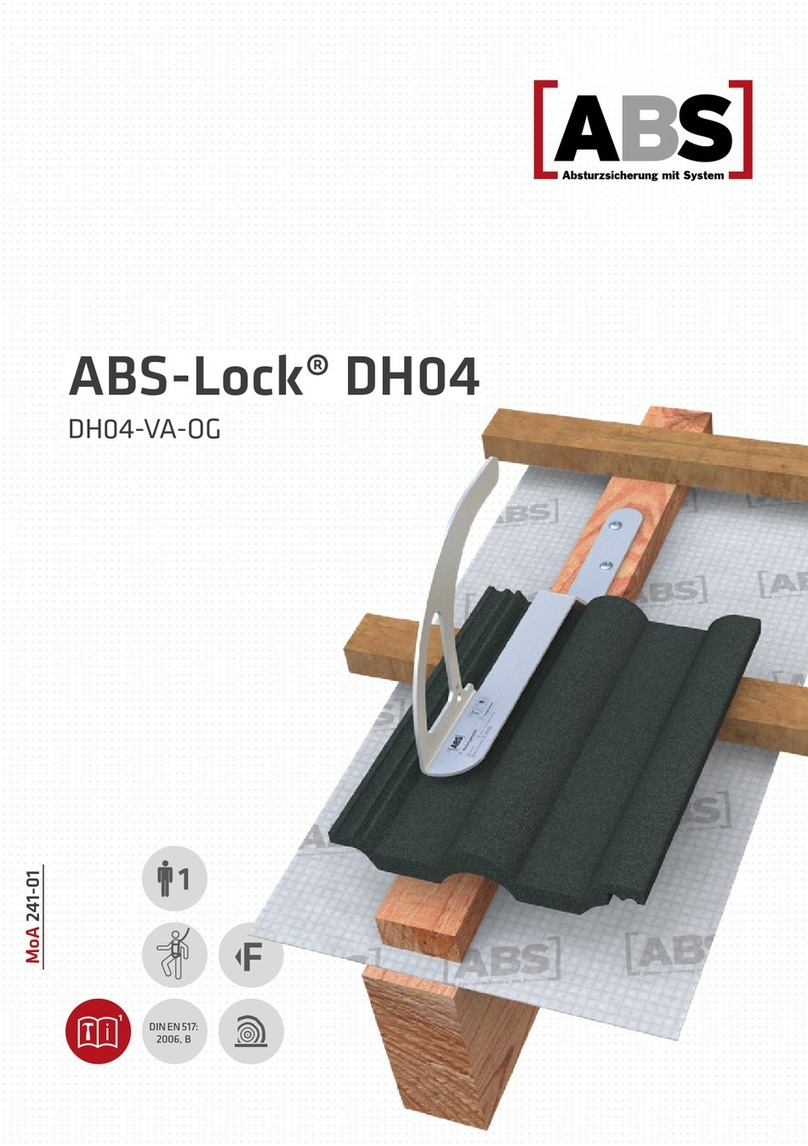

3.3 ULD-400-TE Transmitter

The ULD-400-TE Transmitter is included with the ULD-420-EUR kit and is optional for the

ULD-410-EUR kit.

When a leak is not pressurized sufficiently the Receiver will not be able to detect it. In these

circumstances, the ULD-400-TE Transmitter can be used to emit an ultrasonic sound that

the Receiver can read. The Transmitter is programmed with three signal levels for precise

pinpointing of leaks.

Speaker

Low battery

indicator

LEDs:

high/

medium/low

signals

On/Off button

Signal level “+/-”

button

Figure 3.3: ULD-400-TE Transmitter

7

3.4 Accessories

The ULD-400-EUR comes supplied with additional Receiver accessories that are helpful

in leak identification. Plug the headphones into the Receiver to audibly hear the leak

and verify its source (for example hissing sound of an air leak versus ticking sound of an

electric discharge). Use the Parabola attachment in situations where there is a high level

of background noise to help direct the ultrasound towards the sensor. Use the Tubular

Extension with the Adapter in hard to reach areas for additional reach.

Note: There is no speaker on the Receiver. Without headphones, no noise will be audible.

Parabola (PB-1) Adapter (TEA-1) Tubular Extension

(TE-1)

Tubular Extension

(TE-1)

Adapter (TEA-1)

Parabola (PB-1)

Figure 3.4: ULD-400-EUR Accessories

3. KIT COMPONENTS

8

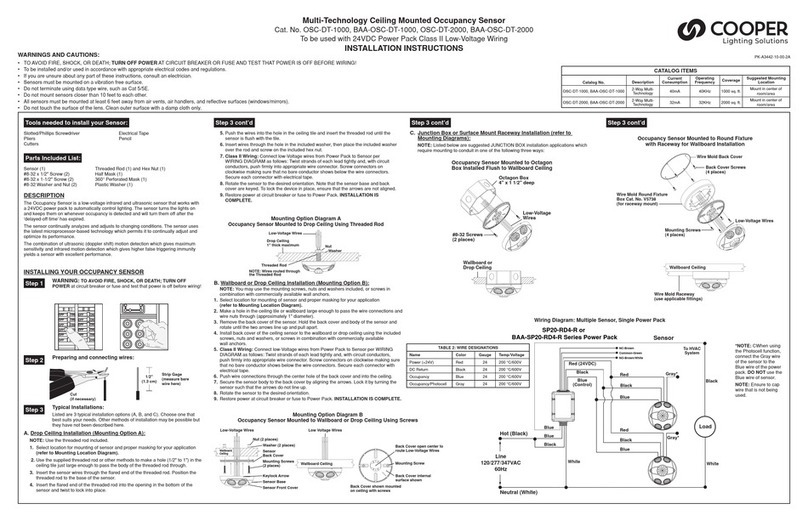

4.1 Using the ULD-400-RE Ultrasonic Leak Detector Receiver

1. Turn on the Receiver and plug the headphones into the jack located on the front of the

Receiver. Any standard set of 3.5 mm jack headphones are compatible.

2. Before moving to the target area, press “+” or “-” sensitivity buttons to adjust signal

strength sensitivity to the highest possible level where bargraph still shows either 0 or

a value close to 0. If signal strength cannot be adjusted down and the LCD still shows a

maximum value regardless on sensitivity adjustments, press the Filter button.*

3. Scan the target area with the microphone sensor.

4. As you move nearer to the source of the leak, vibration or electric discharge, the signal

strength will increase. This will be indicated on a screen with increasing signal strength

number and level of the bargraph.

5. The bargraph is a relative measurement only, so when the signal strength reaches

maximum, lower the sensitivity by pressing the “-” sensitivity button until the displayed

signal strength is less than 75. Repeat this process until you have isolated the source of

the ultrasound.

6. The audible sound emitted via headphones will help to verify the source of the leak,

for example hissing sound of the air leak versus ticking sound of the electric discharge.

The Receiver screen alone will not provide an indication of the leak source.

Note:

• For surroundings with a high level of background noise use the Parabola (PB-1) to

direct the ultrasound towards the sensor.

• For locations that you cannot point the Receiver directly at the leak, the Tubular

Extension can be used (TE-1 with the TEA-1 Adapter).

Figure 4.1a: Using the Receiver to find a leak

4. MAIN APPLICATIONS

9

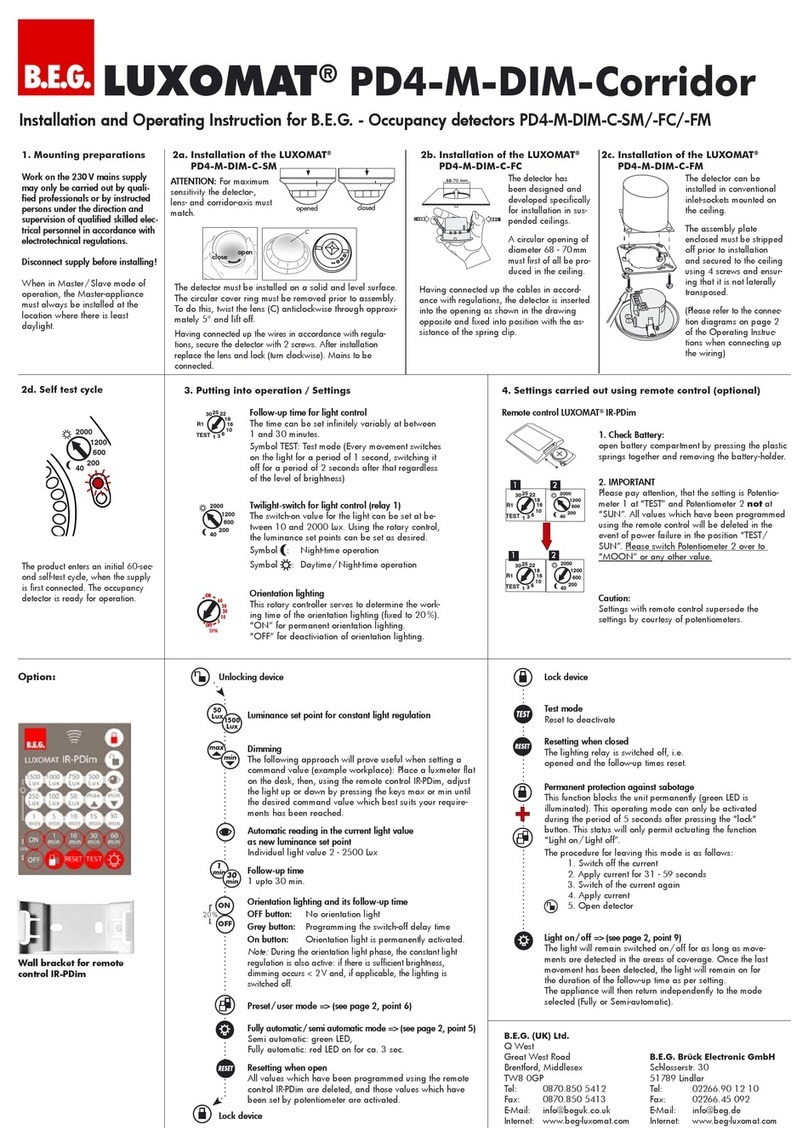

*ULD-400-RE Filter Operation

In some situations, there might be strong ultrasonic noise generated by running machinery, motion

sensors or other equipment. This noise will cause the Receiver to read the maximum signal strength

on the display regardless of the sensitivity settings and make it unusable for detecting leaks.

In such cases, press the “Filter” button. The firmware will automatically detect the main noise

frequency and filter it out by applying digital non-pass bandwidth filter within +/- 5 kHz. If the

signal level does not decrease down close to 0, then the firmware will automatically repeat the

process for other noise frequencies. Up to three frequencies can be filtered out automatically. The

filter icon will be displayed on the screen and will indicate the number of filters applied, from zero

(no noise detected) to a maximum of three.

3

Figure 4.1b: Filter applied

Note: The filter will be applied to the visual signal indication on a screen (signal strength number

and bargraph). The filter will NOT be applied to the audio frequency in order to preserve

original sound of the leak and allow the user to better determine the source of the leak.

Note: When working with the Transmitter, make sure to apply the filter on the Receiver before

the Transmitter is turned on, or in an area where the Transmitter signal can not be detected.

Otherwise, the Transmitter signal frequency will be filtered out and Receiver will not be able

to pick it up.

4. MAIN APPLICATIONS

10

4.2 Using the ULD-400-TE Ultrasonic Leak Detector Transmitter

The Transmitter allows for ultrasonic detection of openings in locations where there is no gas or

air pressure, or the pressure is not sufficient to detect the leak with the Receiver alone.

Typical applications include verifying tightness or pinpointing places of air, water or gas leaks in:

• Fluid or gas tanks

• Building windows, doors or roofs

• Car windows and windshields

• HVAC vents

• Refrigerant pipelines

The process involves placing the Transmitter inside an object (such as tank, house or a car),

sealing the entryways and scanning the object from the outside with the Receiver to verify

tightness and pinpoint potential leaks.

1. Turn on the Transmitter.

2. Select the output signal level using the “+” or “-” signal level adjustment buttons.

Note: High setting is the default setting. For most applications and specifically for large

objects this setting is particularly useful. The High signal may cause the Receiver to read

maximum value away from the place of the leak even when lowest sensitivity was

selected. Press “-” once to get to Medium signal and press “-” again to get to Low signal

strength. Adjust signal level to allow for more precise pinpointing of the leaks.

3. Place the Transmitter inside the object to be verified and make sure entryways are sealed.

4. Preform leak detecting with the Receiver as described in section 4.1.

Figure 4.2: Using the Transmitter and Receiver to find a leak

4. MAIN APPLICATIONS

11

5. MAINTENANCE

5.1 Changing the Receiver Batteries

The ULD-400-RE uses four 1.5 V AA (LR6) batteries (supplied). To replace the batteries, follow

these steps:

1. Make sure that the Receiver is turned off.

2. Use a screw driver to unscrew the captive screw.

3. Remove the battery cover.

4. Replace the batteries as shown in Figure 5.1. Observe the battery polarity shown in the

battery compartment.

5. Replace the battery cover and secure it with the provided screw.

AA

AA

AA

AA

Figure 5.1: Changing the Receiver batteries

12

5.2 Changing the Transmitter Batteries

The ULD-400-TE uses two 1.5 V AAA (LR03) batteries (supplied with ULD-420-EUR). To replace

the batteries, follow these steps:

1. Make sure that the Transmitter is turned off.

2. Loosen the battery-door lock with a flat screwdriver.

3. Remove the battery cover.

4. Replace the batteries as shown in Figure 5.2. Observe the battery polarity shown in the

battery compartment.

5. Replace the battery cover to the lock position.

AAA

AAA

Figure 5.2: Replacing the Transmitter batteries

5.3 Cleaning

The only maintenance the ULD-400-EUR requires is inspection and cleaning. Periodically wipe the

exterior with a mild solution of detergent and water. Apply sparingly with a soft cloth and allow to

dry completely before using. Do not use aromatic hydrocarbons, gasoline or chlorinated solvents

for cleaning.

5. MAINTENANCE

13

6. SPECIFICATIONS

Features ULD-400-RE ULD-400-TE

Sensitivity Adjustment Yes N/A

Volume Adjustment Yes N/A

Signal Level Adjustment N/A Yes

Earphone Jack Yes

(compatible with 3.5 mm audio jack)

N/A

Display Size LCD 6.35 cm (2.5 in) N/A

Display Dimensions 36.72 x 48.96 mm (1.45 x 1.93 in) N/A

Display Resolution 240(RGB) x 320 pixels N/A

Display Type TFT-LCD (262 K) N/A

Display Color True, 16bit/color N/A

Frequency Range 20 kHz to 90 kHz Typical 40 kHz squarewave

Filter ±5 KHz of main noise frequency,

up to three filters N/A

Power Supply 4 x 1.5 V AA (LR6) alkaline batteries

2 x 1.5 V AAA (LR03) alkaline batteries

Power Consumption

(typical)

75 mA 33 mA

Battery Life (typical) 105 hours (Alkaline) 60 hours (Alkaline)

Low battery indication Yes (Red LED)

APO function 60 minutes when in idle 60 minutes when in idle

Weight Approx. 0.235 kg (0.518 lb) Approx. 0.335 lb (0.152 kg)

Dimensions 183 x 75 x 43 mm

(7.547 x 2.984 x 1.791 in)

137 x 65 x 33 mm

(5.295 x 2.559 x 1.326 in)

Operating Temperature -20 °C to 50 °C (-4 °F to 122 °F)

Storage Temperature -20 °C to 70 °C (-4 °F to 158 °F)

Operating Humidity <80% RH

Pollution Degree 2

Protection IP40

Certifications

Electromagnetic

Compatibility (EMC)

EN 61326-1

Korea (KCC): Class A Equipment (Industrial Broadcasting & Communication

Equipment) [1]

[1] This product meets requirements for industrial (Class A) electromagnetic

wave equipment and the seller or user should take notice of it. This

equipment is intended for use in business environments and is not to be used

in homes.

ULD-400-EUR

Ultraschall-Leckdetektor

ULD-410-EUR

ULD-420-EUR

Bedienungsanleitung

10/2019, 6012571 A

©2019 Beha-amprobe.

Alle Rechte vorbehalten.

Deutsch

Eingeschränkte Garantie und Haftungseinschränkungen

Innerhalb von zwei Jahren ab Kaufdatum oder innerhalb des gesetzlich vorgeschriebenen

Mindestzeitraums garantieren wir, dass Ihr Beha-Amprobe-Produkt keinerlei Material-

und Herstellungsfehler aufweist. Sicherungen, Trockenbatterien sowie Schäden durch

Unfall, Fahrlässigkeit, Missbrauch, Manipulation, Kontamination sowie anomale Nutzung

und Einsatzbedingungen werden nicht durch die Garantie abgedeckt. Händler sind nicht

berechtigt, jegliche Erweiterungen der Garantie im Namen von Beha-Amprobe in Aussicht zu

stellen. Um Serviceleistungen während der Garantiezeit in Anspruch zu nehmen, übergeben

Sie das Produkt mitsamt Kaufbeleg einem autorisierten Beha-Amprobe-Servicecenter oder

einem Beha-Amprobe-Händler oder -Distributor. Details dazu finden Sie im Reparatur-

Abschnitt. SÄMTLICHE ANSPRÜCHE IHRERSEITS ERGEBEN SICH AUS DIESER GARANTIE.

SÄMTLICHE SONSTIGEN GEWÄHRLEISTUNGEN ODER GARANTIEN, OB AUSDRÜCKLICH,

IMPLIZIT ODER SATZUNGSGEMÄSS, SOWIE GEWÄHRLEISTUNGEN DER EIGNUNG FÜR EINEN

BESTIMMTEN ZWECK ODER HANDELSTAUGLICHKEIT WERDEN HIERMIT ABGELEHNT. DER

HERSTELLER HAFTET NICHT FÜR SPEZIELLE, INDIREKTE, BEILÄUFIGE ODER FOLGESCHÄDEN

SOWIE FÜR VERLUSTE, DIE AUF ANDERE WEISE EINTRETEN. In bestimmten Staaten oder

Ländern sind Ausschlüsse oder Einschränkungen impliziter Gewährleistungen oder

beiläufiger oder Folgeschäden nicht zulässig; daher müssen diese Haftungseinschränkungen

nicht zwingend auf Sie zutreffen.

Reparatur

Sämtliche innerhalb oder außerhalb der Garantiezeit zur Reparatur oder Kalibrierung

eingereichten Geräte von Beha-Amprobe sollten mit folgenden Angaben begleitet

werden:Ihr Name, Name Ihres Unternehmens, Anschrift, Telefonnummer und Kaufbeleg.

Zusätzlich fügen Sie bitte eine Kurzbeschreibung des Problems oder der gewünschten

Dienstleistung bei, vergessen Sie auch die Messleitungen des Produktes nicht. Gebühren für

Reparaturen oder Austausch außerhalb der Garantiezeit sollten per Scheck, Überweisung,

Kreditkarte (mit Angabe des Ablaufdatums) oder per Auftrag zugunsten Beha-Amprobes

beglichen werden.

Reparatur und Austausch innerhalb der Garantiezeit – Alle Länder

Bitte lesen Sie die Garantiebedingungen und prüfen Sie den Zustand der Batterie, bevor

Sie Reparaturleistungen in Anspruch nehmen. Innerhalb der Garantiezeit können sämtliche

defekten Prüfwerkzeuge zum Austausch gegen ein gleiches oder gleichartiges Produkt an

Ihren Beha-Amprobe-Distributor zurückgegeben werden. Eine Liste mit Distributoren in

Ihrer Nähe finden Sie im Bereich Vertriebspartner unter beha-amprobe.com. In den USA

und in Kanada können Geräte zum Austausch oder zur Reparatur auch an das Amprobe-

Servicecenter (Anschrift weiter unten) eingesandt werden.

Reparatur und Austausch außerhalb der Garantiezeit – Europa

In Europa können Geräte außerhalb der Garantiezeit gegen eine geringe Gebühr von Ihrem

Beha-Amprobe-Distributor ausgetauscht werden. Eine Liste mit Distributoren in Ihrer Nähe

finden Sie im Bereich Vertriebspartner unter beha-amprobe.com.

Beha-Amprobe

Abteilung und registrierte Marke von Fluke Corp. (USA)

Deutschland*

In den Engematten 14

79286 Glottertal

Deutschland

Telefon: +49 (0) 7684 8009 - 0

beha-amprobe.de

Vereinigtes Königreich

52 Hurricane Way

Norwich, Norfolk

NR6 6JB United Kingdom

Telefon: +44 (0) 1603 25 6662

beha-amprobe.com

Niederlande – Hauptsitz**

Science Park Eindhoven 5110

5692 EC Son

The Netherlands

Telefon: +31 (0) 40 267 51 00

beha-amprobe.com

* (Nur Korrespondenz – weder Reparatur noch Austausch über diese Adresse. Europäische

Kunden wenden sich bitte an ihren Distributor.)

**Einzelne Kontaktadresse in EEA Fluke Europe BV

This manual suits for next models

2

Table of contents

Languages:

Popular Security Sensor manuals by other brands

Cooper

Cooper OSC-DT-1000 installation instructions

B.E.G.

B.E.G. LUXOMAT PD4-M-DIM-Corridor Series Installation and operating instruction

elobau

elobau 120 2 Series manual

Sonotec

Sonotec SONOCHECK ABD05 Series operating manual

ooma

ooma Smart Security Door and Window Sensor quick start guide

NAPCO

NAPCO IQ PROFILER - brochure

Genius KYE Systems

Genius KYE Systems WCS-110 user manual

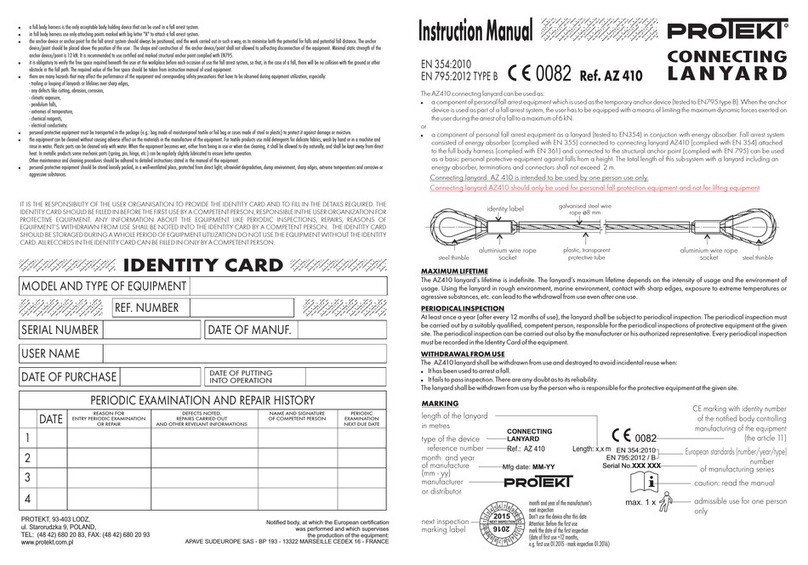

Protekt

Protekt AZ 410 instruction manual

Parker

Parker icountPD user manual

KTR

KTR Radisen PEDRA-1417M user manual

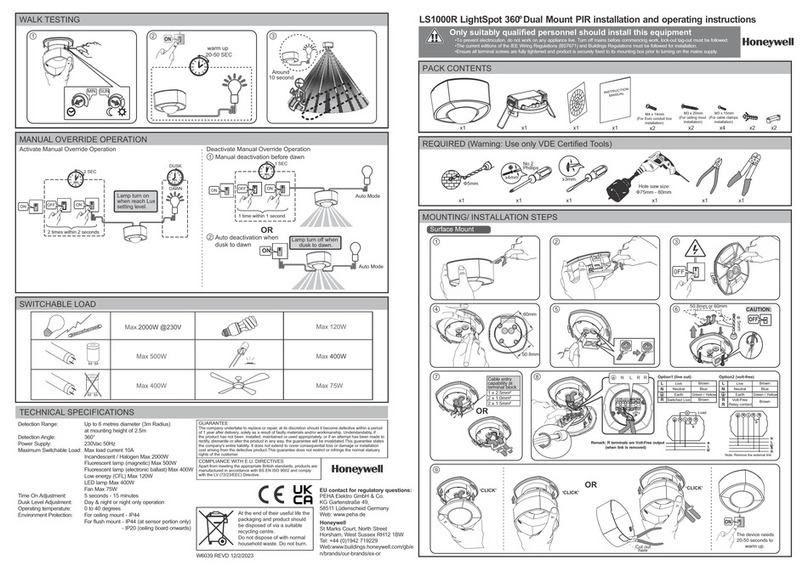

Honeywell

Honeywell LightSpot LS1000R Installation and operating instructions

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY CMDN Installation operation & maintenance