Behlen Country AHW100 User manual

F-20404-4 TECHNICAL INFORMATION 70118 Rev. 1-10-19 10-3-05

Extreme Weather Poly Electric Drinker

Model AHW100 (54150158)

CUSTOMER SERVICE CENTER

PO Box 569

Columbus, NE

68602-0569

Ph: 800-447-2751

Fax: (402) 563-7447

www.behlencountry.com

Hardware Kit

54900078

THANK YOU FOR PURCHASING THIS PRODUCT

Behlen Country has been in the business of providing quality products for more than 80 years.

Our products will provide many years of service when maintained by the owner and used in

accordance with the capabilities of the product. For questions about this product,

or for parts inquiries, please contact our Customer Service Center listed below.

Before beginning, please read the

instructions thoroughly to make sure you

have all of the necessary components for

your installation.

Location of the Drinker

If you are installing your drinker in a new

location some things can be done to enhance

the performance of your drinker and lower your

operating costs. If the drinker can be located in

a sheltered area, especially shielded from the

north wind, then the heater will need to operate

less and livestock will be more likely to drink

more.

However, we realize that it is not always

possible to locate the drinker in a sheltered

area, but even if the drinker is exposed and out

in the open, it would still be advantageous by

locating the drinker with the access door to the

south.

Water Supply Line

When installing your drinker please comply

with all local plumbing codes. The horizontal

underground water supply line should be ¾”

with a ¾” supply riser pipe. A ¾” I.D. pressure

hose is supplied with your drinker. We suggest

connecting the flex hose with 3/4” NPT x 3/4”

hose barb connectors and hose clamps (these

can be purchased locally) to the riser pipe.

If desired, a shut-off valve can be installed

under the drinker to allow for easier servicing.

NOTE: If the heat is going to be shut off during

the winter, a means must be provided to drain

the supply line down below the frost line to

prevent freezing of the riser pipe. Tip: Behlen

Country has a Shut-Off Valve Kit (54130168)

that can be used to shut off the water supply

and drain the riser pipe.

Before hooking up your drinker, the supply

line MUST BE flushed to ensure that no

contaminates will foul the valve upon start up of

your drinker. NOTE: Your drinker is equipped

with an MC valve that is easy to clean and

adjust. If low water pressure conditions exist

and a higher flow rate is desired, a larger inlet is

available (3888247).

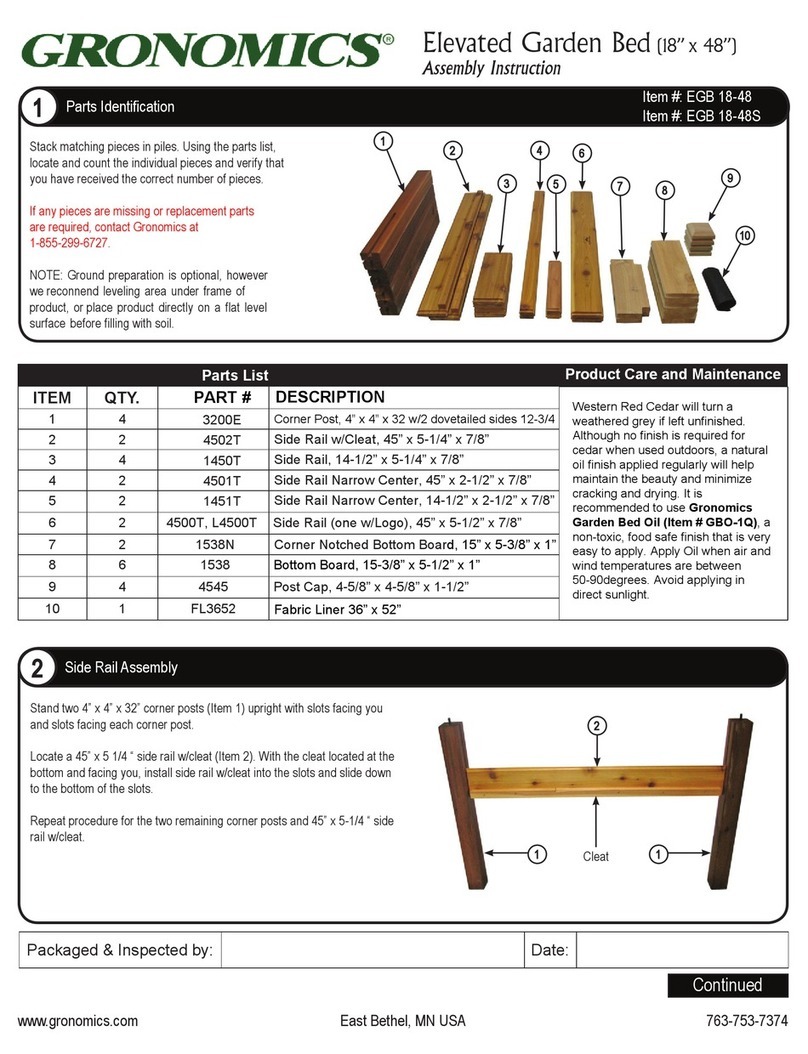

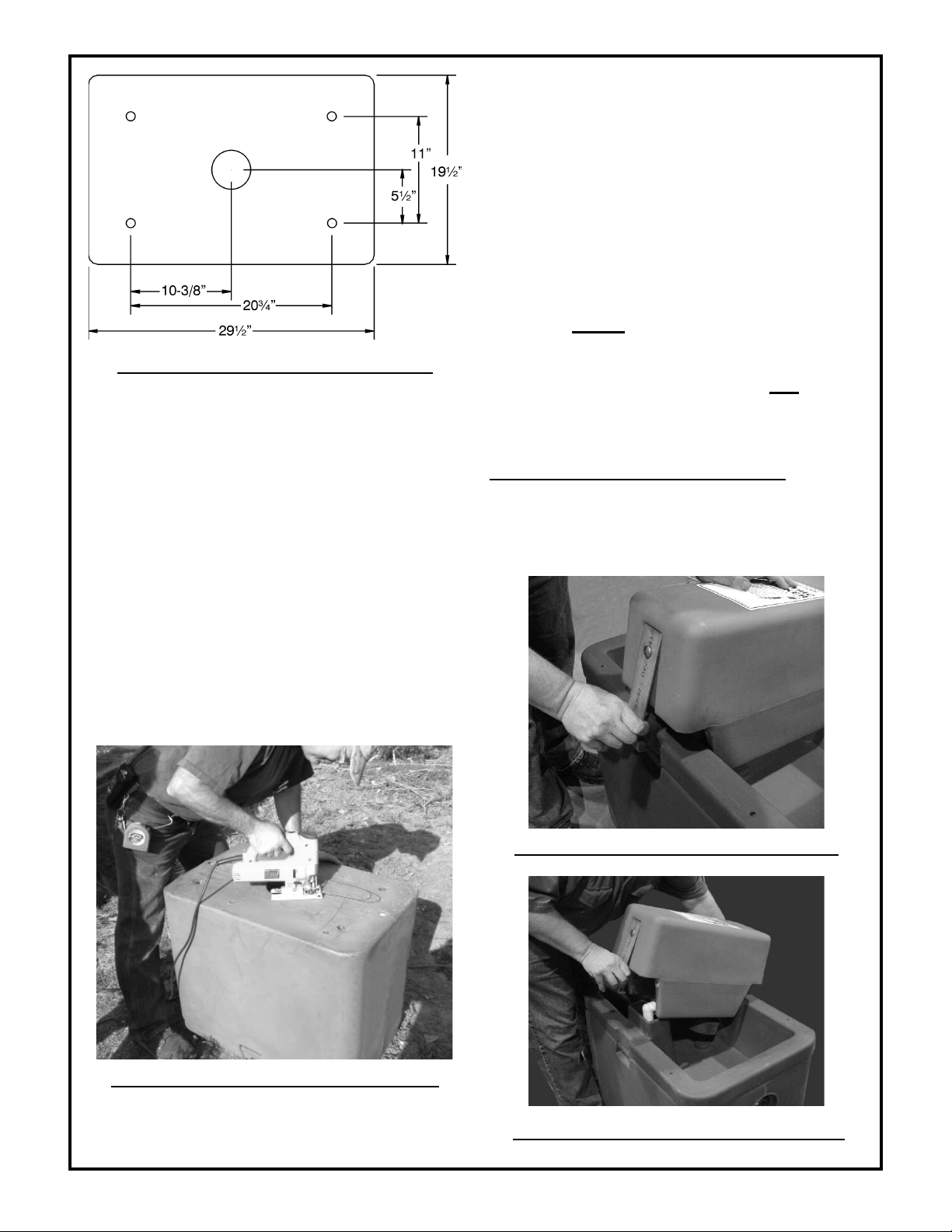

Preparing the Mounting Platform

Install the drinker on a 4” (minimum) thick

concrete base, slightly raised above the ground

level for better drainage. (Note: The pad should

be a minimum of 4” larger than the drinker.)

For the AHW100 Drinker, a 24” x 34” minimum

pad is required. If you are replacing a drinker

and going to use an existing platform made

for a different drinker, it must have a 24” x 34”

flat mounting area. If it doesn’t have a large

enough area, you can pour a cap over the

existing platform to enlarge it or replace the

platform.

Extending the platform provides animals with

a secure place to stand while drinking. If you

extend the platform beyond the minimum it is

advisable to slope the platform outside of the

mounting area to promote better drainage.

A smooth surface is recommended for the

mounting area of the drinker and rough surface

on the area where the animals will stand to

drink. If you are pouring a new platform you

have the option of using anchor bolts set into

the concrete when wet or drilling and using

expandable anchor bolts after the concrete

has cured to mount your drinker. Refer to

illustration # 1 for detailed measurements of the

hole pattern.

F-

Illustration #1 - Anchor Bolt Placement

Illustration #2 - Enlarge Hole As Needed

Illustration # 3A - Pull on Latch Handles

Illustration # 3B - Removing Float Cover

Before pouring the concrete, have the water

line routed up through a 4” or larger tile in the

center of the pad for final connections to the

drinker. Tip: Behlen Country poly earth tubes

(54130038) are an excellent way to route water

to your drinker. Also, if electrical power is going

to be routed underground to your drinker, an

appropriate conduit for the electrical service

must be installed at this time also. Please follow

local electrical codes and use the recommended

materials to route power to your drinker. Note: If

you are using an existing platform and the water

supply line is not in the center of the platform,

you can enlarge the existing opening as required

with a jig saw. If this is done, it is recommended

that the exposed foam be coated with silicone

sealant. See illustration 2 for details.

Make sure the tile or earth tube extends below

the frost line for your area. The tile or earth tube

must be left open to give access to warmer air

from below the frost line, thus preventing the

riser from freezing. If the soil in your area does

not drain well it is recommend that a gravel

bed be used under the earth tube to promote

drainage if water happens to get in the earth

tube. The top of the earth tube should be flush

with the platform to allow flush mounting of the

drinker.

Be sure the riser pipe does not touch the sides

of the earth tube. If desired, a shut-off valve can

be installed under the drinker to allow for easier

servicing. NOTE: If the heat is going to be shut

off during the winter a means must be provided

to drain the supply line down below the frost line

to prevent freezing of the riser pipe. Tip: Behlen

Country has shut-off valve kit (54130118) that

can be used to shut off the water supply and

drain the riser pipe.

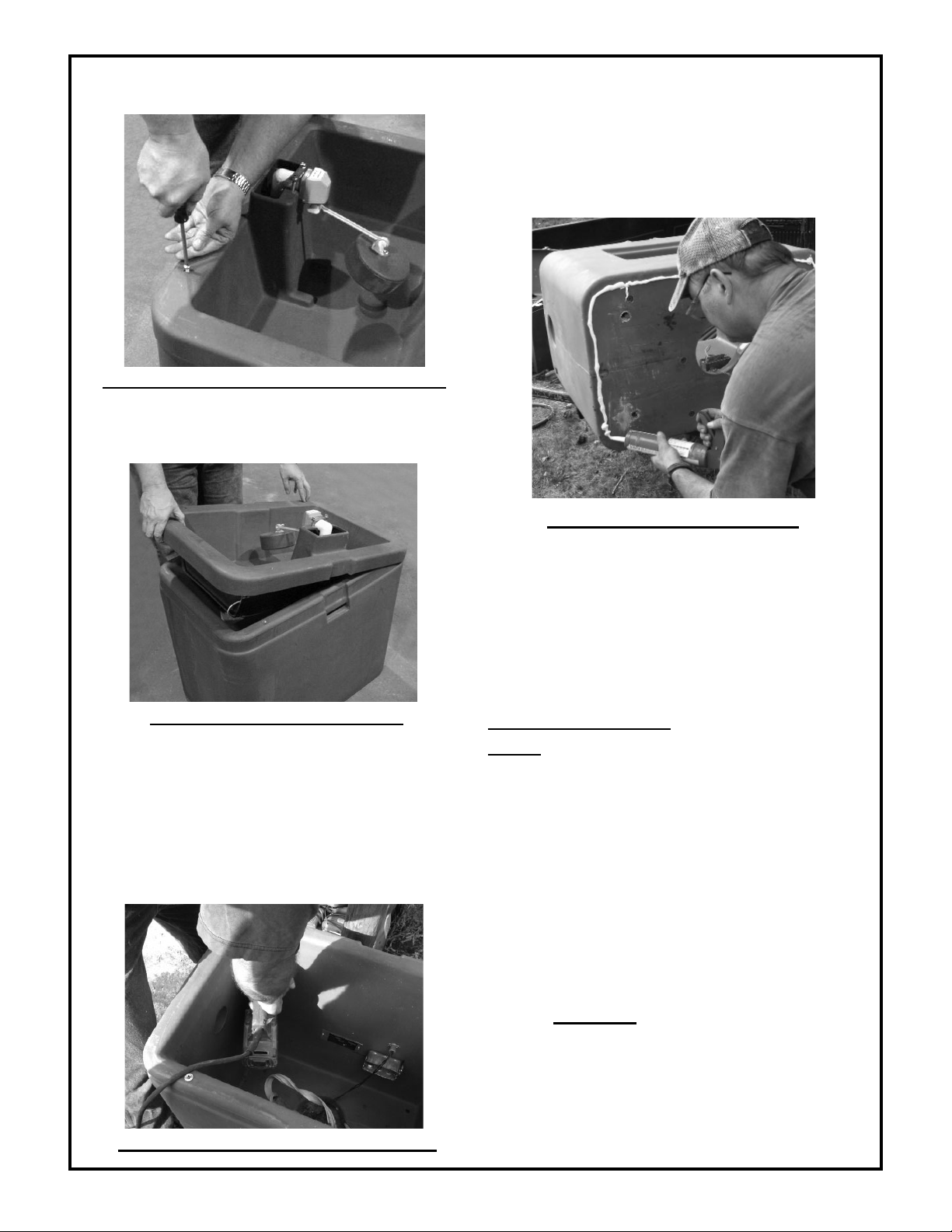

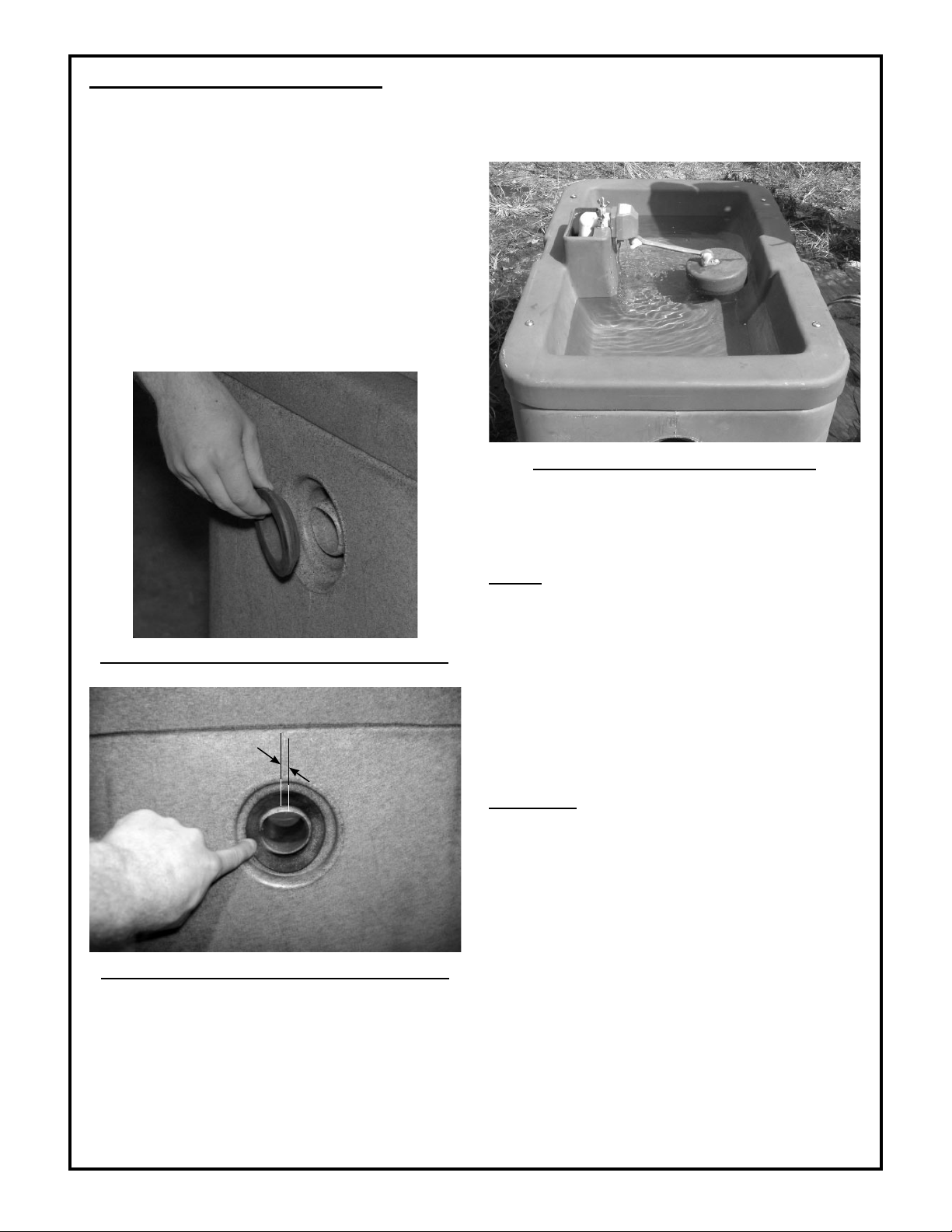

Mounting the Drinker to the Platform

To make mounting your drinker easier it is best

to disassemble it first. Remove the float cover

by pulling out on the two latches, see illustration

3A and 3B.

F-20406 10-3-05

Illustration 7 - Caulking Bottom

Illustration 5 - Removing Basin

Illustration 4 - Removing Screws From Top

Illustration 6 - Transfer & Drilling Holes

Next remove the four screws from the rim of the

basin, illustration 4.

You can now remove the basin with the heat pad

assembly by lifting up on the rim of the basin

opposite of the drain, illustration 5.

You will now have three pieces, the float cover

assembly, the basin assembly and the base

assembly.

If you are using expandable anchor bolts,

proceed as follows: Center the drinker base

assembly on the pad and transfer the mounting

hole locations to the pad, illustration 6.

Following these marks drill four 3/8” dia. x 2”

deep holes in the concrete platform. Turn the

drinker on its side and apply caulking around

the bottom outer edge and center opening.

Make sure to apply enough caulking to seal

any irregularities between the drinker and the

platform, see Illustration # 7.

Secure the drinker base to pad using four 3/8”

x 4” expandable anchor bolts with 3/8” fender

washer (purchased locally),

While the basin is off, it is good time to install

the ¾” hose barb connection to the riser pipe.

Reinstall the basin assembly to the base and

remove the side access door. You can leave the

float cover off until the water level is adjusted.

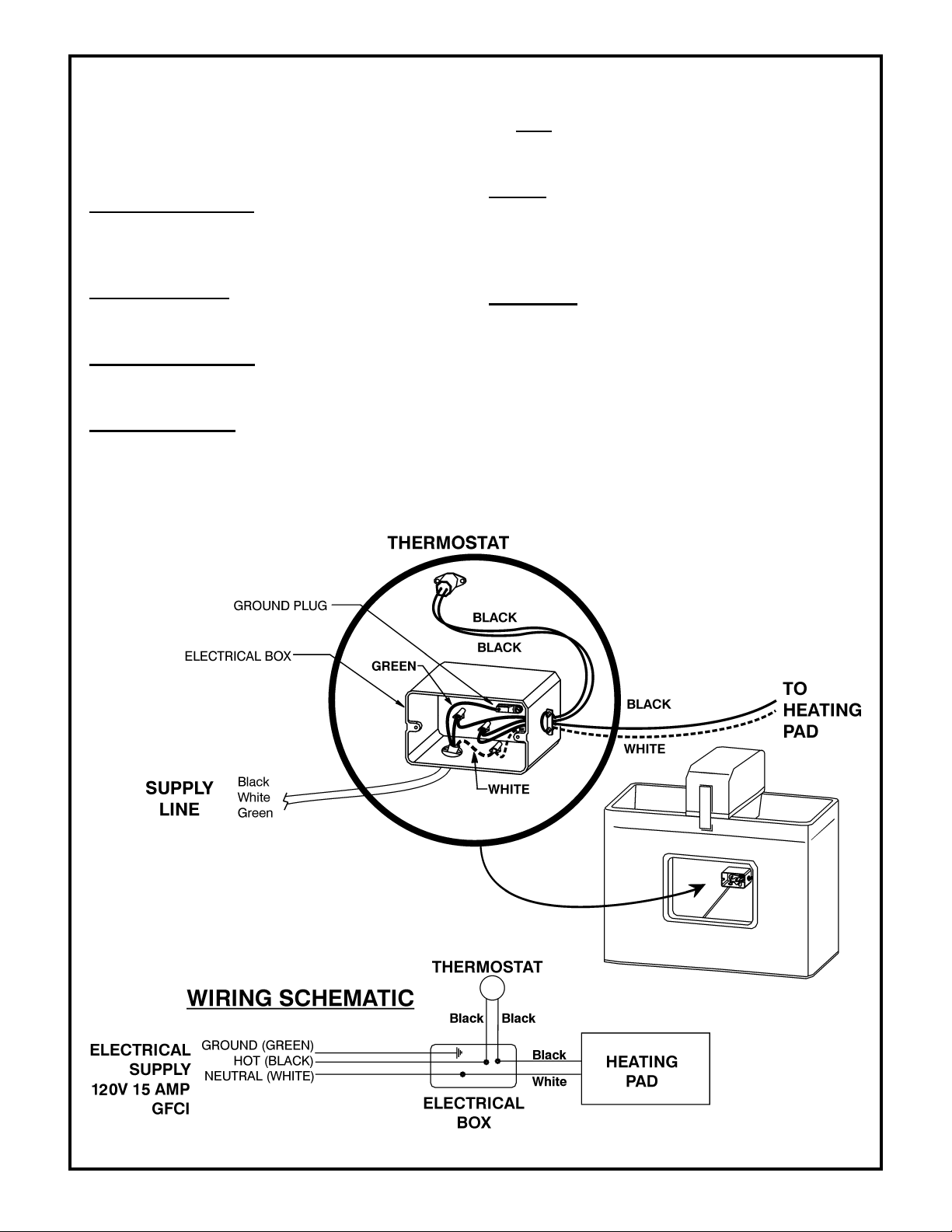

Electrical Connections

NOTE: Electrical connections should be

made by a qualified electrician and all local

codes need to be followed. The heating pad

is 220 watt, 120 volt AC, 1.8 amp unit. It is

thermostatically controlled so it only operates

when there is a demand for heat. It is

recommended that you shut off the power to the

drinker during warm weather when heat is not

required.

A 120 volts of AC power that is grounded and

contains Ground Fault Circuit Interruption (GFCI)

is required to operate this drinker. Normally,

a 15 amp power supply is used to power the

drinker. CAUTION: This drinker contains live

electrical components, disconnect the power

before servicing.

There are three connections and a ground that

are required to connect your drinker. These

connections are to be made with the three

supplied DRYCON wire nuts. These wire

F-20407 10-3-05

nuts are silicone filled and provide maximum

protection against moisture. They are a

one time use connector so, if reconnection

is necessary new wire nuts will need to be

obtained. All connections should be made

inside the electrical box.

Ground Connection: The green (ground) wire

from the supply line connects to the grounding

lug inside the electrical box. The wiring will be

easier if you hook up the ground wire first.

First Connection: A black and a white come

from the heating pad. The white wire connects

to the White (neutral) wire of the supply line.

Second Connection: The black wire from the

heating pad connects to either one of the two

black wires of the thermostat.

Third Connection: The other black wire from

the thermostat connects to the black (hot) wire

of the supply line.

Refer to the illustration below for details and

schematic of this wiring connection.

Do NOT turn on the power until after the water

connections have been made and tested to

assure that there are no leaks.

NOTE: The use of the riser pipe as the

grounding rod is not recommended. This is

due to the extensive use of plastic pipe on

the farmsteads and the unknown grounding

properties of the existing pipe on the site.

WARNING: Compliance with the national

electric code (CSA in Canada) and local

electrical codes must be made and maintained

when installing the drinker. Failure to comply

and maintain the drinker to code could result in

loss of livestock, severe personal injury, or even

death.

F-20408-2 Rev. 1-10-19 10-3-05

Illustration 9 - Foam Sealing Ring Installed

Illustration 8 - Installing Foam Sealing Ring

Illustration 10 - Setting Water Level

1/4”

Water Hookup and Float Adjustment

When cutting the flex hose, leave a little extra

length to allow for movement of the platform

during cold weather. However, do not leave too

much length or the hose will kink and restrict

the water flow. Slide the hose over the barb and

secure it with the hose clamp. Make sure all

connections are tight.

Insert the foam sealing ring coneside first from

the outside of the drinker. Push the edges of the

ring with finger so that the ring is in a quarter of

an inch past the rim. The drain plug is installed

in the end of the drain spout from the outside of

the drinker. See Illustrations #8 & 9).

The water can now be turned on and the float

level set.

Adjust the float by using the two thumb screws.

Set the float to maintain a water level in the

trough of 1” to 1½” below the top of the rim of

the trough. See illustration 10.

Check all connections for leaks and if none are

present the power can be turned on to the unit

and the access door installed.

NOTE: Your drinker is equipped with an MC

Valve that is easy to clean and adjust. If low

water pressure conditions exist and a higher

flow rate is desired, a larger inlet is available

(3888247).

If you encounter problems after hooking up your

drinker, please refer to the trouble shooting chart

for information on possible solutions.

Warranties

All Behlen Country Electric Drinkers carry a 5

year limited warranty on the body and a 1 year

limited warranty on the valve and controls.

F-20201-2 Rev. 1-101-9 11-4-04

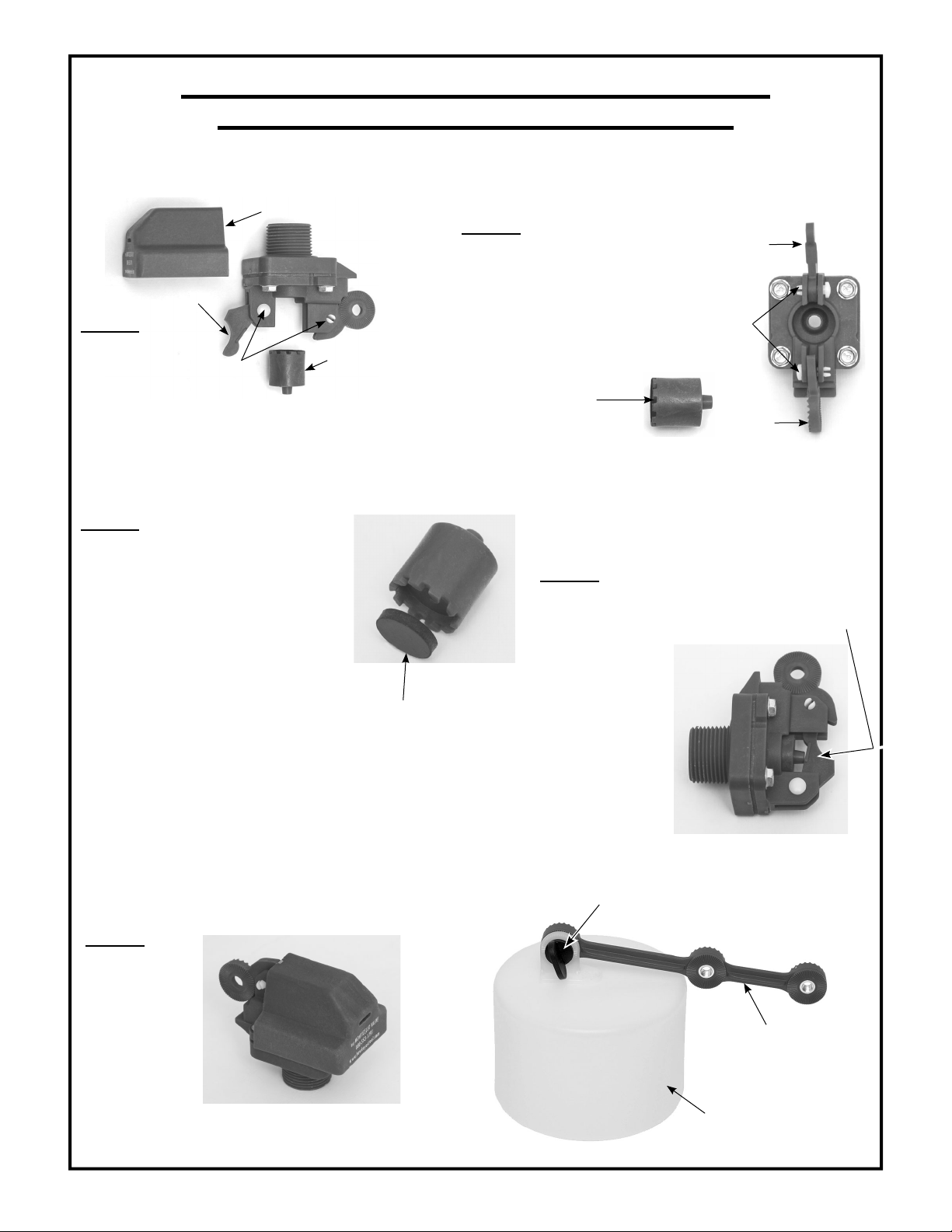

STEP 5

Replace the

Cover to

complete the

cleaning of

the Valve.

STEP 3

If the Rubber Seal is grooved but

still pliable (not hard and brittle),

you may flip it over and use the

backside of the seal. If both sides

of the Seal are hard, replacement

Seals are available. In some

instances both the Plunger

and the Seal may need to be

replaced.

STEP 2

Clean the Rubber Seal in the

Plunger and opening to the

Valve of any mineral deposits

or dirt buildup that may

be obstructing the normal

operation of the Valve.

Rubber Seal is

inserted inside Plunger

Rubber Seal

Plunger

Upper Arm

Plunger

w/seal

Cover

Pins

STEP 1

Slide off Cover,

pivot Upper

Arm up, and

remove the

Plunger.

Upper

Arm

Lower

Arm

Pins

STEP 4

Replace the Plunger with the nipple facing

out, and the rubber facing the valve. Pivot

Upper Arm down over Plunger.

Float

Float Arm

Thumb

Screw

Complete

Assembly

Instructions for Cleaning the MC Valve

and Replacing the Plunger & Seal

F-20569-2 Rev. 1-10-19 3-17-08

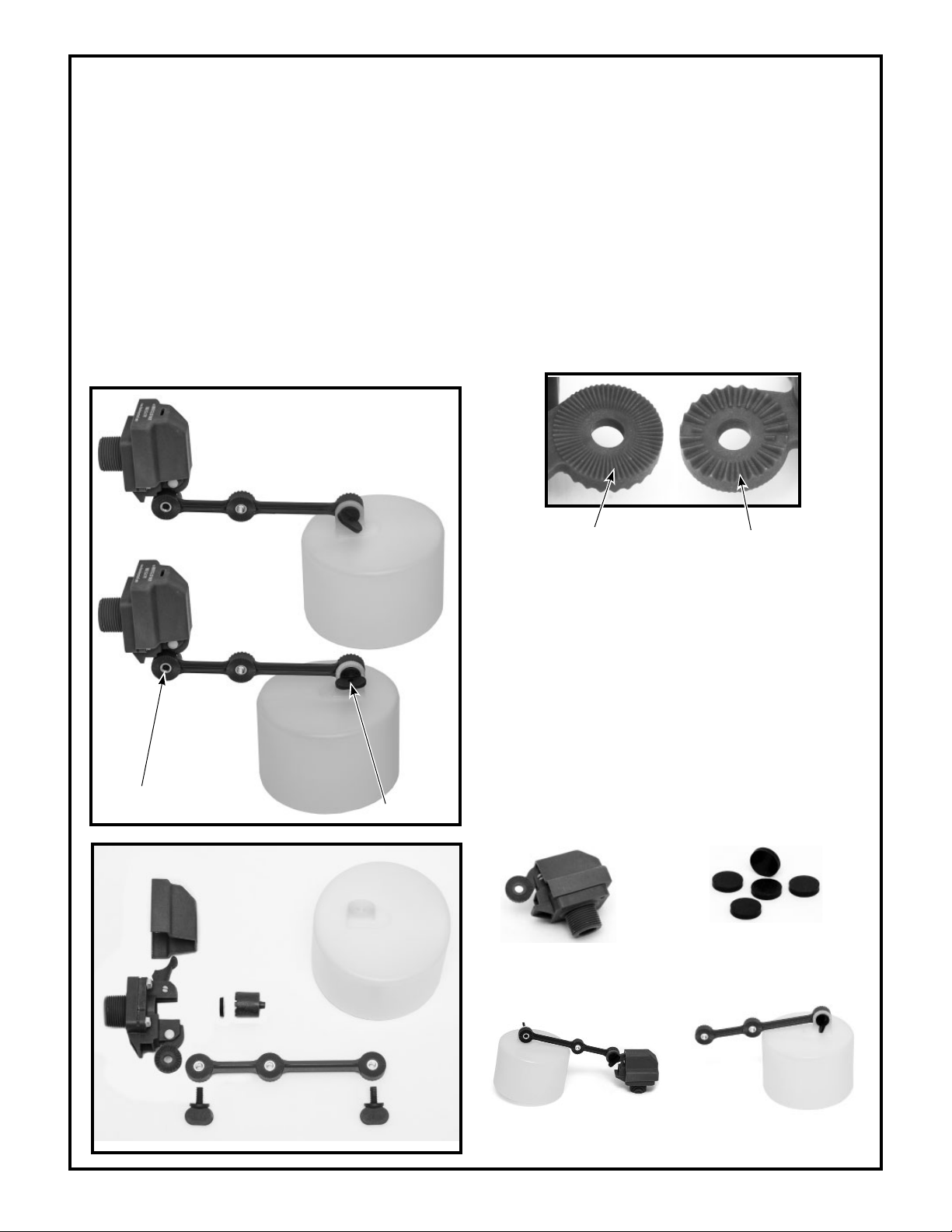

Instructions How To Assemble The Float And Arm To

The MC Valve And How To Adjust The Valve

The MC Valve is already attached to the

drinker. The float and arm assembly is with the

hardware kit. They are packaged separately to

prevent undue wear to the valve caused by the

arm bouncing up and down during shipping.

The float and arm are attached to the valve by

a thumb screw. The float can be positioned

either closer or further away from the valve (see

photo below left for the two float positions).

Further away increases the shut off force of

the valve. However depending upon which

drinker is being used, the closer position may

be required to maintain proper clearance for

the float to the side of the drinker. A clearance

of at least 1/2” should be maintained to ensure

smooth operation of the valve.

When attaching the float arm to the valve, be

sure to attach the arm to the correct side of the

valve. The grooves on the valve and float arm

must match. Please note that the valve has

coarse grooves on one side and fine grooves

on the other. The fine grooved side is used with

the float arm (see below for details).

To adjust the water level in the drinker, loosen

the thumb screws and position the float and arm

so that the valve is turned off when the water is

at the desired level (see photo at left). It may

take a couple of adjustments to get the correct

level (1-1½” below the top of the trough). To

speed the adjustment process, remove the drain

plug and drain a little water out so that the valve

turns on. Put the drain plug back and let water

fill until the valve shuts off. If the level is not

correct, repeat the process until the correct level

is obtained and then replace the float cover.

Your drinker is now ready for use.

Adjust

Adjust

Fine Coarse

Parts for MC Valve

MC Valve Only

3888245S

MC Valve & Float Ass’y

3888244S

MC Float Ass’y

3888251S

Rubber Seals for MC

Valve 54300988

(Pkg of 5)

F-20409 10-3-05

TROUBLE SHOOTING CHART

For Behlen Country Electric Drinkers

Ice in

Trough

•Check fuses or circuit breakers.

•Check to see if there are any gaps that allow cold air to enter the base of the

drinker.

- Make sure the fountain is sealed from wind between the concrete platform and

bottom of the drinker.

- Make sure there are no air leaks around the access door.

•Check to make sure that you have a full 120 volts at the drinker and that the 120

volts are maintained when the heater is on.

•Check the heating elements to make sure they are working and hot.

•Check that heater is wired properly.

•Check voltage after thermostat to fountain with and without electrical load (Note: to

close the thermostat to complete the circuit, hold a piece of ice in a plastic bag next

to sensing surface).

•Adjust thermostat to higher temperature by moving it further away from the heat

pad (make moves in 2” steps).

Water

Freezing in

the Valve or

Supply Line

•Make sure supply line is properly installed.

- Riser tube with supply line centered, and there is an air space between riser tube

and supply line.

- Horizontal supply line is at least 1’ below frost line.

• Check for missing or damaged insulation.

• Check for air gaps against wind penetrations.

- Make sure the fountain is sealed from wind between the concrete platform and

bottom of the drinker.

- Make sure there are no leaks around the access door.

- Make sure that the latches are holding the float cover securely to drinker. If the

latches are loose, adjust spring tension on the latch and, if necessary, bend the

latch ends in vise thus enabling the latches to hold the cover tighter.

Valve

Won’t

Stop

Dripping

or

Shut Off

•Check the float adjustment. Check for waterlogged float, or float rubbing on side of

the valve compartment. Ensure that the float moves freely.

•Disassemble valve and check for sand or scale in valve rubber. Also check valve

orifice outlet for wear and damage. A screen or filter may be required with sandy

or scaly water. Please refer to the valve cleaning instructions supplied with your

drinker.

•Turn valve rubber over and re-assemble.

•Check for excessive water system pressure (greater than 55 psi). If needed, change

to our higher pressure APEX valve, or install a pressure regulator, available at most

plumbing shops.

Low Water

Flow

•Check that the valve inlet is not plugged or supply hose is not kinked.

•Check system pressure from supply hose by installing a tee and a pressure gauge

directly in front of the valve and then check pressure drop when valve is open. A

severe pressure drop indicates a restriction or undersized supply system.

•Check that shut off valves are fully open.

This manual suits for next models

1

Table of contents

Other Behlen Country Lawn And Garden Equipment manuals

Behlen Country

Behlen Country 80900240 User manual

Behlen Country

Behlen Country AHW30 Manual

Behlen Country

Behlen Country M-15 User manual

Behlen Country

Behlen Country Arena Ace 80117385 Reference guide

Behlen Country

Behlen Country 80900190 Installation instructions

Behlen Country

Behlen Country 80119070YEL User manual