2

Safety, performance, and dependability have been given

top priority in the design of your petrol pole pruner.

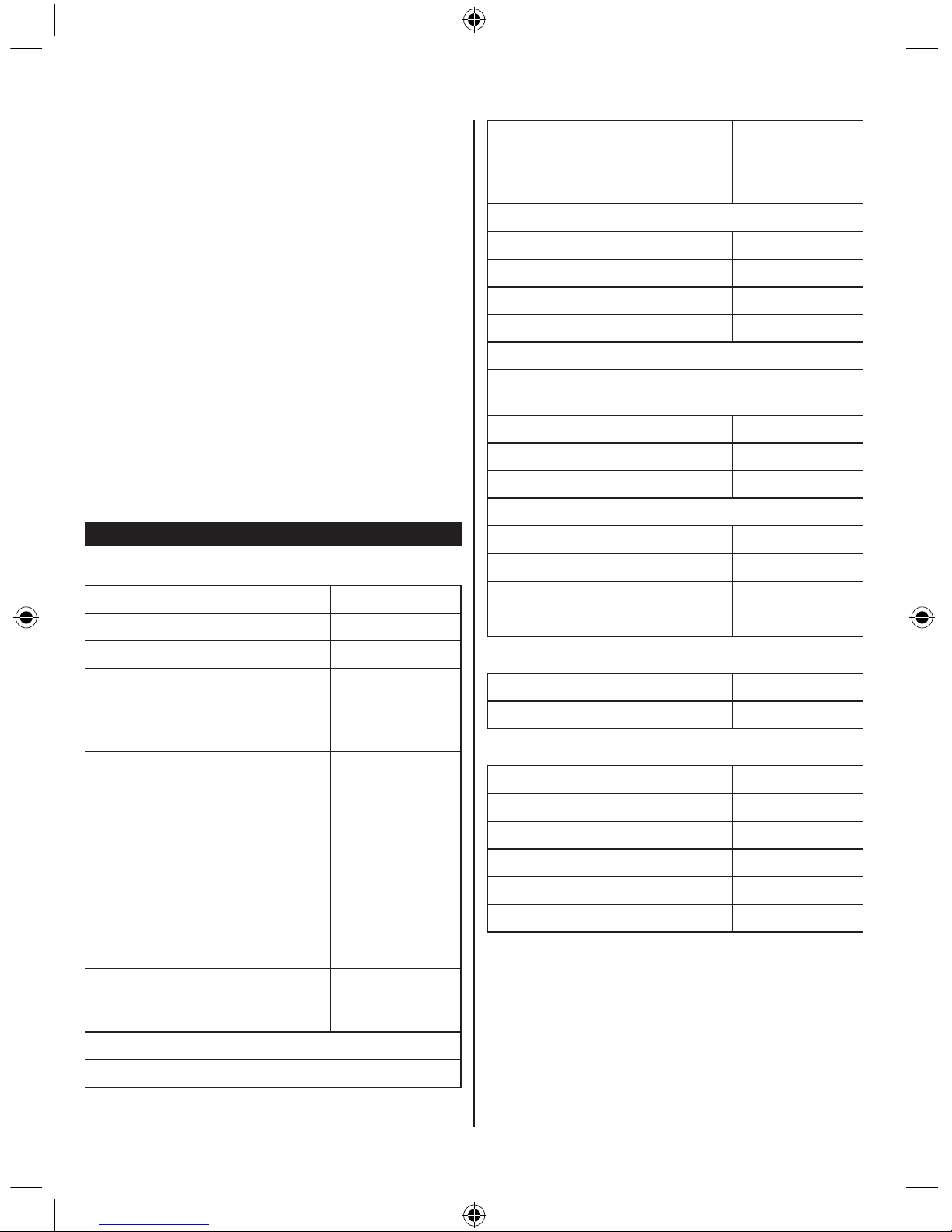

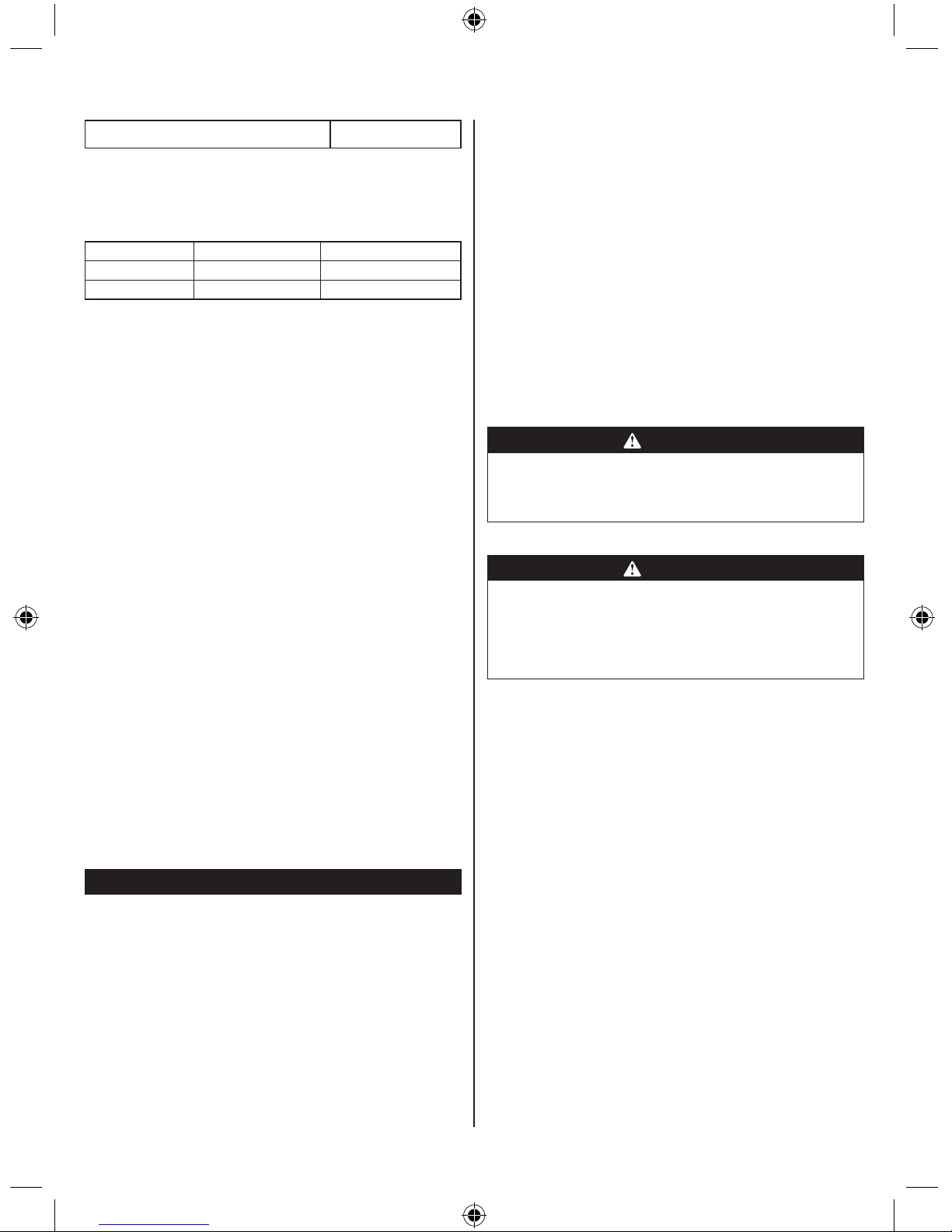

INTENDED USE

The petrol pole pruner is only intended for use outdoors.

For safety reasons, the product must be adequately

controlled by using two-handed operation.

The product is designed for cutting and pruning of small

limbs and branches whose diameter is less than or equal

to the bar length, and are located high in the tree while the

operator maintains a steady footing on the ground. The

product is designed to be extended to a maximum length

of 2.7 m. Do not exceed this working length.

It is not intended to be used while climbing or as a

conventional chainsaw for close quarter limbing and

pruning of material at ground level.

Do not use the product for any other purpose.

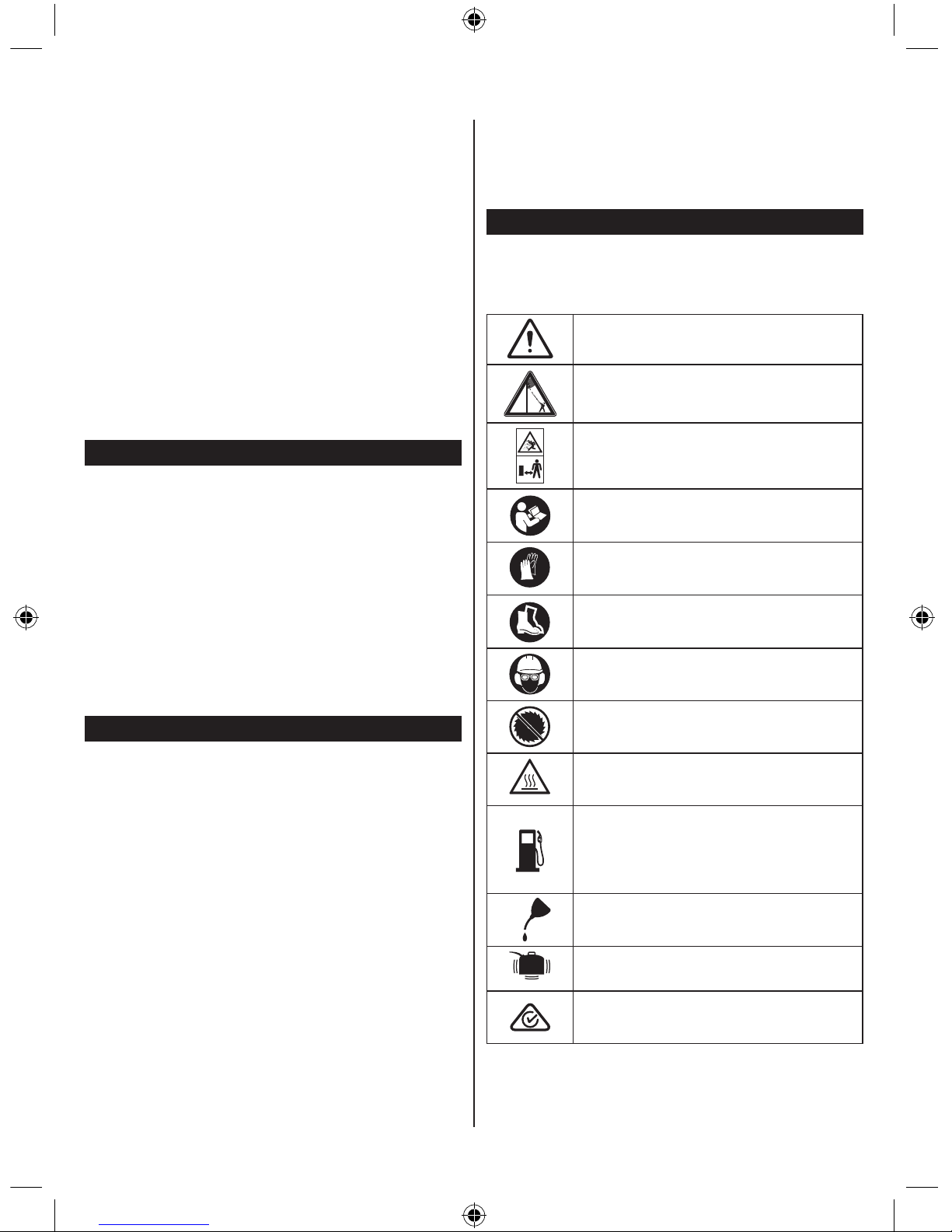

GENERAL SAFETY WARNINGS

WARNING

For safe operation, read and understand all

instructions before using the product. Follow all

safety instructions, information on correct working

posture, the need for rest periods, and changing working

positions. Failure to follow all safety instructions listed

below, can result in serious personal injury.

READ ALL INSTRUCTIONS

■Do not allow children or untrained individuals to use

the product.

■Never let anyone use the product who has not received

adequate instructions in the product’s proper use. This

applies to rentals as well as privately owned products

and also to the power head it is attached to.

■Always wear safety glasses with side shields.

Everyday glasses have only impact resistant lenses.

They are NOT safety glasses. Following this rule will

reduce the risk of eye injury.

■Product users in some states, must comply with fire

prevention regulations. The product is equipped with

a spark arrestor; however, other user requirements

may apply. Check with your federal, state, or local

authorities.

■Wear eye, hearing, and head protection when

operating the product. Hearing protection may restrict

the operator’s ability to hear warning sounds, pay

particular attention to potential hazards around and

inside the working area.

■Wear heavy-long pants, boots, and gloves. Do not

wear loose fitting clothing, short pants, or go barefoot.

Do not wear jewellery of any kind.

■Heavy protective clothing may increase operator

fatigue, which could lead to heat stroke. During

weather that is hot and humid, heavy work should be

scheduled for early morning or late afternoon hours

when temperatures are cooler.

■Never operate the product on the operator’s left side.

■Secure long hair above shoulder level to prevent

entanglement in moving parts.

■Keep all bystanders, children, and pets at least 15 m

away. Bystanders should be encouraged to wear eye

protection. If you are approached, stop the engine and

cutting attachment. In the case of bladed units, there is

the added risk of injury to bystanders from being struck

with the moving blade in the event of a blade thrust or

other unexpected reaction of the saw.

■Do not operate the product when you are tired, ill, or

under the influence of alcohol, drugs, or medication.

■Do not operate in poor lighting. The operator needs

clear unrestricted vision to identify potential hazards.

■Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or exposure

to hot surfaces.

■Keep all parts of your body away from any moving

part.

■To avoid hot surfaces, never operate the product with

the bottom of the engine above waist level.

■Do not touch area around the muffler or cylinder of the

product. These parts get hot from operation. Failure

to heed this warning could result in possible serious

personal injury.

■Carry the pruner with the engine stopped, the guide

bar and saw chain to the rear, scabbard on the guide

bar and saw chain, and the muffler away from your

body.

■Always stop the engine before making any

adjustments.

■Inspect the product before each use for loose

fasteners, fuel leaks, etc. Replace any damaged parts

before use.

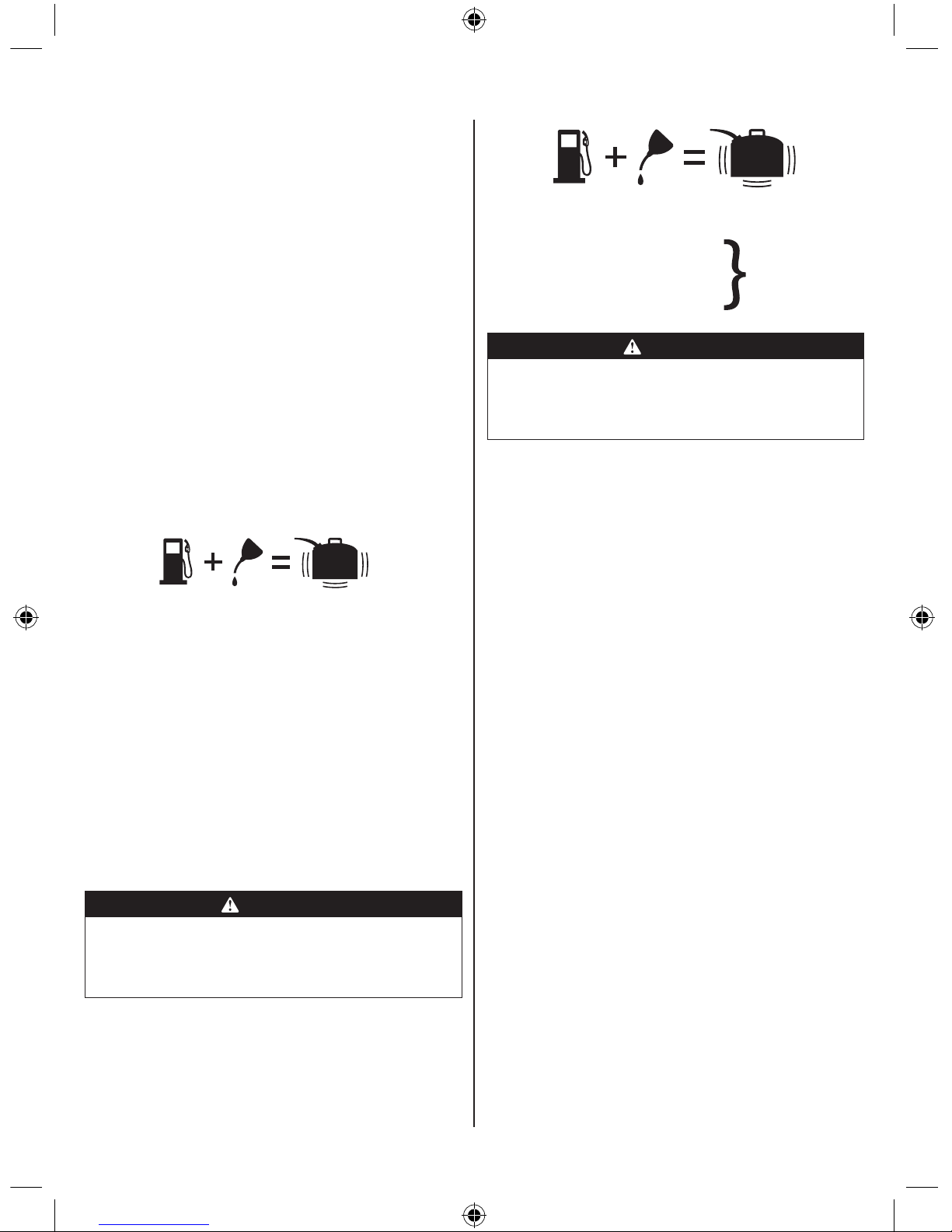

■Mix and store fuel in a container approved for petrol.

■Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 9 m away from

refueling site before starting engine.

■Stop the engine and allow to cool down before

refueling or storing the product.

■Allow the engine to cool, empty the fuel tank, and

secure the product from moving before transporting in

a vehicle.

■Stop the engine. Make sure all moving parts have

come to a complete stop:

●before servicing

●before leaving the product unattended