BEHLMAN INV 2500 Use and care manual

0

USER'S GUIDE AND

TECHNICAL REFERENCE

DC TO AC INVERTER

BEHLMAN MODEL INV 2500

FOR SERVICE ASSISTANCE

CONTACT BEHLMAN

CUSTOMER SERVICE DEPARTMENT

PHONE TOLL FREE 1-800-874-6727

OR WRITE

BEHLMAN

CUSTOMER SERVICE DEPARTMENT

80 CABOT COURT

HAUPPAUGE, NY 11788

PHONE: (631) 435-0435

FAX : (631) 951-4341

FOR SALES INFORMATION:

PHONE: (631) 435-0435

USA : (800) 874-6727

FAX : (631) 951-4341

DATE:01/13 REV. 1

1

SAFETY SUMMARY

The following safety precautions must be observed during all phases of operation,

service, and operation of this equipment. Failure to comply with these precautions

or with specific warnings elsewhere in the manual violates safety standards

associated with the design and intended use of this equipment.

GROUND THE EQUIPMENT

To minimize shock hazard, the equipment chassis(s) must be connected to an electrical

safety ground (protective earth). This equipment is supplied with a three conductor line

connection for single phase applications and a five wire connection for three phase

applications. Both types include an earth terminal intended for safety ground

connections. Failure to use the protective earth connection may expose operating

personnel to hazardous voltages. In addition this earth connection provides a return path

for the equipment EMI filter(s).

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERE

Do not operate the equipment in the presence of flammable gases or fumes. Operation

of any electrical instrument in such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove equipment covers. Component replacement and

internal adjustments must be made by qualified maintenance personnel. Do not replace

components with power applied. Under certain conditions, dangerous voltage may exist

even with the power removed. To avoid injuries, always disconnect power and discharge

circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation is present .

DO NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT

Because of the danger of introducing additional hazards, do not install substitute parts or

perform any unauthorized modification to this equipment. Contact Behlman Electronics

for proper replacement parts and specific service information.

!DANGEROUS PROCEDURE WARNINGS

Warnings will precede potentially dangerous procedures in this manual. Instructions

contained in the warning must be followed.

2

CLAIM FOR DAMAGE IN SHIPMENT

Under the FOB factory terms of sale, ownership and responsibility are transferred to the customer when the

equipment leaves the factory. Each Behlman equipment is shipped from the factory in proper operating

condition.

Immediately upon receiving equipment, unpack and inspect it for evidence of damage incurred in shipment.

File a claim with the freight carrier if the equipment has been damaged in any way or it fails to operate

properly. Forward a copy of the damage claim report to Behlman. Include the model number, serial number

and date the shipment was received. Behlman will advise the disposition of the equipment and will arrange

for necessary repair or replacement.

RETURNING EQUIPMENT TO FACTORY

Do not return equipment to the factory without prior authorization from Behlman.

A RETURN MATERIAL AUTHORIZATION NUMBER (RMA) is required to return equipment.

This equipment, like all precision electronic equipment, is susceptible to shipping damage. It contains

heavy magnetic components as well as delicate electronic components.

If equipment is returned without prior authorization, the shipment will be refused, the customer being liable

for all shipping, handling and repair costs.

When packing for reshipment, use the original shock absorbent material and shipping container to preclude

damage to the equipment.

Insure that the return authorization numbers (RMA) is available on the container for identification.

SHIPPING INSTRUCTIONS

RACK MOUNTED UNITS

1) Box (es) must be double wall with minimum 350 lbs. bursting test.

2) Box (es) must provide for a minimum of 3to 4 inches of clearance around sides, top and bottom of

unit.

3) When packing unit, utilize either a foam-in-place system or high density foam. Clearance provided

for above must be completely filled with foam.

FAILURE TO COMPLETELY SECURE UNIT IN BOX WILL ALLOW

MOVEMENT DURING SHIPPING, RESULTING IN DAMAGE.

4) Secure box (es) to pallet (s). This is necessary to insure proper handling and protection during

shipping.

5) Place the following warning label on box (es)

DO NOT STACK

6) Ship unit (s) using a freight cargo carrier; air or ground.

CABINET MOUNTED UNITS

Cabinet mounted units require that a special crate be used. The crate should be manufactured of plywood

(3/8" or thicker) and reinforced (using 1 x 3 or larger pine) on all edges. The unit must be firmly secured to

the crate’s base. The crate must be shock mounted to avoid damage during shipping. Detail drawings for

Behlman's crates are available upon request.

3

WARRANTY CERTIFICATE

Behlman Electronics, Inc. warrants to the original purchaser, for a period of one (1) year from the

shipment from Behlman, each item to be free from defects in material and workmanship. Behlman’s

obligation and the Purchaser’s sole remedy for any breach or violation of this agreement is limited to

adjustments, repair or replacements for parts which have been promptly reported by the Purchaser as

having been in its opinion, defective and so found by Behlman upon inspection. All replacement parts will

become the property of Behlman on an exchange basis. This warranty will not apply if such adjustment

repair or parts replacement is required because accident, neglect, misuse, failure of environmental controls,

transportation damage or causes other than normal use.

If during the warranty period a defect should impair the performance of the unit, Behlman agrees, at its

option, to repair or replace the unit or its defective components F.O.B. Behlman at 80 Cabot Court,

Hauppauge NY 11788 or at another Behlman service facility at Behlman’s option. To obtain service under

this warranty, the original Purchase shall notify Behlman at the above address or by telephone at 631-435-

0410 and provide information about the defect or impairment of performance. Behlman with then supply

the Purchaser a Return Material Authorization (RMA) number. This number must be attached to the

equipment sent back for warranty repair. Equipment must be shipped back to Behlman prepaid. No collect

shipments will be accepted.

Behlman shall be excused from supplying warranty service if the unit’s case has been open or if the unit

has been subject to unauthorized repair. All service outside the scope of this warranty shall be paid for by

the Purchaser at Behlman’s rates in effect at the time of this repair. Behlman will not perform any repairs

outside of the warranty without written authorization by the Purchaser. If the repair is a warranty repair,

Behlman will ship the unit back to the Purchaser, by a method determined solely by Behlman, prepaid. If

the Purchaser requests, any other means of transportation it shall be at the Purchaser’s expense.

The use of the equipment shall be under the Purchaser’s exclusive management and control. The Purchaser

will be responsible for assuring the proper installation, use, management and supervision of the equipment.

Behlman will not be liable for personal injury or property damage.

The forgoing warranties are in lieu of all other warranties, expressed or implied including without

limitation warranties of merchantability and fitness for purpose.

In no event shall Behlman be liable for loss of profits, loss of use, or any indirect, consequential or

incidental damages. Purchaser agrees that Behlman will not be liable for any damages caused by the

Purchaser’s failure to fulfill any of the Purchaser’s responsibilities set forth herein.

4

TECHNICAL REFERENCE

MODEL SERIES INV2500 DC TO AC INVERTERS

TABLE OF CONTENTS

1.0 INTRODUCTION

1.1 Specifications

2.0 INSTALLATION

2.1 General

2.2 Wiring

2.3 Optional Alarm Contacts

2.4 Optional Step-up Transformer

3.0 OPERATING INSTRUCTIONS

3.1 Controls and Indicators

3.2 Optional alarm contacts

3.3 Operational Considerations:

Load Limitations

Powering Reactive Loads

Powering Lamps

Powering Motors

Powering Non-Linear Loads

4.0 TROUBLESHOOTING

4.1 Theory of Operation

4.2 Trouble Shooting

4.3 Maintenance

5.0 MECHANICAL OUTLINE

5

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 1

GENERAL INFORMATION

1.0 INTRODUCTION

The Behlman INV 2500 series of DC to AC power inverters incorporate the latest in

switched mode power technology to provide regulated AC power from a user

supplied DC source. These devices produce a sinewave output comparable to that

which is available from typical utility power. Each model provides electronic

protection along with a high short term overload capacity making them ideal for many

loads requiring large “in - rush” currents. All units are housed in a rugged steel

enclosure making them well suited to operation in industrial applications.

Available options include an AC input bypass and signaling contacts. The AC

bypass option is available in two configurations. The “DI” option favors the DC input

and will switch to AC when the DC input is lost. The second option , A1, will favor the

AC line input and will switch to the inverter if the line is lost. These features allow the

unit to be incorporated into a user defined back-up power system.

1.1 SPECIFICATIONS

INPUTS:

MODEL DC INPUT DC BURDEN (full load) DC BURDEN ( no load)

2500 - 125 125 DC +/- 20 % 31 AMPS @ 100 VDC 550 mA +/- 20%

2500 - 48 48 VDC +/- 20 % 80 AMPS DC @ 38 VDC 1.7 A +/- 20%

AC INPUT (optional bypass mode only) 130 Vac max @ 15 amps ( internal fuse )

OUTPUT

Power: 2500 VA

Voltage: 120 VAC +/-2% 60 Hertz ( available @ 50 and 400 Hertz)

220-240V output available with external transformer option.

Current: 21 amps RMS continuous ( 30 amps peaks )

Waveform: Sine wave with less than 3% T.H.D. ( linear load)

efficiency: Better than 85% at nominal input.

PROTECTION

Input: DC circuit breakers (optional AC input has 15 amp fuse)

Output: Electronic over current protected.

Thermal: Thermal cut-out monitors temperature. Shuts down during

Over-temp conditions. Automatic Reset.

MECHANICAL

10.45"H x 19" W x 19"D ( rack mountable)

ENVIRONMENTAL

Operating temperature 0 to +55C , 95% RH non - condensing

6

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 2

INSTALLATION

2.1 INSTALLATION

! WARNING

INSTALLATION AND OPERATION OF THIS DEVICE MAY EXPOSE HAZARDOUS

VOLTAGES. REFER TO QUALIFIED PERSONNEL ONLY.

The INV 2500 series inverters are designed to be installed in a standard 19" relay

rack or EIA type enclosure. The front panel has a set of “ears” provided for this

purpose. The mounting holes are designed to conform to EIA rack standards.

Mount the unit in a suitable location as not to block the flow of cooling air at the front,

rear, and sides of the inverter chassis. This device will pull in cool air from the front

and sides and exhaust warm air from the rear. It is recommended that a minimum

clearance of 3 inches be provided at the front and rear and 1 to 2 inches on the

sides. Enclosures must be vented.

When rack mounting,

DO NOT

mount the inverter by the mounting ears only. If

the unit is intended for use in a mobile or other high vibration application the use

of additional support for the rear of the chassis is mandatory.

2.2 WIRING

Wiring to the inverter will vary depending on input voltage and any options ordered.

In addition local electrical codes must be considered for permanent installations. The

NEC (National Electrical Code) requires that separately derived AC sources such as

back-up generators, inverters, etc., must have one output conductor tied to a

protective earth. This may be accomplished with the 2500 series by following the

recommended hook up diagrams provided here.

! WARNING

ALL INSTALLATIONS AND VERSIONS OF THIS DEVICE REQUIRE THE USE OF

THE SAFETY EARTH CONNECTION TO THE CHASSIS. FAILURE TO DO SO MAY

CREATE A SHOCK HAZARD. THE VOLTAGE AND CURRENT PRODUCED BY THIS

UNIT CAN BE LETHAL.

7

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 2

INSTALLATION

2.2 WIRING ( continued )

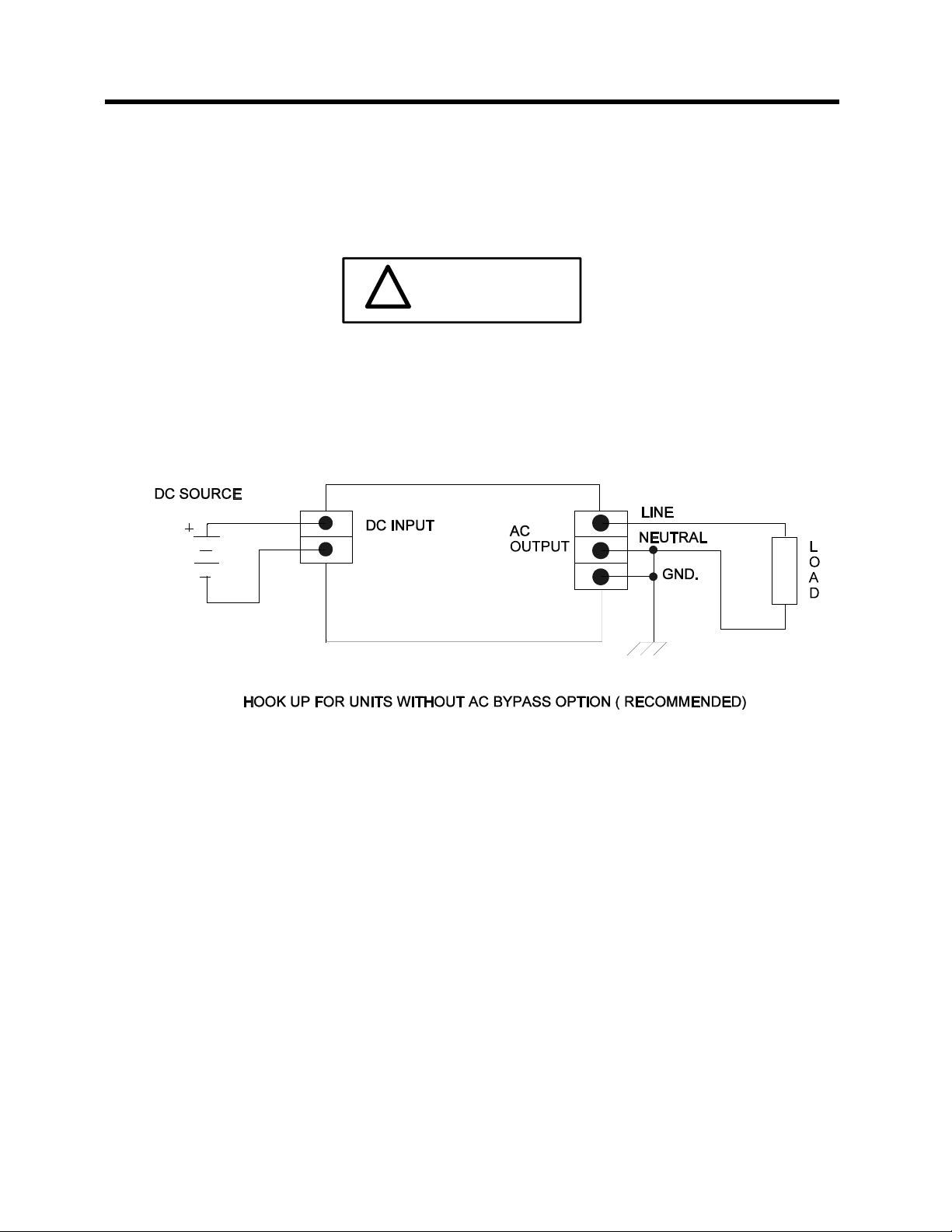

Figure 2-1 illustrates the wiring for models that do not include any options. The units

have two a screw type terminal block located on the rear panel. Compatible loads

may be connected into this terminal block. See section three of this manual for more

information.

!CAUTION

!

FAILURE TO OBSERVE DC POLARITY ON THE INPUT TO THIS DEVICE MAY

CAUSE DAMAGE TO INTERNAL CIRCUITRY. THIS WILL VOID EQUIPMENT

WARRANTY

FIGURE 2-1

8

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 2

INSTALLATION

2.2 WIRING ( continued )

Units supplied with the AC input bypass option will wired slightly differently. To

conform to NEC 250 the neutral is “carried through” to the output but is not shorted

to the GND terminal. This will place one side of the inverter output at the neutral

potential. It should be noted that this is only recommended to satisfy the NEC

requirements. The output of the inverter is isolated from the DC input and the line.

This allows the output to be floating if required by end user’s application. Maximum

continuous common mode potential is limited to 250Vac or 360Vdc. Figure 2-2

illustrates a typical bypass configuration.

.

Figure 2-2

The recommended wire size for each model is listed below in table 2-1. These sizes

are based on a maximum wire length of 10 to 15 feet. Longer wires should be

increased in diameter.

MODEL # DC INPUT WIRING AC INPUT \ OUTPUT WIRING

2500-48-XX # 6 AWG ( 60 A) # 10 AWG ( 25 A max.)

2500-125-XX # 10 AWG (23 A typ.) # 10 AWG ( 25 A max )

Table 2-1

9

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 2

INSTALLATION

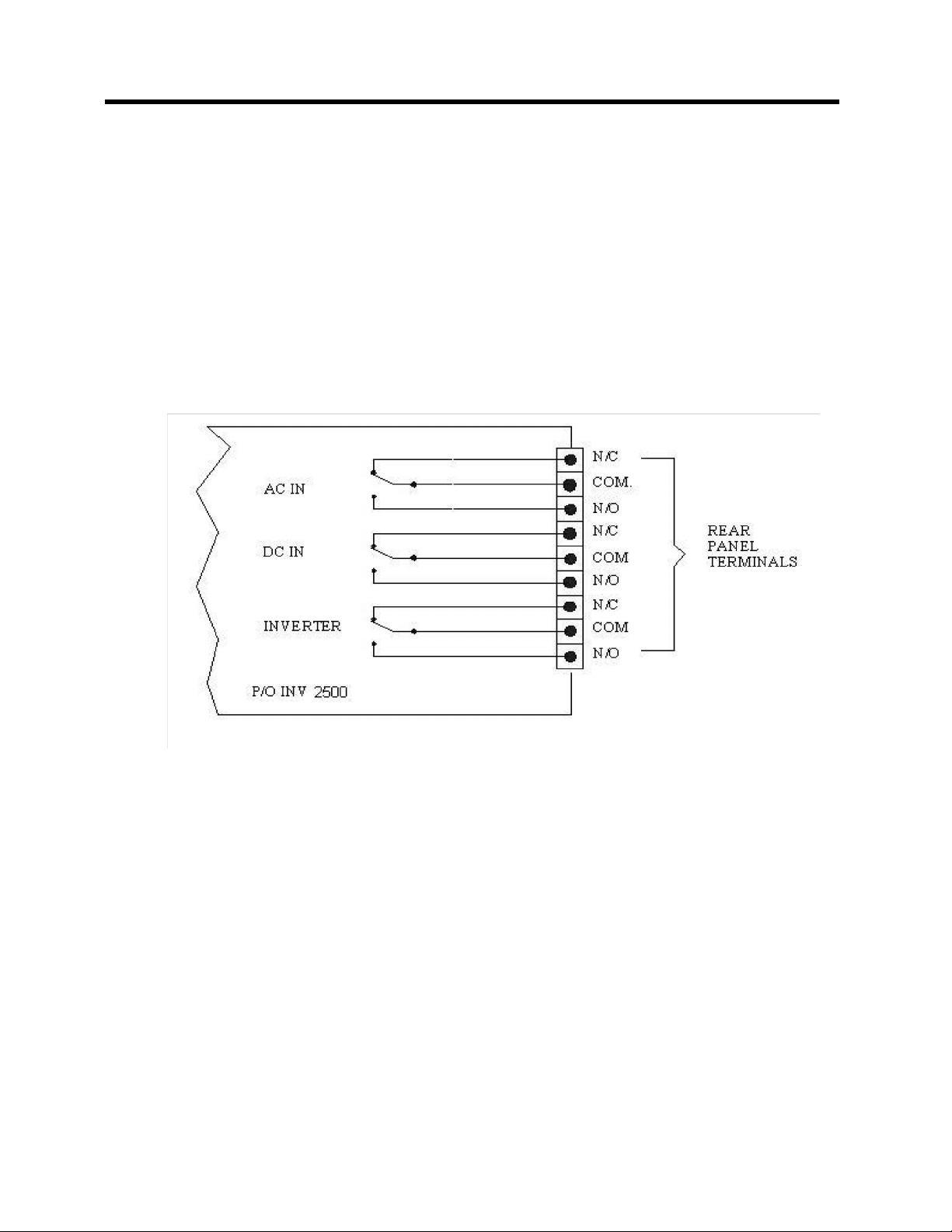

2.3 OPTIONAL ALARM CONTACTS

Units supplied with the bypass option also provide signal contacts that can be used

to set alarms or trigger other system related responses to operating conditions.

The alarm contact option provides the user with a convenient means of monitoring

of the status of : DC input, AC input, and INVERTER (inverter AC output). Each

function provides one set of “dry” C form contacts which accommodate any logic

required. The internal relays will change state if any of the three voltages are missing

or too low to provide proper operation. The contact rating of the alarm functions are

0.3 amp @ 125 Vac maximum. The figure 2-3 below illustrates the alarm internal

wiring.

Figure 2-3

To prevent possible EMI ( electro-magnetic interference ) alarm wiring should be

accomplished with twisted pairs. Shielding is also recommended. This will prevent

interference from entering or leaving the unit. All alarm connections should be made

with #6 inside diameter ring lugs. A rear panel terminal block is provided. See section

three of this manual for further information.

2.4 OPTIONAL STEP-UP TRANSFORMER

The INV series can provide a 220V or 240V output with the addition of an external

transformer chassis . With this option a second rack mountable chassis is provided

to convert the standard 120V output to the higher value. In addition, the bypass

option can also be included with the external transformer.

10

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 2

INSTALLATION

2.4 OPTIONAL STEP-UP TRANSFORMER ( continued )

A block diagram of the optional transformer configurations is provided in figure

2-4. Special units may vary and will be identified by a four digit engineering code.

Interconnecting wiring should be rated at 250Vac or better. Ring lugs are

recommended for all connections.

Figure 2-4 External Step-up transformer block diagrams

11

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 3

OPERATION

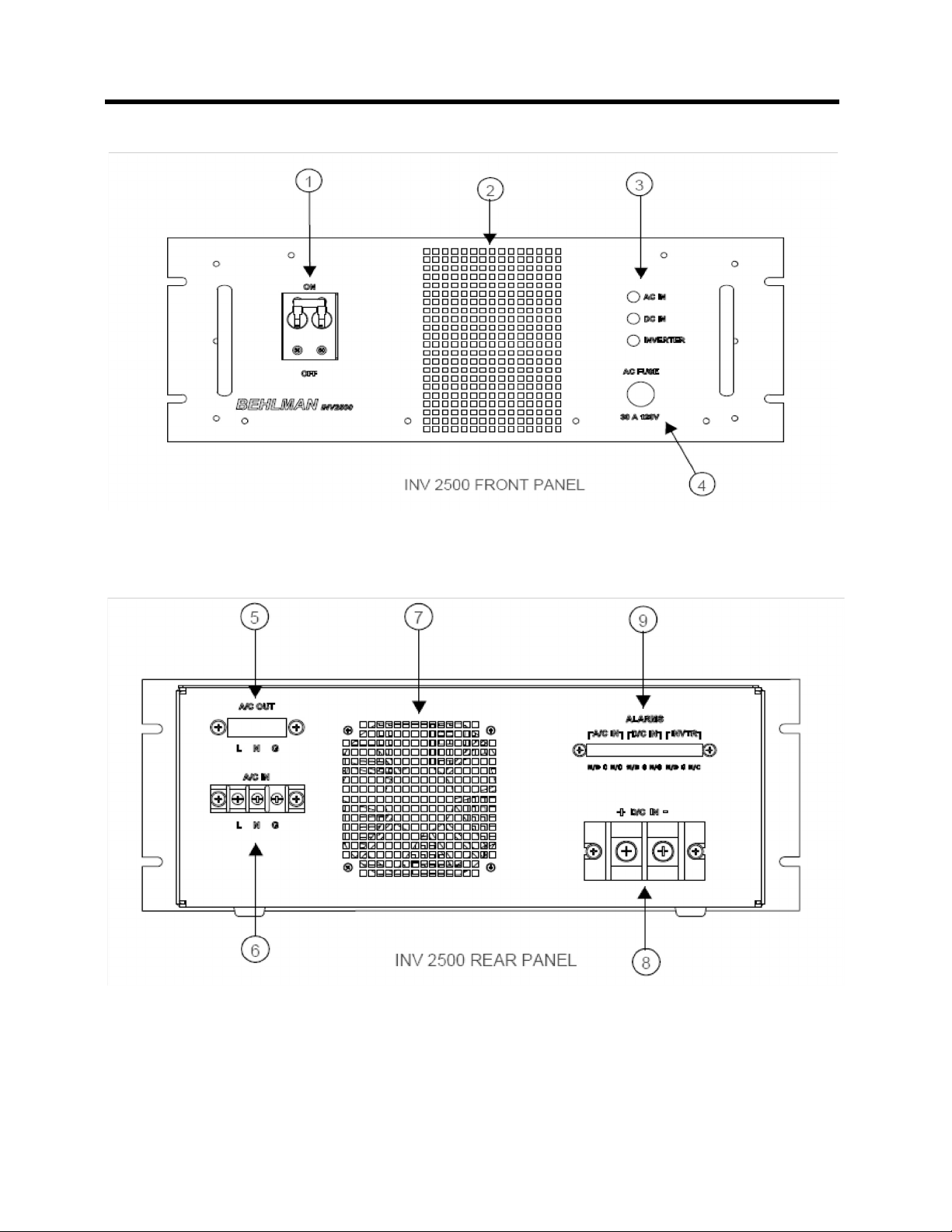

3.1 CONTROLS AND INDICATORS

Table 3-1 below lists and describes the various control, indicator, and connectors

associated with this model. Figures 3-1 & 3-2 illustrate the location of items listed

in table 3-1.

ITEM DESIGNATION FUNCTION

1 POWER Front panel mounted magnetic circuit breaker,

also serves as DC on/off switch.

2 AIR INTAKE Pulls in air for cooling internal power components.

3 STATUS LEDS Provided with alarm by/pass option. Used to

indicate status of alarm circuits. Green LEDs

indicate a O.K. condition for :

AC input, DC input, and inverter output.

4 LINE BYPASS FUSE Provided with alarm /bypass option. Used to

protect AC wiring due to load fault. Fuse rating is

30A @ 120V.

5 OUTPUT CONNECTOR Standard units provide screw type terminal blocks.

6 AC LINE INPUT TERMINALS Screw type terminal block provided with

alarm/bypass option. For connection to bypass

source.

7 FAN EXHAUST Heated air exhaust. Minimum 4 inch clearance

required for full power operation.

8 DC INPUT Screw type terminal block to connect DC input.

9 ALARM SIGNAL TERMINAL Screw type terminal block to connect alarm

signals.

The table above lists the most common configurations for this model series. It should be

noted that Behlman has produced many modified or semi-custom version of this model. This

will be indicated by a four digit engineering code number appearing at the end of the model

number. For this reason this table may not contain all the information for special units.

Addendums will be placed at the beginning of this manual to address any important

variations and/or operating considerations.

When requesting information for this series any four digit engineering code should be

provided

.

12

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 3

OPERATION

3.1 CONTROLS AND INDICATORS

FIGURE 3-1

FIGURE 3-2

13

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 3

OPERATION

3.2 OPERATION

1 Connect the load to the inverter. If multiple loads are used it is good practice to switch all loads

off before switching on the inverter. This will prevent multiple in - rush currents from tripping

protective circuits in the inverter.

2. Switch on the inverter. At this point, the sound of the cooling fans should be evident.

3. If the inverter contains the alarm \ bypass option, the appropriate front panel LEDs

should be illuminated.

4. To test the inverter, use a True RMS type meter to confirm the output voltage is as

specified.

5. Units provided with the AI bypass option are AC preferred. This means that the incoming AC

line voltage will be routed to the inverter output terminals ( or outlets ) when ever it is present.

During this time the inverter is in a standby condition. If the AC input is removed the output

terminals will be switched to the inverter and operation from the DC source begins.

The AI bypass function can be verified by removing the AC line input. This will cause the AC

IN LED to turn off and the AC IN alarm contacts to change state. During this time the

INVERTER and DC IN LEDs should remain on. Confirm an AC output from the output

terminal or outlet.

Units provided with the DI bypass option are DC preferred. This means that the inverter is

routed to the output terminals ( or outlets ) whenever DC is available. If the DC is lost or the

inverter malfunctions, the incoming AC line will be routed to the output terminals.

The DI bypass function can be verified by removing the DC input (leave front panel breaker

on ). Confirm that the DC IN and INVERTER LEDs turn off and the corresponding rear panel

alarm contacts change state. The AC IN LED will remain on and the AC IN contacts do not

change state . Use a voltmeter to confirm that the input AC is routed to the unit’s output

terminals or outlets.

3.3 OPERATIONAL CONSIDERATIONS

LOADING LIMITATIONS:

The INV series are designed to produce a power level of 2500 Watts( real power) under continuous

operating conditions. In addition, they can supply bursts of over 1500 watts for several seconds. Peak

repetitive currents on the order of 50 amps may also be supplied continuously as long as they do not

exceed the RMS value of 25 amps.

This high peak current capability allows the INV 2500 series to start most high in - rush loads in it’s

power range. It must be understood that the DC power source suppling the inverter must also have

this capability in order to derive these benefits. A poorly regulated or high internal resistance DC power

source will adversely affect operation of the inverter.

POWERING REACTIVE LOADS

Capacitors and inductors are reactive in nature. With capacitors, if the load is applied during the peak

of the AC cycle there may be a considerable in rush of current several magnitudes larger than the

steady state current. This current is only limited by any series resistance that may be present in the

load circuit. Under the right conditions, this could trip the overload protection circuits in the inverter.

Certain transformers and solenoids (inductance) present the same problem due to magnetizing

currents.

14

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 3

OPERATION

3.3 OPERATIONAL CONSIDERATIONS

POWERING REACTIVE LOADS

( continued )

Several methods can be used to prevent tripping the protection circuits in the power source . One

common method is to insert a limiting impedance in series with the load. This could be in the form of

a fixed resistor or NTC (negative temperature coefficient) thermistor. Also, zero crossing switching can

be employed. Most commercial DC power supplies present a capacitive in-rush characteristic. Line

filters with large shunt capacitance may also cause considerable in rush current “spikes”. If not

accounted for these loads can trip protective circuits in the inverter.

POWERING LAMPS

Tungsten filaments lamps, when cold, present a very low resistance. Once they are energized, their

resistance quickly climbs to it’s steady state value. This characteristic must be accounted for when

driving tungsten filament lamps. Like incandescent lamps, certain Ni-Chrome based heaters will

present a 2:1 or 3:1 in rush when cold. The same methods for limiting in rush current for reactive loads

can be applied to tungsten or Ni-Chrome base elements.

POWERING MOTORS

Driving an AC motor presents a special problem. Most motors require a starting current that can be

several times higher than the running current. This current may last for a few cycles to several seconds

depending on the construction and mechanical load on the motor. This current is sometimes referred

to as the motor’s “locked rotor” current. This current is not to be confused with the in- rush current that

usually occurs over the course of one or two cycles of the AC waveform.

The model 2500's fold back current limiting can be an advantage when starting motors. During the

starting period the motor will attempt to draw excessive power from the inverter. The fold back circuit

will reduce the output voltage in order to maintain the maximum output current. During this time the

current supplied to the motor will remain sinusoidal, this allows the motor to start rotating. Once the

motor reaches it’s normal operating speed, it generates the required “back EMF” to reduce the supply

current to the nominal “run” value for the motor.

POWERING NON-LINEAR LOADS

Loads utilizing rectifiers and SCRs interact with the AC power source and have a significant effect

on the distortion of the output waveform. Consider the use of a bridge rectifier followed by a capacitive

filter, the current waveform associated with this circuit is illustrated below in figure 3-3. The input

current to this type of circuit is drawn in large “gulps” whenever the voltage across the capacitor falls

below the peak of the input waveform. The capacitor charging current is limited only by the series

impedance present in the wiring and capacitor .Because the impedance of large electrolytic capacitors

is very small this action causes a current wave form with a peak value several times the RMS value.

This ratio of peak current to RMS current is known as “ Crest Factor”. High values of crest factor cause

distortion of the AC voltage waveform.

The amount of distortion incurred is dependant on many factors and is beyond the scope of this

manual. It should be noted that this type of load may cause the output waveform to exhibit “flat topping”

This should not be associated with a defect of the inverter. Most “real world” electric distribution

systems exhibit this distortion for this reason.

15

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 3

OPERATION

3.3 OPERATING CONSIDERATIONS

Figure 3-3 below give an example of a non-linear load. In this case the load current is said to be

discontinuous as it does not flow over the full cycle of the output waveforms. This action can cause

perturbations on the output waveform. This may show up as ringing or clipping. Ringing can be

reduced by adding a small resistive “ pre-load” of about 10 to 20 watts across the output terminals.

FIGURE 3-3

16

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 4

TROUBLE SHOOTING

4.1

THEORY OF OPERATION

The INV 2500 series utilizes high frequency, switched mode, power conversion to convert

the incoming DC to an AC output. The first stage is a DC to DC converter which “steps - up”

the input voltage to a regulated +/- 200 Vdc. This voltage is applied to a second high

frequency “housekeeping” supply and the output inverter. The housekeeping supply provides

operating voltages for the output inverter and alarm circuits. The output section consists of

a crystal controlled sine wave oscillator and class “D” power amplifier. The crystal derived

clock frequency is divided down and applied to a counter, PROM, D/A converter

combination. The resulting sine wave at the output frequency is applied to the power

amplifier and boosted to the 120 VAC level required on the output.

The power amplifier consists of a pulse width modulated ( PWM ) “half bridge” circuit utilizing

IGBT output devices. The devices are switched at a rate of 20 KHZ and modulated with the

sine wave information. The result is a 400V p/p pulse train at the output that contains the

original sine wave information. The 20 KHz “carrier” frequency is removed by a low pass LC

filter . This provides an amplified version of the original modulation signal to the output

terminals. The control circuitry on the output inverter assembly also provides output

regulation and protective functions. The output voltage RMS value is monitored and used to

keep the output regulated. Output current is measured and used to provide fold back type

limiting in the event of an overload. Output short circuits will disable the inverter stage,

requiring the input power to be recycled to return proper operation.

The alarm and bypass circuits ( if provided ) allow for external monitoring of input and output

status. The AC input/ bypass feature allows the AC power line to be applied to the model INV

2500 and sent directly to the output terminals. In the event the AC is interrupted, a relay will

switch the output to the inverter. Units supplied with the D1 option will switch the line through

when the DC is not available or the inverter has a fault. The AC input is fused at 30 amps.

Figure 4-1 INV 2500 Block Diagram ( with By-pass option)

17

INV 2500 SERIES MANUAL REV 1 1/13

SECTION 4

TROUBLE SHOOTING

4.2 TROUBLESHOOTING

In the event problems are encountered during the installation and operation of the inverter refer to the

chart below before assuming the inverter is at fault. If It is determined the fault is with the inverter,

contact Behlman Electronics for service information.

SYMPTOM POSSIBLE CAUSE ACTION

Low or no output Output overloaded Check load current . Disconnect

load and recheck

output voltage using TRMS

meter. Recycle power.

Erratic operation Input voltage fluctuating Monitor voltage at DC input

terminals of inverter. Make

sure it is with in specifications

No AC input alarm

( optional)

AC - Bypass fuse blown Check fuse. Measure AC input

at rear panel.

Output distorted High peak load current Reduce loading if distortion

is objectionable.

DC breaker repeatedly trips DC polarity reversed or internal

fault in inverter.

Check polarity, if ok, the unit

may have an internal fault.

Return for service

! WARNING

Service of this device requires specialized equipment and trained personnel. There are no internal

user serviceable parts. Removing the cover will expose individuals to hazardous voltages.

Refer

service to qualified persons only !

4.3 MAINTENANCE

The INV 2500 series requires very little in the way of routine maintenance. If the unit is operated in a

dirty or dusty environment it should be removed from service periodically and cleaned. The use of

forced air is perfect for cleaning dust and debris from fan intakes and heat sink assemblies. Light

brushing and vacuuming is also effective.

If the unit is to be supplied from batteries, the condition of the batteries will have a significant affect on

the operation of the unit. Poorly maintained batteries can cause the unit malfunction when heavily

loaded. If this device is to be used as part of a back-up power system a battery maintenance schedule

should be discussed with the battery manufacturer. Behlman does not provide batteries for these units.

18

INV 2500 SERIES MANUAL REV 1 1/13

5.0 MECHANICAL OUTLINE

Table of contents

Other BEHLMAN Inverter manuals

Popular Inverter manuals by other brands

IBS

IBS US40 user guide

Statpower

Statpower Portawattz 3000 owner's manual

Mitsubishi Electric

Mitsubishi Electric F700 instruction manual

Mastervolt

Mastervolt AC Master 12/2500-230 User and installation manual

GYS

GYS PSW 600 W Translation of the original instructions

SOLINTEG

SOLINTEG INTEG M MHT Series Quick installation guide

DASS Tech

DASS Tech saleaf DSP-125i-ODS Manual for use and installation

Pulsar

Pulsar PG4500BiSRCO Operator's manual

Coleman

Coleman 55 WATT SOLAR 12 VOLT POWER GENERATOR KIT user manual

Generac Power Systems

Generac Power Systems 005342-6 owner's manual

Kemot

Kemot PROsolar-5000 owner's manual

Vinco

Vinco QL1000i instruction manual