BEIFANG VALVE ACTUATOR 920 Series User manual

920 SERIES ELECTRIC ACTUATORS

FOR MULTI-TURN APPLICATION

INSTRUCTION MANUAL

TIANJIN BEIFANG VALVE ACTUATOR CO.,LTD

BF/TM-920.03-E2016A

Issue 201603

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

1

Thank you for purchasing

and using our products. This

manual is valid for 920 series

electric multi-turn actuators.

Please before you operate

your product, be sure to read this

booklet carefully. These operation

instructions are only valid for

“clockwise closing”, i.e. driven

shaft turns clockwise to close the

valve

Address: Yi Xing Fu Science & Technology

Area Beichen District, Tianjin 300410, China

Tel: 86(022)26308907 26309159

Fax: (022)26300975

http://www.tj-beifang.com

e-mail: bf@tj-beifang.com

Please tell us some information about your

product when contact us:

Model, Factory number, Manufacturing date

WHERE TO FIND INFORMATION

1. Summarize

1.1 Brief

1.2 Range of application

1.3 Warnings and notes

2. Performance parameters

3. Identifiers

4. Structure

4.1 Size 9201

4.2 Sizes 9202~9205

5. Transport and storage

5.1 Transport

5.2 Storage

6. Lubrication

7. Installation

7.1 Installing handwheel

7.2 Installation to valves or gearboxes

7.2.1 Plug sleeve connection

7.2.2 Stem nut connection

8. Electrical connection

8.1 Before wiring

8.2 Wiring

9. Manual operation

10.Setting the torque switch

11.Setting the limit control mechanism

11.1 Setting the limit switch

11.2 Setting the counter

12.Setting the position indicator

13.Installing the cover

页码

2

2

2

2

3

5

6

6

7

8

8

8

8

9

9

9

9

10

11

11

11

12

13

13

13

14

15

16

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

2

920 series electric multi-turn actuators provide a reliable position control of

gate, stop valve, as well as similar ones, and they can be combined with

gearbox. About other applications, please contact us.

For any damage caused by improper use, the manufacture is not

responsible for warranty. Such risk shall be borne by user alone. Strictly

complying with the instruction manual is part of the operational requirements.

1. Summarize

1.1 Brief

1.2 Range of application

• 920 series electric multi-turn actuators powered by electric have limit and

torque switch in both end position. In addition they can output torque or

thrust.

• According to customer’s requirements, 920 series electric actuators can be

made the standard type, integral control with open/close, integral control

with regulator module.

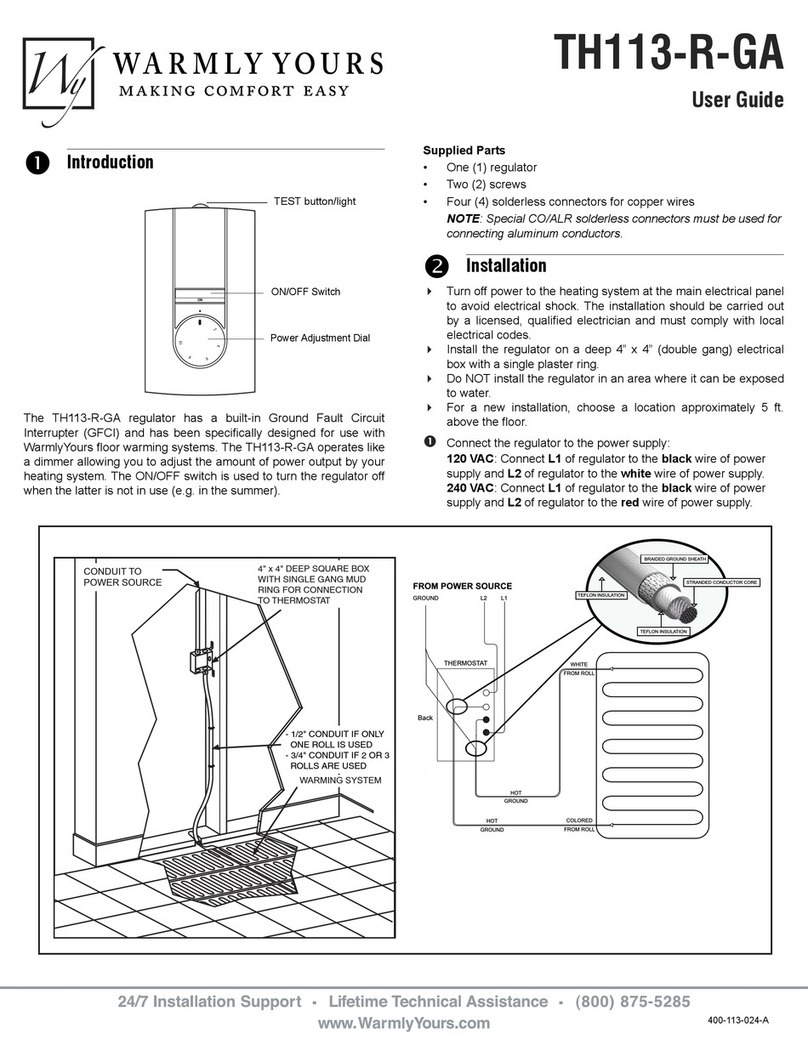

1.3 Warnings and notes

Non-observance of the warnings and notes may lead to serious injuries or

damages. Qualified personnel must be thoroughly familiar with all warnings

and notes in these operation instructions.

This sign means:Hint!

Explain the topic in detail.

This sign means :Note!

Non-observance of these notes may lead to the blight to products or

the failure of operation.

This sign means :Warning!

If not carried out the “warnings” correctly can affect the safety of

persons or material.

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

3

Standard: 2-G3/4”

Options: 2-NPT1”

2-M33×2

Or according to user need.

Conduit entries

Automatic reset structure for motor mode first. Whenever the motor is

energized, the clutch automatically revert to motor mode in order to ensure

safe operation

The electric actuator can be locked by additional lock.

Hand /auto switch

Continuous display of adjustable dial with “Open” and “Close” mark.position indicator

Torque switches are provided for “Open” and “Close” separately

Standard:1NC and 1NO.

Options:Add up to two torque switches (On and off can be specified by the

user).

Torque control

Limit range of counter from ”Open” to “Close”.

Standard: 1~50 turns.

Options:1~490 turns

Travel switches are provided for “Open” and “Close” separately.

Standard: 1NC and 1NO ( Switches on and off can be changed on the

worksite ).

Options: 1NC and 2NO( Switches on and off can be changed on the

worksite ).

1NC and 3NO ( Switches on and off can be changed on the

worksite ).

Add up to four the middle position switches.

Limit control

Have. The actuator is not self-locking when the output speed is more than

48r/min.

Self-locking

Standard: F, heat resistance.

Options: H, heat resistance.

Insulation grade

A temperature protection switch embedded in the windings of the motor will

trip the actuator control circuit if the motor winding overheat.

Protection

Standard: 380V/50Hz/3ph AC, voltage vibration range:±10%, frequency

vibration range:±5%.

Options: 220V/50H/1ph AC (Apply to 9201 and 9202).

Power

Standard: S2-15 minutes short time work type. No more than 15 minutes

cyclic running time, the startup interval is 2~3 times running time.

60 starts/hour for application, do not exceed 600 starts/hour

when adjusting.

Options: S4-25% intermittent work type. Used for precise adjusting, do not

exceed 1200 starts/hour.

Work type

2. Performance parameters

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

4

Options: Flashing switch for runningRunning indicator

Standard: IP65 (GB4208-2008)

Options: IP67 (GB4208-2008)

IP68 (Protection from dust and operating 10 times when

submersing in water to a depth of 3m for 48 hours.)

Ex-proof type: ExdⅡCT4 Gb(GB3836.1-2010、3836.2-2010)

Protection provided by

enclosure

Standard: Epoxy and acrylic acid coating.

Options:Other coating required by customer。

Coating

Standard: Gray (RAL7030)

Option: Other color required by customer.

Coating color

Ambient humidity below 90% (25℃).Humidity

At least 8000 times.(Cycle of operation: Open—Close—open, each cycle is

20 turns).

Lifetime

Standard: Installing the actuator below 2000 meters above seal level.

Options: When installing the actuator above 2000 meters above seal level,

please contact us.

Installation height

Standard: -25℃~ +70℃。

Low temperature type: -40℃~ +70℃。

Ultralow temperature type: -60℃~ +50℃。

Ex-proof: -20℃~ +40℃。

Temperature

Standard: Self-adjusting potentiometer.

Option: Feedback 4~20mA analog position indication signal.

Feedback signal

It is natural that the temperature of the motor surface reach

or exceed 80℃when working, do not touch the motor for

fear scald.

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

5

• “BF” logo is cast in the apparent position of each electric actuator.

• Each electric actuator has a nameplate printed with company name, ”BF”

logo, “CE” mark and so on. Content of nameplate includes:

•Type code

•Main code

•Wiring diagram No.

•Maximum torque

•Output speed

•Allowable thrust: Used for stem nut connection

•Supply voltage

•Rate power of motor

•Rate current of motor

•Degree of protection provided by enclosure

•Manufacturing No.

•Manufacturing date

•Address

Content nameplate of ex-proof product also includes:

•Ex-proof degree of protection provide by enclosure

•Certification No.

Only manufacturing No. in each product is a basis of accurately tracing

product. Please keep it well.

3. Identifiers

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

6

4.Structure

21

20

19

18

17

16

15

14

13

No.

Wiring-box cover

Main house

Conduit entries

Body of handwheel

Clutch

Driven shaft component

Driven sleeve

Output flange

Cover

Name

Terminal strips

Position indicator

Torque switch

Limit switch

counter

Torque transmission component

Limit transmission component

Hand /auto lever component

Handwheel component

Screwed plug for injection grease hole

Worm shaft component

Motor

Name

11

7

5

6

12

10

9

8

4

3

2

1

No.

4.1 Size 9201 1

2

3

4

5

6

7

8

9

10

11

13

14

15

17

16

18

19

20

21

12

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

7

1

4.2 Sizes 9202 ~9205

23

4

5

9

10

6

14

13

12

16

17

18

20

21

19

22

23

7

8

23

22

21

20

19

18

17

16

15

14

13

No.

Wiring-box cover

Housing cover component

Hand /auto lever component

Main house

Screwed plug for injection grease hole

Handwheel shaft

Handwheel component

Worm shaft component

Conduit entries

Driven shaft component

Driven sleeve

Name

Output flange

Cover

Terminal strips

Position indicator

Torque switch

Limit switch

counter

Torque transmission component

Limit transmission component

Clutch

Hand /auto component

Motor

Name

11

7

5

6

12

10

9

8

4

3

2

1

No.

11

15

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

8

5. Transport and storage

5.1 Transport •It is necessary to use solid package during transportation.

•When lifting the electric actuator by hoist, please attach ropes or hook

to enclosure. Do not attach ropes or hooks to handwheel, hand/auto

lever or wiring-box.

•If the electric actuator has been mounted to the gearbox, please

attach ropes or hooks to the gearbox rather than to the electric

actuator for the purpose of lifting by hoist.

•If the electric actuator has been mounted to the valve, please attach

ropes or hooks to the valve rather than to the electric actuator for the

purpose of lifting by hoist.

•Do not stand under the dangling electric actuator.

5.2 storage • Units should be stored in the well ventilated, dry, non-corrosive room.

• Units should be placed on bracket or the dry wooden flooring.

• If necessary, units are covered with dust guard.

• Long-term storage (more than 6 months).

• To avoid corrosion, wipe handwheel shaft, driven shaft, driven sleeve and

mounting surface with anti-rust oil.

• Check the units for rust every 6 months. If there is any rust, please treat

again for rust prevention.

6. Lubrication

-25 ~ +120℃Temperature range

Lithium soap thickened mineral oilPrincipal component

• There are O-rings or lip seal between the main house and its contacting

portion. The main house is fully filled with 00# lithium grease to lubricate the

worm shaft, worm gear, gears, bearings and so on.

• No seal can remain absolutely tight at all time, therefore, it is not unusual to

find a very small amount of weeping around shaft sealing-especially during

long periods of idleness such as long-term storage. Once the equipment

has begun operating, this phenomenon will automatically disappear.

• It is not need to refresh the lubricating grease periodically. If the lubricant is

deficient in quantity or its quality has changed, please infuse the lubricating

grease with the same trademark or the same performance from the

injecting grease hole.

00# gear lubricating grease used by the standard units

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

9

7. Installation

7.1 Installing handwheel For easier transport, the handwheels of sizes 9202~9205 are placed

separately, so please mount the handwheel on the manual shaft, before

doing manual operation.

• Handwheel of size 9201 is directly mounted on the product.

• Design of 920 series ensure man power can drive manual operation, no

need to use the force rod.

7.2 Installation to valves or gearboxes

• Apply for the valve stems which can rotate and not lift: Driven sleeve has

two types of structure-one with hole and keyway and one with jaw.

1.Check whether each mating surface of joint flange fits the valve’s.

2.Check whether dimensions of input shaft and key or jaw in the valve or

gearbox fit the electric actuator’s.

3.Clean up grease on the mating surface of joint flange.

4.When connecting with shaft and key, a little of greases is smeared on the

shaft

5.When installing the electric actuator, tighten the screws after ensuring

mating of the joint flange and shaft or jaw is good.

• Without removing joint flange #1, drive sleeve #2 can be directly removed.

Therefore install the drive sleeve to the shaft or jaw of the valve ,and then

connect the electric actuator with the flange of the valve.

• When the valve stem is shaft with key, the valve stem must have a step for

prevent drive sleeve from moving.

• After installation is complete, check and repair the damage coating .

Material performance level of the parts which connect the electric actuator

with the valve or gear is 8.8 class. Yield strength is 628N/mm² .

7.2.1 Plug sleeve connection

•Warning: If electric actuators are installed in the hazardous gas area,

must check whether the ex-proof degree on the nameplate is

appropriate.

• In the hazardous area, it is prohibited that conductive body and thermal

conductor contact with the electric actuator. Except special allowable work,

the units must be cut off power, remove from the hazardous area for repair

or maintenance.

Driven sleeve with

hole and keyway

Driven sleeve with

jaw

1

2

1

2

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

10

• Apply for the valve stem which can lift and not rotate: 920 series apply

independent thrust plate component to bear thrust. The stem nut is supplied

with a pilot hole or blind hole. Before installing the actuator to the valve,

users need to machine the stem nut according to the dimension of the valve

stem.

Machining the stem nut:

1.Put down the electric actuator, and then loosen the screw fixed seam

allowance #4.

2.In turn take out seam allowance with O-rings and stem nut with bearings

from the thrust plate component.

3.Take out O-rings #1 and thrust bearings #2 in sequence from the stem nut.

Notice: Do not damage to O-ring.

4.Machine the stem nut to make sure the thread must match the thread of

the valve tem;

5.Clean up foreign matter on the stem nut, assemble thrust bearings with

some lithium grease, and then assemble the O-rings.

6.Re-insert the assembled stem nut and seam allowance into the actuator,

and then screw.

Connecting to the valve:

1.Check whether the flange of the actuator fit one of the valve.

2.Clean up the grease on the mounting surface of joint flange.

3.Smear some grease on the thread of the stem nut or the valve stem.

4.Install the actuator to the valve stem, engage manual operation, and turn

handwheel to make the stem nut mesh with the valve stem.

5.Continue to turn handwheel until the flange of the actuator touch the flang

of the valve, turn the hanwheel two laps again to make the flanges fit

closely, and then screw the bolts to fix the actuator and the valve.

• When disassembling and assembling, do not damage the O-rings.

• The flange of the valve can bear enough thrust.

• After installation is complete, check and repair the damage coating.

Material performance level of the parts which connect the electric actuator

with the valve or gear is 8.8 class. Yield strength is 628N/mm².

7.2.2 Stem nut connection

1

2

3

2

1

4

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

11

If you do not obey the warning ,will cause serious injury or property damage.

• Electrical connection must be done by the qualified personal。

• Before wiring, please comply with the relevant provisions of the clause 。

• There are the wiring diagram and <920 series electric actuators for multi-

turn application instruction manual> in the sealed plastic bag with the unit.

You can also directly ask for them fromTianjin Beifang Valve Actuator Co.,

Ltd by offering Manufacturing No in the nameplate, or you can get them

from www.tj-beifang.com。

8. Electrical connection

8.1 Before wiring Check whether current type, voltage and frequency of the power fit the motor

parameters in the nameplate.

8.2 Wring

• If the cable joint is not used, remove it, and block the conduit entry with the

plug. The openings are 2-G3/4″for the standard products

• To ensure IP on the nameplate, the cable joints must be compatible with

the cable.

• Check whether the PE wire of the cable is connected with the . If do not

connect the PE wire, electrocution can occur.

Electrical component in the unite with high voltage, work on

the electrical system or equipment must only be carried out by

an electrician who possess operating certificate or by

specially instructed personnel under the control and

supervision of such an electrician and in accordance with the

applicable electrical engineering rules.

1.Shut off all incoming power.

2.Open the cover, keep the compartment of the main house clean and dry.

3.Check the stickup code to ensure that it coincides with the code of the

wiring diagram supplied with the unit and connect wires properly

according to the wiring diagram

4.Conduit entries in the main house provide two openings for routing the

pilot cable and the dynamic cable. Seal the opening after wiring.

5.Manual operate the unit to keep the valve in the intermediate position,

turn power on and check the rotating direction of the valve, then cut off

power supply. If the direction is wrong, interchange any two leads of the

three phase.

When finish installation, connect wires according to the wiring diagram

supplied with the unite.

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

12

9.Manual operation

• When adjusting the product or trail run of the product, the manual operation

can be used.

• If the motor or power is failure, the manual operation is used.

Carry out manual operation:

1.After the motor operation, the handwheel is separated from the output

component automatically. If need the handwheel to operate, please move

the hand/auto lever to the direction of arrow on the lever and gently turn the

handle until the handwheel and the clutch are in full engagement.

2.After loosening the hand/auto lever, the manual operation is engaged.

3.Turn the handwheel according to need. If close the valve, turn the

handwheel clockwise, and the output shaft will be turn clockwise to close

the valve.

The hand/auto lever can be locked in the motor mode by a padlock to

prevent the local manual operation. Our company does not supply the

padlock.

• During the motor operation, pull and hold the hand/auto lever to make the

electric drive disengage imminently.

• No need to use the force rod for manual operation.

If the hand/auto switch failure occurs, do not move the lever forcibly.

Turn the handwheel until the hand/auto switch succeed.

The hand/auto lever

for sizes 9202~9205

The hand/auto lever

for size 9201

Stop manual operation:

When opening or closing the valve, the motor operation will be engaged

automatically, and the manual operation will stop.

During the period of the motor operation, the handwheel will not rotate.

Do not move the hand/auto lever forcibly after finishing the manual

operation. Energization of the motor will make the clutch

automatically out of jointing with handwheel, and re-engage power

operation.

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

13

10.Setting the torque switch

Open

12

Close 12

1.Clear the adjustment direction of the torque: White mark is “Open”, and

black mark is “Close”.

2.Loosen lock screw #1 on the torque dial #2 to adjust torque.

3.Turn the torque dial #2 to the required output torque. When turning the

indicator to “Min”, reduce the torque value. When turning the indicator to

“Max”, increase the torque value.

4.Tighten lock screw #1 on the torque dial #2.

5.Applying power, motor operate the valve to check whether the torque is

meet the requirement when the torque switch automatically cut off the

power. If not, repeat the above process to reset.

The torque switch is respectively designed to protect the actuator and the

valve in the direction of “open” and “close”. The switch was set at the

factory. The setting torque is equal to “Rate output torque” in the

nameplate. It is not need to reset generally.

When need to adjust the torque switch, set the torque of “open” and

“close” respectively as follow after the manufacturer agree.

When adjusting the torque, must cut off the power.

11.Setting the limit control mechanism

When the actuator first installed or re-installed, must adjust the limit

control mechanism to make the responding contacts can be accurately

operated once the valve reaches the required position.

For 920 series products, the limit control mechanism includes limit

switches used for disconnecting the power and a counter used for

memorizing the turns of the driven shaft.

• According to requirement, the limit switches of 920 series product can

be provide in up to four control positions, respectively “Full open”, “Full

close” and the middle position of “Open” and “Close” . Up to four

contacts are provided in each control position. The upside contacts on

“Full open” and “Full close” are used for cutting off the power to motor

when the valve reaches to the full open position or the full close

position, and the others are auxiliary contacts.

• Each switch is independent contact, and the contact can be wilfully

change to open or close. Adjusting method as follow:

11.1 Setting the limit switch

1.Loosen the screws #1 fastening switches.

2.Take out conductive seat #3 from switch seat #2.

3.Rotate the conductive seat for 90°, and re-insert the switch seat.

4.Tighten the screw #1.

1

2

3

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

14

Adjustment process of the counter as follows:

1.Disconnect all incoming power to the unit prior to opening the cover。

2.Making the actuator in the state of manual operation, manual operates

the valve to the full open position, then turn the handwheel back for

one turn to leave a short buffer for the operation of driven shaft.

3.Push the sleeve (B), clockwise turn it, lock it in the depressed position,

and then loosen it.

4.If the upside contact is off state, turn adjusting pole (A) to opposite

direction of the arrow till the contact on the opening valve position is

on state. Then turn adjusting pole to the same direction of the arrow

till once the contact on the opening valve position just disconnect. The

adjustment finishes. (When clockwise rotating to open valve, turn

adjusting pole to opposite the direction described above, the same as

below.)

5.If the upside contact is off state, turn adjusting pole to the same

direction of the arrow till once the contact on the opening valve

position just disconnect. The adjustment is finished。

6.After adjustment of full open position finishes, counter-clockwise turn

the sleeve (B), and it will come to initial position by spring action. The

counter is well engaged if the adjusting pole mildly rotated could not

be turned, so can do the following adjustment.

7.Refer to process 3~6 to adjust other positions.

•Must cut off all incoming power to the unit prior to opening

or closing the cover.

•Check to ensure the valve is in full open position before

removing the unit from the valve.

•When finishing adjusting, the sleeve (B) must come to the

initial position. If not, the adjustment will be damaged by any

manual or motor operation.

11.2 Setting counter When the actuator first installed or re-installed, must adjust the counter to

make the responding contacts can be accurately operated once the valve

reaches the position required by user.

•Limit control mechanism is not factory set. It must be set

when the unit installs on the valve.

•After replacing the valve or reinstalling the unit, reset the

limit control mechanism prior to motor operation.

•Do not motor operate the valve without first setting the limit

control mechanism.

•The adjustment force will increase when the contact changes

from on state (or off state) to off sate (or on state), which is

normal during adjusting.

•When the counter setting is finished, the user should motor

operate the unite to ensure the limit control meet the

requirement, or reset the counter.

Counter Switch

☞

Open the

valve

Close the

valve

By observing the location of white mark on the switch, judge the

top switch contacts is the state of on or off. As shown in the left

image, the switch is on when the white marks are connected

together, and the switch is off when the white marks are

disconnected.

On state

Off state

(B)(A)

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

15

• Determine the turns of driven shaft, and then select and change the

potentiometer gear #3.

• The way of changing the potentiometer gear #3 is shown below.

1.Referring to the table below, select the potentiometer gear with

corresponding mark according to the turns of driven shaft.

2.If the potentiometer gear matching the turns of driven shaft is

default, the following steps can be omitted .

3.If the potentiometer gear matching the turns of driven shaft is one

marking 2 or 3, pick out the potentiometer gear marking 2 or 3

with the unit.

4.Loosen the screw #5 (no need to screw out completely), loose the

platen #4, replace the potentiometer gear required, and confirm

the gears meshing completely.

5.Adjust well the position of platen, and tighten the screw #5

1

2

• Adjusting the sleeve #1.

1.Move the sleeve #1 hard up and down to make the number of hole

#2 completely exposed correspond with the turns of driven shaft,

referring to the table below, and the bottom hole only can be

exposed half of hole (refer to the position of A in the left image).

Turn the sleeve #1 to conform it rotates freely.

2.Operating the electric actuator to the full close position, clockwise

turn the sleeve #1 until it does not rotate, and then measure the

resistance between terminal 2 and terminal in the wiring diagram.

The resistance valve should be between0~10Ω.

3.Gently move the sleeve up to make the bottom half hole exposed

fully (refer to the position of B in the left image ), and then turn the

sleeve to confirm it does not rotate. The adjustment is finished.

3

45

6 7 8

A

B

When the sleeve can not be moved up and down, operate the

actuator to close or open for a short trip, and then try to move the

sleeve up and down. If not, operate the actuator in reverse for a

smaller trip than last operation.

12.Setting the position indicator

•The position indicator must be set after finishing the setting

of counter.

920 series electric actuator provide mechanical valve position indicator,

and a potentiometer is supplied for remote indication.

The consumer may use a voltmeter according to the relevant wiring

diagram to remotely read the valve position indication signal or

accept 4~20mADC analog position indication signal output by the

transmitter VPT2 or VPT4 purchased at the time of order.

Adjustment process of mechanical valve position indicator as follows:

Poten

tiomet

er

gear

Number of the hole completely exposed on the sleeve

Turns of driven

shaft

331~49090~134.524.5~36.56.6~101.8~2.7Mark 3

217~33159~9016~24.54.3~6.61.2~1.8Mark 2

134.5~21736.5~5910~162.7~4.31~1.2Default

43210

Tianjin Beifang Valve Actuator Co.,Ltd. 920 series Instruction Manual

16

Full close position

of the valve

Full open position

of the valve

• Adjusting the dials #6 and #7:

1.Motor operates the valve to the full close position, and loosen

screw #8.

2.Adjust the dial #6 to the full close position of the valve as shown in

the figure, and tighten the screw #8.

3. Motor operates the valve to the full open position, hold on dial #6,

and then loosen screw #8.

4.Keep dial #6 fixed, rotate dial #7 to the full open position of the

valve as shown in the figure, and tighten screw #8.

13.Installing the cover

• Clean the sealing surface of cover and main house.

• Smear a thin layer of acidic grease evenly on the sealing surface.

• Check whether O-ring is intact.

• Mount the cover。

• Engage the motor operation, check whether the indicator aims at the

mark on the dials indicating position. If not, removing the cover, re-

adjust the dials indicating position.

• Symmetrically tighten the fastening screws.

After installation is completed, check the surface paint of the

electric actuator, and repair the damage coating to prevent

corrosion.

Operating the valve to close, the dials rotate clockwise. Operating

the valve to open, the dials rotate counterclockwise.

Table of contents

Other BEIFANG VALVE ACTUATOR Controllers manuals

Popular Controllers manuals by other brands

Hobby-Wing

Hobby-Wing XERUN XD10 Pro user manual

Samwontech

Samwontech Nova Series instruction manual

Hobby-Wing

Hobby-Wing EZRUN MAX8 V3 user manual

Signature Control Systems

Signature Control Systems 810 Series Installation and programming guide

BJ Live

BJ Live Control USB M Quick user guide

Atlas IED

Atlas IED ASP-MG2240 General description