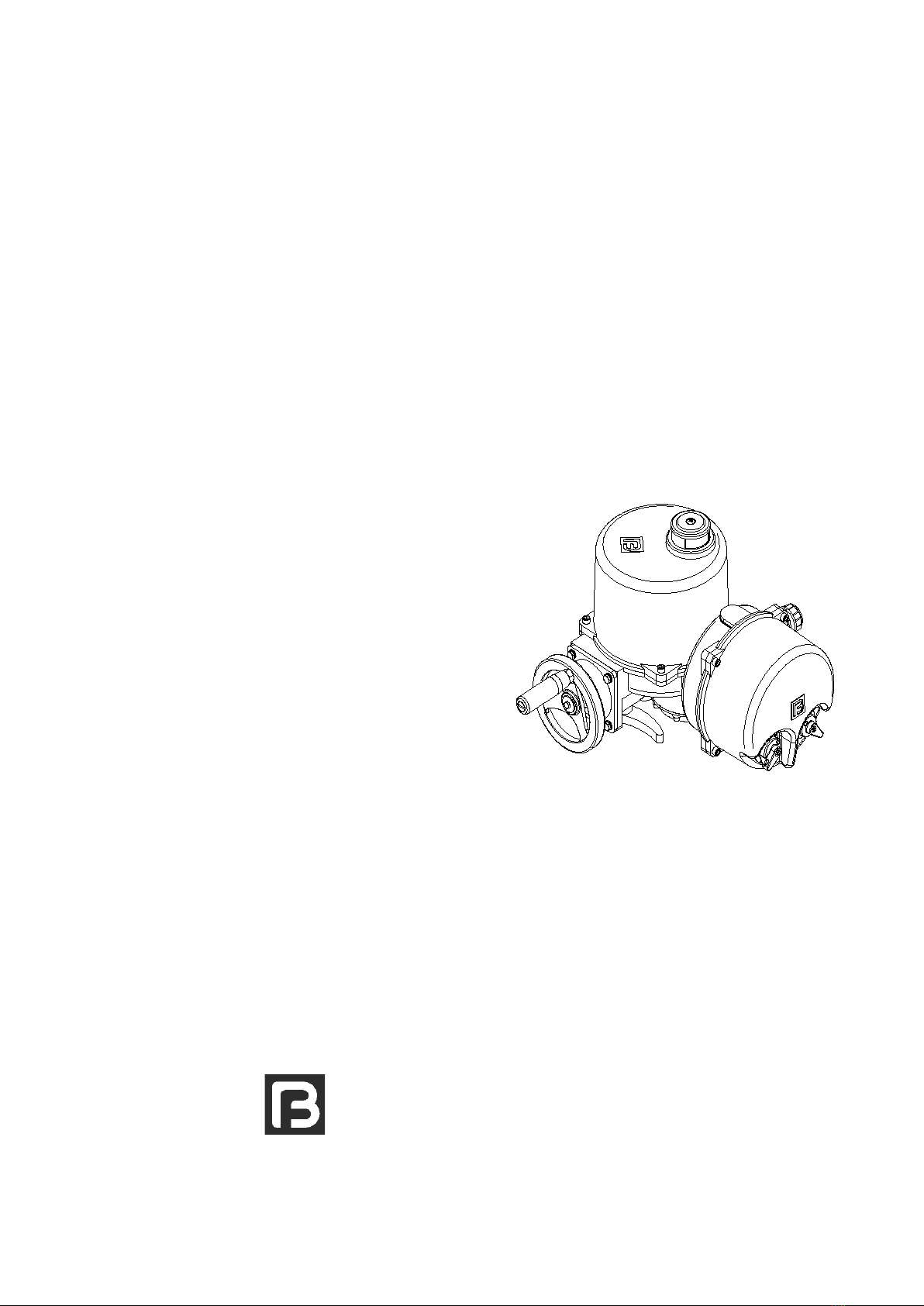

BEIFANG VALVE ACTUATOR 810 Series User manual

810 SERIES ELECTRIC ACTUATORS

WITH CONTROL PACKAGE

INSTRUCTION MANUAL

TIANJIN BEIFANG VALVE ACTUATOR CO., LTD.

Issue 201202

BFSE810-03

This manual should be used together with

《810 series electric actuators instruction manual》.

Tianjin Beifang Valve Actuator Co., Ltd. 1

810 series electric actuators with control package

Thank you for purchasing

and using our products. This

manual is valid for the control

package of 810 series electric

quarter-turn actuators.

Please tell us some information about your product when contact

with us:

Model, Factory Number, Production Date, etc.

Contents

Warnings and notes

This sign means:Hint!

Explain the topic in detail.

This sign means :Note!

Non-observance of these notes may lead to the

blight to products or the failure of operation.

This sign means :Warning!

If not carried out the “warnings” correctly can affect

the safety of persons or material.

Non-observance of the warnings and notes may lead to

serious injuries or damages. Qualified personnel must be

thoroughly familiar with all warnings and notes in these

operation instructions.

61.4.4 Advanced settings

51.4.2 Technical data

71.4.5 Factory default

51.4.3 Settings and calibration

1.4.1 Major function 4

72. Installation and debugging

41.4 Regulating module

31.3 Functional module

21.2 Control knob

21.1 Structure of the control package

21. Functions and operating instructions

Tianjin Beifang Valve Actuator Co., Ltd. 2

810 series electric actuators with control package

远程/停/现场旋钮

锁片

锁孔

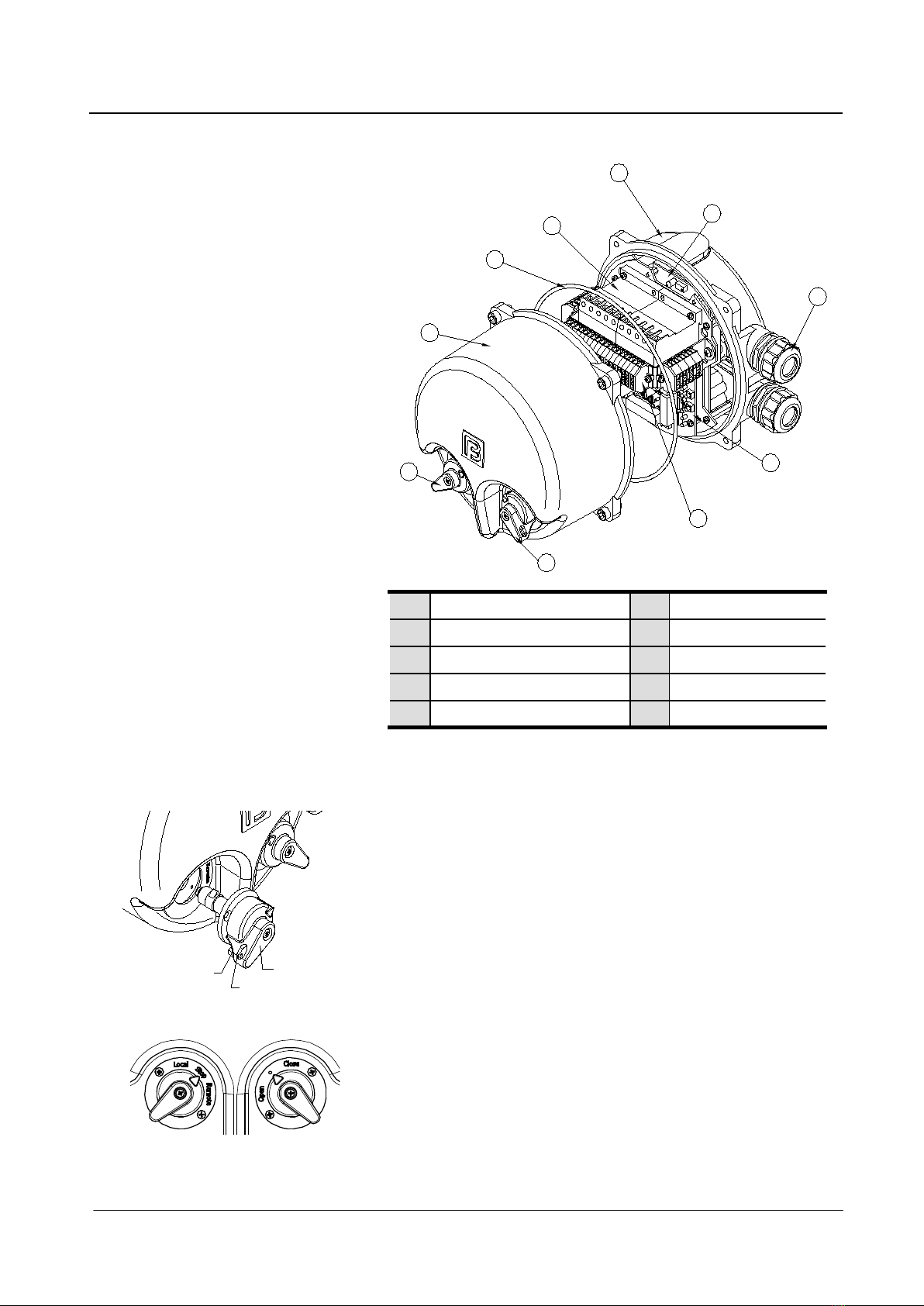

Functional module10“Local/Stop/Remote” selector5

Cable connector9Package cover4

Regulating module8Seal ring3

Terminal strips7Components group2

Local control knob

6Control box1

1.1 Structure of the control package 2

1

3

4

5

6

7

8

9

10

The package cover ④is equipped with a “Local/Stop/Remote”

selector ⑤and an open/stop/close local control knob ⑥. The

selector in three positions can be locked to prevent from mistaken

operation.

1.2 Control knob

• When the selector ⑤is in “Remote”, the Local control knob ⑥

doesn’t work and the product is in the remote operation condition.

• When the selector ⑤is in “Local”, turning the local control knob

⑥may control the actuator in site.

• When the selector ⑤is in “stop”, the actuator can’t be remote or

local operated.

1. Functions and operating instructions

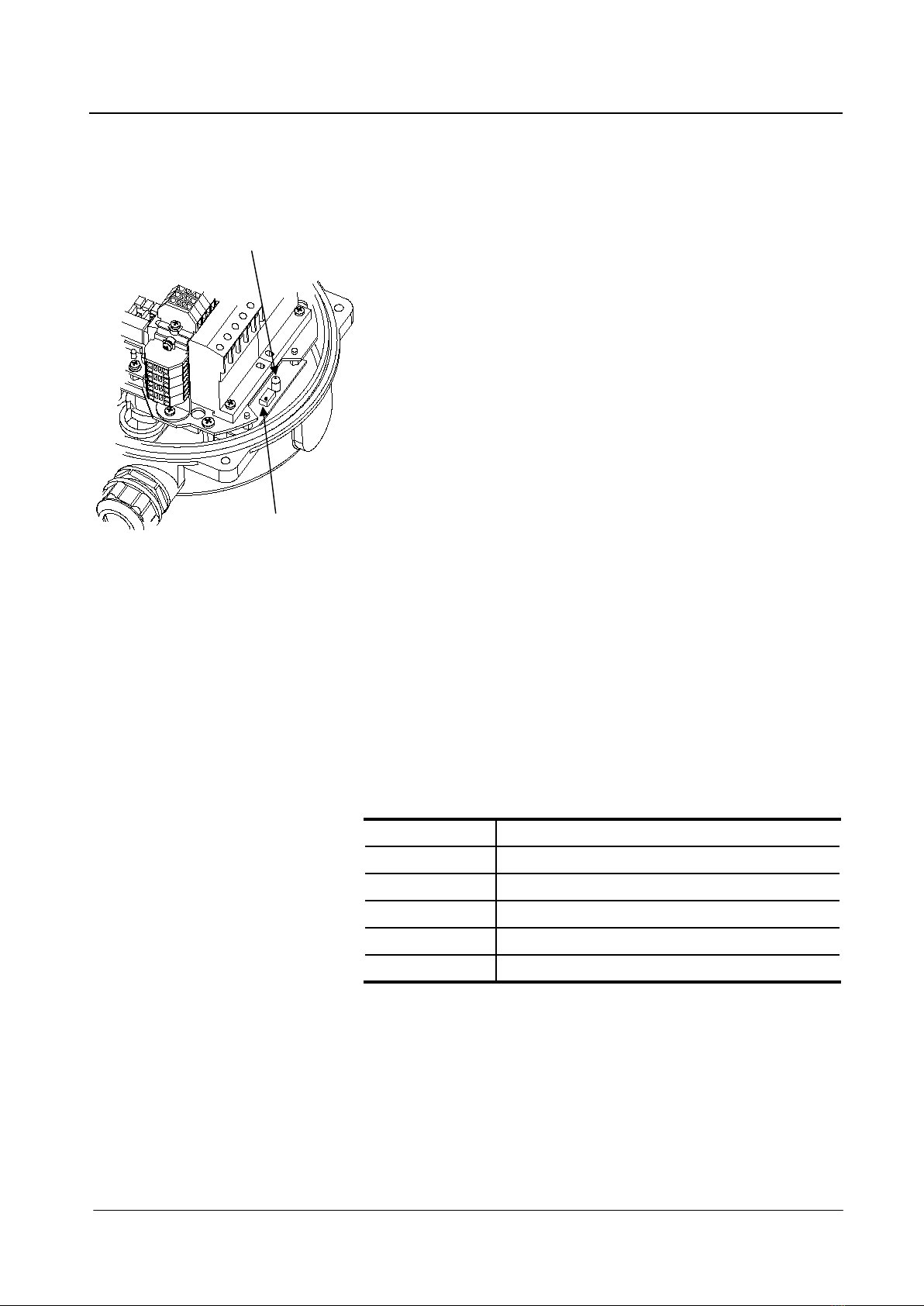

The selector ⑤can be locked when push in the locking piece.

Remote/Stop/Local

selector

Locking piece

Lockhole

Tianjin Beifang Valve Actuator Co., Ltd. 3

810 series electric actuators with control package

Flashes three times and intermittent once.Over-current

Does not light.Other faults

Intermittent flashes.Loss of phase

Flashes twice continuously.Misphase

Lights. Normal

State of indicatorFault type

The functional module with functions of sequence identification,

missing-phase protection and over-current protection consists of

transformer, relay, singlechip, unicircuit, etc.

·Sequence identification and missing-phase protection (only for

three-phase power products).

The functional module real-time monitor the power sequence and

missing-phase fault. Once the fault appears, the module will cut off

the control circuit, at the same time prompt the fault type by

function indicator.

·Over-current protection

Motor stall or other reasons may lead to motor current rising rapidly

and even burning motor. The functional module real-time monitor

the line current of the motor. When the current exceeds the control

value and for one second, the module will judge to be the over-

current fault and cut off the control circuit, at the same time prompt

the fault type by function indicator.

1.3 Functional module

The potentiometer in the functional module is for setting the current

control value, which was set at the factory. Please don’t adjust this

value freely, so as not to affect the normal use.

The functional module will re-test after 10 minutes of over-current

protection. If the fault has been ruled out, the actuator will be back

to normal work.

When the actuator is energized the first time, the functional module

tests for 3 seconds and the indicator flashes 3 times, then the

actuator begins to work properly.

• State table of function indicator:

Potentiometer

Indicator light

Tianjin Beifang Valve Actuator Co., Ltd. 4

810 series electric actuators with control package

1.4.1 Major function The module proportional control the valve by receiving 4~20mA (or

0~5V) signal. With embedded CPU system, the module has

features of high precision, rich functions and great applicability.

•Auto-adjusting the accuracy

According to its own parameters, the valve position signal, the

control input signal and the mechanical error, the module auto-

adjust the tracking accuracy by optimization.

•Adjustable sensitivity

There are 16 grades to signal responding range (±0.5%, ±1%,

±1.5%, ±3%, ±4%, ±5%~±15%), the bigger the value, the

lower sensitivity you get. Users may set it according to control

need.

•Off signals protection (Note: 0~5V input signal has no this

function)

The input signal of less than 3mA is judged to be signal loss, which

will lead to system out of control, and even cause catastrophic

accidents. The module has the function of off signal protection, and

there are four choices in case of signal loss: keep in place, full open,

full close, middle position. The factory setting is keeping in

place.

•Running delay protection

The current shock of motor caused by instant start and stop leads

to the lack of tracking precision. The setting of running delay

protection is to reduce the lack and overcome the effect of inertia

of actuators. The delay time can be set to 2S, 3S, 4S and 5S. The

factory setting is 4S.

1.4 Regulating module The regulating module is only mounted in the

regulating product.

If users need to modify it, the running delay time should be set

greater than the inertia stopped time of actuators, otherwise it may

lower control accuracy although it can increase the response speed

of the module.

Tianjin Beifang Valve Actuator Co., Ltd. 5

810 series electric actuators with control package

1.4.2 Technical data

2S, 3S, 4S, 5S could be set.

Running

delay time

5

Adaptive adjustment of precision.

Control

accuracy

4

±0.5%, ±1%, ±1.5%, ±3%, ±4%~±15%, 16 grades

could be set.

Sensitivity3

Isolated 4~20mA, load capacity≤450ΩOutput

signal

2

4~20mA(or 0~5V), input impedance is 250Ω

Control

signal

1

DetailsItem

1.4.3 Settings and calibration

The zero and full must be calibrated before the

module putting into work, and the full must be

calibrated after the calibration of zero.

If the users need to replace the module, please connect wires

correctly according to the wiring diagram supplied with the actuators.

Set the module together with the operation of the actuator. When

the selector of actuator is in "Local", the module can only output

4~20mA valve position signal; When the selector is in "Remote", the

module can trace the input signal and analog regulate the valve

position. (Note: According to the different wiring diagram, when the

actuator is in "Remote" state, the inputting mode could be manual

or auto, the module can only work properly in "auto" mode.)

The module must be set after the setting of the limit switch and the

position indicator of the actuator (please refer to the instruction

manual provided with the valve actuator).

This module with strong and weak electricity must

only be installed in accordance with the applicable

rules by electricians who possess electrician safe

operation permits.

Tianjin Beifang Valve Actuator Co., Ltd. 6

810 series electric actuators with control package

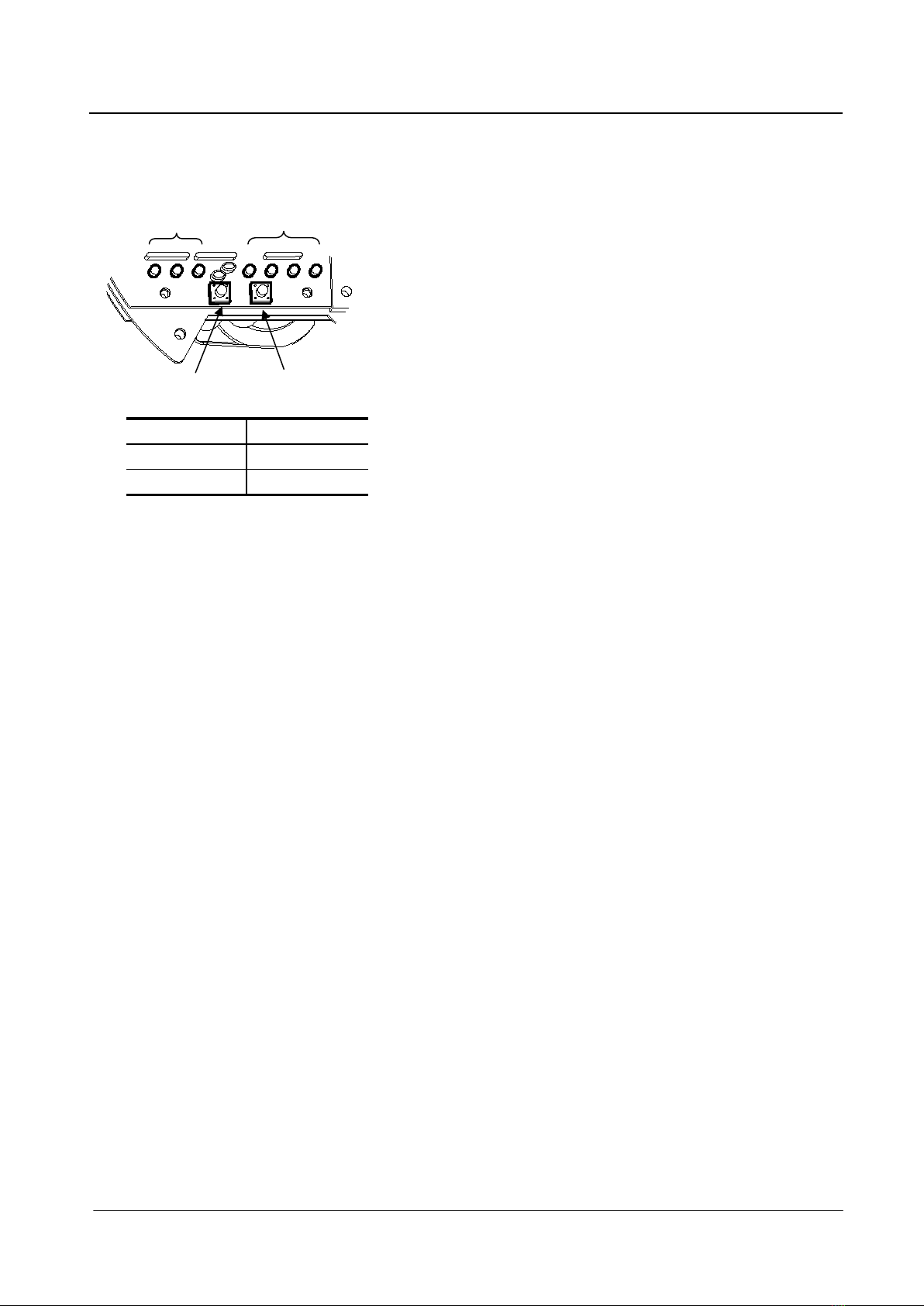

Calibration steps

(The output signal 4mA corresponds to zero, 20mA corresponds to full.)

•Calibration the zero

Fully close the valve, then press the function key to make the

function indicator light as "Zero calibration" state, then press the

adjust key until the four adjust indicators flash and the zero

calibration is finished. At this time the output signal is 4mA.

•Calibration the full

Fully open the valve, then press the function key to make the

function indicator light as "Full calibration" state, then press the

adjust key until the four adjust indicators flash and the full

calibration is finished. At this time the output signal is 20mA.

•Return to auto working state

Press function key until the first indicator next to the function key

flashes, or without pressing any key for 30s, the module will

automatically return to the auto working state.

○

●

●

○

Function indicatorFunction

○

Calibration the full

○

Calibration the zero

●On 〇Off

Function

key

Function

indicator

Adjust

key

Adjust

indicator

After calibration and parameter setting, before the actuator putting

into use, the necessary adaptive operations are suggested to run to

adapt to inertia effect of different actuators (or the error is bigger

during the several initial use).

Set the actuators in "Remote" state, then input control signal (e.g.

10mA ~ 15mA) to make the valve run in a reciprocating way at least

four times.

The module can finely tune the output signal: Set the slide switch

SW1 to ON and the adjust indicators lighting shows the calibration is

finished and the fine-tuning can be carried out, here the function

and adjust keys are turned to "+" and "-" keys. Press the function

key to slightly increase the output signal and press the adjust key to

slightly reduce the output signal until outputting 4mA/20mA. Set the

slide switch SW1 to OFF to finish the zero/full fine-tuning.

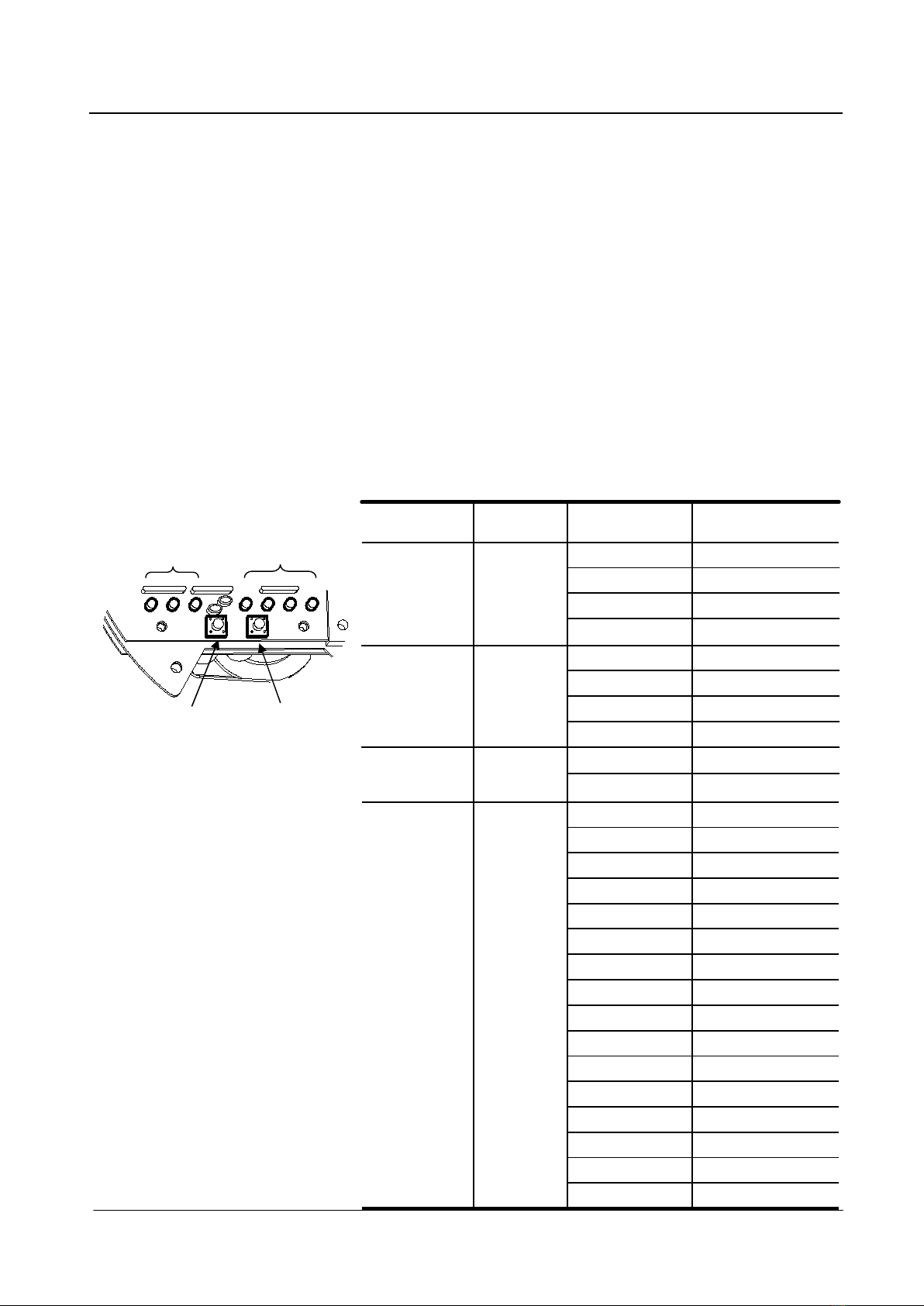

1.4.4 Advanced settings

Please make sure that the operators are familiar with all parameters

before the advanced settings, or else normal operation of the

actuator could be affected.

Users can further flexible use the module by setting the parameters.

Tianjin Beifang Valve Actuator Co., Ltd. 7

810 series electric actuators with control package

①Unlock first : In the normal, pressing adjust key makes three

function indicators light and the four adjust indicators light after 5s,

thus open the parameter setting function.

②Press Function key repeatedly to make the three function

indicators show the state of setting the parameter.

③Press Adjust key repeatedly to make what the four adjusting

indicators show meets the setting need.

④Repeat the above steps to set other parameters.

⑤End of the parameter setting: Press Function key until to auto

working state, or automatically exit to auto working state without

pressing any key for 30s.

Setting steps

●

○

●

○

●

○

●

○

●

○

●

●

●

○

○

●

●

○

○

●

●

○

●

●

●

●

○

○

○

○

●

●

●

●

●

●

●

●

●

●

●

○

○

○

○

●

○

●

○

○

○

●

○

○

○

●

○

○

○

○

●

●

○

○

●

○

○

●

○

○

○

●

○

○

●

○

○

○

○

○

○

○

○

●

○

○

○

●

○

○

○

○

○

○

○

●

○

○

○

●

○

○

○

●

Adjust indicator

●

●

○

○

●

●

●

○

Setting value

Function

indicator

Setting parameters

15%

14%

13%

12%

11%

10%

9%

8%

7%

6%

5%

4%

3%

1.5%

1%

0.5%

○

Sensitivity

(The minimum

difference

between the input

signal to start the

valve and the

valve position

signal.)

4mA close, 20mA open.

4mA open, 20mA close.

●

Open mode

5s

4s

3s

2s

●

Delay

(The delay time of

re-start the motor.)

Set to middle position.

Set to full close.

Keep in place.

Set to full open.

●

Off signal

protection

(Set the valve

movement in case

of off signals.)

Function

key

Function

indicator

Adjust

key

Adjust

indicator

Indicators status:● On 〇Off

Tianjin Beifang Valve Actuator Co., Ltd. 8

810 series electric actuators with control package

If the factory settings are need to be restored, long press the

function and adjust keys at the same time while all indicators light

until all indicators go out after 10s.

The factory settings are:

4mA close

4S

Keep in place1.5%

Open modeDelay timeOff signalSensitivity

2. Installation and

debugging

Work on the electrical system or equipment must only

be carried out by an electrician who possess operating

certificate and operate in accordance with the

applicable electrical engineering rules.

Disconnect all incoming power to the unit prior to

opening the package cover.

Open the package cover carefully to avoid damaging

switches or terminals for the control knob is wiring the

terminal strip.

Installation with control package’s underside should

be avoided or the reliability and life time of the

contacts will be reduced.

When finish installation,connect wires according to the wiring

diagram supplied with the unit.

•Wire connection

Connect the wire to the terminal strip according to the wiring

diagram. The connection is finished if the wire can’t be pulled out.

•Debugging

Calibration the zero and full is necessary before the regulating

actuator is used. Please refer to the section 1.4.3 for the calibration

steps.

1.4.5 Factory default

Tianjin Beifang Valve Actuator Co., Ltd. 9

810 series electric actuators with control package

Address :Yi Xing Fu Science & Technology

Area Beichen District, Tianjin 300410, China

Tel:(022)26308907 26309159

Fax:(022)26300975

http://www.tj-beifang.com

e-mail: [email protected]

Tianjin Beifang Valve Actuator Co., Ltd

Table of contents

Other BEIFANG VALVE ACTUATOR Controllers manuals