BEING L Series Operating instructions

®

PGROGRAMMING UIDE

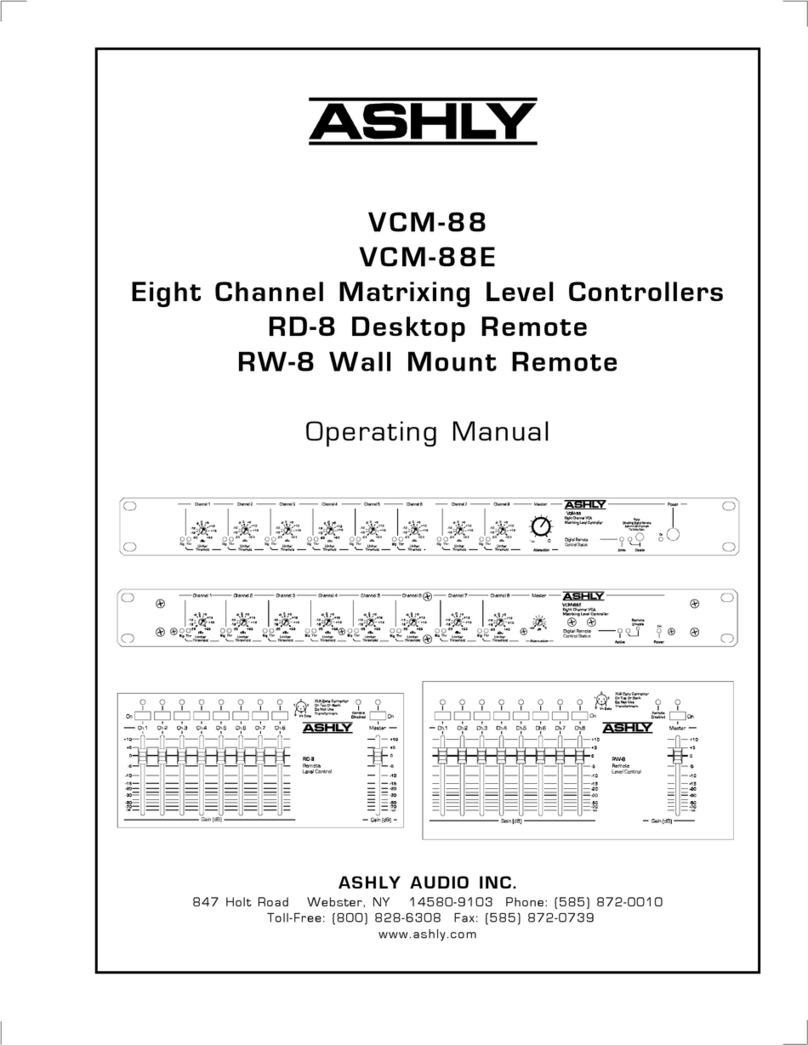

LCD CONTROLLER

L Series

PROG STEP

TI

M

E

SET

RUN

C

C

TE

M

P

88

8888

888

888

8

8

88

UV

H

L

F

F

Controller used on the following product

BOF/BON Drying Ovens

BIT/BIF Heating Incubators

BIC Cooling Incubators

BOV Vacuum vensO

BWB Water Bath

User Edition

BEING Scientific Inc. User Edition

1.0 INTRODUCTION

This programming guide provides the user of the following BEING laboratory instruments the

ability to change the backlit LCD controller’s internal parameters to allow the instrument to

work more effectively and efficiently for your operation, process, or experiment.

BIF-16, -35, -55, -120, -200, -400

Mechanical Convention Incubators

BIT-16, -35, -55, -120, -200

Natural Convention Incubators

BIC-60, -120, -250

Cooling incubators

BOF-30, -50, -120, -200, -400

Mechanical Convention Drying Ovens

BON-30, -50, -115, -200

Natural Convention Drying Ovens

BOV-20, -50, -90

Vacuum Ovens

BWB-05, -12, -22

General Purpose Water Bath

2.0 TABLE OF CONTENTS

Safety Messages ................................................................................................................................. 03

Controller elements overview ............................................................................................................. 04

Changing temperature unit of measurement ..................................................................................... 05

Calibration after unit of measurement change ............................................................................ 06 - 07

What is a multi-step program ............................................................................................................. 08

Turn on/off multi-step programs ......................................................................................................... 09

Programming multi-step programs ..................................................................................................... 10

Selecting multi-step program to run ................................................................................................... 11

Setting up program cycling ................................................................................................................. 12

Setting up RUN delay — fixed value (single-step) programs ............................................................ 13

Setting up RUN delay — multi-step programs ................................................................................... 14

Changing power-up mode .................................................................................................................. 15

Internal parameters overview ...................................................................................................... 16 - 17

02

BEING Scientific Inc.

User Edition 03

Safety Messages

Safety Message

Be sure that you are completely familiar with the safe operation of each BEING series. This unit may be connected to other

machinery, such as a vacuum pump. Improper use can cause serious or fatal injury.

Installation and repair procedures require specialized skills with laboratory equipment and electricity. Any person that installs

or repairs this unit must have these specialized skills to ensure that this unit is safe to operate. Contact BEING Instrument,

Inc. or their local authorized distributor for repairs or any questions you may have about this unit’s safe installation and

operation.

The precaution statements are general guidelines for the safe use and operation of these instruments. It is not practical to list

all unsafe conditions. Therefore, if you use a procedure that is not recommended in this programming guide, you must determine

if it is safe for the operator and all personnel in the proximity to the instrument. If there is any question of the safety of a procedure,

please contact BEING Instrument before starting or stopping the instrument.

This equipment contains high voltages. Electrical shock can cause serious or fatal injury. Only qualified personnel should

attempt the startup procedure or troubleshoot this unit.

• Documentation must be available to anyone that operates this equipment at all times.

• Keep non-qualified personnel at a safe distance from this unit.

• Only qualified personnel familiar with the safe installation, operation, and maintenance of this unit should attempt start-

up or operating procedures.

• Always stop the instrument before making or removing any connections.

Symbols used in this Programming Guide

The following signal word panels, safety symbols, and non-safety symbols are used to alert you to potential personal injury hazards

or information of importance. Obey all safety messages that follow these symbols to avoid possible personal injury or death.

• Signal word panels

Signal word panels are a method for calling attention to a safety messages or property damage messages and designate a

degree or level of hazard seriousness. It consists of three elements: a safety alert symbol, a signal word and a contrasting

rectangular background. The following signal word anels are in accordance with ANSI Z535.4-2111 (R2017) and ISO

3864 standards.

• Safety symbols

Safety symbols are graphic representations—of a hazard, a hazardous situation, a precaution to avoid a hazard, a result

of not avoiding a hazard, or any combination of these messages—intended to convey a message without the use of

words. The following safety symbols are used in this quick start guide.

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate injury.

Mandatory Warning

Prohibition

General alert. Mandatory action.

Wear protective gloves.

Safety Alert Symbol. General caution.

Do not touch fluid.

Hot Surface

BEING Scientific Inc. User Edition

04

PROG STEP

TI

M

E

SET

RUN

C

C

TE

M

P

88

8888

888

888

8

8

88

H

L

F

F

Run ON Audible Alarm Disabled

Keys

Visible Alarm

Temperature Setpoint

Actual Temperature

Countdown Timer (HH:MM)

Heat ON

Program Number

Step Number

(-)08

(-)18 (99 hours, 99 minutes maximum)

Cooling ON

Fan ON w/Speed Indication

Water Level

SETTING SHIFT DECREASE INCREASE RUN/STOP

PROG Area: Displays the program working or setting group. Controller is

capable of programming and storing up to 8 programs.

STEP Area: Displays the number of the step within a program. There are 9

steps available for each program.

TIME Area: Displays the running time or parameter value.

TEMP Area: Displays the measured (actual) temperature within the unit’s

chamber. Also, displays the ambient room temperature when requested.

SET Area: Displays the temperature setpoint.

RUN: Illuminates when the unit’s program is working. Turns off when

program is stopped.

HEAT: Arrows illuminate and blinks when the unit’s heater is on. Turns off

when heating elements are off.

COOLING: Snowflake illuminates and blinks when the unit’s cooling is on.

Turns off when cooling system is off. Series BIC only.

FAN: Fan blades illuminate and blinks when the unit’s circulation fan is on.

H (high), M (medium), and L (low) indicate the fan speed. Turns off when

fan is off. Series BIF, BIC, and BOF only.

Water Level: Indicates high and low water bath levels.

Visible Alarm: Illuminates when the program has completed, has been

stopped by user, or when an over temperature condition occurs. Addition-

ally, when the visible alarm illuminates an audible alarm will start.

Audible Alarm Disabled: Illuminates when the user presses any key or

when the unit’s power is turned off.

Keys

SETTING: Starts the programming of the temperature and run time.

Accepts the temperature and run time values.

SHIFT: For changing the parameter value being set and viewing ambient

temperature.

DECREASE: Used for setting parameter value, modification of various

values, or start/stop auto-tuning.

INCREASE: Used for setting parameter value, or press and hold for more

than 2 seconds to view the remaining program time.

RUN/STOP: Press for 2 seconds to run or stop the controller.

Controller Element Overview

BEING Scientific Inc.

User Edition

STEP 1: Enter Level 3 of controller internal parameters

Press the SETTING and SHIFT keys for 3 seconds to

enter the controller’s internal parameter settings.

Time area will change and first digit will blink.

Temperature setpoint must be changed manually.

Units are shipped with the temperature measurement set to

Celsius (OC). Parameter CF=0000.

05

Changing Temperature Unit of Measurement

STEP 2: Enter Level 3 code LK=0088

STEP 3: Scroll to parameter CF

STEP 4: Change parameter CF

STEP 5: Set parameter and return to standard state

Press the INCREASE key to enter the first code digit.

Press the SHIFT key to move to the second code

digit. Digit will blink. Press the INCREASE key to

enter the second code digit.

Press the SETTING key to enter the Level 3 controller

parameters.

First available parameter will appear.

Press the SETTING key 15 times to scroll through

parameters until the parameter CF appears.

Press the INCREASE or DECREASE key to change

the first digit.

CF=0000 Celsius (OC)

CF=0001 Fahrenheit (OF)

Press the SETTING key 2 times to set parameter

CF and return to standard state.

Upon changing the temperature unit of measure-

ment, the present value (PV) temperature will

change its value.

STEP 7: Scroll to parameter Ht

STEP 8: Change parameter Ht

Press the SETTING key 11 times to scroll through

parameters until the parameter CF appears.

Press the INCREASE or DECREASE key to

change the first digit. Press the SHIFT key

to move to the second or third digit. Press

the INCREASE or DECREASE key to change

setting.

Ht=0300 Celsius (OC)

Ht=0572 Fahrenheit (OF)

STEP 6: Repeat Steps 1 and 2

STEP 9: Set parameter and return to standard state

Press the SETTING key 6 times to set parameter Ht and return to standard state.

BEING Scientific Inc. User Edition

06

Calibration After Unit of Measurement Change

Check the instrument’s chamber temperature after

changing the unit of measurement to ensure the

controller is measuring it accurately.

Tools Needed:

A remote-monitoring thermocouple thermometer with a

NIST-traceable calibration certificate.

Compare the thermometer’s and probe’s temperature ratings against

the series operating range to ensure compatibility.

Series BOV: A ribbon lead thermocouple is required so as not to damage

the door seal. Additionally, the lead’s and probe’s materials must be

rated for temperatures up to ambient + 200OC (ambient + 392OF).

Thermometer probe’s outer diameter must be less than 5mm.

Make sure thermometer is stable. Then record the set temperature

(SV1 & SV2), present measured value (PV1 & PV2), and thermometer

reading (TV1 & TV2).

Series BIF, BIT, BOF, and BON

Series BIC

Series BOV

STEP 1: Place test materials in chamber, set program,

and press run for 3 seconds.

STEP 2: Insert thermometer probe into test hole.

Upon reaching the set temperature,

insert thermometer probe into the

test hole.

STEP 3: Run test again at a second set temperature

(SV2) at least 10OC (18OF) greater than the first.

STEP 4: Compare thermometer readings to set and

present temperatures. If SV1≠PV1≠TV1 or

SV2≠PV2≠TV2, move to STEP 5.

STEP 1: Place test materials in chamber, set program,

and press run for 3 seconds.

The test hole / accessory port is Ø25mm and

located on the right side of the incubator.

Upon reaching the set temperature and opening the test

hole, insert thermometer probe into the test hole.

Make sure thermometer is stable. Then record the set temperature

(SV1 & SV2), present measured value (PV1 & PV2), and thermometer

reading (TV1 & TV2).

STEP 3: Run test again at a second set temperature

(SV2) at least 10OC (18OF) greater than the first.

STEP 4: Compare thermometer readings to set and

present temperatures. If SV1≠PV1≠TV1 or

SV2≠PV2≠TV2, move to STEP 5.

STEP 2: Open test hole / accessory port and insert

thermometer probe into test hole.

STEP 1: Place test materials in chamber. Place

temperature probe in the center of the chamber.

Close and lock door. Set program and press

run for 3 seconds.

Make sure thermometer is stable. Then record the set temperature

(SV1 & SV2), present measured value (PV1 & PV2), and thermometer

reading (TV1 & TV2).

STEP 2: Run test again at a second set temperature

(SV2) at least 10OC (18OF) greater than the first.

STEP 3: Compare thermometer readings to set and

present temperatures. If SV1≠PV1≠TV1 or

SV2≠PV2≠TV2, move to STEP 4.

BEING Scientific Inc.

User Edition 07

STEP 4/5: Perform the following calculations to deter-

mine Pb and PK.

Series BWB

STEP 1: Fill chamber. Place test materials in chamber.

Close chamber cover. Set program and press

run for 3 seconds.

Make sure thermometer is stable. Then record the set temperature

(SV1 & SV2), present measured value (PV1 & PV2), and thermometer

reading (TV1 & TV2).

STEP 3: Run test again at a second set temperature

(SV2) at least 10OC (18OF) greater than the first.

STEP 4: Compare thermometer readings to set and

present temperatures. If SV1≠PV1≠TV1 or

SV2≠PV2≠TV2, move to STEP 5.

STEP 2: Upon reaching set temperature, oven chamber

cover. Insert the thermometer probe into the

center of bath.

The Math

For example:

SV1= 37OC TV1 = 36OC

SV2= 50OC TV2 = 48OC

Full Scale Adjustment (Slope)

PK = {[(TV2-TV1) ÷ (SV2-SV1)] - 1} x 4000

PK = {[(48-36) ÷ (50-37)] - 1} x 4000

PK = -308

Zero Adjustment (Intercept)

Pb = TV2 - {[PK ÷ (4000 ÷ SV2)] + SV2}

Pb = 48 - {[-308 ÷ (4000 ÷ 50)] + 50}

Pb = 1.9

STEP 5/6: Enter Level 2 of controller internal parameters

Programming Correction

Press the SETTING and SHIFT keys for 3 seconds to

enter the controller’s internal parameter settings.

Time area will change and first digit will blink.

SET

C

C

TE

M

P

00

22

63

4

0

00 Blink

STEP 6/7: Enter Level 2 code. LK=0003

STEP 7/8: Change parameter Pb

Press the INCREASE key to enter the code digit.

Press the SETTING key to enter the Level 2 controller

parameters.

The tM parameter will appear. Press the SETTING

key 3 times to scroll through parameters until the

parameter Pb appears.

Press the INCREASE or DECREASE key to

change the first digit. Press the SHIFT key

to move to the second digit. Digit will blink.

Press the INCREASE key to enter the second

digit. Continue until parameter is set.

Press the SETTING key 1 time to move to the

PK parameter.

SET

C

C

TE

M

P

00

22

63

4

0

00 Blink

Y

STEP 8/9: Change parameter PK

Press the INCREASE key to change the first

digit. Press the SHIFT key to move to the

second digit. Digit will blink. Press the

INCREASE key to enter the second digit.

Continue until parameter is set.

Press the DECREASE key immediately if you

want a negative parameter value.

Press the SETTING key 2 times to set parameter

PK and return to standard state.

BEING Scientific Inc. User Edition

08

What is a Multi-step Programs

Target Temp 1

Running Time 1

Target Temp 1

Target Temp 2

Target Temp 3

Room Temp

Step 1Start

Climb Time 1 Climb Time 2 Climb Time 3

Step 2 Step 3

Target Temp 2

Running Time 2

Target Temp 3

Running Time 3

M-T TULTI EMPERATURE ESTING

Legend

Target temp: The temperature you want it to run as planned. (Input / set temperature)

Climb time: The time it takes to reach your target temperature setting. The temperature rise rate will be controlled automatically based on the controller’s settings. The

step’s run time will not start counting down until the chamber reaches ±0.5 OC / OF of the set temperature.

Running time: The time you want the chamber to run at the set temperature. The controller automatically launches the next step when time runs out unless it is the last step

in the program then the unit shuts down and the audible and visual alarm goes off.

Numerous applications — like materials testing, quality assurance, environmental simulation, and many more — in

many industries require precise, multi-temperature (heating or cooling) testing.

BEING’s L Series controller allows the user to easily program up to 8 multi-step (multi-temperature) programs with

up to 8 steps (temperature and run time) per program. Each program can be cycled from 1 to 99 times.

The following chart shows a 3-step program, where for example, Step 1 is 25OC for 60 minutes, Step 2 is 99OC for 45

minutes, and Step 4 is 199OC for 99 minutes.

Programs

PROG O - Fixed Value and Time

PROG 1 - Multi-step, Step 1 to Step 8

PROG 2 - Multi-step, Step 1 to Step 8

PROG 3 - Multi-step, Step 1 to Step 8

PROG 4 - Multi-step, Step 1 to Step 8

PROG 5 - Multi-step, Step 1 to Step 8

PROG 6 - Multi-step, Step 1 to Step 8

PROG 7 - Multi-step, Step 1 to Step 8

PROG 8 - Multi-step, Step 1 to Step 8

BEING Scientific Inc.

User Edition 09

Turning On/Off Multi-step Programs

STEP 1: Enter Level 4 of controller internal parameters

Press the SETTING and SHIFT keys for 3 seconds to

enter the controller’s internal parameter settings.

Time area will change and first digit will blink.

Upon initializing the unit for the first time, user needs to set the

temperature and time for each step in a program.

Units are shipped with the controller set to fixed value

(single-step) programs. Parameter Mo=0000.

STEP 2: Enter Level 4 code. LK=8286

STEP 3: Change parameter Mo

STEP 4: Set parameter and return to standard state

Press the INCREASE key to enter the first

code digit. Press the SHIFT key to move to the

second code digit. Digit will blink. Press the

INCREASE key to enter the second code digit.

Follow the same procedure for the third and

fourth code digits.

Press the SETTING key to enter the Level 4 controller

parameters.

The Mo parameter will appear.

Press the INCREASE or DECREASE key to change

the first digit.

Mo=0000 Fixed value (Single-step) program

Mo=0001 Multi-step programs

Press the SETTING key 1 time to set parameter Mo

and return to standard state.

Upon changing to multi-step progams, the controller

screen will change to PROG 1.

BEING Scientific Inc. User Edition

10

Programming Multi-step Programs

STEP 1: Select program number to set up

Press the INCREASE key to select the

program number to program.

STEP 2: Set the STEP temperature

STEP 3: Set the STEP run time

Press the INCREASE or DECREASE key

to enter the tenths temperature value.

Press the SETTING key to accept the

run time.

The next program step will appear.

The tens temperature value will blink.

Upon setting all of the steps, the controller will

return to multi-step program standard state.

Press the SETTING key to accept

temperature setpoint. The first TIME

digit will blink.

Units are shipped with the controller initially set to PROG 1

when multi-step programs are turned on. If multi-step

programs are turned off and later turned on, the last

program run or selected will be displayed.

Press the SETTING key for 3 seconds. The “PROG 1”

will initially blink. Then the number will blink.

Units are shipped with all steps in each program set to zero temperature

and zero run time.

Pressing the SETTING key starts the

programming process.

STEP 1 will appear. “End” in TIME

area will change to run time digits.

PROG and the tenths temperature

value blinks.

Press the SHIFT key to move to the next

parameter digits. Each move will cause

parameter to blink.

Use INCREASE or DECREASE key to set

each temperature value.

Use INCREASE or DECREASE key to

set each minute and hour value.

Press the SHIFT key to move to the

next parameter digits.

STEP 4: Repeat Steps 2 and 3 for each program step

Leave step temperature and run time at zero for each step not needed

for the program.

BEING Scientific Inc.

User Edition 11

Selecting Multi-step Program to Run

STEP 1: Press SETTING key

Units are shipped with the controller initially set to PROG 1

when multi-step programs are turned on. If multi-step

programs are turned off and later turned on, the last

program run or selected will be displayed.

Press the SETTING key one (1) time. The “PROG”

area will blink.

STEP 2: Select program number

Press the INCREASE or DECREASE to select

program number.

Press the SETTING key to confirm the pro-

gram to be run.

Pressing the RUN key for 2 seconds starts the

program. STEP area, RUN, HEAT, and run time

illuminate.

STEP 3: Press RUN key

BEING Scientific Inc. User Edition

12

Setting up Program Cycling

STEP 1: Ensure the multi-step program function is

turned on. See “Turning On/Off Multi-step Programs”

instructions on page 09.

Units are shipped with program cycling set to 1.

Parameter Cy=0001.

This function is for multi-step

programs only.

Press the SETTING and SHIFT keys for 3 seconds to

enter the controller’s internal parameter settings.

Time area will change and first digit will blink.

STEP 2: Press SETTING key

STEP 3: Scroll to parameter Cy

Press the SETTING key to enter Level 1 parameters.

Press the INCREASE key to enter the first

cycle value. Press the SHIFT key to move to

the second cycle digit. Digit will blink. Press

the INCREASE key to enter the second cycle

value.

Press the SETTING key 1 time to scroll

through parameters until the parameter

Cy appears.

STEP 2: Select program (1 - 8) to run multiple cycles.

See “Selecting Multi-step Program to Run” instructions

on page 11.

STEP 3: Enter Level 1 of controller internal parameters

When entering the controller’s internal parameters, Level

1, LK =0000, will always come up first.

Parameter Cy=0001 to 0099.

STEP 4: Set parameter and return to multi-step

program standard state.

Press the SETTING key 2 times to set parameter Cy

and return to multi-step program standard state.

BEING Scientific Inc.

User Edition

Setting up RUN Delay

Fixed Value (Single-step) Programs

BEING’s L Series controller allows the user to delay the

start of a program for up to 99 hours and 59 minutes.

Once the delay times out, the program will start operation.

Press the SETTING and SHIFT keys for 3 seconds to

enter the controller’s internal parameter settings.

Time area will change and first digit will blink.

STEP 2: Press SETTING key

Press the SETTING key to enter Level 1 parameters.

STEP 1: Enter Level 1 of controller internal parameters

When entering the controller’s internal parameters, Level

1, LK =0000, will always come up first.

Press the SETTING key 1 time to set

parameter dy and return to fixed value

program standard state.

Press the INCREASE key to enter the first

time value. Press the SHIFT key to move to

the second time digit. Digit will blink. Press

the INCREASE key to enter the second time

value.

Parameter dy=00:00 to 99:59.

STEP 4: Set parameter and return to multi-step

program standard state.

13

BEING Scientific Inc. User Edition

14

SET

C

C

TE

M

P

00

22

63

4

0

08

P

Y

PROG

STEP 4: Set parameter and return to multi-step

program standard state.

Press the SETTING key 1 time to set parameter dy

and return to multi-step program standard state.

Setting up RUN Delay

Multi-step Programs

STEP 1: Ensure the multi-step program function is

turned on. See “Turning On/Off Multi-step Programs”

instructions on page 09.

Press the SETTING and SHIFT keys for 3 seconds to

enter the controller’s internal parameter settings.

Time area will change and first digit will blink.

STEP 2: Press SETTING key

Press the SETTING key to enter Level 1 parameters.

STEP 2: Select program (1 - 8) to run multiple cycles.

See “Selecting Multi-step Program to Run” instructions

on page 11.

STEP 3: Enter Level 1 of controller internal parameters

When entering the controller’s internal parameters, Level

1, LK =0000, will always come up first.

SET

C

C

TE

M

P

222

0

4

0

PROG

000 1 Blink

2

times

SET

C

C

TE

M

P

00

22

63

4

0

00

P

YBlink

PROG

STEP 3: Scroll to parameter dy

Press the INCREASE key to enter the first

time value. Press the SHIFT key to move to

the second cycle digit. Digit will blink. Press

the INCREASE key to enter the second time

value.

Press the SETTING key 2 times to scroll

through parameters until the parameter

dy appears.

BEING Scientific Inc.

User Edition 15

Changing Power-up Mode

Units are shipped with power-up mode set to 2. The

controller starts running from the last power-off.

Parameter Po=0002.

STEP 1: Enter Level 2 code. LK=0003

Press the INCREASE key to enter the code digit.

Press the SETTING key to enter the Level 2 controller

parameters.

SET

C

C

TE

M

P

20

22

63

4

0

50 Blink

1

time

STEP 2: Scroll to parameter Po

The tM parameter will appear. Press the SETTING

key 1 time to scroll through parameters until the

parameter Po appears.

STEP 3: Change parameter Po

Press the DECREASE key to change the first

digit.

Po=0000 The controller is in a stopped

state after power-on, and user must start the

operation pressing START/STOP button for 2

seconds.

Po=0001 The controller automatically the step

operation after power-on.

Po=0002 The controller starts running from

the last power-off.

Press the SETTING key 4 times to set parameter Po

and return to standard state.

STEP 4: Set parameter and return to standard state.

BEING Scientific Inc. User Edition

Level 1

LK [ ] = 0000

PROMPT INITIAL VALUEFUNCTION NAME FUNCTION RANGE EXPLANATION

Pn Working Group 0 – 8 For multi-step program control only, set up a working group for instrument

operation. When Pn is set to 0, group 0 is fixed value (single-step) control.

Cy 0001

No. of Cycles 0 – 99

Controls number of times a multi-step program runs. When Cy is 0, the

instrument has been running between the work groups. When Cy IS NOT 0, the

instrument will automatically stop after cycling Cy times in the work group. The

value will automatically return to 1 after shutdown.

dy 00:00

Run Delay 00:00 – 99:59

(hh:mm)

00:00 - No delay. Other values - Start of a program will be delayed dy time after

pressing the RUN key.

16

PROMPT INITIAL VALUEFUNCTION NAME FUNCTION RANGE EXPLANATION

tM 200.0

Maximum Allowable

Temperature Setting

Set within the

measuring range Stop heating and alarm when the maximum temperature is exceeded

Po 0002

Power-up Mode 0 – 2

Po=0000: Controller is in a stopped state after power-on. User must start the

operation by pressing the RUN/STOP button for 3 seconds. Po=0001: Controller

automatically starts the step operation after power-on. Po=0002: Controller starts

running from the last power-off.

AL 003.0Alarm Setting 0 – Full Range Alarm illuminates with audible output (and HOLD function) when the temperature

exceeds the Setpoint+AL value.

Pb 000.0

Zero Adjustment

(Intercept) -100.0 – 100.0 When the zero error of the meter is large and the full-scale error is small, adjust

this value. Generally, PT100 rarely adjusts this value.

PK 0000

Full Scale Adjustment

(Slope) -1000 – 1000

When the zero error of the meter is small and the full-scale error is large, adjust

the value. PK=4000 x (mercury thermometer value-display value)/display value,

generally PT100 first adjust this value.

PA 000.0

Ambient Temperature

Correction -80 – 80 When there is an error between the actual ambient temperature and the controller

display ambient temperature, adjust the value

Level 2

LK [ ] = 0003

Internal Parameter Settings Overview

Press increase key to change

first digit value. Value will blink

as it is being set.

Press the shift key to move to the

next parameter digits. Each move

will cause digit to blink.

Press and hold SETTING and

shift keys for 3 seconds to

view the controller’s internal

parameters.

Press SETTING key once

entering required code for

the parameter level you

want to change.

First available function parame-

ter within level will appear. Press

increase key to change first digit

value. Value will blink as it is

being set.

Press the shift key to move to the

next parameter digits. Each move

will cause digit to blink.

Press SETTING key once

entering parameter value.

Next parameter will appear

or controller will return to

standard state.

STEP 1

STEP 2

STEP 3 STEP 4 STEP 5

Changing parameter value process

BEING Scientific Inc.

User Edition

PROMPT INITIAL VALUEFUNCTION NAME FUNCTION RANGE EXPLANATION

Mo 0000Program Type Selection 0 – 1 Mo=0000: Fixed Value (Single-step Program)

Mo=0001: Multi-step Program

Level 4

LK [ ] = 8286

17

BEING Scientific Inc. User Edition

18

INTENTIONALLY BLANK

BEING Scientific Inc.

User Edition 19

INTENTIONALLY BLANK

®

®

Scientific Inc.

1050 W Lakes Dr., Suite 225 & 250 | West Covina, CA 91790

PG-Lseries-User-V2-032022

Other manuals for L Series

1

Table of contents

Other BEING Controllers manuals

Popular Controllers manuals by other brands

Ecodhome

Ecodhome Z-Wave installation manual

Morningstar

Morningstar TrakStar TriStar TS-MPPT-60M Installation, operation and maintenance manual

Audiovox

Audiovox GCS owner's manual

MidNite Solar

MidNite Solar Classic 150 owner's manual

Baseus

Baseus CGNL020101 user manual

Hunter

Hunter PRO-C Hydrawise Reference card