Beinlich ECO.pump EP Series Manual

Operating and maintenance instructions

2

Page

1. Important information and legal notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Details of the pump type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Permissible use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Safety and warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. 2. General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Safety instructions for operators/users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Safety instructions for maintenance / inspection and assembly work . . . . . . . . . . . . . . . . 7

4.3 Unauthorized operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

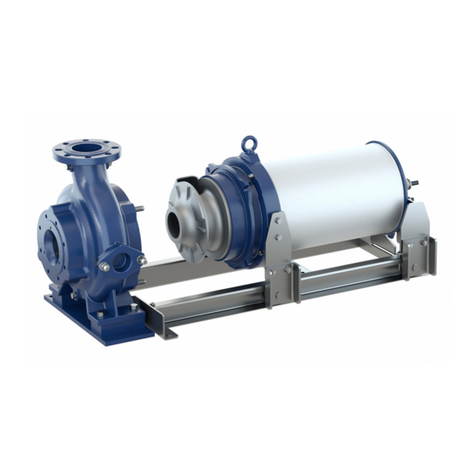

5. Structural design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Commissioning – Preparation work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7. Commissioning – In General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.1 Installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.2 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.3 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8. Storage, return and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9. Maintenance, service life and warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

10. Disassembly and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10.1 Basic regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10.2 Disassembly of the pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10.4 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10.5 Shaft seal disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.6 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

11. Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

12. Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

13. Model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

14. Certificate of non-objection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

TABLE OF CONTENTS

3

1. IMPORTANT INFORMATION AND LEGAL NOTICES

Dear customer, dear user,

These operating instructions for the "ECO.pump" external gear pumps from Beinlich Pumpen GmbH (Beinlich)

contain information required to properly install and commission the pump for its intended purpose.

Any installation, commissioning, operation, maintenance and testing may only be carried out by trained and

authorized personnel. The operating instructions must be read carefully and followed in detail to ensure trouble-free,

proper and safe operation of the pump. In particular, the safety instructions must be observed.

These operating instructions must be kept in a place where they can be viewed by authorised personnel at all

times. The contents of the operating instructions must not be removed at any time. Missing operating instructions

or missing pages must be replaced immediately if lost. The operating instructions can be requested from Beinlich or

downloaded from our website www.beinlich-pumps.com at any time. The operating instructions must be passed on

to any subsequent user of the pump.

These operating instructions are not subject to any modification service by Beinlich. Beinlich reserves the right to make

technical changes at any time without notice.

Beinlich makes no warranties, express or implied, with respect to commercial qualities and suitability for a particular

purpose.

Beinlich accepts no liability for damage and malfunctions resulting from operating errors, failure to observe these

operating

instructions, improper installation, commissioning or maintenance as well as improper use of the pump.

Opening the pump is generally not permitted. If the pump is opened or modified without authorization, or after a

single incorrect connection, Beinlich's warranty and product liability will expire.

The publication of these operating and maintenance instructions renders all information from previous publications invalid. Beinlich

reserves the right to make modifications and differences. Beinlich accepts no liability for possible printing errors. Reproduction, even

in excerpt form, is permitted only following written consent from Beinlich. Beinlich reserves the right to make technical modifications

at any time. Last updated: 05/2023

4

2.1 Details of the pump type

For a complete type description, refer to the techni-

cal specifications or the order confirmation. The serial

number consists of the order number and a sequential

serial number (e.g. 16/0000-00). It is affixed to the type

plate or directly to the pump.

2.2 Technical specifications

The technical specifications are part of our order con-

firmation and include all important technical details that

were agreed to by the purchaser and the manufacturer.

These operating instructions form part of the delivery and

must be read before working with the pump. Compliance

with the instructions in these operating instructions is

mandatory. Store these operating instructions near the

pump.

NOTE

No liability will be accepted for damages or malfunctions

resulting from non-compliance with these operating

instructions. In the context of continued development,

Beinlich Pumpen GmbH reserves the right to make

changes to the individual components or assemblies that

are deemed to make sense for the improvement of the

product while maintaining the main characteristics.

2. GENERAL INFORMATION

2.3 Permissible use

The pump/pump assembly is exclusively designed for

the permissible use that is listed in the technical speci-

fications of our order confirmation. We recommend

checking the compatibility of the material with the

medium. Deviating operating conditions require new

contractual agreements.

5

You must comply with all safety warnings in the operating

instructions that are identified as followed:

3. SAFETY AND WARNING SIGNS

Warning of mechanical hazard

Warning of hot surface

Warning of hazardous electric voltage

Important information for safe and

fault-free operation

Read the operating instructions/

comply with regulations

Enable

Secure

Information, tips

6

Every delivery must be checked for any damage sus-

tained during transport immediately after it is received.

Commissioning may need to be cancelled. The customer

is responsible for the correct set-up of the pump.

Confirmed properties of the pump require compliance

with the information in these operating instructions. Ensure

that you never use damaged products.

Read the operating instructions carefully before starting

any set-up, assembly or maintenance work. Assembly,

connection, commissioning and maintenance or repair

work must only be carried out by suitably qualified pro-

fessionals taking account of

•These instructions;

•All other project management documentation, com-

missioning instructions and circuit diagrams pertaining

to the drive;

•National and regional regulations currently in force

governing safety and accident prevention.

4.1 Safety instructions for the user/operator

4. GENERAL SAFETY INSTRUCTIONS

Assembly and maintenance work must only be carried out with the drive stationary!

The unit must be isolated and secured to prevent accidental start-up.

If hot or cold machine parts present a hazard, these parts must be secured against being touched

during installation.

Contact protection for moving parts, such as the coupling, must not be removed when the machine is

in operation.

Leakage (e.g. the shaft seal) of hazardous materials (e.g. explosive, toxic, hot) must be dealt with and

disposed of so that neither people nor the environment are endangered. Legal obligations are to be

complied with.

Hazards caused by electrical energy must be eliminated in all instances. (For details of these, see the

regulations provided by the VDE, for example, and the energy supply companies). Electrical connec-

tions must be installed by trained personnel.

Opening of the pump during the warranty period is only permitted following consultation with and

approval from Beinlich Pumpen GmbH!

7

4.3 Unauthorized operating modes

The operational safety of the machine that was delivered

is only warranted with intended use according to Section

1 “General notes” of these operating instructions. Any

exceedance or shortfall of the specified limit values in

the technical specification must be prevented under any

circumstances.

The pump consists of a front plate (1), combined

plate (2), drive shaft (3), pin (4) and gears (5). The

suction and pressure connections are designed as BSP

inner threads.

5. STRUCTURAL DESIGN

4.2 Safety instructions for maintenance / inspection and assembly work

The operator must make ensure that all maintenance, in-

spection and assembly work is exclusively performed by

authorized qualified specially trained personnel who are

sufficiently informed after carefully studying the opera-

ting instructions.

Any work on the pump must be performed when

the pump is at standstill.

Adherence to the procedures that are described in the

operating instructions for stopping the machine is impe-

rative. Pumps and pump assemblies that convey media

that pose a health risk must be decontaminated. All safe-

ty and protective equipment must be reinstalled and acti-

vated immediately following the completion of the work.

All items listed in the “Commissioning” section must be

observed prior to restart.

86. COMMISSIONING PREPARATION WORK

7. COMMISSIONING IN GENERAL

The pump must only be commissioned when:

•The information of the technical specifications in the

order confirmation matches the information in the use

conditions.

•There is no visible damage, such as due to storage or

transport.

•Sealing caps and protective covers are not damaged.

•There are no visible leaks.

•There is no corrosion or any other indication of

improper or damp storage.

•All packaging material was removed without remnants.

7.1 Installation position

any

7.2 Direction of rotation

Standard direction of rotation

clockwise (CW)

7.3 Connections

0.15 cm³ – 2.40 cm³ G 1/4

3.00 cm³ G 3/8

4.80 cm³ – 6.00 cm³ G 1/2

7.4 Temperature

The minimum and maximum temperature is contingent

upon the sealing material! Observe a possible change of

viscosity of the medium when the temperature changes.

Reference the technical specifications.

The use of sealing materials such as hemp or putty is prohibited due to a risk of contamination!

SuctionPressure

98. STORAGE, RETURN AND DISPOSAL

Storage

All Beinlich pumps are supplied with sealing plugs and

in suitable packaging for all destinations and modes of

transport to ensure optimum protection. The pumps should

always be stored in their original packaging. The units

must not be exposed to temperatures below -20°C or

above +60°C and must be protected from moisture and

its effects.

Return

1.

Only cleaned, medium-free pumps can be accepted by

Beinlich Pumpen for maintenance or repair. The pump

must therefore be properly cleaned by the customer

before being returned to prevent the risk of poisoning/

contamination by harmful, explosive and other high-

risk pumped media for humans and the environment.

2. If media have been conveyed whose residues with

atmospheric humidity lead to corrosion damage

or ignite on contact with oxygen, the pump must be

additionally neutralised and thoroughly cleaned with

anhydrous, inert gas to dry.

3. The return of the pump must always be accompanied

by a fully completed declaration of non-objection

(see section 14, page 14). All applied safety and

decontamination measures must be indicated. Pumps

for which this safety certificate has not been completed

and signed cannot be inspected or repaired for safety

reasons and will be returned uninspected at your

expense. The declaration of no objection can be

requested from Beinlich Pumpen or downloaded from

our website.

4. When returning the pump, it must be packed in

accordance with the applicable logistics standards

and sealed with sealing plugs.

Disposal

Beinlich actively promotes environmental awareness

and has an operational management system that meets

the requirements of ISO 9001:2015. The impact on the

environment and people should be minimised during the

production, storage, transport, use and disposal of our

products and solutions.

•

Collect rinsing liquid as well as residual liquid

and dispose of it in accordance with the statutory

provisions and regulations.

•

Wear protective clothing and protective mask/+

goggles if necessary.

Materials must be disposed of properly as follows:

•

Metal

•

Plastics

•

Grease and lubricants

•

Electronic components

•

etc.

When disposing of the materials, ensure that the waste-

relevant rules and regulations of the respective country of

destination are observed!

10

10.1 Basic regulations

The unit must be secured to prevent reactivation before commencing disassembly work. The shut-off

devices in the supply line must be closed. The pump must be at the ambient temperature.

10. DISASSEMBLY AND REASSEMBLY

Beinlich gear pumps are maintenance free under

standard conditions. A continuous control of the technical

parameters is recommended. The use of corresponding

control equipment like working hour counter, pressure

and temperature switches, etc. should be done in relation

to general regulations.

During maintenance on the unit please consider the

following:

• Check all fastening screws and connections to

ensure they are securely tightened and

re-tighten if necessary.

• Control the alignment of the coupling. Check

elastomers for wear.

• Control the tightness of the pump, especially the

shaft seal.

Depending on the operating conditions, the service

life and therefore the specific properties of the pumps

are limited by wear, corrosion, deposits or ageing.

The operator is responsible for regular inspection,

maintenance and recalibration. Any observation of a

malfunction or damage prohibits further use. On request,

we can provide you with a loan unit for the duration

of the overhaul. We recommend an annual check and

recalibration. Under normal operating conditions, the

service life is 10,000 hours. The warranty period is 12

months.

9. MAINTENANCE, SERVICE LIFE AND WARRANTY

11

1

4

7

8

11

2

3

5

9

10

14

13

12

6

10.2 Disassembly of the pump

10.2.1 Pull the key (4) off the shaft

10.2.2 Unscrew the 4 cylinder bolts M6 (1)

10.2.3 Carefully remove the front plate (6)

10.2.4 Pull the drive shaft with gear out (7, 9, 10)

10.2.5 Pull the driven gear out (8)

10.2.6 Remove the circlip (10)

10.2.7 Pull the gear off the shaft

Note

The pin (12) is pressed into the combined plate (14) and

cannot be removed.

10.3 Cleaning

10.3.1 Use only suitable cleaning agents.

Do not use abrasive media.

10.3.2 Remove the O-ring (11) and replace it after

cleaning.

10.3.3 The pump must be dried and then lubricated

with liquid, that does not react with the medium

to be conveyed.

10.4 Assembly

10.4.1 Aligne pins (13) in the combined plate (14).

10.4.2 Slide the gear (8) onto the pin (12).

10.4.3 Slide the gear (9) onto the drive shaft (7) and

secure it with a circlip (10).

10.4.4 Make sure that the O-ring (11) is correctly fitted

in the groove.

10.4.5 Carefully mount the front plate on the combined

plate. The bearing position in the front plate

centres the shaft for the radial shaft seal.

10.4.6 Insert the cylinder bolts (1).

Tighten the bolts step-by-step in a cross-diago-

nal pattern to 15 Nm

12

Note

The front plate must be disassembled to remove the radial

shaft seal. See Disassembly Instructions (10.2.1 – 10.2.3)

10.5 Shaft seal disassembly

10.5.1 Remove the key (4)

10.5.2 Remove the locking ring (2)

10.5.3 Remove the front plate

(see Disassembly 10.2.1 – 10.2.3)

10.5.4 Remove the support ring (3) (does not apply to

PTFE version) and remove the radial shaft seal (5)

10.6 Assembly

10.6.1 Press the radial shaft seal and the support ring

into the front plate to the shaft seal below the

groove for the locking ring.

10.6.2 Fit the locking ring in the groove

10.6.3 Carefully mount the front plate on the combined

plate. The bearing position in the front plate

centres the shaft for the radial shaft seal.

10.6.3 The aligning pins centre the front plate on the

combined plate.

10.6.4 Insert the cylinder bolts (1)

Tighten the bolts step-by-step in a cross-diagonal

pattern to 15 Nm

Note

The drive shaft should be rotated manually while tighte-

ning the bolts.

2

3

5

4

13

All related documents is included in the technical specifi-

cations or the order confirmation.

Provide the following information to place orders for

spare parts:

•Order No.

•Item no. of the pump

•Part no. according to the parts list

•Quantity

Maintaining a supply of the most important spare parts

and wear parts at the installation location is an important

requirement for the operational readiness of the pump.

As an alternative, we recommend maintaining a standby

pump on site and send the disassembled pump to our

plant for repairs as needed. Our parts list with sectio-

nal view is available for ordering spare parts. We ad-

vise explicitly that spare parts and accessories that are

not supplied by us are not checked and approved by us.

Therefore, the installation and/or use of such products

may negatively impact the constructively specified cha-

racteristics of the pump and affect the active and/or pas-

sive safety.

We are not liable for or provide warranty services for

damages resulting from the use of spare parts and ac-

cessories other than original spare parts and accesso-

ries.

11. SPARE PARTS

12. RELATED DOCUMENTS

13. MODEL CODE

Size

1

Mounting

FBare shaft

Special design code

Coating

HS0 Without coating

HS1 With coating

Connections

P1 Suction /pressure connection G1/4

P2 Suction /pressure connection G3/8

P3 Suction /pressure connection G1/2

Design

Version

EE Stainless steel

LE Aluminium

KI Nitriding steel

Displacements

cc/rev

Rotation

RRight (cw)

EP 1 2.40 EE R F / HS 0 / P2 / 000

14 14. CERTIFICATE OF NON-OBJECTION

No Yes

No Yes

No Yes

SAFETY DECLARATION

(CERTIFICATE OF NONOBJECTION)

If yes, which

Solvents

Toxic liquids

Biologically active liquids

Radioactive liquids

Corrosive liquids

Alkali

Explosive liquids

Other media

No Yes

No Yes

No Yes

No Yes

No Yes

No Yes

No Yes

No Yes

The pump was used in media which are hazardous to health/environment.

The pump was carefully emptied before dispatch and cleaned

inside and outside.

Special safety measures or treatment is necessary or expected.

The pump, including accessories were last used with the following media:

Yes* No

Part no. Serial no.

Manufacturer

Manufacturer

CAS no.

CAS no.

Pump type

Reason for return

Pumped medium

Cleaning medium

Safety data sheet

for the cleaning medium

*if positive, please enclose as an attachment

Yes* No

Safety data sheet

for the pumped medium

Pumps for which this safety certificate has not been completed and signed can neither be inspected

nor repaired for safety reasons and will be returned unchecked at your expense.

Last revised: 04/2023

P. 1/2

Beinlich Pumpen GmbH

Gewerbestraße 29 | 58285 Gevelsberg | Germany

Phone +49 (0) 23 32 / 55 86 -0

15

The undersigned assures that the above information is correct and complete and the shipping is

carried out according to legal regulations. The undersigned is liable for all damages which arise as

a result of the non-marked decontamination of the returned pump.

Beinlich expressly points out that repairs and verification work is carried out by trusting the

correctness of the completion of this safety declaration (certificate of non-objection). Should

physical injuries, death or even damage to property occur, claims for damages will be asserted.

Contact

(in capitals)

Enclosed

Postcode / Town

Company

Street / Building no.

Email

Phone

Fax

Date

Signature

(company stamp)

SAFETY DECLARATION

(CERTIFICATE OF NONOBJECTION)

P. 2/2

Beinlich Pumpen GmbH

Gewerbestraße 29 | 58285 Gevelsberg | Germany

Phone +49 (0) 23 32 / 55 86 -0

05/23 www.plakart.de EP 12/16 - E - BW - 1/12 HKAT003 0006

Beinlich Pumpen GmbH

Gewerbestraße 29

58285 Gevelsberg/Germany

Phone +49 (0) 23 32 / 55 86 0

info@beinlich-pumps.com

www.beinlich-pumps.com

TÜV NORD CERT

GmbH

I

S

O

9

0

0

1

/

1

4

0

0

1

/

4

5

0

0

1

/

5

0

0

0

1

Table of contents

Popular Water Pump manuals by other brands

Graco

Graco Premier 970199 Instructions-parts list

Wayne

Wayne WAPC250 Operating instructions and parts manual

KSB

KSB Vitaprime Installation & operating manual

MasterCraft

MasterCraft 62-3515-0 owner's manual

Pressol

Pressol mobiMASTER OPERATING INSTRUCTIONS AND SAFETY NOTES

Lincoln

Lincoln B Series Service & operating manual