Belden Hirschmann OZD Profi 12M Pro Series Owner's manual

Please read and notice the detailed

”Manual F/O Fieldbus epeater OZD Profi 12M … P O“.

Use the fax form on page 6 of this leaflet to order a free copy of this manual (Order No. 039 690-001).

General Safety Instructions

䊳This device is electrically operated. Adhere strictly to the safety requirements relating to voltages applied to the device

as described in the operating instructions!

䊳Make sure that the electrical installation meets local or nationally applicable safety regulations.

Warning!

Failure to observe the information given in the warnings could result in serious injury and/or major damage.

Only personnel that have received appropriate training should operate this device or work in its immediate vicinity.

The personnel must be fully familiar with all of the warnings and maintenance measures in these operating

instructions.

Correct transport, storage, and assembly as well as careful operation and maintenance are essential in ensuring

safe and reliable operation of this device.

Never start operation with damaged components!

Warning!

Any work that may have to be per formed on the electrical installation should be performed by fully qualified

technicians only.

Warning!

LED- or LASER components according to EC 60825-1 (2007):

CLASS 1 LASER PRODUCT.

L GHT EM TT NG D ODE - CLASS 1LED PRODUCT.

Certified Usage

Please observe the following:

Warning!

The device may only be employed for the purposes described in the catalog and technical description, and only in

conjunction with external devices and components recommended or approved by Hirschmann. The product can

only be operated correctly and safely if it is transported, stored, installed and assembled properly and correctly.

Furthermore, it must be operated and serviced carefully.

Safety Guidelines Power Supply

䊳Switch the basic devices on only when the housing is closed.

Warning!

The devices may only be connected to the supply voltage shown on the type plate. The devices are designed for

operation with a safety extra-low voltage.Thus, they may only be connected to the supply voltage connec tions and

to the signal contact with PELV circuits or alternatively SELV circuits with the voltage restrictions in accordance with

EC/EN 60950-1.

Relevant for North America:

䊳The subject unit is to be suppplied by a Class 2 power source complying with the requirements of the National Electrical

Code, table 11(b). f power is redundant supplied (two individual power sources) the power sources together should

comply with the requirements of the National Electrical Code, table 11(b).

䊳Use 60/75 °C or 90 °C copper(Cu) wire/conductor only.

Startup Information

OZD Profi 12M … P O

Hirschmann. Simply a good Connection.

de

en

fr

2

Safety Guidelines Environment

Warning!

The device may only be operated in the listed ambient temperature range at the listed relative air humidity

(non-condensing).

䊳The installation location is to be selected so as to ensure compliance with the climatic limits listed in the Technical Data

(see page 3).

䊳To be used in a Pollution Degree 2 environment only ( EC 60664-1).

Note on CE Identification

7The devices comply with the regulations of the following European directive:

89/336/EEC

Council Directive on the harmonization of the legal regulations of member states on electromagnetic compatibility

(amended by Directives 91/263/EEC, 92/31/EEC and 93/68/EEC).

The EU declaration of conformity is kept available for the responsible authorities in accordance with the above-mentioned

EU directives at:

Hirschmann Automation and Control GmbH

Stuttgarter Strasse 45 – 51

72654 Neckartenzlingen

Germany

Tel. +49 (0)1805 14-1538

E-Mail [email protected]

FCC ULES

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equip-

ment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communi-

cations. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

C-Tick

Australia/New Zealand

This product meets the requirements of the AS/NZS 3548 standard.

N13320

3

Approvals

cUL508 and CSA C22.2 No. 142-M1987

Please note the important information in: ”Relevant information for North America“, below.

ISA 12.12.01 (replaces UL 1604) und CSA C22.2, No. 213-M1987

Hazardous Locations Class1 Div 2 Groups A, B, C und D

Please note the important information in: ”Relevant information for North America“, below.

ATEX Directive 94/9/EC Zone 2 3G

Please note the important information in: ”Relevant information for use in Ex zone 2 according to ATEX 94/9/EC“, see page

5.

Note::

Only the certifications indicated on the label attached to each device are applicable.

elevant information for use in Hazardous Locations according to ISA 12.12.01:

䊳Only for connection with a Class 2 power supply.

䊳For use in Class 2 Circuits.

䊳Use class 1 wire only.

䊳Use 60/75 or 90 °C copper(CU)wire only.

Additional Information for Use in Hazardous Locations:

This product may be operated in hazardous locations only if the product label is marked accordingly.

The following information applies when operating this equipment in hazardous locations:

Products marked ”Class , D V 2, Group A, B, C and D“ are suitable for use in Class Division 2 Groups A, B, C, D,

Hazardous Locations and nonhazardous locations only. Each product is supplied with markings on the rating nameplate

indicating the hazardous location temperature code. When combining products within a system, the most adverse

temperature code (lowest ”T“ number) may be used to help determine the overall temperature code of the system.

Combinations of equipment in your system are subject to investigation by the local Authority Having Jurisdiction at the time

of installation.

䊳The peripheral equipment must be suitable for the location in which it is used.

䊳Restrictions to the fault contacts of 7 pole connector for use in Hazardous Locations:

V < 30 V < 90 m A Li= 0.5 µH typ. Ci= 20 pF typ.

䊳The tightening torque for field wiring terminals is max. 4.4 lb in (0.5 Nm).

z

Observe the Control Drawing 000144944DN on page 6.

Technical Data

Operating voltage NEC Class 2 power source 18 to 32 V DC (typ. 24 V DC) safety

extra-low voltage (SELV/PELV) (redundant inputs decoupled),

5 A max., buffer time min. 10 ms at 24 VDC

Current input for +18 VDC 195 mA

for +32 VDC 130 mA

Switched on peak value 220 mA max.

Power consumption 2.6 W

Ambient temperature

OZD Profi 12M ... PRO without “EEC“ feature“ 0 °C to +60 °C

OZD Profi 12M G12(-1300) EEC PRO 1) –20 °C to +60 °C

(IEC 60068-2-1, IEC 60068-2-2)

Relative humidity

OZD Profi 12M ... PRO without “EEC“ feature <95 %, non-condensing

OZD Profi 12M G12(-1300) EEC PRO 1) 100 %, condensing 2)

(IEC 60068-2-3)

Protection class IP 20

1) The DIP switches on the OZD Profi 12M G12(-1300) EEC PRO may also only be operated at ambient temperatures between

0 °C and +60 °C.

2) Protect the device against dripping water that may form.

4

Operating Voltage

䊳The repeater should only be supplied with a regulated safety extra-low voltage (SELV) in accordance with

EC/EN 60950-1, EN 61131-2 with a maximum of +32 V DC (typ. +24 V DC).

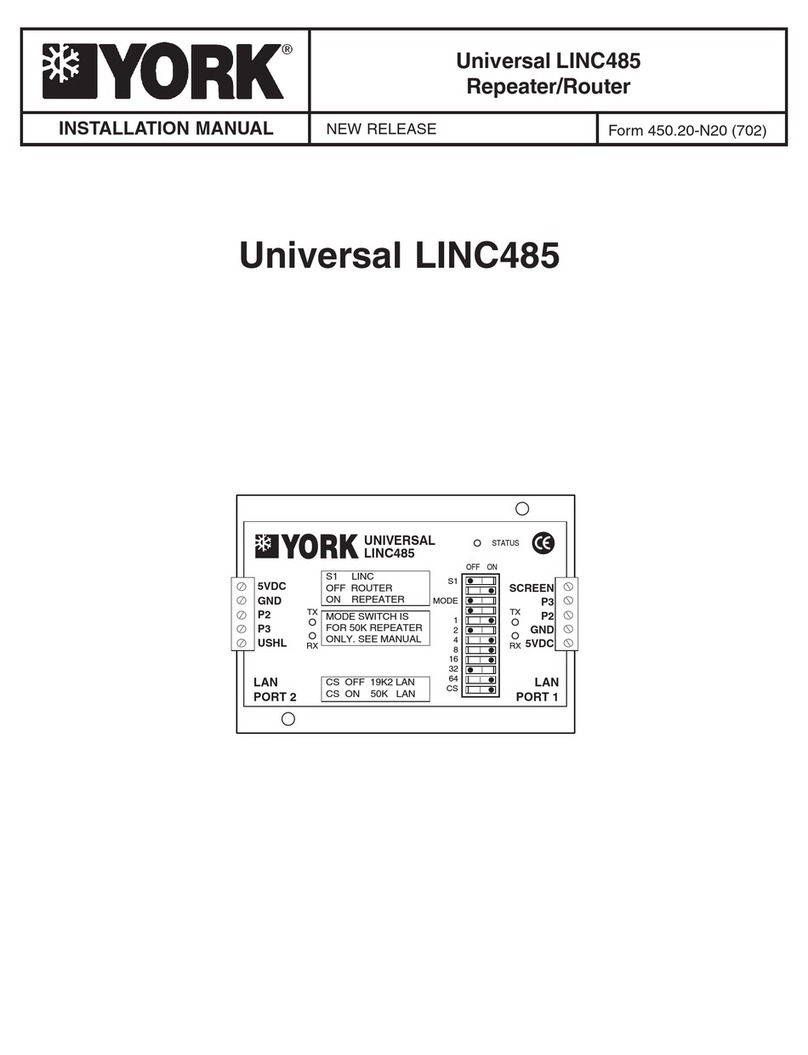

t can be fed in using the 7-pin screw-type terminal block (see Fig. 1) on the upper side of the repeater.

The operating voltage inputs are protected against incorrect pole connection.

Electrical channel

The repeater are fitted with an RS 485 electrical channel. This is a 9-pin Sub-D socket with a screw lock (inside thread

UNC 4-40) (see Fig. 2). The pin assignment complies with the PROF BUS stan dard. At Pin 6 there is a short circuit-proof

5 V output for supplying external pull-up/pull-down resistors.

Signaling Contacts

At the 7-pin screw-type terminal block (see Fig. 3) on the upper side of the repeater, floating contacts of a relay are

provided as a signaling contact.

If the OZD Profi 12M … PRO is functioning correctly the contact is closed.

If a fault or power failure occurs, the contact is opened.

䊳Always ensure that the correct assignment is provided for the 7-pole terminal block. Make sure that the connecting

leads of the signaling contacts are adequately insulated. ncorrect assignment can result in destruction of the repeater.

Limit values of relay contact

– Max. switching voltage: 60 V DC; 42 V AC

– Max. switching current: 1,0 A

– Max. switching capacity: 30 W (resistive load)

䊳The voltage connected to the relay must correspond to a safety extra-low voltage (SELV) to EC/EN 60 950 and must

comply with NEC, Class 2, regulations as stipulated by UL/CSA.

Analog Voltage Outputs

The device features two analog voltage outputs: CH2 and CH3. Each of these delivers a short-circuit-proof output voltage

in the range 0 - 5 V that is dependent on the optical input power at port 2 or port 3 and is for diagnostic purposes, e.g. for

preventive maintenance.

䊳These voltage outputs are connected to the front side of the repeater with a 3-pin screw terminal (see Fig. 4).

䊳The screw terminal is suitable for cable leads that have a cross section between 0.2 - 2.5 mm2.

Assignments

Fig. 2: Electrical channel – assignment of Sub-D socket

(Designation in line with PROF BUS standard)

9 / n.c.

8 / RxD/TxD –N

7 / n.c.

6 / + 5 V Output

Ground

n.c.

RxD/TxD –P

Ground

Shield

/ 5

/ 4

/ 3

/ 2

/ 1

+24 V(L1+)

0 V

FAULT

+24 V(L2+)

0 V

Fig. 3: Fault relay contact – assignment of 7-pin terminal block

CH2

GND

CH3

Receive

Signal

Intensity

Fig. 4: Analog voltage outputs – connections for 3-pin

terminal block

+24 V(L1+)

0 V

FAULT

+24 V(L2+)

0 V

Fig. 1: Operating voltage supply – assignment of 7-pin

terminal block

Connections

5

elevant information for use in Ex zone 2 according to ATEX 94/9/EC

This product may be operated in EX zone 2 only if the product label is marked accordingly.

The following information applies when operating this equipment in EX zone 2 (ATEX 94/9/EC):

3G

Ex nA C T5 Gc

KEMA 09ATEX0139 X

Temperature Code T5 Standard types: Ambient Ta: 0 … +60 °C

EEC types: Ambient Ta: –20 … +60 °C

List of Standards EN 60079-0 : 2012 + A11:2013

EN 60079-15 : 2010

Special conditions for safe use

䊳The modules shall be installed in a suitable enclosure in accordance with EN60079-15, taking into account the

environmental conditions under which the equipment will be used.

䊳When the temperature under rated conditions exceeds 70 °C at the cable or conduit entry point, or 80 °C at the

branching point of the conductors, the temperature specification of the selected cable shall be in compliance with the

actual measured temperature values.

䊳nstallation, addition, removal or replacement of modules, connectors or fuses shall only take place when the system

supply and the field supply are switched off, or when the area is known to be non-hazardous.

䊳Do not open when energized.

Power supply: 24 V DC (18 ... 30 V DC), 195 ... 130 mA

Fault relay contacts: max. 60 V DC / 42 V DC, 1 A, max. 30 W (resistive load)

6

7

Mail/FAX Reply (Call Number +49 (0)7127 14-1551)

To

Hirschmann Automation and Control GmbH

Abteilung 01RD-NT

Stuttgarter Strasse 45 – 51

72654 Neckartenzlingen

Germany

From

Company

Name

Dept.

Street

Z P

City

Country

Phone

Dear customer

You can order your gratuitous manual for the PROF BUS-Repeater OZD Profi 12M … PRO by letter or fax

using this coupon.

Yours Hirschmann Automation and Control GmbH

䡺Please send me a free copy of ”Manual PROFIBUS-Repeater OZD Profi 12M … PRO“.

We apply the following Multimode/Singlemode modules:

䡺OZD Profi 12M P11 PRO 䡺OZD Profi 12M G11 PRO 䡺OZD Profi 12M G11-1300 PRO

䡺OZD Profi 12M P12 PRO 䡺OZD Profi 12M G12 PRO 䡺OZD Profi 12M G12-1300 PRO

䡺OZD Profi 12M G12 EEC PRO 䡺OZD Profi 12M G12-1300 EEC PRO

We apply the following network topology:

䡺Line topology with optical cable monitoring 䡺Star

䡺Line topology without optical cable monitoring 䡺Redundant optical ring

We use the following transmission rate:

䡺12 Mbit/s 䡺1.5Mbit/s 䡺500 kbit/s

䡺187.5 kbit/s 䡺others: ……………

Our PROFIBUS Network consists of _____ participants at this time; _____ Fibre Optic ines are integrated;

it‘s in use for

We submit the following suggestions and desires to new modules for Field Bus Systems witch will be developed:

Hirschmann Automation and Control GmbH

Stuttgarter Strasse 45 – 51

72654 Neckartenzlingen

Germany

Tel.: +49 (0)1805 14-1538

E-Mail: [email protected]

Internet: http://www.hirschmann.com

We reserve the right to make technical modifications.

© Hirschmann Automation and Control GmbH 2015

All Rights Reserved

This manual suits for next models

8

Table of contents

Other Belden Repeater manuals