Belief 4W2005 12C11 Parts list manual

4KW Air Parking Heater

Technical Description, Installation, Operation and Maintenance Instructions

Production Type Order No.

Diesel electric DC12V/220VAC 4W2005 12C11

Version:Apr.25,2019

Foreword

Thank you for using the Belief parking heater.

This manual describes the technical description, installation,

operation and maintenance instructions for the parking heater. To

ensure the correct use of the heater please read this manual carefully

before installation and use. Please keep it properly after reading it

for review.

Note:

● The contents of this manual are subject to change without prior

notice, but the instructions are guaranteed to be consistent with

the products purchased.

● we try our best to express the problems that users should know

through the instructions. If you have questions or find something

wrong, please contact us directly.

● When the user unpacks for the first time, check the main unit and

accessories against the packing list. If you find any problems,

please contact the dealer immediately.

● If there is a problem in use, please contact the company's marketing

department or our authorized customer service station. We will be

happy to help you.

Please carefully save the after-sales service warranty sheet and

provide feedback as required. This sheet is the only valid proof of

after-sales service.

Note:

Must be installed and used in accordance with the requirements of the manual

to ensure long-term use of the product!

20190425 Edition Subject to Change

1

1.Application

FYJH-D5E/1 Model air parking heater (hereinafter

referred to as heater) is a special heater for

caravan that integrates hot water and warm air. This

heater cannot be used in bus or dangerous goods

carriers.

2. Main Technical Data

Table 1

3.Function

The heater is a hot water and warm air integrated

machine, which can provide domestic hot water

while heating the occupants. This heater allows

use during driving. This heater also has the

function of using local electricity heating.

In hot water warm air work mode, this heater can

be used to heat both the room and the hot water.

If only hot water is needed, please choose hot

water working mode.

When the ambient temperature is below 3°C, please

empty the water in the water tank to prevent

freezing of the water tank.

There are three energy options to choose from:

-- Diesel Mode

Heater automatic adjust the power.

-- Electrical Mode

Manually select the 900W or 1800W heating mode

according to the power supply capacity of the RV

camp site.

-- Hybrid Mode

When the power demand is low (for example,

maintaining the room temperature stage), the

electrical heating is preferred. Until the city

electricity cannot meet, the diesel heating is

started, and the diesel heating function is turned

off first in the power adjustment phase.

In hot water working mode,gas mode or electrical

mode is used to heat the tank。The tank temperature

can be set to 40°C or 60°C.

-- Diesel Mode

The heater operates at the lowest power. Stop

heating immediately after reaching the set

temperature.

-- Electrical Mode

Manually select the 900W or 1800W heating mode

according to the power supply capacity of the camp

site.

Rated Voltage

DC12V

Operating Voltage Range

DC10.5V~16V

Short-term Maximum Power

8-10A

Average Power Consumption

1.8-4A

Fuel type

Diesel

Fuel Heat Power (W)

2000

400

5000

Fuel Consumption (g/H)

220

440

550

Quiescent current

1mA

Warm Air Delivery Volume m3/h

287max

Water Tank Capacity

10L

Maximum Pressure of Water Pump

2.8bar

Maximum Pressure of System

4.5bar

Rated Electric Supply Voltage

~220V

Electrical Heating Power

900W

1800W

Electrical Power Dissipation

3.9A

7.8A

Working (Environment)

-25℃~+80℃

Working Altitude

≤1500m

Weight (Kg)

15.6Kg(without water)

Dimensions (mm)

510×450×300

Protection level

IP21

2

4. Safety work environment

-- The device can only be operated with appropriate

control panels and accessories

--Danger of toxic exhaust fumes.The heater’s

exhaust can be toxic in enclosed

spaces(e.g.garages,workshops).If the vehicle is

parked in closed rooms:Shut off the fuel supply

to the heater、Deactivate the time switch、Switch

off the heater at the control panel.

--If the cowl has been placed near or directly

beneath an opening window,the appliance must be

equipped with an automatic shut-off device in

order to prevent operation with the window open.

--Heat sensitive objects(e.g.spray cans)or

flammable materials/liquids must not be stored in

the same compartment where the appliance is

installed because nunder certain conditions,this

area may be subject to elevated temperatures.

--The openings for circulated air intake,the

installation compartment and the space around the

unit must be kept free of obstacles so that the

unit does not overheat.

--Keep the cowl for the exhaust duct and

combustion air intake free of

contamination(slush,ice,leaves etc.)at all

times.

Danger from hot surfaces and exhaust gas.Do not

touch the area around the wall cowl and do not lean

any objects against the wall cowl or the vehicle.

Obligations of the operator/vehicle owner

--The operator is responsible for the water with

which the boiler is filled and for its quality.

--The vehicle owner is responsible for correct

operation of the appliance.

--Liquid fuel system must comply with the technical

and administrative regulations of the respective

country of use.The national legislation and

regulations must be observed.

--Pressure regulating devices and hoses must be

replaced with new ones no more than 10 years after

their date of manufacture(every 8 years if used

commercially).

--Inspect hose lines regularly and have them

replaced if they are broken.

--If the heater is not being used,always drain off

the water if there is a risk of frost.NO claims

may be made under the warranty for damage caused

by frost.

Safe operation

--The flow rate of the pressure regulating

equipment must correspond to at least the maximum

consumption of all devices installed by the system

manufacturer.

--Ensure that the inside of the vehicle is

sufficiently ventilated when the unit is started

up there may be some smoke and /or smell due to

dust or dirt.Especially if it has not been used

for a long time.

--This appliance can be used by children aged 8

and over,as well as by persons with reduced

physical.

--The integrity and tight fit of the exhaust double

duct must be checked regularly,particularly at the end

of long trips.Also check the mounting of the unit and

the cowl.

--When cleaning the vehicle,do not spray water

directly into the cowl.

3

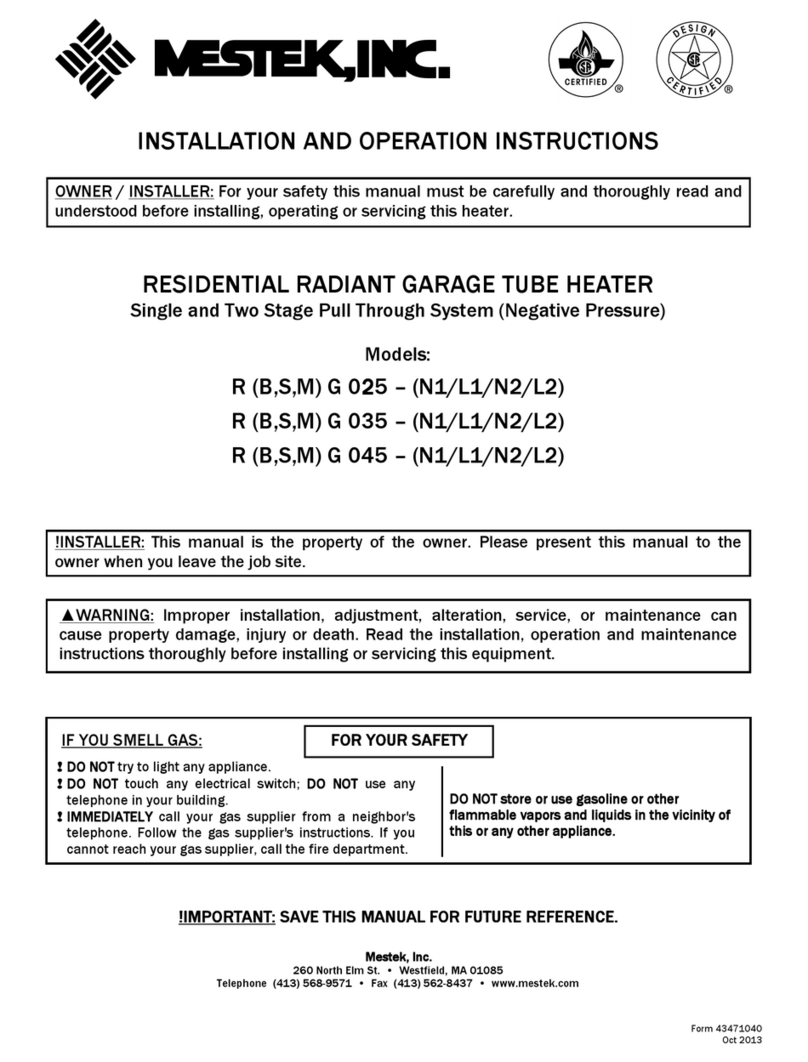

1-LCD switch 9- Combustion air inlet

2- External temperature sensor 10-Electronic control unit

3-Cold water inlet 11-Water container

4-Hot water outlet 12-Burner

5-Fuel connection 13-Heat exchanger

6-Warm air outlets 14-Power electronic

7-Circulated air intake 15-Heating elements

8-Exhaust discharge 16-Overheating switch

5. Heater installation

The typical installation of the heater is shown in

figure1.

★ Must be installed and repaired by professionals

authorized by the company!

The company does not bear any responsibility for the

following acts:

--Modified heater and accessories

--Modification of exhaust lines and accessories

--Do not follow the operating installation instructions

--Do not use our company's special accessories

Figure 1

1-LCD control switch

2-External temperature sensor

3-Recirculating air inlet (minimum

150cm2)

4-Heat pipe

5-Heat outlet

6-Smoking cowl

4

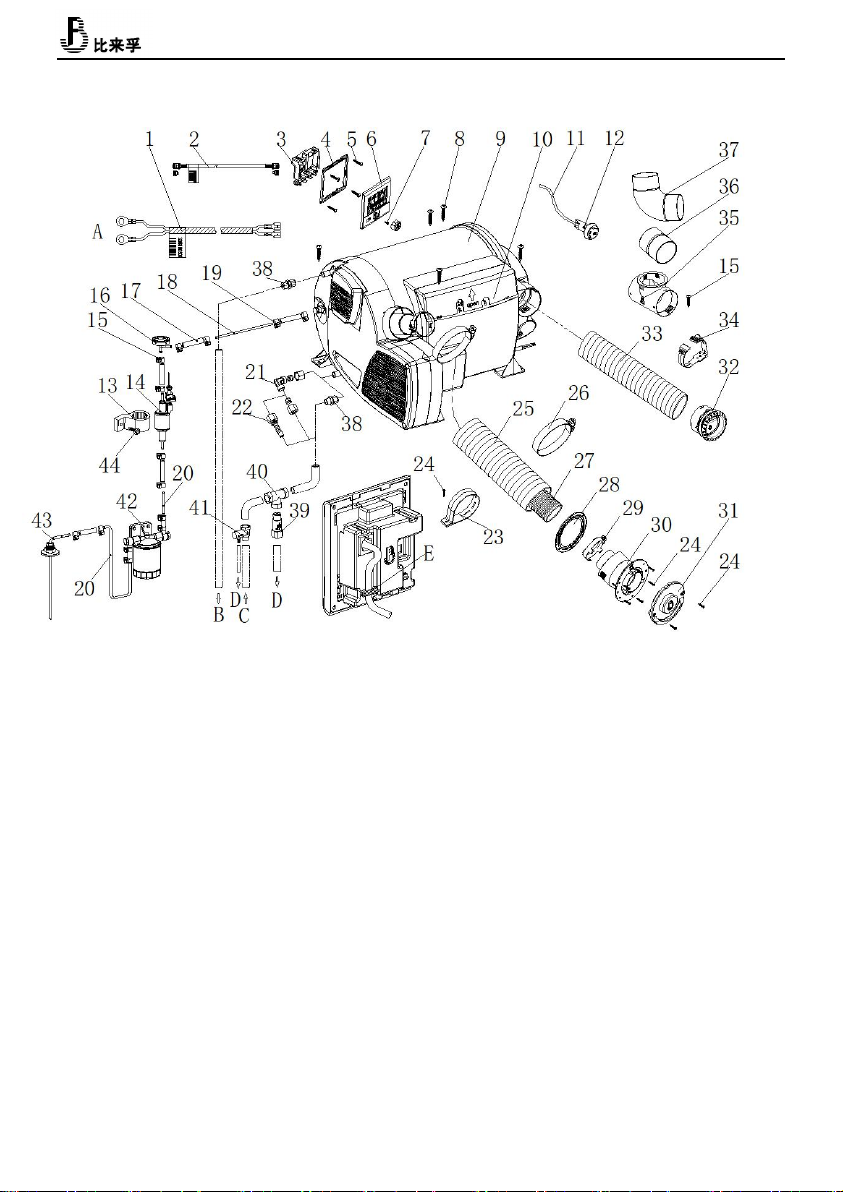

Heater installation Figure 3.

The heater installation location should be selected

from load-bearing floor, double floor or underfloor.

If there is no suitable floor, you can first make a

load bearing surface with plywood.

★The heater must be firmly fixed to the mounting

surface with

screws to prevent damage to the gas pipeline during

driving and cause danger.

Depending on the actual installation, may only

install three screws. Two die-cast aluminum fixing

screws are fixed then choose a plastic right angle

1_12V Power cord 2_ LCD switch Lead wire 3_ LCD switch back cover 4_ LCD switch bracket 5_ Self-tapping

screw M3*10 6_ LCD control switch 7_ Cross countersunk head flat tail self-tapping screw M3*6 8_ Self-tapping

screw ST5*25 9_ Heater 10_ Controller cover 11_ External temperature sensor lead wire 12_ External temperature

sensor 13_Fuelpump connector 14_Fuel pump 15_Fuel pipe clamp(φ9-11)16_Damper 17_Fuel pipe connector

18_6-Fuel pipe(trsparent,from heater to fuel pump)19_Fuel pipe clamp(φ8-10)20_ Fuel pipe(blue,from fuel

tank to fuel pump)21_φ10 Steel (water) pipe elbow transition fitting 22_ Hose(water) transition fitting

23_ Intake pipe mounting clamp 24_ Self-tapping screw ST3.5×25 25_ Air intake pipe 26_ German type clamp

27_ Exhaust pipe 28_ Sealing rubber spacer 29_(Exhaust pipe) clamp 30_ Intake and exhaust combine cowl31_

Intake and exhaust combine cover 32_ Air outlet 33_ Hot air ducting 34_ Ducting clamp 35_φ60T-pipe 36_

φ60connector 37_φ60 Elbow 38_ G1/2-φ10 Ferrule fitting 39 Frost valve 40_ G1/2 T pipe 41_ Reducing valve

42_Filter 43_Fuel suction pipe 44_Self tapping self drilling screw ST5*30

A_ Connect to 12V Battery B_ connect to water equipment C_ connect to system water tank

D_Flow out of the car E_ Hook,clamp LCD switcher cord

Figure 3

5

to fix it.

To ensure that the heater evenly distributes heat,

the heater should be installed in the center as much

as possible to ensure that the heating circuit is

equal long as possible.

No cover is allowed to add to the heater surface.

The size with* is the smallest size, leaving enough

space to connect accessories such as gas and water

pipes.

To prevent the danger from heater accidentally

loosening, the upper cover of the heater compartment

is screwed to the upper cover (Figure 4-1). Next to

the installation location it is necessary to install

a strong partition strip in front of the heater,

perpendicular to the direction of travel. Above the

floor height180mm can be attached to a septum

(minimum 30*50mm).

Heat sensitive objects and flammable objects should

be placed away from the heater.

★ The exhaust cowl must be on the side wall or

ceiling.

In the exhaust cowl installed area, there is no

ventilation window in the range of 300mm, and there

is no refueling port or tank respirator in the range

of 500mm.

The exhaust cowl is mounted below the window that is

close to or operable. A window switch should be

installed to ensure that the heater is turned off

automatically when the window is opened.

Air Inlet Hose Installation

The exhaust pipe is passing through the intake pipe.

The length of the intake and exhaust pipe is as shown

in Fig. 6, and the shortest is 60cm and the longest

is 100cm. The exhaust cowl is only allowed under the

exhaust outlet 20cm.

After the intake and exhaust pipes are pierced from

the through holes, they must be cut short, and the

exhaust pipes are slightly shorter than the intake

pipes. Avoid excessive expansion or tension on the

exhaust pipe.

Figture.4

Figture.5

Figure.6

6

The length of the intake and exhaust pipes is 100 cm

to 200 cm, as shown in Figure 7. The piping must be

arranged in the ascending direction.

The Exhaust Cowl (air inlet and outlet)

Installation

Select a flat mounting surface so that combustion air

can enter from all sides. Drill one hole of φ83. Seal

(Fig. 8-8), with the plane facing the exhaust cowl.

Wear the fixing clip before installing the exhaust

pipe (Figure 8-3). Pay attention to the installation

of the smoke cap upwards.

20mm at the end of the exhaust pipe should be

compressed, do not straighten. Insert the exhaust

pipe into the exhaust cowl interface(Figure 8-10),

as deep as possible. Try to fix the clips on the top,

tighten.

Place the air intake pipe (Figure 8-2) over the

exhaust cowl tooth (Figure 8-11). Set on the fixed

clip(Figure8-7), tighten.

Secure the exhaust cowl with 6 screws (Figure 8-9).

Use 2 screws to fix the exhaust cowl.

Fix the exhaust pipe on the side wall with mounting

clip.

Connect Air Inlet Pipe to The Heater

20mm at the end of the exhaust pipe should be

compressed, do not straighten.

Try to insert the exhaust pipe on exhaust port as deep

as possible。fix the clip on top, tighten.

Place the air intake pipe (Figure 9-3) over the air

inlet port (Figure 9-5). Set on the fixed clip

(Figure9-6), tighten.

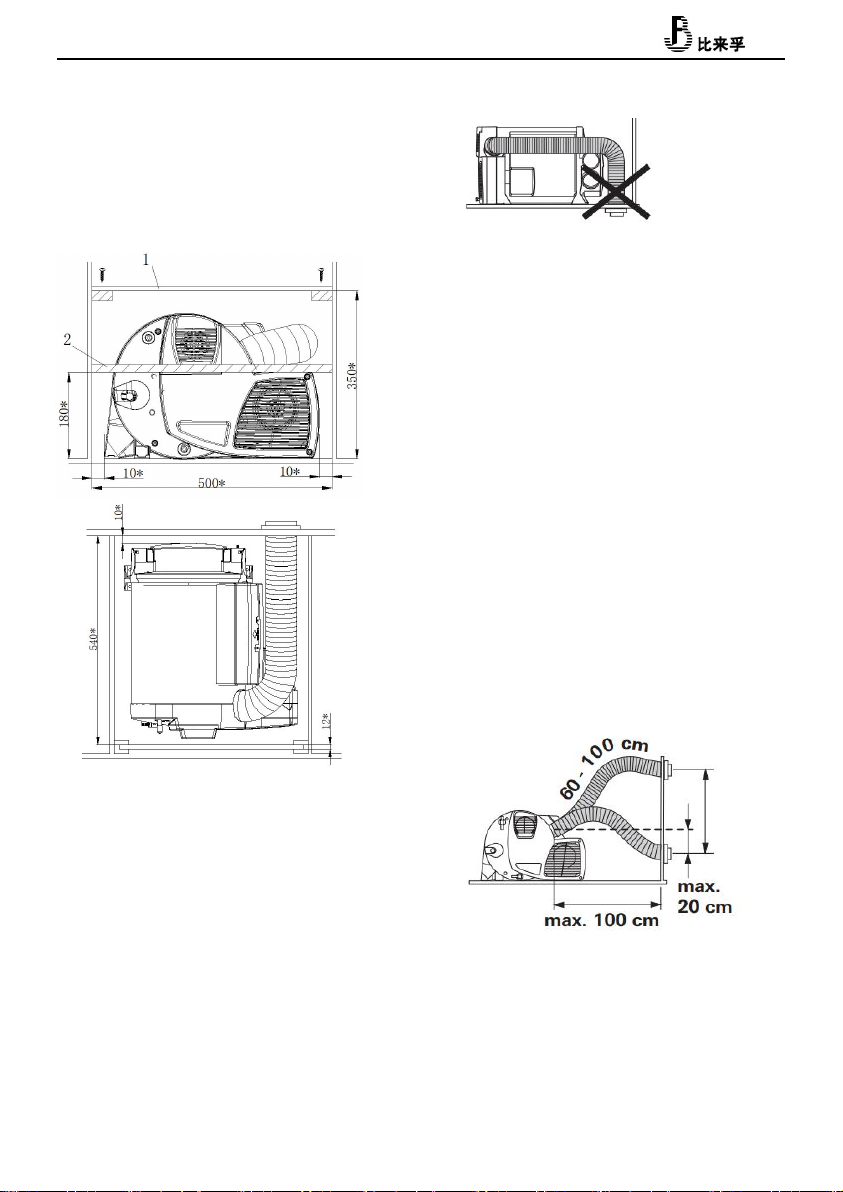

Warm Air Intake

The warm air intake is drawn in by the heater. There

must be a total area between the room and the heater

not less than 150cm2 opening.

Figure.7

Figture.10

Figture.8

Figture.9

7

Ensure that the warm air intake is not contaminated

by the engine or heater exhaust, if necessary, with

structural isolation measures.

Warm Air Distribution

Most of the warm air is imported into the floor area

of the living compartment through the bellows.

The four air outlets on the heater are connected to

the φ65 bellows. Use only pressure piping that meets

the quality requirements of the Belief. Other pipes

that do not meet our quality standards (especially

wind resistance, pipe diameter and number of ripples)

shall not be used. If the warm air duct must withstand

a considerable amount of bending immediately after

the hot air outlet of the heater in a limited space,

we recommend using a 90° elbow (Figure 3-37). This

elbow can be connected to a diameter of 65mm hot air

duct.

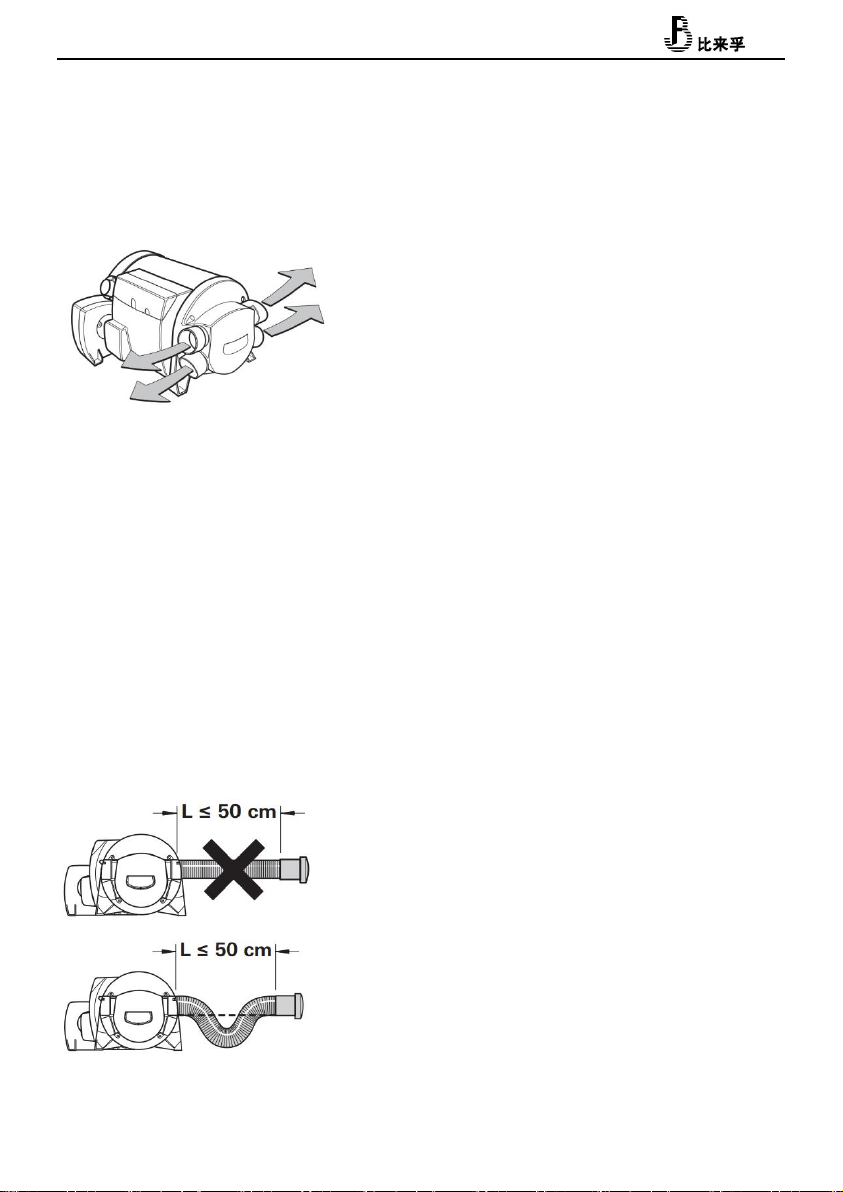

In the case where the length of the pipe is less than

2 meters, the air outlet cannot be installed at a

height higher than the connection of the warm air

duct. When the pipe length is less than 50cm, the pipe

must be siphon between the connector and the outlet.

These measures prevent the undesirable heating

caused by (fairing effect) convection of the vehicle

during summer operation.

★The warm air pipe must be firmly inserted into the

connection port.

To get the best warm air distribution, Belief

recommends using 4 warm air outlets for the heater.

If only three warm air outlets are required, then a

lower warm air outlet must be selected to seal.

★ The cross section of the heater duct must not be

reduced due to pipe connections or the analogue.

In other words, no less than four warm air outlets

(figure 3_32) are opened. Make sure that more than

four warm air outlets are opened.

Fuel system connection

The fuel is extracted from the vehicle fuel tank or

supplied from the 10L special fuel tank. The fuel is

transferred and the fuel supply is adjusted through

the special fuel pump (provided by the

manufacturer).Fuel extraction from the vehicle

engine return system or downstream of the vehicle

internal delivery pump is not permitted. Please

install only the fuel hose and piping within the

delivery range.

The fuel shall meet national standards

GB19147-2013 diesel standard for vehicles

Winter fuel should meet the low temperature

requirements brand, do not allow the use of

biofuels.

Figure.12

Figture.11

8

Fuel line system

Installation of oil pipe

Only the flexible nylon pipe, which has good

light-resistance and thermal stability, supplied

with the heater can be used as the fuel pipe.

Allowable length of fuel line: the maximum length of

fuel line on the inlet side is 2 meters, and the

maximum length on the pressure side is 6 meters. As

shown in figure 13.

Safety Regulations for Fuel Pipe

Use a hose cutter or sharp cutter to cut the fuel hose

and pipeline into a certain length. The cut area

cannot be compressed and must be free of burrs. Fuel

pipelines must be firmly connected to prevent

vibration-induced damage or noise (the recommended

distance between connecting points is about 50 cm).

Fuel pipelines must be protected from mechanical

damage. The laying of fuel pipelines will not

adversely affect the stability of vehicle rotation

and engine operation. Protect fuel-carrying parts

from high temperatures that may affect operation

(use appropriate glass fiber lined aluminum thermal

protection hoses). Do not install or fix fuel lines

near the exhaust pipes of heaters or vehicle engines.

If the lines are crossed, keep enough distance from

the thermal components - provide a thermal radiation

shield if necessary. Pipe installation should be

able to prevent flying stones from hitting, and keep

away from heating parts of vehicles. Protective

devices should be installed when necessary.

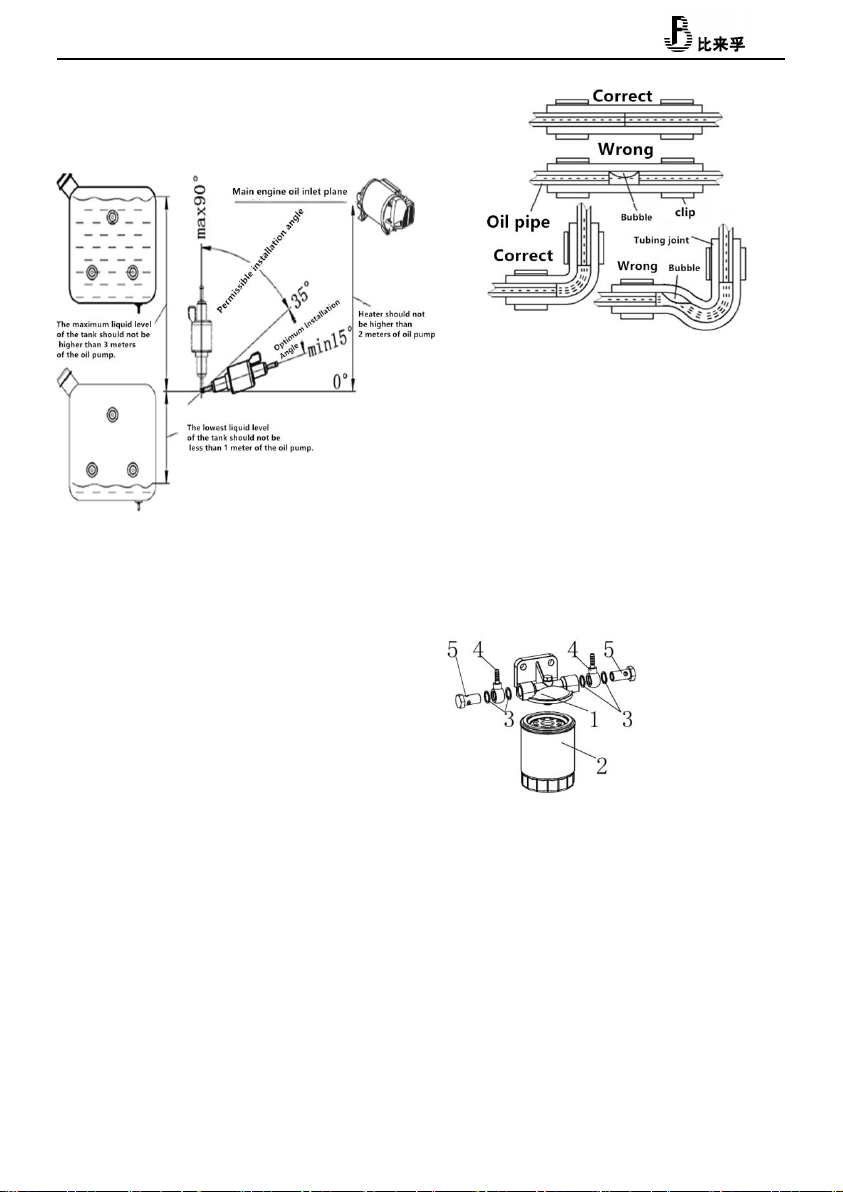

Installation of oil pump

The oil pump shall be fixed with a fixed jacket

(rubber) of the oil pump. The outlet of the oil pump

should be inclined upward, and its installation

angle should be selected in the range of 15- 35 as

shown in Figure 14. When conditions permit, the

tubing between the pump and the heater mainframe

should gradually rise. In order to prevent the oil

pump from being heated (the maximum operating

temperature is 40 C), do not install it near the

exhaust pipe.

The height difference between the fuel level and the

oil pump, and the height difference between the oil

pump and the main engine inlet, will generate

pressure (or suction) in the oil pipeline, so these

dimensions should meet the requirements of Figure 14

(negative pressure will occur in the closed tank,

when the minimum liquid level of the tank is required

to be no more than 0.4m).

Connection between heater and oil pump

The pipeline from the oil pump to the main engine

should go up as far as possible. Mark the appropriate

position on the floor of the vehicle for passage the

hole of the fuel pipeline and the oil pump connecting

9

the cable. Before drilling, pay attention to check

the hidden cable, fuel pipeline, frame section, etc.

The lower body protection device is then used to seal

the edges of the openings on the floor of the vehicle.

In order to prevent the cable between the tubing and

the oil pump from being cut, please add the lead-in

bushing or section edge protection material. The

tubing should be bundled at the appropriate place for

fixing, and the bundling distance is not more than

50 cm.

Connections between tubing and oil pump, main engine

and oil tank (oil intake nozzle) shall be made by

using tubing joints matched by this unit and using

oil. The pipe clip is clamped tightly. Prevent

bubbles from forming at the junction (Pic. 15).

Installation of Fuel Filter

Install the fuel filter before the oil inlet of the

oil pump. When installing, it should be noted that

the fuel filter must be vertical upward (to ensure

that impurities deposit downward). Fuel filter

replacement cycle for two years, tubing connection

head and clip must be replaced at the same time.

Installation of oil intake nozzle

(Pic17)

Firstly, the oil intake nozzle is fitted with O-ring,

and then it passes through the bottom hole

(self-processing) through the inside of the tank.

Put gaskets on the outside of the tank and tighten

them with nuts. The tightening torque is 6Nm+1Nm. The

O-ring must be clamped between the inner wall of the

Figure 15

Figure14

Figure16

1- Fuel filter aluminum base

2- Fuel filter

3- Sealing gasket

4- Articulated hose joint

5- Articulated bolt

10

Oil intake nozzle

O ring

Washer

Nut

Figure 17

Figure18

tank and the oil intake nozzle to ensure good sealing

between the oil intake nozzle and the oil tank.

(Accessories such as oil intake nozzles are attached

to the tank)

Installation of suction pipe(Pic.21)

Use when drawing fuel from the fuel tank of the

vehicle itself. When installing, attention should be

paid to the size of the installation hole on the tank

(or the cover of the tank) is 25 (+0.2), the edge is

neat and the surrounding is smooth, so as to ensure

good sealing between the suction pipe seat and the

tank. The distance between the bottom of the suction

pipe and the bottom of the tank should be 30-40 mm,

which can not only ensure the full absorption of fuel,

but also prevent the deposition of impurities at the

bottom of the tank from being inhaled.

The connection of water pipe

A pressure pump or submerged pump with a pressure of

2.8 bar can be used to supply water to the water tank.

If the water tank is connected to a centralized water

supply (rural or urban connection), or if a

high-pressure pump is used, a decompress or must be

used, which will prevent pressure above 2.8 bar.

★Before the relief valve is triggered, the

temperature rise and expansion of the water may cause

up to 4.5 bar of pressure (which may also occur with

the submerged pump). Water pipes connected to water

tanks and safety/drainage valves must be safe for

drinking water, pressure-resistant (up to 4.5 bar)

and hot water resistant up to 80°C. Antifreeze valve

(Pic3-39, Freeze-proof automatic water discharger),

A mechanical safety/drainage valve. When there is a

danger of frost, it will automatically drain water

from the tank through the drain.

Pressure relief valves must be installed(Pic3-41,

0.5MPa).If there is too much pressure in the system,

the pressure will automatically be released

intermittently through the relief valve.

Installation of External Temperature

Sensor

Install the car and measure the room temperature. The

installation position of the sensor is determined by

the manufacturer of the RV according to the specific

conditions of the vehicle. When choosing the

installation location, please note that the external

temperature sensor should not be subjected to direct

thermal radiation. In order to obtain the best room

temperature control, an external temperature sensor

is installed above the entrance door.

Suction pipes are only used in

metal tanks

Minimum distance 25 mm

Aperture

11

Make sure that the external temperature sensor is

always mounted on the vertical wall. It must be

surrounded by free-flowing air.

Drill a hole 10 mm in diameter. The single-wire

terminal passes through the opening from the back and

connects the end of the cable to the sensor with an

insulating plug (without observing polarity). Slide

into the external temperature sensor and connect the

two ends of the cable with two insulating connectors

to the heater electronic devices (if necessary,

extend the cable to a maximum length of 10 meters,

2 *0.5 mm 2 cable). The external temperature sensor

provided must always be connected, otherwise the

heater will switch to failure.

Install LCD switch

Gas heater must be operated by special liquid crystal

switch. See the relevant instructions for details.

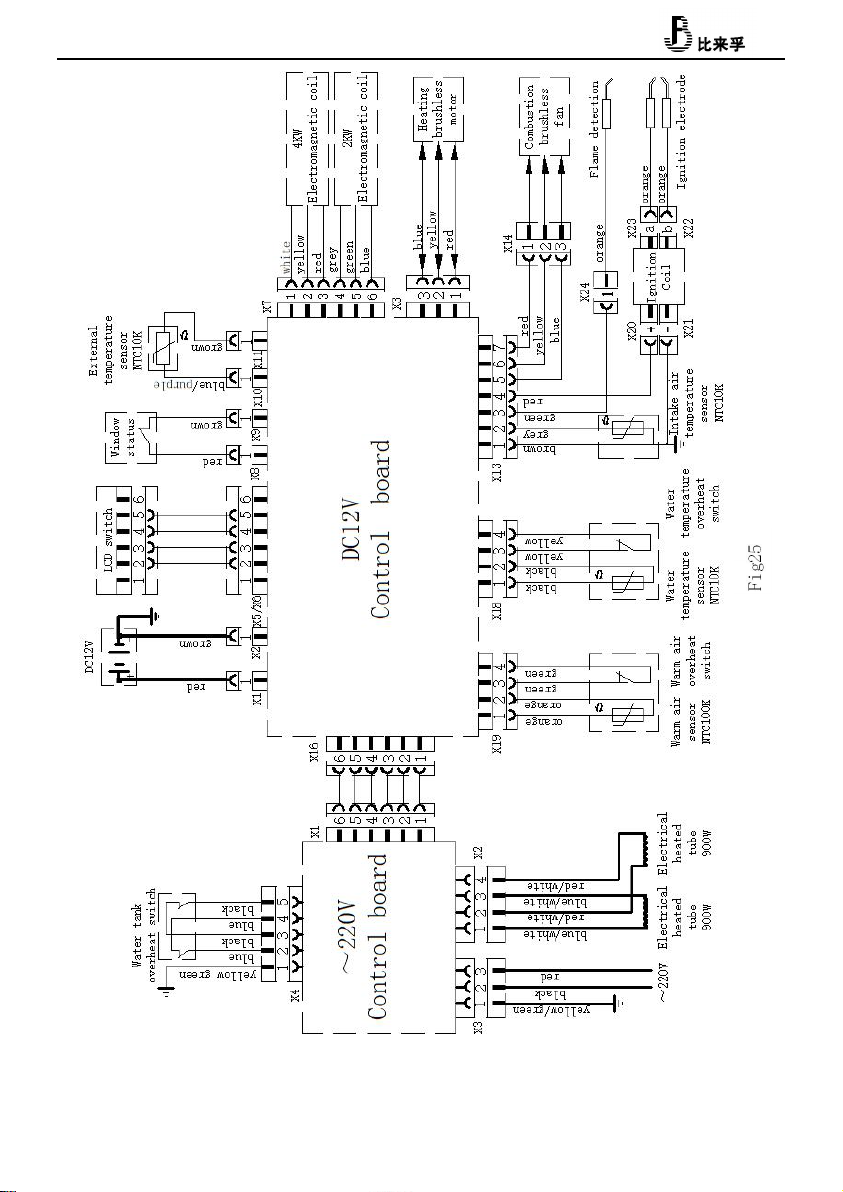

Electrical Connection

Lay wires to avoid scratches. If there are sharp

edges, such as metal panel threading, please use lead

bushing or edge protection accessories. Connector

cables shall not adhere to or touch metal surfaces,

exhaust pipes or hot air pipes.

The electrical connection socket is located below

the controller cover. The controller cover can be

removed by pressing and sliding along the arrow at

the same time. When removing or installing the

controller cover, make sure that the connecting

cable is not pulled out or squeezed.

1- DC12Vpositive electrode

2- DC12Vnegative electrode

3- Fuse

4- Window Switch

5- External temperature sensor

6- 7-control switch

When the window switch is not installed, the short

wiring cannot be removed. All cables connected to the

heater should be poked in a sagging direction. This

prevents condensate from slipping off the connector

cable and entering the heater.

Pic21

Figure19

Figure20

12

Connector cables and plugs must not be subjected to

force.(Pic19),Tie connector cables and fasten them

to the housing with straps to eliminate tension.

All cables must be firmly connected together. They

should not be loosened or disconnected by vibration,

resulting in fire hazards!

DC12V Power

The electric circuit, switch and control equipment

of the heater must be located in a position that will

not adversely affect its operation under normal

working conditions. The heater has reverse polarity

protection. If the controller is not properly

polarized, the LED indicator will not work.

In order to provide the best power supply, the heater

must be connected to the on-board power supply (or

battery) protected by fuse (10A) with a 2 x 2.5 mm

2 cable (2 x 4 mm 2 for a length exceeding 6 m). If

necessary, the voltage drop of the power supply line

must be considered. Connect the negative pole line

to the main grounding. If the heater is directly

connected to the battery, the positive and negative

lines must be protected. Do not connect other

power-consuming equipment.

Electrical connection of oil pump

Make sure the plug is firmly connected.

Figure22

Pic23

Pic24

13

14

6. Operating precautions

Heaters are not allowed to operate during refueling

or in enclosed spaces (enclosed parking lots, repair

shops or ferry compartments). Check regularly

whether the intake and exhaust pipes are in good

condition and the fixing is reliable, especially

after a trip. Also check the fixing of intake and

exhaust pipes and smoke caps.

When black smoke is found, the company's authorized

professionals are requested to carry out the

inspection. Ensure that the exhaust pipe and intake

pipe at the smoke exhaust cap are free from blockages

such as snow, ice and leaves. Warm air outlet and

circulating air inlet are unobstructed to avoid

overheating of heater. In the case of overheating,

the overheating switch will immediately cut off the

fuel supply.

If the fuel heater wants to meet the heating needs

in driving, it should install safety shut-off

device.

★If there is no safety shut-off device, the heater

must be turned off before driving.

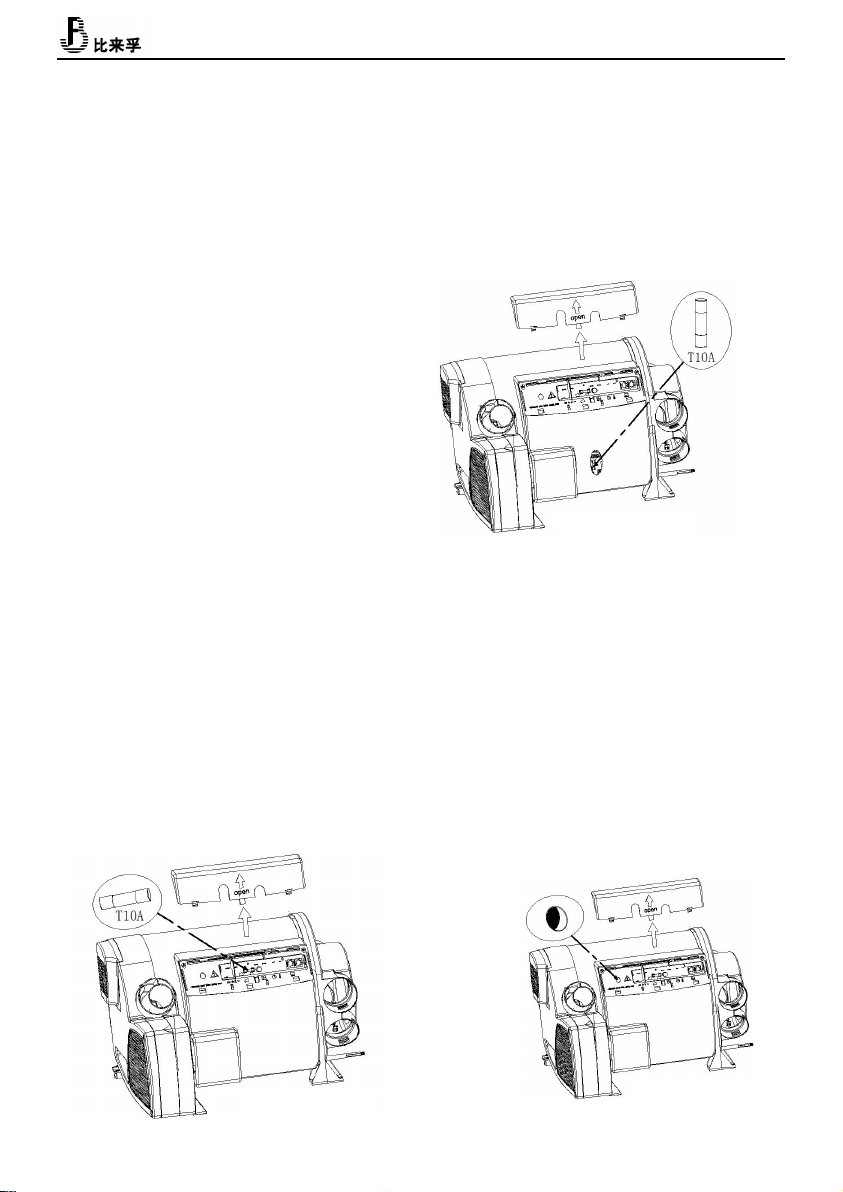

12V Fuse

Replacement with exactly the same fuse T20A is

allowed only.

~220V Fuse

★Fuses and wiring harnesses must be replaced by

professionals authorized by the Company.

★ All power supply must be disconnected before

opening the control housing.

Fuse Specification: T10A Slow Fuse

~220V Overheat protection

The municipal electric heating function has a

mechanical overheating protection switch. If the 12V

power supply is interrupted during or after the

heating process, the excess heat of the heater will

trigger the overheating protection switch.

When the temperature of the water tank decreases,

disconnect the power supply from 220V, remove the

cover of the controller, and reset the overheat

protection switch by pressing the reset button by

hand.

Figure26

Figure27

Figure28

15

7. Operational instructions

Please read the instructions carefully before

operation.

Start-up heater

Use special liquid crystal switch to operate.

Fuel oil, electricity, mixing mode, heating water

tank or unheated water tank for main engine heating

are set according to need.

Check the power supply capacity of RV camps, and

choose the operation mode of 900W (3.9A) or 1800W

(7.8A) accordingly. -- Check whether the smoke

exhaust cap is unobstructed

-- Open Liquefied Gas Tank Switch Valve

-- The tank is full of water when needed

Filling of water

Check whether the relief valve/drain valve is

closed.

——Turn on the pump power supply (main gate or pump

switch)

——Open the hot water tap in the kitchen or bathroom

and keep the valve open until the air in the container

is discharged and the water is continuously

discharged.

——In the absence of water heater heating, if only

the cold water system is in operation, the water

heater will also be full of water. To avoid frost

damage, the water heater must be drained through a

safety/drainage valve, even if it is not running.

——In the case of frost, the frozen residual water

can prevent filling. The water heater can thaw (no

more than 2 minutes) if it is turned on for a while.

The ice can be thawed through the inside of the

heater.

——If the heater is connected to the central water

supply system (rural or urban water supply system),

a pressure reducer must be used to prevent pressure

exceeding 2.8 bar (0.28 MPa).

-- Open the circulating pump

-- Open the hot tap in the kitchen and bathroom until

the air is exhausted and the water tank is filled,

and the water is not interrupted.

Turn off the heater

-- Use special liquid crystal switch to operate.

-- After the heater is closed, the

combustion-supporting fan and heating fan will

continue to work for several minutes according to the

temperature of the furnace body.

In case of freezing danger, it is necessary to ensure

that the water tank is emptied.

-- Close the circulating pump

-- Turn on the hot tap in the kitchen and bathroom

Heater drainage

——If the RV is not used during the frost. The heater

must drain the water.

——Turn off the power supply (main power supply or

pump switch) of the pump unit.

——Turn on the hot tap in the kitchen and bathroom.

— — In order to check the effluent, the

safety/drainage valve (user-fitted, for manual

emptying of the water tank) is installed. The

anti-freeze valve cannot ensure that the water tank

is completely emptied. Place a suitable container

under the drain tank.

——Open the safety/drainage valve.

——The heater will be discharged directly to the

outside through the safety/drainage valve. Check

whether all water in the heater has been discharged

into the container through the safety/drainage valve.

16

Claims for damage caused by frost shall not be filed

during the warranty period.

★The 10L bucket can be used for water inspection

to ensure that the water tank is empty.

The valve of liquefied gas tank must be closed before

heater is not used for a long time or running.

Maintenance/repair/cleaning

-- The device can only be repaired and cleaned by

experts.

-- Maintenance, repair and cleaning cannot be done

by children.

-- With new equipment, or the equipment has not been

used for some time, thoroughly flush all hot/cold

water hoses before use.

8. Failure

8.1 General Failure Handling

8.1.1 During the use of the heater, it may appear that

it cannot start normally or turn off it after

starting and is in the fault lock state. At this time,

the heater can be turned off for more than 5S and

restart.

8.1.2 The heater may cause circuit failure due to the

following reasons: the connector is rusted, the poor

contact, the plug is incorrect, the wire or fuse is

rusted, the battery pile is rusted, etc.

Pay attention to inspection, maintenance and prevent

these phenomena from occurring during use.

8.1.3 When the following conditions occur, it can be

handled and eliminated by the user:

●The heater does not start after the power is turned on and

the LCD switch screen does not light. The reason is that the

fuse is open, or the wiring is wrong. In addition, check

whether the plug on the LED switch lead wire is properly

connected to the host.

8.2 Fault Lock Status

8.2.1 The fault generated by the heater is indicated by

the fault code on the LED switch.

8.2.2 The faults can be eliminated according to the methods

Listed in Table 2.

17

Fault Lock Status Debug Method

Fault

Code

Fault Name

Fault Debu Method

10

Overvoltage fault

a. Check vehicle power supply system

11

Under voltage fault

a. Check vehicle power supply system

21

Warm air outlet temperature sensor

disconnection

a. Check if the sensor is in good condition

22

Warm air outlet temperature sensor short

circuit

a. Check if the sensor is in good condition

23

Water temperature sensor disconnection

a. Check if the sensor is in good condition

24

Water temperature sensor short circuit

a. Check if the sensor is in good condition

25

External temperature sensor disconnection

a. Check if the sensor is in good condition

26

External temperature sensor short circuit

a. Check if the sensor is in good condition

27

Combustion support temperature sensor

disconnection

a. Check if the sensor is in good condition

28

Combustion support temperature sensor

short circuit

a. Check if the sensor is in good condition

31

Combustion failure

a. Check gas supply system

b. Check whether combustion inlet and outlet are

blocked

c. Check the Ignition coil, ignition

electrode, flame sensor

18

Fault Lock Status Debug Method

Fault

Code

Fault Name

Fault Debug Method

32

Combustion failure

a. Check gas supply system

b. Check whether combustion inlet and outlet are blocked

c. Check the flame sensor

33

Flame sensor fault

a. Check the flame sensor lead wire

b. Check the flame sensor

41

Warm air outlet overheats

a. Check whether air outlet is blocked

42

Warm air overheats switch protection

a. Check whether air outlet is blocked

b. Check warm air overheat switch

43

Water overheat

a. Check whether water depletion in the tank

b. Check if the sensor is in good condition

c. Check whether air outlet is blocked

44

Warm air overheats switch protection.

a. Check whether air outlet is blocked

b. Check warm air overheat switch

45

Overheating fault

a. Check whether air outlet is blocked

b. Check water temperature sensor

c. Check warm air sensor

51

Communication fault

a. Check interconnecting cable

61

Oil Pump Break

a.Check whether the oil pump lead is damaged or not b.

Check whether the connection of oil pump leads is reliable

C. refurbishment oil pump

d. Replacement of motherboard

62

Short circuit of oil pump

a. Check whether the oil pump lead is damaged

b. Check whether the connection of oil pump leads is reliable

C refurbishment oil pump

d. Replacement of motherboard

63

Circuit Breaking of Electric Plug

A Check the power supply voltage

B Check the resistance of the plug at room temperature (0.2/12V)

C Cleaning up Carbon Accumulation in Electric Plug D

Replacement of motherboard

Table of contents

Other Belief Heater manuals

Popular Heater manuals by other brands

Kambrook

Kambrook KFH340 Instruction booklet

VTsistema

VTsistema EHC Series manual

NARVI Oy Finland

NARVI Oy Finland KOTA Kuru 14 installation, user and maintenance instructions

bewello

bewello BW2101 user manual

BONAIRE

BONAIRE Pyrox Heritage Operator's manual

Beyerdynamic

Beyerdynamic SIR 802 operating instructions