Mestek R(B User manual

Form 43471040

Oct 2013

INSTALLATION AND OPERATION INSTRUCTIONS

OWNER / INSTALLER: For your afety thi manual mu t be carefully and thoroughly read and

under tood before in talling, operating or ervicing thi heater.

RESIDENTIAL RADIANT GARAGE TUBE HEATER

Single and Two Stage Pull Through Sy tem (Negative Pre ure)

Model :

R (B,S,M) G 02

22

25 – (N1/L1/N2/L2)

R (B,S,M) G 035 – (N1/L1/N2/L2)

R (B,S,M) G 045 – (N1/L1/N2/L2)

!INSTALLER:

Thi manual i the property of the owner. Plea e pre ent thi manual to the

owner when you leave the job ite.

▲WARNING: Improper in tallation, adju tment, alteration, ervice, or maintenance can

cau e property damage, injury or death. Read the in tallation, operation and maintenance

in truction thoroughly before in talling or ervicing thi equipment.

IF YOU SMELL GAS: FOR YOUR SAFETY

FOR YOUR SAFETYFOR YOUR SAFETY

FOR YOUR SAFETY

!

!!

!

DO NOT

DO NOTDO NOT

DO NOT try to light any appliance.

!

!!

!DO NOT

DO NOTDO NOT

DO NOT touch any electrical witch; DO NOT

DO NOTDO NOT

DO NOT u e any

telephone in your building.

!

!!

!IMMEDIATELY

IMMEDIATELYIMMEDIATELY

IMMEDIATELY call your ga upplier from a neighbor'

telephone. Follow the ga upplier' in truction . If you

cannot reach your ga upplier, call the fire department.

DO NOT

DO NOT DO NOT

DO NOT tore or u e ga oline or other

tore or u e ga oline or other tore or u e ga oline or other

tore or u e ga oline or other

flammable vapor and liquid in the vicinity of

flammable vapor and liquid in the vicinity of flammable vapor and liquid in the vicinity of

flammable vapor and liquid in the vicinity of

thi or any other appliance.

thi or any other appliance.thi or any other appliance.

thi or any other appliance.

!IMPORTANT:

!IMPORTANT:!IMPORTANT:

!IMPORTANT:

SAVE THIS MANUAL FOR F

SAVE THIS MANUAL FOR FSAVE THIS MANUAL FOR F

SAVE THIS MANUAL FOR FUTURE REFERENCE.

UTURE REFERENCE.UTURE REFERENCE.

UTURE REFERENCE.

Me tek, Inc.

Me tek, Inc.Me tek, Inc.

Me tek, Inc.

260 North Elm St. • We tfield, MA 01085

Telephone (413) 568-9571 • Fax (413) 562-8437 • www.me tek.com

Form 43471040

Oct 2013 -1-

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0) Safety ................................................................................................................................................... 2

2.0) In taller Re pon ibility ...................................................................................................................... 2

3.0) General Information........................................................................................................................... 2

4.0) Minimum Clearance to Combu tible ........................................................................................... 4

5.0) Specification ...................................................................................................................................... 5

6.0) Packing Li t ......................................................................................................................................... 5

6.1) Acce ory Package .......................................................................................................................... 7

7.0) Dimen ion ......................................................................................................................................... 8

8.0) Heater A embly Overview ............................................................................................................... 9

9.0) Typical Su pen ion Method .......................................................................................................... 10

10.0) Heater A embly .............................................................................................................................. 11

11.0) Ga Connection and Regulation ................................................................................................. 14

12.0) In truction for Pre ure Te t Gauge Connection ....................................................................... 16

13.0) Electrical and Thermo tat Connection ........................................................................................ 17

14.0) Venting ............................................................................................................................................... 25

15.0) Air for Combu tion ........................................................................................................................... 30

15.1) Direct Out ide Air for Combu tion ................................................................................................. 30

16.0) Lighting and Shutdown In truction .............................................................................................. 32

17.0) Sequence of Operation .................................................................................................................... 32

18.0) Control Component Location .......................................................................................................... 33

19.0) Cleaning and Annual Maintenance ............................................................................................... 34

20.0) Trouble hooting Guide..................................................................................................................... 35

21.0) Replacing Part ................................................................................................................................ 38

21.1) Removal of Spark Electrode ........................................................................................................... 38

21.2) Removing Main Burner and Ga Valve ......................................................................................... 39

21.3) Air Switch Pre ure Check .............................................................................................................. 39

21.4) Ignition Sy tem Check ................................................................................................................... 40

21.5) Motor and Blower Wheel Check ..................................................................................................... 41

22.0) In tallation Data ............................................................................................................................... 41

23.0) Replacement Part Guide ............................................................................................................... 42

24.0) Warning Card .................................................................................................................................. 46

Thi heater complie with ANSI Z83.20 (current tandard) and CSA 2.34. Copie of the National Fuel Ga Code (ANSI

Z223.1-late t edition) are available from the CSA at 8501 Ea t Plea ant Valley Road, Cleveland, Ohio 44131 or 55 Scar dale

Road, Don Mill , Ontario M3B 2R3. All NFPA code are available from the National Fire Protection A ociation, Batterymarch

Park, Quincy, Ma achu ett 02269.

For in tallation with mounting height le than 10 feet, in tall the

heater at the highe t po ible height for the be t radiant energy

di tribution.

Form 43471040

-2- Oct 2013

1.0) SAFETY

Thi heater i a elf-contained infrared radiant tube heater. Safety information required during in tallation and

operation of thi heater i provided in thi manual and the label on the product. The in tallation, ervice and

maintenance of thi heater mu t be performed by a contractor qualified in the in tallation and ervice of ga

fired heating equipment.

All per onnel in contact with the heater mu t read and under tand all afety information, in truction and label

before operation. The following ymbol will be u ed in thi manual to indicate important afety information.

SAFETY

SAFETYSAFETY

SAFETY

REQUIREMENTS

REQUIREMENTSREQUIREMENTS

REQUIREMENTS

•

••

•The heater area mu t be kept clear and free from combu tible material , ga oline and other flammable

vapor and liquid .

•

••

•Thi heater i de igned for u e with one type of ga (LPG or Natural). Make ure that the type of ga to be

upplied to thi heater matche that hown on the heater rating plate.

•

••

•DO NOT

DO NOTDO NOT

DO NOT in tall thi heater directly onto an LPG container or propane cylinder without direction from your

propane company. LPG container (propane cylinder ) mu t not be tored indoor or in the vicinity of any

ga -burning appliance.

•

••

•Children and adult hould be alerted to the hazard of high urface temperature and hould tay away to

avoid burn or clothing ignition.

•

••

•Clothing or other flammable material hould not be hung from the heater or placed on or near the heater.

•

••

•Young children hould be carefully upervi ed when they are in the ame pace a the heater.

•

••

•NEVER

NEVERNEVER

NEVER attempt to ervice the heater while it i plugged in, operating or hot. Any guard or other protective

device removed for ervicing a heater mu t be replaced prior to operating the heater.

Warning

WarningWarning

Warning

in truction mu t be followed to prevent or avoid hazard which

may cau e eriou injury, property damage or death.

Caution

CautionCaution

Caution

in truction mu t be followed to prevent incorrect operati

on or

in tallation of

the heater which may cau e minor injury or property

damage.

2.0) INSTALLER RESPONSIBILITY

The in taller i re pon ible for the following:

•

••

•The heater and venting, a well a electrical and ga upplie mu t be in talled in accordance with the e

in tallation in truction and any applicable code and regulation .

•

••

•Every heater hall be located with re pect to building con truction and other equipment o a to permit

acce to the heater.

•

••

•Each in taller mu t follow the clearance to combu tible material for the heater .

•

••

•In tall the heater o that the upport and hanger are correctly paced in accordance with the e

in truction . The heater mu t be upported by material having a working load limit of at lea t 115lb .

•

••

•Supply the owner with a copy of the e In tallation and Operation In truction .

•

••

•Where unvented heater are u ed, gravity or mechanical mean hall be provided to upply and exhau t at

lea t 4 CFM per 1,000 Btu/hr input of in talled heater .

•

••

•Never u e the heater a a upport for a ladder or other acce equipment. Do not hang anything from the

heater.

•

••

•Supply all in tallation material nece ary that are not included with the heater.

•

••

•Check the nameplate to make ure that the burner i correct for the ga type in the building and the

in tallation altitude.

3.0) GENERAL INFORMATION

Thi heater i a elf-contained infrared radiant tube heater for u e in location where flammable ga e or vapor

are not generally pre ent (a defined by OSHA acceptable limit ) and i intended for pace heating of garage ,

ve tibule and entry way , work hop , enclo ed patio , golf practice range and mo t indu trial and commercial

application . DO NOT

DO NOTDO NOT

DO NOT in tall thi heater in re idential bedroom or bathroom , mobile home or recreational

vehicle .

Form 43471040

Oct 2013 -3-

INSTALLATION RE

INSTALLATION REINSTALLATION RE

INSTALLATION REQUIREMENTS

QUIREMENTSQUIREMENTS

QUIREMENTS

The in tallation mu t conform to local building code or in the ab ence of local code , with the National Fuel Ga

Code ANSI Z223.1/NFPA54 or the Natural Ga and Propane In tallation Code CSA B149.1. Heater hall be

in talled by a licen ed contractor or licen ed in taller. Clearance to combu tible a outlined in thi manual

hould alway be ob erved. In area u ed for torage of combu tible material where they may be tacked

below the heater, NFPA54 require that the in taller mu t po t ign that will “ pecify the maximum permi ible

tacking height to maintain the required clearance from the heater to combu tible .”

Every heater hall be located with re pect to building con truction and other equipment o a to permit acce

to the heater. Each in taller hall u e quality in tallation practice when locating the heater and mu t give

con ideration to clearance to combu tible material , vehicle parked below, light , overhead door , torage

area with tacked material , prinkler head , ga and electrical line and any other po ible ob truction or

hazard . Con ideration al o mu t be given to ervice acce ibility.

The heater, when in talled in aircraft hangar and public garage , mu t be in talled in accordance with

ANSI/NFPA 409-late t edition (Standard for Aircraft Hangar ), ANSI/NFPA 88a-late t edition (Standard for

Parking Structure ), and ANSI/NFPA 88b-late t edition (Standard for Repair Garage ) with the following

clearance :

a. At lea t 10 feet above the upper urface of wing or engine enclo ure of the highe t aircraft that may be

hou ed in the hangar and at lea t 8 feet above the floor in hop , office , and other ection of hangar

communicating with aircraft torage or ervice area .

b. At lea t 8 feet above the floor in public garage . ▲

▲▲

▲WARNING:

WARNING:WARNING:

WARNING: Minimum clearance marked on the heater

mu t be maintained from vehicle parked below the heater.

(FOR CANADA ONLY)

a.

In tallation of thi appliance i to be in accordance with late t edition of

CSA

B149.1 (

Natural Ga and

Propane In tallation Code).

b. For in tallation in public garage or aircraft hangar , the minimum clearance from the bottom of the

infrared heater to the upper urface of the highe t aircraft or vehicle hall be 50 percent greater than the

certified minimum clearance, but the clearance hall not be le than 8 feet.

Although the e heater may be u ed in many application other than pace heating (e.g., proce heating),

Me tek will not recognize the warranty for any u e other than pace heating.

For indoor in tallation only. No

For indoor in tallation only. NoFor indoor in tallation only. No

For indoor in tallation only. Not for u e in re idential dwelling .

t for u e in re idential dwelling .t for u e in re idential dwelling .

t for u e in re idential dwelling .

Thi heater i for Indoor In tallation and Covered Patio In tallation only and can be u ed in either Vented or

Unvented mode. The term Unvented actually mean Indirect Vented. While the product of combu tion are

expelled into the building, national code require ventilation in the building to dilute the e product of

combu tion. Thi ventilation may be provided by gravity or mechanical mean .

Thi heater i not an explo ion proof heater.

Thi heater i not an explo ion proof heater.Thi heater i not an explo ion proof heater.

Thi heater i not an explo ion proof heater. Where the po ibility of expo ure to volatile and low fla h point

material exi t , it could re ult in property damage or death. Thi heater mu t not be in talled in a pray booth

where the heater can operate during the praying proce . Con ult your local fire mar hal or in urance company.

High Altitude:

High Altitude:High Altitude:

High Altitude:

Appliance are upplied a tandard for altitude of O to 2,000 feet (0-610 m). High-altitude rating are obtained

by a change in the orifice ize. When ordered for high altitude in tallation , burner are upplied by the factory

ready for high altitude in tallation. Check the nameplate for altitude before proceeding with the in tallation. In

Canada the adju tment for altitude i made in accordance with Standard CGA 2.17, Ga -Fired Appliance for U e

at High Altitude .

Form 43471040

-4- Oct 2013

4.0) MINIMUM CLEARANCES TO COMBUSTIBLES

Failure to do so may result in death, serious injury or

property damage.

Combustible material must be located outside the

clearance dimensions listed.

Minimum clearance to combu tible hall be mea ured from the outer urface a hown in the following

diagram. For reduced clearance below the heater, u e the Deflector Kit (Part No. 43504010), de cribed in

Section 6.1), and maintain the minimum clearance pecified in the note below. Follow the in truction

packaged with the kit for in tallation. In tall the warning card (ordered eparately) and complete the blank

pace u ing the clearance from combu tible table below. See Section 24 for a printed copy of the warning

card.

End End

Ceiling

Below

Front Rear

45° Angle (Maximum)

* Ceiling

Below

Side Side

Horizontal

MINIMUM CLEARANCES TO COMBUSTIBLES

MINIMUM CLEARANCES TO COMBUSTIBLESMINIMUM CLEARANCES TO COMBUSTIBLES

MINIMUM CLEARANCES TO COMBUSTIBLES

Model No.

Model No.Model No.

Model No.

Mounted Horizontally

Mounted HorizontallyMounted Horizontally

Mounted Horizontally

Angle Mounted at 45º

Angle Mounted at 45ºAngle Mounted at 45º

Angle Mounted at 45º

Side

SideSide

Side

Ceiling

CeilingCeiling

Ceiling1

11

1

Below

BelowBelow

Below2

22

2

End

EndEnd

End

45º Front

45º Front45º Front

45º Front

45º Rear

45º Rear45º Rear

45º Rear

R (B,S,M) G

0

25

8

”

4

”

4

1

”

*

8

”

30

”

4

”

R (B,

S,M) G

0

35,

0

45

12

”

4

”

57

”

**

8

”

4

0

”

4

”

1 The clearance i 12” when in talled in an UNVENTED

UNVENTEDUNVENTED

UNVENTED configuration in indu trial and commercial in tallation .

2 IN CANADA

IN CANADAIN CANADA

IN CANADA, clearance below the heater are:

R (B,S,M) G 025: 36” (27” with deflector);

R (B,S,M) G 035, 045: 48” (36” with deflector)

* The clearance i 33” with deflector.

** The clearance i 42” with deflector / 30” ide clearance with deflector.

▲WARNING:

▲WARNING:▲WARNING:

▲WARNING:

Certain material or object , when tored under the heater, will be ubjected to radiant heat and

Certain material or object , when tored under the heater, will be ubjected to radiant heat and Certain material or object , when tored under the heater, will be ubjected to radiant heat and

Certain material or object , when tored under the heater, will be ubjected to radiant heat and

could be eriou ly damaged.

could be eriou ly damaged.could be eriou ly damaged.

could be eriou ly damaged.

Ob erve the Minimum Clearance to Combu tible li ted in the manual and on the

Ob erve the Minimum Clearance to Combu tible li ted in the manual and on the Ob erve the Minimum Clearance to Combu tible li ted in the manual and on the

Ob erve the Minimum Clearance to Combu tible li ted in the manual and on the

heater at all time .

heater at all time .heater at all time .

heater at all time .

NOTE:

NOTE:NOTE:

NOTE:

1.

1. 1.

1. The cleara

The clearaThe cleara

The clearance pecified above mu t be maintained to combu tible and other material that may be

nce pecified above mu t be maintained to combu tible and other material that may be nce pecified above mu t be maintained to combu tible and other material that may be

nce pecified above mu t be maintained to combu tible and other material that may be

damaged by temperature 90ºF above ambient temperature.

damaged by temperature 90ºF above ambient temperature.damaged by temperature 90ºF above ambient temperature.

damaged by temperature 90ºF above ambient temperature.

Clearance to combu tible are po ted on the

Clearance to combu tible are po ted on the Clearance to combu tible are po ted on the

Clearance to combu tible are po ted on the

control box.

control box.control box.

control box.

In area u ed for torage of combu tible material whe

In area u ed for torage of combu tible material wheIn area u ed for torage of combu tible material whe

In area u ed for torage of combu tible material where they may be tacked below the heater,

re they may be tacked below the heater, re they may be tacked below the heater,

re they may be tacked below the heater,

NFPA54 require that the in taller mu t po t ign that will “ pecify the maximum permi ible tacking height

NFPA54 require that the in taller mu t po t ign that will “ pecify the maximum permi ible tacking height NFPA54 require that the in taller mu t po t ign that will “ pecify the maximum permi ible tacking height

NFPA54 require that the in taller mu t po t ign that will “ pecify the maximum permi ible tacking height

to maintain the required clearance from the heater to combu tible .”

to maintain the required clearance from the heater to combu tible .”to maintain the required clearance from the heater to combu tible .”

to maintain the required clearance from the heater to combu tible .”

Me tek

Me tekMe tek

Me tek

recommend po ting the e ig

recommend po ting the e igrecommend po ting the e ig

recommend po ting the e ign

n n

n

adjacent to the heater thermo tat or other uitable location that will provide enhanced vi ibility.

adjacent to the heater thermo tat or other uitable location that will provide enhanced vi ibility.adjacent to the heater thermo tat or other uitable location that will provide enhanced vi ibility.

adjacent to the heater thermo tat or other uitable location that will provide enhanced vi ibility.

2. The tated clearance to combu tible repre ent a urface temperature of 90

2. The tated clearance to combu tible repre ent a urface temperature of 902. The tated clearance to combu tible repre ent a urface temperature of 90

2. The tated clearance to combu tible repre ent a urface temperature of 90

ºF

ºFºF

ºF

(32

(32(32

(32

ºC) above room

ºC) above room ºC) above room

ºC) above room

temperature. Building material with a low heat tole

temperature. Building material with a low heat toletemperature. Building material with a low heat tole

temperature. Building material with a low heat tolerance ( uch a pla tic , vinyle iding, canva , tri

rance ( uch a pla tic , vinyle iding, canva , trirance ( uch a pla tic , vinyle iding, canva , tri

rance ( uch a pla tic , vinyle iding, canva , tri-

--

-ply, etc.)

ply, etc.) ply, etc.)

ply, etc.)

may be ubject to degradation at lower temperature . It i the in taller’ re pon ibility to a ure that adjacent

may be ubject to degradation at lower temperature . It i the in taller’ re pon ibility to a ure that adjacent may be ubject to degradation at lower temperature . It i the in taller’ re pon ibility to a ure that adjacent

may be ubject to degradation at lower temperature . It i the in taller’ re pon ibility to a ure that adjacent

material are protected from degradation.

material are protected from degradation.material are protected from degradation.

material are protected from degradation.

Form 43471040

Oct 2013 -5-

5.0) SPECIFICATIONS

Model

Model Model

Model

Serie

Serie Serie

Serie No.

No.No.

No.

R (

R (R (

R (B,S,M)G

B,S,M)GB,S,M)G

B,S,M)G

Btu/hr

Btu/hrBtu/hr

Btu/hr

Input

InputInput

Input

Heat

Heat Heat

Heat

Exchanger

Exchanger Exchanger

Exchanger

Length

LengthLength

Length

Total

Total Total

Total

Heater

Heater Heater

Heater

Length

LengthLength

Length

Flue Re trictor

Flue Re trictorFlue Re trictor

Flue Re trictor

Plate

PlatePlate

Plate

I.D. &

I.D. & I.D. &

I.D. & Part #

Part #Part #

Part #

Orifice Size

Orifice SizeOrifice Size

Orifice Size

Minimum *

Minimum *Minimum *

Minimum *

Mounting Height

Mounting HeightMounting Height

Mounting Height

Natural Ga

Natural GaNatural Ga

Natural Ga

Propane Ga

Propane GaPropane Ga

Propane Ga

@

@@

@

Horizontal

HorizontalHorizontal

Horizontal

@

@@

@

45º Angle

45º Angle45º Angle

45º Angle

025

2

5

,000

16’ 9’-3”

7/8”

#4

2741120

#4

2

(0.

0

94

)

#52

(0.0

64

)

8’

8’

0

3

5

35

,000

1”

#4

2741041

#35

(0.1

10

)

1.75mm

(0.0

69

)

8’

8’

0

45

45

,000

1

-

1/8”

#4

2741031

1/8”

(0.1

25

)

5/64”

(0.0

78

)

8’

8’

* MOUNT HEATERS AS HIGH AS POSSIBLE. Minimum are hown a a guideline for human comfort and uniform

energy di tribution for complete building heating application . Con ult your Me tek repre entative for the

particular of your in tallation requirement .

Type

TypeType

Type

Ga

GaGa

Ga

Ga Pipe

Ga PipeGa Pipe

Ga Pipe

Connection

Connection Connection

Connection

Tube

TubeTube

Tube

Diameter

DiameterDiameter

Diameter

Flue

FlueFlue

Flue

Connection

ConnectionConnection

Connection

Fre h Air

Fre h Air Fre h Air

Fre h Air

Connection

ConnectionConnection

Connection

Electrical

ElectricalElectrical

Electrical

Supply

SupplySupply

Supply

Current

CurrentCurrent

Current

Rating

RatingRating

Rating

Natural

or Propane

½” MPT

(Male) 3” 4” Round 4” Round

120 Volt,

60Hz,

1 Pha e 2.6 Amp

Fu e

Fu eFu e

Fu e

Rating:

Rating:Rating:

Rating:

Ignition Sy tem (direct park):

Ignition Sy tem (direct park):Ignition Sy tem (direct park):

Ignition Sy tem (direct park):

Spark Module: 2

Amp 250V

(for 24V Circuit) 30 econd pre-purge period

6.0) PACKING LIST

A.

A.A.

A. Control/Draft Inducer

Control/Draft InducerControl/Draft Inducer

Control/Draft Inducer

Package

PackagePackage

Package

Part De cription

Part De cription Part De cription

Part De cription

QTY

QTYQTY

QTY

Control Box A embly

................................

................................

................................

..............................

1

Draft Inducer A embly (with 4” Starting Collar

#40504020

)

................................

.........................

1

Flue Re trictor Plate (refer to

5.0)

for I.D. & part number)

................................

................................

.

1

15” Pla tic Vacuum Air Tube (#03988150)

................................

................................

..........................

1

Control

Fa tene

r Kit

(#42

787000

)

................................

................................

................................

........

1

Containing:

¼

-

20 Locknut

(#02167010)

................................

.............................

6

Ga

C

onnector 5/8” OD x 36”

(#30302360)

................................

................................

.......................

1

In tallation & Operation In truction

(#4

34

710

1

0)

................................

................................

...........

1

CONTROL/DRAFT INDUCER

CONTROL/DRAFT INDUCER CONTROL/DRAFT INDUCER

CONTROL/DRAFT INDUCER PACKAGE NUMBERS

PACKAGE NUMBERSPACKAGE NUMBERS

PACKAGE NUMBERS

1

11

1

-

--

-

STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS

-

--

-

MESTEK

MESTEKMESTEK

MESTEK

2

22

2

-

--

-

STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS

-

--

-

ME

MEME

ME

STEK

STEKSTEK

STEK

MODEL NO.

MODEL NO.MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

MODEL NO.

MODEL NO.MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

RMG025N1U0

44499010

NATURAL

RMG025N2U0

44499510

NATURAL

RMG035N1U0

44499030

NATURAL

RMG035N2U0

44499530

NATURAL

RMG045N1U0

44499050

NATURAL

RMG045N2U0

44499550

NATURAL

RMG025L1U0

44499020

PROPANE

RMG025L2U0

44499520

PROPANE

RMG035L1U0

44499040

PROPANE

RMG035L2U0

44499540

PROPANE

RMG045L1U0

44499060

PROPANE

RMG045L2U0

44499560

PROPANE

Form 43471040

-6- Oct 2013

1

11

1

-

--

-

STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS

-

--

-

STERLING

STERLINGSTERLING

STERLING

2

22

2

-

--

-

STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS

-

--

-

STERLING

STERLINGSTERLING

STERLING

MODEL NO.

MODEL NO.MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

MODEL NO.

MODEL NO.MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

RSG025N1U0

44497010

NATURAL

RSG025N2U0

44497510

NATURAL

RSG035N1U0

44497030

NATURAL

RSG035N2U0

44497530

NATURAL

RSG045N1U0

44497050

NATURAL

RSG045N2U0

44497550

NATURAL

RSG025L1U0

44497020

PROPANE

RSG025L2U0

4

4497520

NATURAL

RSG035L1U0

44497040

PROPANE

RSG035L2U0

44497540

NATURAL

RSG045L1U0

44497060

PROPANE

RSG045L2U0

44497560

NATURAL

1

11

1-

--

-STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS –

––

–

BEACON/MORRIS

BEACON/MORRISBEACON/MORRIS

BEACON/MORRIS

2

22

2-

--

-STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS –

––

–

BEACON/MORRIS

BEACON/MORRISBEACON/MORRIS

BEACON/MORRIS

MODEL NO.

MODEL NO.MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

MODEL NO.

MODEL NO.MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

RBG025N1U0

44501010

NATURAL

RBG025N2U0

44501510

NATURAL

RBG035N1U0

44501030

NATURAL

RBG035N2U0

44501530

NATURAL

RBG045N1U0

44501050

NATURAL

RBG045N2U0

44501550

NATURAL

RBG025L1U0

44501020

PROPANE

RBG025L2U0

44501520

PROPANE

RBG035

L1U0

44501040

PROPANE

RBG035L2U0

44501540

PROPANE

RBG045L1U0

44501060

PROPANE

RBG045L2U0

44501560

PROPANE

B.

B.B.

B. Body Package De cription

Body Package De criptionBody Package De cription

Body Package De cription

Part De cription

Part De cription Part De cription

Part De cription

QTY

QTYQTY

QTY

#4

3468000

,

8

Ft. Body Package

................................

................................

................................

...........

1

Containing:

#4

3469

000, Pre

-

a embled

8

’ ALC teel tube a e

mbly with reflector

..........

1

#42762010, Control End Reflector

................................

................................

...........

1

#42761010, Foot End Reflector

................................

................................

................

1

#02125

1

30,

#10

-

24x1/2 Screw

................................

................................

..............

4

#02266010, Speed Clip

................................

................................

...........................

1

4

#42769010, Sliding Clamp

................................

................................

......................

4

Form 43471040

Oct 2013 -7-

6.1) ACCESSORY PACKAGES

A.

A.A.

A.

Exhau t Hood Package, Part #42924000

Exhau t Hood Package, Part #42924000Exhau t Hood Package, Part #42924000

Exhau t Hood Package, Part #42924000

Contains:

Exhau t Hood A embly, #42925550……QTY–1

#8-18 x ½ Self-Drilling Screw , #02189030……QTY–2

4 (10cm)

7 1/2

(19cm)

3 3/4 (10cm)

3 1/2 (9cm)

6

(15cm)

Bird

Screen

Side View Front View

B.

B.B.

B. Deflector Kit, Part #435040

Deflector Kit, Part #435040Deflector Kit, Part #435040

Deflector Kit, Part #4350401

11

10

00

0

The Deflector Kit i available for u e to reduce the

clearance to combu tible below the heater. Refer

to the Minimum Clearance to Combu tible Table

Minimum Clearance to Combu tible TableMinimum Clearance to Combu tible Table

Minimum Clearance to Combu tible Table in

Section 4.0) when u ing thi Deflector Kit. Heater

Heater Heater

Heater

mu t be mounted

mu t be mounted mu t be mounted

mu t be mounted ONLY

ONLYONLY

ONLY

in the horizontal po ition

in the horizontal po ition in the horizontal po ition

in the horizontal po ition

when u ing thi kit.

when u ing thi kit.when u ing thi kit.

when u ing thi kit.

Deflector

Deflector

Bracket

Hanger Bracket

(tube & reflector

components not

shown)

Deflector 10 1/2

(267mm)

5 1/2

(140mm)

Form 43471040

-8- Oct 2013

7.0) DIMENSIONS

15

(381mm) 5 1/2

(140mm)

111

(280cm)

80

(203cm)

10 1/2

(267mm)

5 1/4

(133mm)

Side View

Bottom View

Hanger Bracket

(QTY-2)

Emitter Tube

Reflector

8 FT Body Section

18 1/2

(470mm)

7 1/2

(191mm)

Plastic Vacuum

Air Tube

1/4 O.D.

Tube

Strain Relief

Bushing

Motor

Leads

Sight

Glass

1/2MPT

Gas Connection

8 (20cm)

7 (18cm) 8 (20cm)

Electrical

Connection

End View

Control

Box

Draft Inducer

(vertical mounting)

9 (23cm)

Form 43471040

Oct 2013 -9-

8.0) HEATER ASSEMBLY OVERVIEW

Control Box

Reflector clamp

with screw

Exhauster

assembly Restrictor

airplate

Tube support/

hanger bracket

U bolt clamp &

5/16 Hex nuts

3 OD x 8 tube

Mounting flange

(12 radial holes)

Mounting flange

(12 radial holes)

Suspension chain

with turnbuckle

Reflector, foot end

5-1/2

80

10-1/2

Reflector, control end

Reflector

3

(control box to reflector)

(control box to chain) Suspension

chain

Control box

reflector

3

5-1/2

Side View

U bend

Form 43471040

-10- Oct 2013

9.0) TYPICAL SUSPENSION METHODS

Burner must be secured to the mounting flange with nuts.

All materials used to suspend the heater must have a minimum working load

of 115 lbs.

All S Hooks must be crimped closed.

Never use the heater to support a ladder or other access equipment.

Failure to do so may result in death, serious injury or property damage.

SUSPENSION HAZARD

Variou mean of u pending the heater can be u ed. See the following drawing for typical example .

1. U e only noncombu tible material for u pending hanger and bracket .

2. A minimum No. 2 chain with a working load limit of 115 lb . i required.

3. Turnbuckle can be u ed with chain to allow leveling of the heater. All “S” hook and eye bolt mu t be

manually crimped clo ed by the in taller.

4. When u ing rigid mean for heater u pen ion (rod, flat bar, etc.) provide ufficient length or wing joint to

compen ate for expan ion. See Figure b and c.

5. Heater ubject to vibration mu t be provided with vibration i olating hanger .

6. Heater mu t not be upported by ga or electric upply line and mu t be u pended from a permanent

tructure with adequate load capacity.

Me tek recommend that the tube ection be u pended u ing chain with turnbuckle . Thi will allow light

adju tment after a embly and heater expan ion/ contraction during operation.

If a “trapeze” method i u ed for tube upport/hanger bracket ( hown below), the minimum chain length for the

two connecting chain i 36” to minimize any vibration that might be generated by the draft inducer a embly. If

the e chain mu t be le than 36”, then do not u e the trapeze method and, in tead, u e individual chain on

each tube upport/hanger bracket.

c.

Eyebolt

Turnbuckle

Minimum

No. 2 Chain

Eyebolt

b.

Threaded

Rod

Turnbuckle

Eyebolt

a.

3/16 x 1 wide

Flat Bar

36 (91cm) Minimum

36 (91cm) Minimum

Minimum

No. 2 Chain

S-Hook

(typical)

d.

Form 43471040

Oct 2013 -11-

10.0) HEATER ASSEMBLY

Sheet metal parts, particularly reflectors and vent have sharp

edges. Always use gloves when handling.

Failure to do so may result in death, serious injury or property

damage.

CUT HAZARD

During field a embly of the heater, the recommended procedure i a follow :

1. Put the u pen ion in place (according to Section 7.0) u ing proper u pen ion method ( ee Section 9.0).

1

1

80

chains for suspension

80

Suspension

Chain

18-1/2

18-1/2

1

Trapeze Method

Trapeze MethodTrapeze Method

Trapeze Method

Individual Su pen ion Method

Individual Su pen ion MethodIndividual Su pen ion Method

Individual Su pen ion Method

2. Lift the tube ection and u pend it into place. When lifting, caution hould be u ed to avoid damaging the

a embly. Make ure that the long axi of heater i level.

2

2

Tube Flange

Level indicator

The long axis of heater

Side View

2

2

Form 43471040

-12- Oct 2013

3. A embly the reflector onto the tube ection. Leave 3” pace between the tube flange and the reflector for

later mounting of control box and draft inducer.

4. Place the flange of the control end reflector flu h with the end of the fir t reflector. Secure by liding peed

clip onto reflector edge . Evenly pace 6 peed clip on ide and top of reflector to provide a nug fit.

Place foot end reflector on the oppo ite end of the reflector and ecure a above.

4

Speed

Clip 3

Tube Flange

Side View

Suspension

chain

reflector

3

3

4

5. Attach the control box to the right-hand control tube flange and ecure with 1/4-20 locknut . The control box

mu t be mounted with the perforated fre h air plate on top, facing the ceiling.

6. Attach the draft inducer a embly to the left-hand draft inducer tube flange and ecure with 1/4-20 locknut .

A flue re trictor plate i attached to the draft inducer weld tud . DO NOT DISCARD RESTRICTOR PLATE

DO NOT DISCARD RESTRICTOR PLATE DO NOT DISCARD RESTRICTOR PLATE

DO NOT DISCARD RESTRICTOR PLATE and

make ure thi remain in place while the draft inducer i being attached to the heater body.

5

Flue Restrictor

Plate

Do Not Discard.

Draft Inducer

(vertical position)

1/4-20

Locknuts

Tube Flange

(draft inducer)

Tube Flange

(control)

Control Box

Access

Panel

6

Form 43471040

Oct 2013 -13-

7. Slip the pla tic vacuum air tube over the 1/4” O.D. aluminum tube end of the draft inducer and the air

witch probe in the control box. The air tube hould be hortened to prevent a downward ag which could

allow conden ation build-up in the tube.

8. In ert motor lead wire through the train relief bu hing of the control box and connect to L1 and L2 of

terminal block. Refer al o to the wiring diagram in Section 13.0).

Plastic Vacuum

Air Tube

1/4 O.D.

Tube Motor Leads

(to L1 and L2 of

the terminal block)

Strain Relief

Bushing

7

8

9. Fa ten the reflector to the tube upport/hanger bracket with (2) #10 heet metal crew according to Detail

“A”. Mount the liding reflector clamp (#42769010) per Reflector Clamp In tallation (Detail “B”) on both

tube upport/hanger bracket . Make ure the reflector can lide under the clamp during heater operation.

T

TT

T

he reflector clamp MUST be in talled per reflector

he reflector clamp MUST be in talled per reflector he reflector clamp MUST be in talled per reflector

he reflector clamp MUST be in talled per reflector

clamp in tallation detail which allow the reflector to

clamp in tallation detail which allow the reflector to clamp in tallation detail which allow the reflector to

clamp in tallation detail which allow the reflector to

lide under the clamp during heater operation.

lide under the clamp during heater operation.lide under the clamp during heater operation.

lide under the clamp during heater operation.

9

9

9

Tube Support &

Hanger Bracket

Reflector

Clamp

Reflector Clamp

Screw

Reflector Clamp Installation

9

See Detail A & B

DETAIL A

Fasten screws to tube

hanger/support bracket and reflector

(only the tube hanger/support

bracket closest to the control end)

#10 x 1/2 SHEET METAL

SCREWS (QTY - 2)

DETAIL B

See Detail B

Do not relocate the tube upport/hanger bracket at the control box end of

Do not relocate the tube upport/hanger bracket at the control box end of Do not relocate the tube upport/hanger bracket at the control box end of

Do not relocate the tube upport/hanger bracket at the control box end of

the heater. Thi wi

the heater. Thi withe heater. Thi wi

the heater. Thi wi

ll increa e the weight on the emitter tube and can re ult

ll increa e the weight on the emitter tube and can re ult ll increa e the weight on the emitter tube and can re ult

ll increa e the weight on the emitter tube and can re ult

in premature tube failure.

in premature tube failure.in premature tube failure.

in premature tube failure.

Form 43471040

-14- Oct 2013

ANGLE MOUNTED HEATERS ONLY

ANGLE MOUNTED HEATERS ONLYANGLE MOUNTED HEATERS ONLY

ANGLE MOUNTED HEATERS ONLY

10. The heater can be mounted horizontally or up to an angle of 45º maximum from horizontal. When the heater

i to be angle mounted adjacent to a idewall, make ure the draft inducer a embly i on the lower ide of

the heater o that the control box acce panel i ea ily acce ible. Make ure the long axi of heater i level.

Multiple draft inducer po ition can al o be u ed a hown in the diagram . Thi allow for the de ired

configuration of flue venting.

Horizontal Mounting Angle Mounting

Horizontal

Vertical

45 Deg. (maximum)

11.0) GAS CONNECTIONS AND REGULATIONS

Tighten flexible gas hose and components securely.

Flexible metal gas hoses must be installed without any twists or

kinks in them. The hose will move during operation of the heater

and it can crack if it is twisted.

Failure to do so may result in death, serious injury or property

damage.

IMPORTANT BEFORE CONNECTING THE GAS TO THE HEATER

IMPORTANT BEFORE CONNECTING THE GAS TO THE HEATERIMPORTANT BEFORE CONNECTING THE GAS TO THE HEATER

IMPORTANT BEFORE CONNECTING THE GAS TO THE HEATER

1. Connect to the upply tank or manifold in accordance with the late t edition of National Fuel Ga Code (ANSI

Z223.1), and local building code . Authoritie having juri diction hould be con ulted before the in tallation

i made. (In Canada, refer to the late t edition of CSA Standard B149.1, Natural Ga and Propane

In tallation Code.)

2. Check that the ga fuel on the burner rating plate matche the fuel for the application.

3. Check that the ga upply piping ha the capacity for the total ga con umption of the heater and any other

equipment connected to the line.

4. Check that the calculated upply pre ure with all ga appliance and heater operating will not drop below

the minimum upply pre ure required for the e heater . Check inlet upply pre ure on Section 12.0).

5. All ga upply line mu t be located in accordance with the required clearance to combu tible from the

heater a li ted on the clearance label of the heater and Section 4.0) of thi manual.

6. Pipe joint compound mu t be re i tant to the action of liquefied petroleum ga e .

7. Tube heater will expand/contract during operation. Where local code do not prohibit, a CSA or U.L.

approved flexible connector upplied with thi heater i required for connection between the rigid piping

and the heater. A union hould be in talled before the control box inlet. An approved hut off valve hould be

in talled within 6 feet of the union.

8. The ga pipe, flexible ho e and connection mu t be elf upporting. The ga pipe work mu t not bear any of

the weight of the heater or any other u pended a embly.

9. Thi appliance i equipped with a tep-opening, combination ga valve. The maximum upply pre ure to the

The maximum upply pre ure to the The maximum upply pre ure to the

The maximum upply pre ure to the

appliance i 14” W.C. or 1/2 P.S.I.

appliance i 14” W.C. or 1/2 P.S.I.appliance i 14” W.C. or 1/2 P.S.I.

appliance i 14” W.C. or 1/2 P.S.I. If the line pre ure i more than the maximum upply pre ure, then a

econd tage regulator which corre pond to the upply pre ure mu t be u ed.

Form 43471040

Oct 2013 -15-

10. After all ga connection have been made, make ure the heater and all ga outlet are turned off before

the main ga upply i turned on lowly

main ga upply i turned on lowlymain ga upply i turned on lowly

main ga upply i turned on lowly. Turn the ga upply pre ure on and check for leak . To check for

leak , check by one of the method li ted in Appendix D of the National Fuel Ga Code.

11. If a 2nd tage regulator i u ed, the ball valve down tream in the upply line mu t be clo ed when purging

the ga line to prevent ga eeping through it. If initial ga pre ure i higher than 14” w.c. the redundant

combination ga valve i de igned to lock out. Pre ure build-up in the upply line prior to the heater mu t

be relea ed before proper heater operation.

DO

DO DO

DO not u e an open flame of any kind to te t for leak .

not u e an open flame of any kind to te t for leak .not u e an open flame of any kind to te t for leak .

not u e an open flame of any kind to te t for leak .

END VIEW SIDE VIEW

Alternate Supply

Locations

* Available as Accessories

KEY DIMENSIONS AND COMPONENTS OF THE GAS CONNECTIONS

14 to 17

(36 to 43cm)

Approved

Flexible Connector

36

*Second Stage Regulator with

Vent Leak Limiter to reduce the

Supply Pressure below 14 W.C.

Gas Pressure

= 2 PSIG

Gas Supply

Piping

Sediment Trap

(Drip Leg)

*Manual Gas

Shut Off Valve

Burner Movement

2 (5cm) Max.

Displacement

INCORRECT POSITIONS

Movement

WRONG

Movement

WRONG

Movement

WRONG

Movement

WRONG

US ONLY:

US ONLY:US ONLY:

US ONLY:

Connector MUST be in talled in “

Connector MUST be in talled in “Connector MUST be in talled in “

Connector MUST be in talled in “⊃

⊃⊃

⊃

” configuration. U e only

” configuration. U e only ” configuration. U e only

” configuration. U e only

the 36” long connector that wa furni hed with thi heater.

the 36” long connector that wa furni hed with thi heater.the 36” long connector that wa furni hed with thi heater.

the 36” long connector that wa furni hed with thi heater.

US ONLY:

A ga connector certified for u e on a tubular type infrared heater per the tandard for Connector

A ga connector certified for u e on a tubular type infrared heater per the tandard for Connector A ga connector certified for u e on a tubular type infrared heater per the tandard for Connector

A ga connector certified for u e on a tubular type infrared heater per the tandard for Connector

for Ga Appl

for Ga Applfor Ga Appl

for Ga Appliance , ANSI Z21.24/CSA 6.10 i upplied for in tallation in US only. The ga connector i 36” long

iance , ANSI Z21.24/CSA 6.10 i upplied for in tallation in US only. The ga connector i 36” long iance , ANSI Z21.24/CSA 6.10 i upplied for in tallation in US only. The ga connector i 36” long

iance , ANSI Z21.24/CSA 6.10 i upplied for in tallation in US only. The ga connector i 36” long

and

and and

and 1

11

1/

//

/2

22

2” nominal ID, and mu t be in talled a hown above, in

” nominal ID, and mu t be in talled a hown above, in” nominal ID, and mu t be in talled a hown above, in

” nominal ID, and mu t be in talled a hown above, in

one plane, and without harp bend , kink or

one plane, and without harp bend , kink or one plane, and without harp bend , kink or

one plane, and without harp bend , kink or

twi t .

twi t .twi t .

twi t .

CANADA ONLY:

A Type I ho e connector ho

A Type I ho e connector hoA Type I ho e connector ho

A Type I ho e connector hould be u ed that i certified a being in compliance with the

uld be u ed that i certified a being in compliance with the uld be u ed that i certified a being in compliance with the

uld be u ed that i certified a being in compliance with the

Standard for Ela tomeric Compo ite Ho e and Ho e Coupling for Conducting Propane and Natural Ga

Standard for Ela tomeric Compo ite Ho e and Ho e Coupling for Conducting Propane and Natural Ga Standard for Ela tomeric Compo ite Ho e and Ho e Coupling for Conducting Propane and Natural Ga

Standard for Ela tomeric Compo ite Ho e and Ho e Coupling for Conducting Propane and Natural Ga

(CAN/CGA 8.1) and i of length of 36+/

(CAN/CGA 8.1) and i of length of 36+/(CAN/CGA 8.1) and i of length of 36+/

(CAN/CGA 8.1) and i of length of 36+/-

--

-

6 in (90+/

6 in (90+/6 in (90+/

6 in (90+/-

--

-

15 cm).

15 cm).15 cm).

15 cm).

The ga connector

The ga connector The ga connector

The ga connector mu t be in talled

mu t be in talled mu t be in talled

mu t be in talled a hown

a howna hown

a hown

above

aboveabove

above, in one plane, and without harp bend , kink or twi t .

, in one plane, and without harp bend , kink or twi t ., in one plane, and without harp bend , kink or twi t .

, in one plane, and without harp bend , kink or twi t .

Form 43471040

-16- Oct 2013

12.0) INSTRUCTIONS FOR PRESSURE TEST GAUGE CONNECTION

SUPPLY PRESSURE

SUPPLY PRESSURESUPPLY PRESSURE

SUPPLY PRESSURE

1. The in taller will provide a 1/8” N.P.T. tapped plug, acce ible for te t gauge connection immediately

up tream of the ga upply connection to the heater.

MANIFOLD PRESSURE

MANIFOLD PRESSURE MANIFOLD PRESSURE

MANIFOLD PRESSURE –

––

–

COMBINATION GAS VALVE IS FACTORY SET

COMBINATION GAS VALVE IS FACTORY SETCOMBINATION GAS VALVE IS FACTORY SET

COMBINATION GAS VALVE IS FACTORY SET

1. Turn the ga valve to the “OFF” po ition. Remove the 1/8” plug from the combination ga valve at the Outlet

Outlet Outlet

Outlet

Pre ure T

Pre ure TPre ure T

Pre ure Tap

apap

ap

hown below and connect a 1/8” nipple to the tapped hole. Connect the te t gauge to the

nipple. Turn on the ga upply.

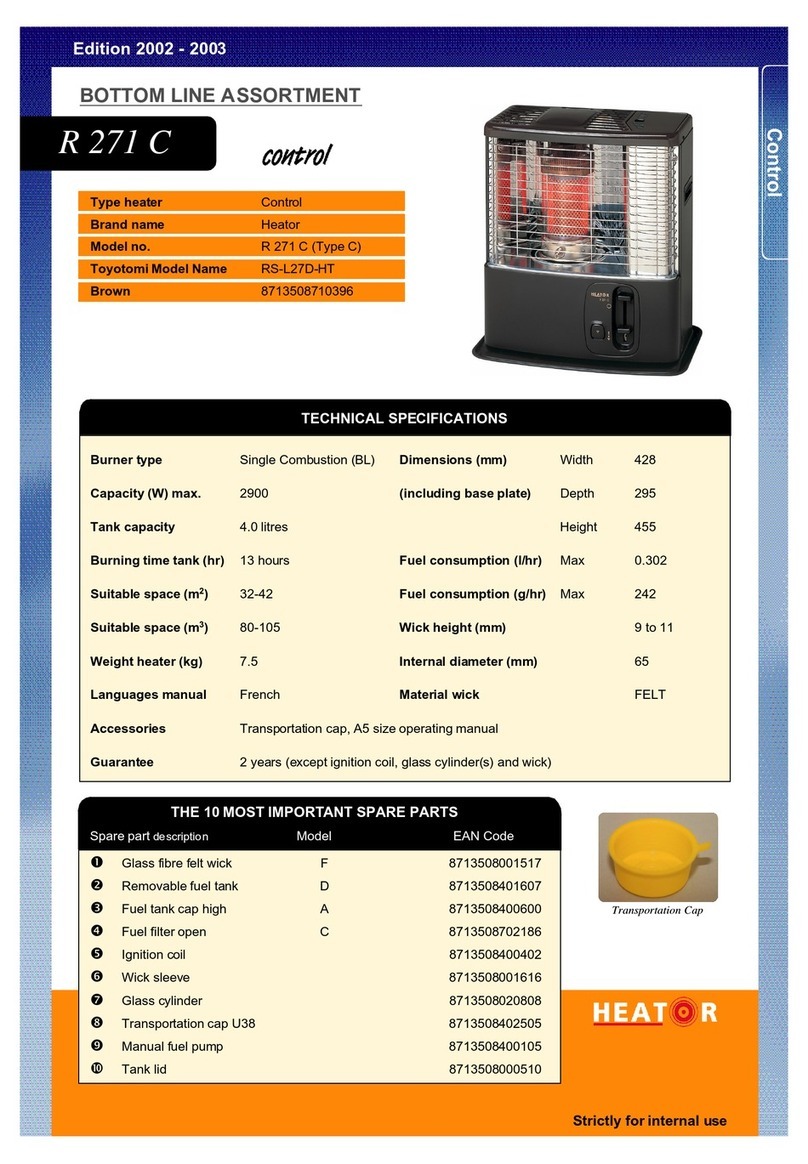

1-STAGE CONTROLS

Pressure Regulator Adjustment

(under cap screw)

1/8 NPT

Inlet Pressure

Tap with 3/16 Hex

Allen Wrench Plug

1/8NPT

Outlet Pressure

Tap with 3/16 Hex

Allen Wrench Plug

Gas Control

Knob

Wiring

Terminals (2)

Ground

Terminals (2)

OUTLET

INLET

CAUTION

Never jumper these terminals. This

shorts out valve coil and may burn

out heat anticipator in thermostat.

STEP-OPENING

GAS CONTROL VALVE

ON

OFF

MV

MV

2-STAGE CONTROLS

HI-LO

Adjustment Screws

(use 3/32 Hex

Allen Wrench)

1/8 NPT

Inlet Pressure

Tap with 3/16 Hex

Allen Wrench Plug 1/8NPT

Outlet Pressure

Tap with 3/16 Hex

Allen Wrench Plug

Gas Control

Knob

Wiring

Terminals (3)

Ground

Terminals (2)

OUTLET

INLET

CAUTION

Never jumper these terminals. This

shorts out valve coil and may burn

out heat anticipator in thermostat.

TWO-STAGE

GAS CONTROL VALVE

HI LO

ON

OFF

LO

C

HI

Electric

Solenoid

Coil

Regulator

Vent Cover

Form 43471040

Oct 2013 -17-

2. With the main burner operating, check the burner manifold pre ure u ing a water column manometer.

Gauge that mea ure pre ure in pound per quare inch are not accurate enough to mea ure or et the

manifold pre ure. All mea urement MUST BE

MUST BEMUST BE

MUST BE made when thi heater and all other ga burning equipment

that i connected to the ga upply y tem are operating at maximum capacity.

3. The combi

The combiThe combi

The combination ga valve i factory et and hould not require adju tment.

nation ga valve i factory et and hould not require adju tment.nation ga valve i factory et and hould not require adju tment.

nation ga valve i factory et and hould not require adju tment. If full rate adju tment i

required, remove the cover crew. U ing a mall crewdriver, turn the adju tment crew clockwi e to

increa e or counterclockwi e to decrea e the ga pre ure to the burner. Replace the cover crew. NOTE:

NOTE: NOTE:

NOTE:

The tep opening pre ure of thi ga valve i not adju table.

The tep opening pre ure of thi ga valve i not adju table.The tep opening pre ure of thi ga valve i not adju table.

The tep opening pre ure of thi ga valve i not adju table.

4. Check the burner at tep pre ure, ob erving burner ignition and flame characteri tic . The burner hould

ignite properly and without fla hback to the orifice, and hould remain lit.

GAS PRESSURE TABLE

GAS PRESSURE TABLEGAS PRESSURE TABLE

GAS PRESSURE TABLE

GAS TYPE

GAS TYPEGAS TYPE

GAS TYPE

MANIFOLD PRESSURE

MANIFOLD PRESSUREMANIFOLD PRESSURE

MANIFOLD PRESSURE

SUPPLY PRESSURE

SUPPLY PRESSURESUPPLY PRESSURE

SUPPLY PRESSURE

Minimum*

Minimum*Minimum*

Minimum*

Maximum

MaximumMaximum

Maximum

Natural Ga 3.5” W.C. 5” W.C. 14” W.C.

Propane Ga 10.0” W.C. 11” W.C. 14” W.C.

* Minimum permi ible ga upply pre ure for purpo e of input adju tment.

13.0) ELECTRICAL AND THERMOSTAT CONNECTIONS

Failure to do so may result in death or serious injury.

This appliance must be connected to a properly grounded electrical source.

Disconnect electrical power and gas supply before servicing.

ELECTRIC SHOCK HAZARD

1. All electric wiring hall conform to the late t edition of the National Electrical Code (ANSI/NFPA No. 70), or

the code legally authorized in the locality where the in tallation i made.

2. The unit mu t be electrically grounded in accordance with the National Electrical Code (ANSI/NFPA No.

70-late t edition). In Canada, refer to current tandard C22.1 Canadian Electrical Code Part 1.

3. The wiring providing power to the heater hall be connected to a permanently live electrical circuit, one that

i not controlled by a light witch.

4. The power upply to the unit hould be protected with a fu ed di connect witch or circuit breaker. A ervice

witch, a required by local code , hall be located in the vicinity of the heater (check local code for

allowable di tance ) and hould be identified a Heater Service Switch. All electrical wiring mu t be located

in accordance with the required Clearance to Combu tible from the heater a li ted on the nameplate on

the heater.

5. When connecting the upply circuit

upply circuitupply circuit

upply circuit to the heater, wiring material having a minimum ize of 14 AWG and a

temperature rating of at lea t 90°C hall be u ed.

Form 43471040

-18- Oct 2013

INCOMMING POWER SUPPLY CONNECTION – 1 STAGE CONTROLS

INCOMMING

POWER SUPPLY

CONNECTION

Viewed From

Inside Control Box

Draft Inducer

Control Box

Ground

Screw

Terminal

Block

L2 L1

GROUND

NEUTRAL

120V

Motor Lead Wires

Motor Lead Wire (black)

Motor Lead Wire (white)

INCOMMING POWER SUPPLY CONNECTION – 2 STAGE CONTROLS

INCOMMING

POWER SUPPLY

CONNECTION

Viewed From

Inside Control Box

Draft Inducer

Control Box

Ground

Screw

Terminal

Block

L2 L1

GROUND

NEUTRAL

120V

Motor Lead Wires

Relay

Inside Control Box

3

Connector Wire

(relay to black

motor lead)

Motor Lead Wire (black)

Motor Lead Wire (white)

Form 43471040

Oct 2013 -19-

1

11

1

-

--

-

STAGE CONTROLS

STAGE CONTROLS STAGE CONTROLS

STAGE CONTROLS

-

--

-

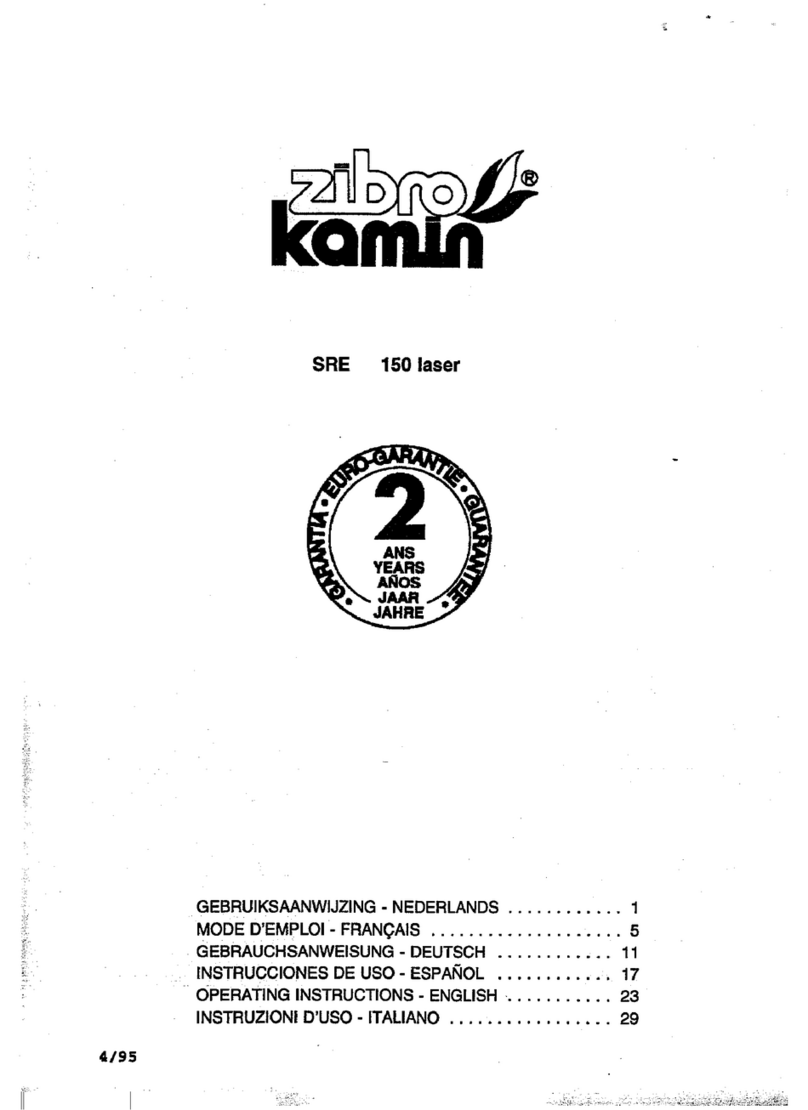

INTERNAL CONNECTION WIRING DIAGRAM

INTERNAL CONNECTION WIRING DIAGRAM INTERNAL CONNECTION WIRING DIAGRAM

INTERNAL CONNECTION WIRING DIAGRAM

—

——

—

Direct Spark Ignition

Direct Spark IgnitionDirect Spark Ignition

Direct Spark Ignition

WIRE LEGEND

ENGLISH FRANCAIS

BK BLACK NOIR

W WHITE BLANC

R RED ROUGE

BL BLUE BLEU

G GREEN VERT

V VIOLET VIOLET

A AMBER AMBRE

42706000 Rev. J 1/2012

BL BL

BKBK

R

W

BK

BK

R

BK

W

BK

BK

BK W

DRAFT

INDUCER

MOTOR

GAS VALVE

AIR SWITCH

TRANSFORMER

120V PRIMARY

24V SECONDARY

A

G

R

HIGH VOLTAGE

CABLE

ELECTRODE

GAP 3/16

CONTINUE TO

ADDITIONAL

HEATERS

NEUTRAL

120V THERMOSTAT

GROUND

L1

L2

TERMINAL

BLOCK

FACTORY WIRING

FIELD WIRING

CONNECTION WIRING DIAGRAM

CONTROL CABINET

If any of the original wire as supplied

with the appliance must be replaced.

It must be replaced with wiring material

having a temperature rating of at least

105oC. (18 AWG. - UL / CSA 600V

Type TEW)

When connecting the supply circuit to

the heater, wiring material having a

minimum size of 14 AWG and a

temperature rating of at least 90oC

shall be used.

MONITORING LIGHTS

Schéma de circuit de connexion

Circuit d'origine

Connexions client

Lampes témoins

Neutre

Terre

Vers les autres

radiateurs

Plaque à

bornes

Transformateur

bobine primaire 120ÊV

bobine secondaire 24ÊV

pressostat

Robinet à gaz

Écartement

d'électrode

4,7Êmm

Haute tension

Armoire de commande

Moteur

d'amorce

d'aspiration

S'il faut remplacer un fil de l'appareil

d'origine, utiliser exclusivement des fils

à température de service nominale

d'au moins 105C (18 AWG. - UL / CSA

600ÊV

Type TEW).

Pour raccorder le circuit d'alimentation

au radiateur, utiliser des fils de calibre

14 AWG ou plus à température de

service nominale d'au moins 90C.

FUSE

2A

G

IGNITION MODULE

GND

(BURNER)

25V

Bloc d'allumage

VALVE VALVE

NOTES:

NOTES:NOTES:

NOTES:

1. If any of the original wire a upplied with the appliance mu t be replaced, it mu t be replaced with wiring

material having a temperature rating of at lea t 105ºC. (18 Ga. CSA 600V Type TEW)

2. When connecting the upply circuit to the heater, wiring material having a minimum ize of 14 AWG and a

temperature rating of at lea t 90ºC hall be u ed.

3. A replaceable 2-amp fu e (1-1/4” long) i located in ide the control box.

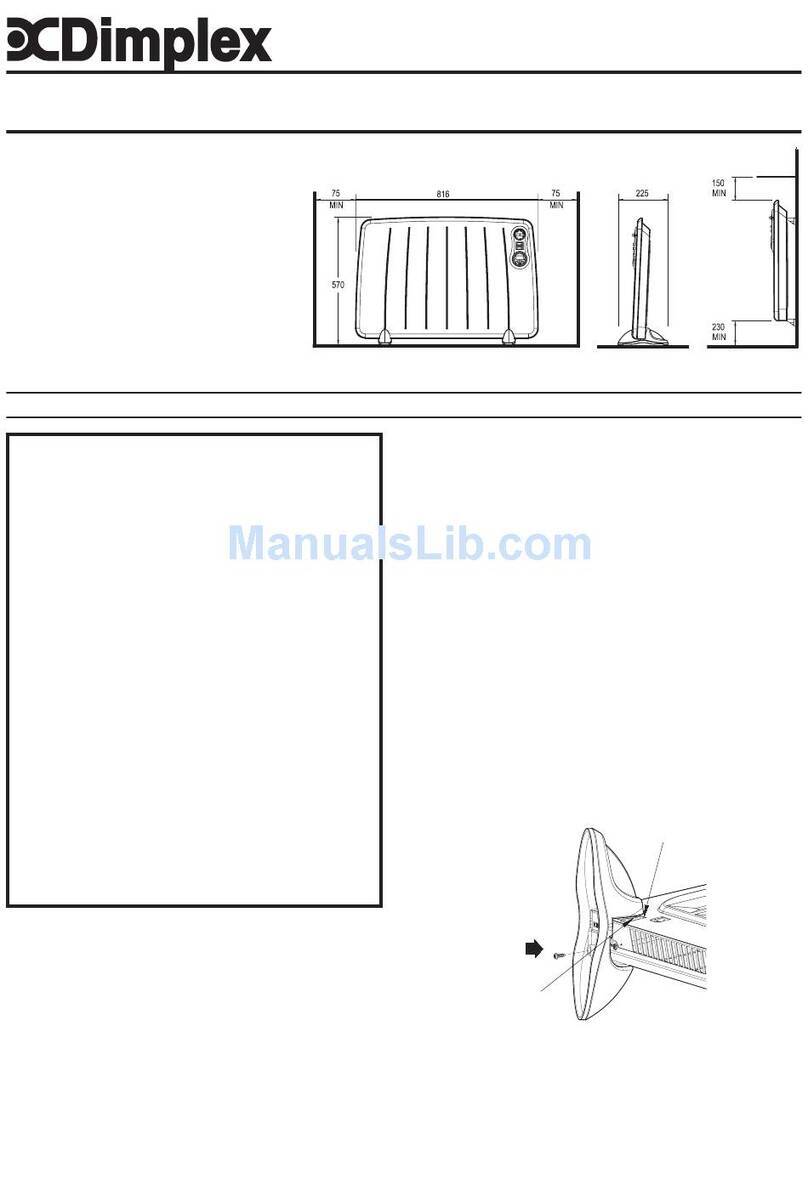

1

11

1

-

--

-

STAGE CO

STAGE COSTAGE CO

STAGE CO

NTROLS

NTROLS NTROLS

NTROLS

-

--

-

SCHEMATIC

SCHEMATICSCHEMATIC

SCHEMATIC

WIRING DIAGRAM

WIRING DIAGRAM WIRING DIAGRAM

WIRING DIAGRAM

—

——

—

Direct Spark Ignition

Direct Spark IgnitionDirect Spark Ignition

Direct Spark Ignition

SCHEMATIC WIRING DIAGRAM

MOT Motor Moteur

GL Green Light Témoin vert

TRANS 24V Transformer Transformateur 24ÊV

RL Red Light Témoin rouge

AS Air Switch pressostat

SM Ignition Module Bloc d'allumage

IG/S Ignitor / Sensor électrode

V Gas Valve Robinet à gaz

AL Amber Light Témoin ambre

MOT

120V

GL

TRANS

RL

AS

IG/S

AL

V

SM

42785000 Rev. C 10/04

25V GND25V

Other manuals for R(B

1

This manual suits for next models

2

Table of contents

Other Mestek Heater manuals

Mestek

Mestek SEPARATED COMBUSTION GAS FIRED PROPELLER UNIT... Datasheet

Mestek

Mestek NXIM-2 User manual

Mestek

Mestek SEPARATED COMBUSTION TUBULAR GAS-FIREDBLOWER STYLE UNIT... User manual

Mestek

Mestek VERTICAL STEAM HOT WATER HEATER User manual

Mestek

Mestek R (B,S,M) D SERIES User manual

Mestek

Mestek Kickspace Series User manual

Mestek

Mestek EMBASSY INDUSTRIES HIDEAVECTOR3 User manual

Mestek

Mestek TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT... User manual