*Teflon is a registered trademark of E.I. DuPont de Nemours and Company.

WARNING: HOT WATER HAZARD

Before draining the system, allow water to cool to at

least 100°F, open the drain valve (take precautions against

water damage) and leave the drain valve open until

servicing is complete. Failure to follow these instructions

could result in serious personal injury, death and/or

property damage.

REMOVAL OF PUMP FROM EXISTING SYSTEM FOR REPLACEMENT

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lockout the power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

WARNING: ELECTRICAL SHOCK HAZARD

Be certain the electrical power is not present at the

motor leads before continuing. Failure to follow these

instructions could result in serious personal injury or death

WARNING: HIGH PRESSURE HAZARD

Pressure may be present in the pump body. This

pressure can be relieved by loosening the flange bolts and

shifting the pump assembly slightly to allow the pressurized

water to escape. Failure to follow these instructions could

result in serious personal injury or death.

1. Close the valves on the suction and discharge sides of the

pump. (If no valves have been installed, it may be neces-

sary to drain the system.)

2. Loosen the conduit box cover screw and remove the cover.

3. Disconnect the electrical supply lines to the pump.

4. Remove the flange nuts and bolts or loosen the union ring

nuts. Then remove the pump from the piping.

MECHANICAL SAFETY

THERMAL SAFETY

ELECTRICAL SAFETY

SAFETY REQUIREMENTS

WARNING: EXCESSIVE SYSTEM

PRESSURE HAZARD

The maximum working pressure of the pump is listed on

the nameplate –DO NOT EXCEED THIS PRESSURE.

Failure to follow these instructions could result in serious

personal injury, death and/or property damage.

WARNING: EXCESSIVE PRESSURE HAZARD

VOLUMETRIC EXPANSION

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of

system components and the release of high temperature

fluids. This can be prevented by installing properly sized

and located compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury, death and/or property damage.

WARNING: EXTREME TEMPERATURE HAZARD

If the pump, motor or piping are operating at

extremely high or low temperature, guarding or insulation is

required. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections are to be made by a qualified

electrician in accordance with all applicable codes,

ordinances and good practices. Failure to follow these

instructions could result in serious personal injury, death

and/or property damage.

WARNING: ELECTRICAL GROUNDING HAZARD

Adequate electrical grounding is required for the safe

operation of B&G Pumps. The use of grounded metal

conduit assures this requirement. If the means of connection

to the supply –connection box (wiring compartment) is

other than grounded metal conduit, ground the pump back

to the service. Use a copper conductor at least the size of

the circuit connectors supplying the pump. Connect the

ground wire to the green grounding screw in the wiring

compartment. Failure to follow these instructions could

result in serious personal injury, death and/or property

damage.

2

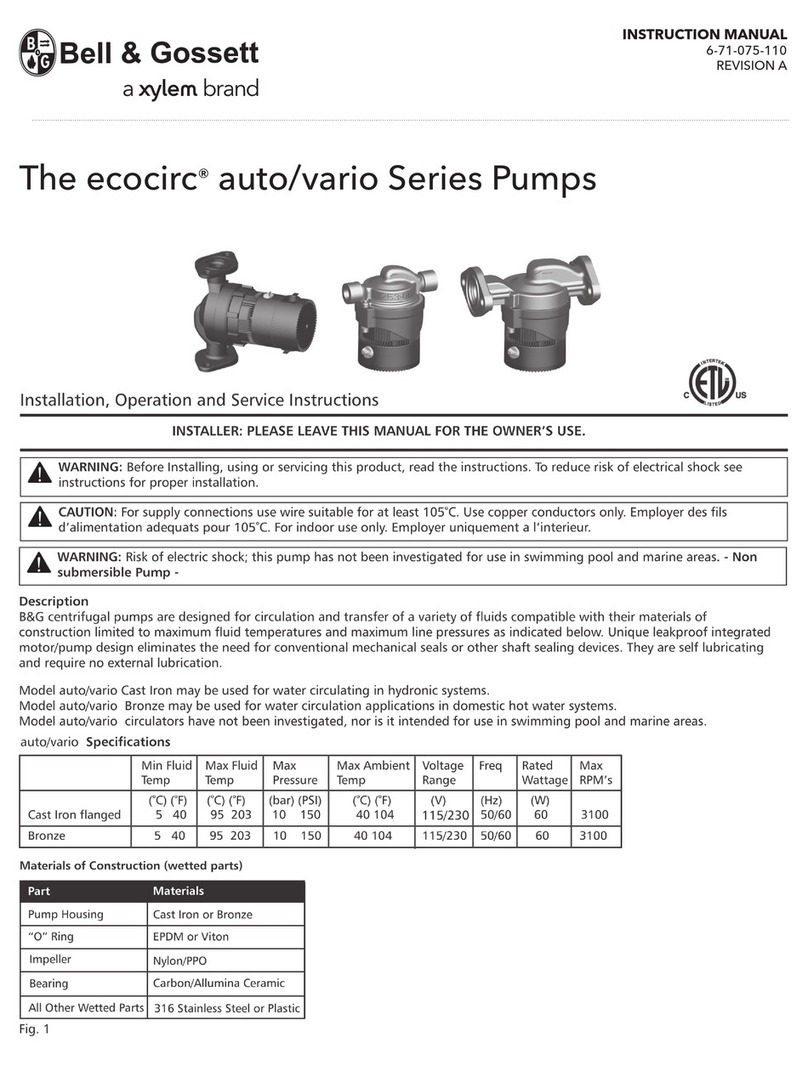

PUMP INSTALLATION

Locate the pump so there is sufficient room for inspection,

maintenance and service. Bell & Gossett recommends the

installation of service valves on the suction and discharge of

all circulators to facilitate servicing or replacement of the

circulator without draining the system.

Install suction and discharge flange connectors on the pipe

ends. The use of Teflon®tape sealer or a high quality thread

sealant is recommended.

Be sure to minimize any pipe-strain on the pump. Support the

suction and discharge piping by the use of pipe hangers near

the pump. Line up the vertical and horizontal piping so that the

bolt-holes in the pump flanges match the bolt-holes in the

pipe flanges. DO NOT ATTEMPT TO SPRING THE SUCTION

OR DISCHARGE LINES IN POSITION. THIS MAY RESULT

IN UNWANTED STRESS IN THE PUMP BODY, FLANGE

CONNECTIONS AND PIPING. The code for Pressure Piping

(ANSI B31.1) lists many types of supports available for various

applications.

Bell & Gossett flange gaskets must be installed between the

NRF/NBF pump body flanges and the suction and discharge pipe

flanges. Use 7/16" diameter x 11/2" long cap screw and matching

nut to connect the pump to the flanges.

WARNING: RISK OF ELECTRIC SHOCK

Do not install this pump in swimming pool or marine

areas. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

CAUTION: The use of Teflon®* impregnated pipe

compound and Teflon®tape on pipe threads pro-

vides lubricity which can lead to overtightening and break-

age. Do not overtighten. Failure to follow this instruction

can result in moderate personal injury from hot water

and/or property damage.