Bell and Howell 770 User manual

PHoToFACT* FolJ"t

tt1 \o

oE

-f rrj

r_o

Hd

la

do

AT

o()

ER

-r lr

J\

lll I

=o

Our

-l\

-N

1a

=\

lrrl\

6

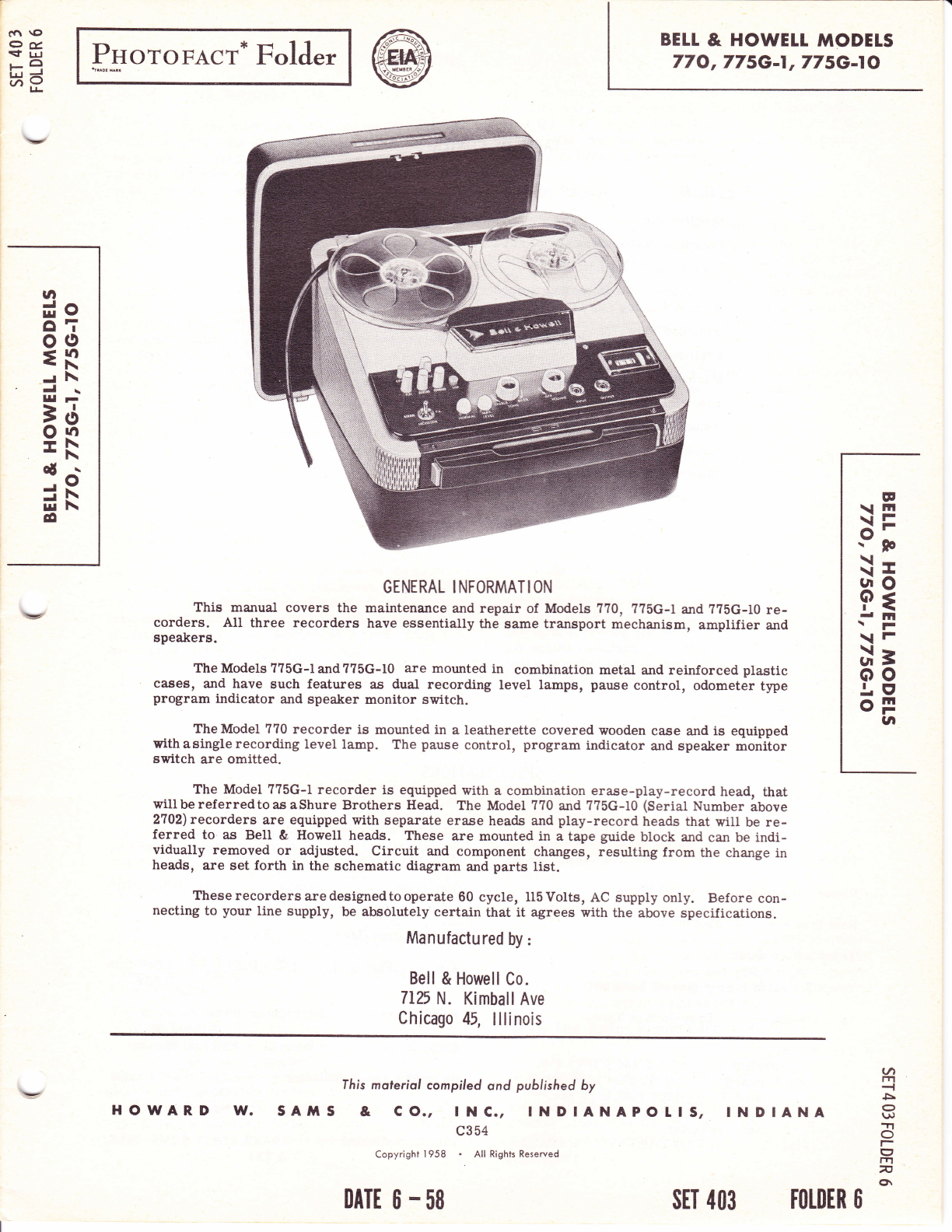

vGENERAL INFORMATION

This manual covers the maintenance and repair of Models 770, 775G-1 and ??5G-I0 re-

corders. AII three recorders have essentially t}te same transport mechanism, amplifier and

spealcers.

The Models ??5G-t and ??5G-10 are mounted in combination metal and reinforced plastic

cases, and have such features a^s dual recording level lamps, pause control, odometer type

program indicator and speaher monitor switch.

The Model 7?0 recorder is mounted in a leatherette covered wooden case and is eguipped

withasinglerecording level lamp. The pause control, program indicator and speaker monitor

switch are omitted.

The Model ??5G-l recorder is equipped with a combination erase-play-record head, that

willbereferredtoas aShure Brothers Head. The Model 770 and 775G-10 (Serial Number above

2702) recorders are equipped with separate erlue heads and play-record heads that will be re-

ferred to as Bell & Howell heads. These are mounted in a tape gurde block and can be indi-

vidually removed or adjusted. Circuit and component changes, resulting from ttre change in

heads, are set forth in the schematic diagram and parts list.

Theserecordersaredesignedtooperate 60 cycle, 115Volts, AC supply only. Before con-

necting to your line supply, be absolutely certain that it agrees with the above specifications.

Manufactured by:

Bell & Howell Co.

7125 N. Kimball Ave

Chicago 45, lllinois

E

\ln

\i=

9;

\-

\I

F3

d lll

\r

\F

c==

oo

.|E'

oF

UI

BEIL & HOWELT NAODETS

77O, 775G-1, 775G-lO

sAfirs &

fhis moteriol compiled ond published by

co., lNc.,

c3 54

Copyright 'l 958 . All Rights Reserved

INDIANAPOIIS, INDIANA

a

trl

5

o

u)

Tr

o

(f

m

7

ch

sET 403 TOLDER O

vHOWAR.D l/.

DATE 6 .58

TABLE OF CONTENTS

Page

Specifications 2

Operating Instructions 3

Disassembly Instructions 5

Instructions For Operating Recorder Without Case'

WhileServicing... ....'. 8

Exploded View. . 6

Exploded View. . 7

MechanicalTroubleChart. ...... I

Electrical Trouble Chart. 12

Adjustments & Tests 14

Schematic 16

ElectricalPartsList .';...... l?-18

Mechanical Parts List i9

Accessories (Parts List). . 22

Case Parts List. . 22,

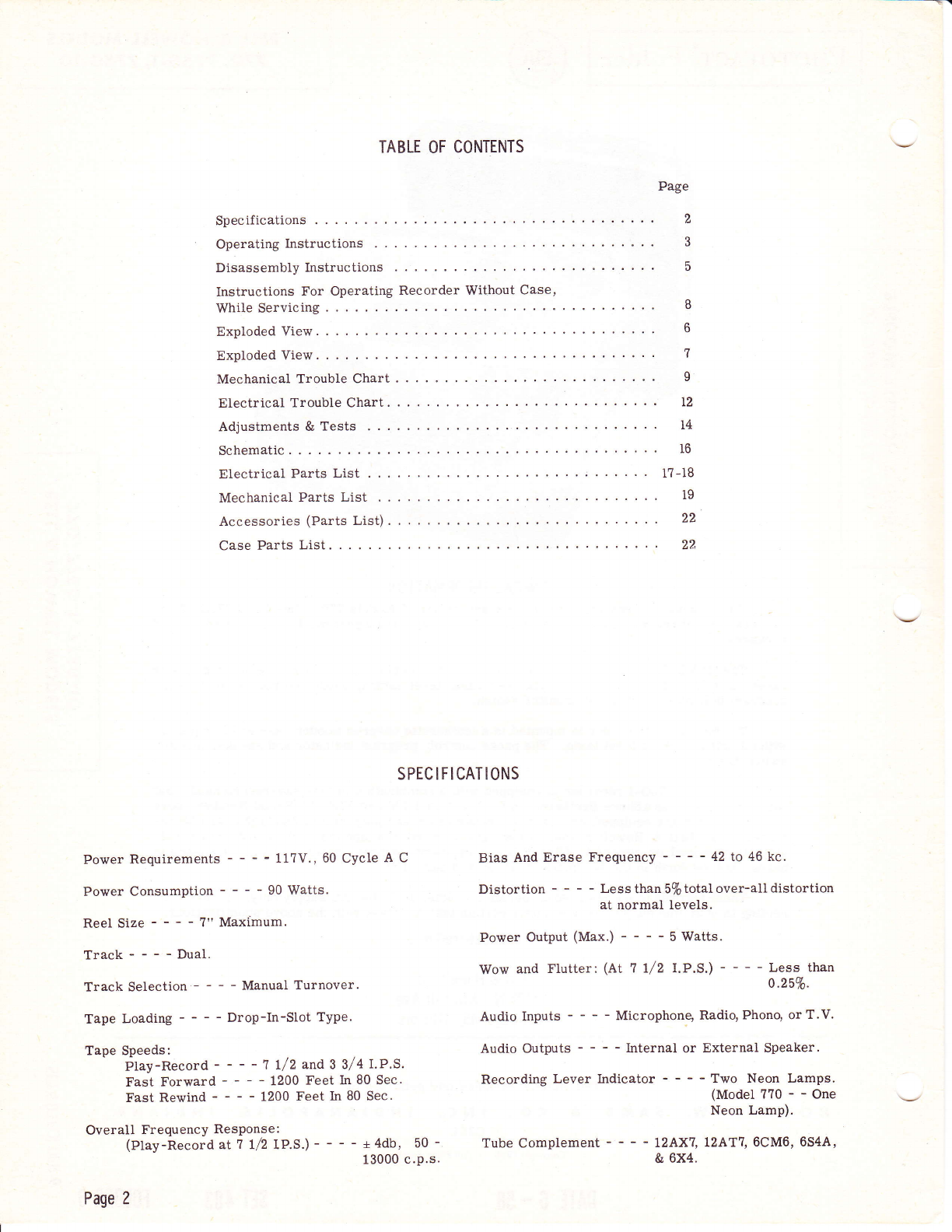

SPEC I FI CATIONS

Power Requirements - - - - 117V., 60 Cycle A C

Power Consumption 90 Watts.

Reel Size ?" Maximum.

Track----Dual.

Track Selection - - - - Manual Turnover.

Tape LoadinC - - - - Drop-In-Slot Type.

Tape Speeds:

Ptay-Record - - - - 7 t/2and 3 3/4 I.P.S.

Fast Forward - - - - 1200 Feet In 80 Sec.

Fast Rewind 1200 Feet In 80 Sec.

Overall Frequency ResPonse:

(Play-RecordatT l/2IP.s.) - - - - +4db, 50 -

13000 c.P.s.

Page 2

Bias And Erase Frequency - - - - 42 to 46 kc.

Distortion Less than 5% total over-all distortion

at normal levels.

Power Output (Max.) - - - - 5 Watts.

Wow and Flutter: (At 1 l/2 LP.S.) Less than

0.25%.

Audio Inputs Microphong Radio, Phonq or T.V.

Audio Outputs - - - - Internal or External Speaker.

Recording Lever Indicator - - - - Two Neon Lamps.

(Model?70--One

Neon Lamp).

Tube Complement - - - - 12AX?, L2AT1, 6CM6, 6544'

& 6X4.

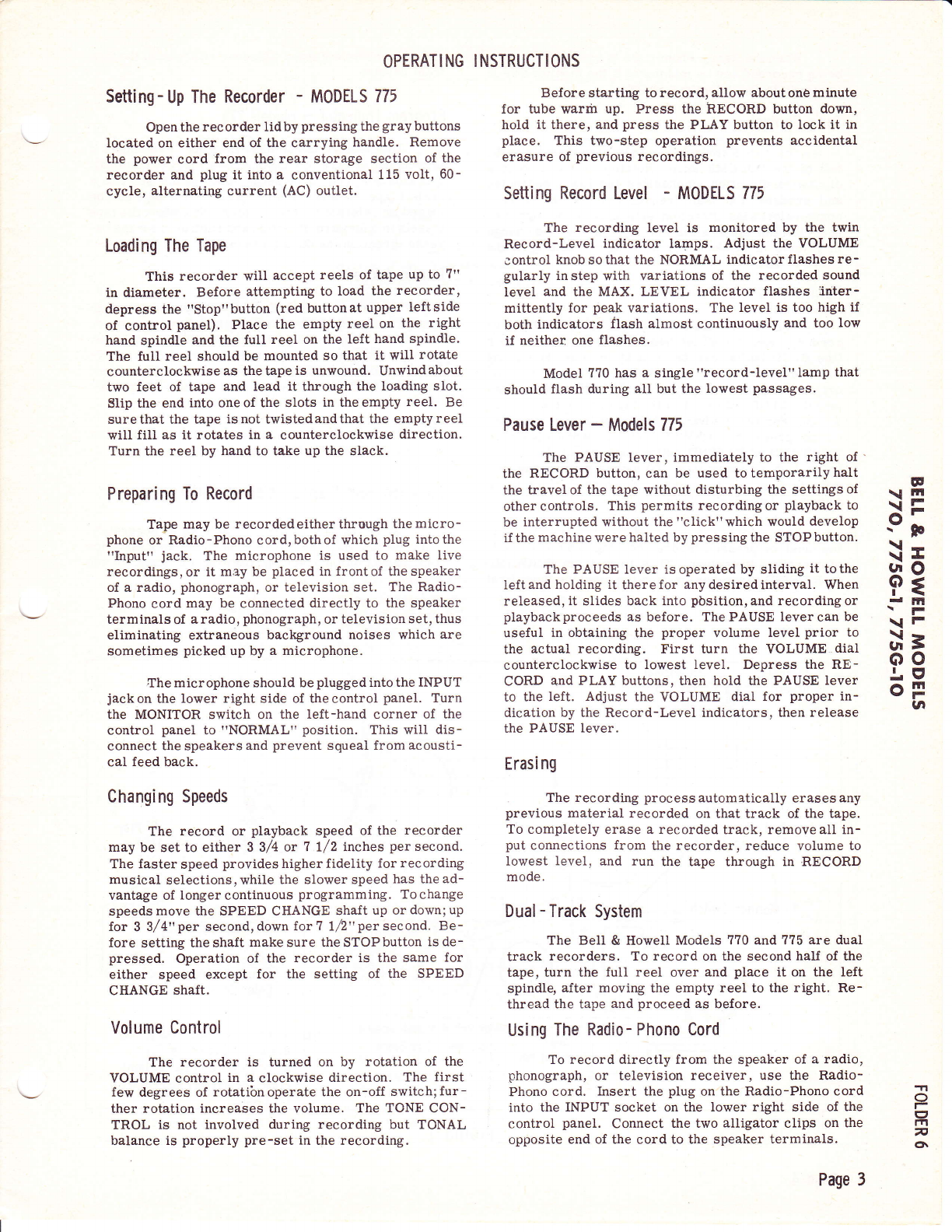

OPERATING

Setting-Up The Recorder - MODELS 775

Open the recorder lid by pressing the gray buttons

located on eitler end of the carrying handle. Remove

the power cord from the rear storage section of the

recorder and plug it into a conventional 115 volt, 60-

cycle, alternatiqg current (AC) outlet.

Loading The Tape

This recorder will accept reels of tape up to ?"

in diameter. Before attempting to load the recorder,

depress the "stop"button (red buttonat upper leftside

of control panel). Place the empty reel on the right

hand spindle and the fuII reel on the left hand spindle.

The full reel should be mounted so that it will rotate

counterclockwise as the tape is unwound. Unrvind about

two feet of tape and lead it through the loading slot.

SIip the end into one of the slots in the empty reel. Be

surethat the tape isnot twistedandthat the emptyreel

witl fill as it rotates in a counterclockwise direction.

Turn the reel by hand to take up the slack.

Preparing To Record

Tape may be recordedeitherthrough themicro-

phone or Radio-Phono cord,bothof which plug intothe

"Inps1" jack. The microphone is used to make live

recordings, or it may be placed in frontof the speaker

of a radio, phonograph, or television set. The Radio-

Phono cord may be connected directly to the speaker

terminals of a radio, phonograph, or television set, thus

eliminating extraneous background noises which are

sometimes picked up by a microphone.

The microphone should be plugged into the INPUT

jackon the lower right side of thecontrol panel. Turn

the MONITOR switch on the left-hand corner of the

control panel to "NORMAL" position. This will dis-

connect the speakers and prevent squeal from acousti-

cal feed back.

Changing Speeds

The record or playback speed of the recorder

may be set to either 3 3/4 or 7 Lf 2 inehes per second.

The faster speed provides higher fidelity for recording

musical selections, while the slower speed has the ad-

vantage of longer continuous programming. To change

speeds move the SPEED CIIANGE shaft up or down; up

for 3 3/4" per second, down for 7 !/2" pet second. Be-

fore setting the shaft make sure the STOPbutton is de-

pressed. Operation of the recorder is the same for

either speed except for the setting of the SPEED

CIIANGE shaft.

Volume Control

The recorder is turned on by rotation of the

VOLUME control in a clockwise direction. The first

few degrees of rotatibnoperate the on-off switch;fur-

ther rotation increases the volume. The TONE CON-

TROL is not involved during recording but TONAL

balance is properly pre-set in the recording.

I NSTRUCT I ONS

Before starting to record, allow about on€ minute

for tube warrir up. Press the RECORD button down,

hold it there, and press the PLAY button to lock it in

place, This two-step operation prevents accidental

erasure of previous recordings.

Setting Record Level - M0DELS 775

The recording level is monitored by the twin

Record-Level indicator lamps. Adjust the VOLUME

control knob so that the NORMAL indicator flashes re-

gularly instep with variations of the recorded sound

level and the MAX. LEVEL indicator flashes ,inter-

mittently for peak variations. The level is too high if

both indicators flash almost eontinuously and too low

if neither one flashes.

Model ??0 has a single "record-level" lamp that

should flash during aII but the lowest passages.

Pause Lever - Models 775

The PAUSE lever, immediately to the right of

the RECORD button, can be used to temporarily halt

the travel of the tape without disturbing the settings of

other controls. This permits recordingor playback to

be interrupted without the "click"which would develop

if the machine were halted by pressing the STOP button.

The PAUSE lever is operated by sliding it tothe

left and holding it there for any desired interval. When

released, it slides back into pbsition, and recording or

playbackproceeds as before. ThePAUSE levercan be

useful in obtaining the proper volume level prior to

the actual recording. First turn the VOLUME. dial

counterclockwise to lowest level. Depress the RE-

CORD and PLAY buttons, then hold the PAUSE lever

to the left. Adjust the VOLUME dial for proper in-

dication by the Record-Level indicators, then release

the PAUSE lever.

Erasi ng

The recording process automatically erases any

previous material recorded on that track of the tape.

To completely erase a recorded track, remove all in-

put connections from the recorder, reduce volume to

Iowest level, and run the tape through in RECORD

mode.

Dual - Track System

The Bell & Howell Models 7?0 and ?75 are dual

track recorders. To record on the second haU of the

tape, turn the full reel over and place it on the left

spindlg after moving the empty reel to the right. Re-

thread the tape and proceed as before.

Using The Radio- Phono Cord

To record directly from the speaker of a radio,

phonograph, or television receiver, use the Radio-

Phono cord. Insert the plug on the Radio-Phono cord

into the INPUT socket on the lower right side of the

control panel. Connect the two alligator clips on the

opposite end of the cord to the speaker terminals.

F

\E

9;

\-

\rL

Fg

{.F

\F

L\3

oo

L9

oF

gr

TI

o

E'

trl

v

o\

Page 3

When t}te Radio-Phono cord is used, the program

being recorded can be monitored if the monitor switch

is moved to the "Monitor" position.

Tone Control

The TONEcontrolknob islocated directty tothe

Ieft of the VOLUME knob. Rotation of the knob in a

clockwise direction emphasizes the low frequencies

and subdues the high frequencies. Rotation in a

counterclockwise direction emphasizes the high fre-

quencies and subdues ttre low frequencies. No change

in volume is produced by a change in setting of ttre

TONE control.

Rewind And Fast Forward

When a tape has been completely played or re-

corded, press the STOP button to stop the recorder

(the STOP button can be used at anytime during any

moQe ofoperation). To return the tape back to the

original supply reel, press the REWIND button, then

use the STOP button when the tape is completely re-

wound. For rapid advanceof the tapein aforwarddir-

ection, press the FORWARD button. When either the

FORWARD or REWIND buttons are pressed the tape

travels at approximately 180 inches per second. Be

sure to take up any slack in the tape before using

either of these fast speeds.

The recorder is designed so that the STOP but-

ton must be pressed before changing from one mode

of operation to another. Thus to go from FORWARD

or REWIND toanotherfunction the machine must first

come to a complete stop. This feature protects the tape

from damage.

Program lndicator - Models 775

This feature is useful in'Iogging,'materialas it

is recorded or in relocating previously logged material.

The indicator should be set to "000" at the start of a

reel of tape, then any desirdd point on the tape can be

logged or relocated. The counter adds when the tape

travels in a forward direction and subtracts for the re-

verse direction, as during rewind.

Public Address

The Bell& Howell Model ??SGtaperecordercan

be usedasa public-address unit in the following manner.

Plug the microphone into the front panel INPUT jack

and turn the power on. Remove all tape from the re-

corder. Setthe MONITOR switchatthe "P.A." position.

Press the RECORDbutton and lockit inplace by press-

ing the PLAY button.

Keep the microphone to one side or behind the

speakers to avoid feed-back squeal.

Dictation And Transcription Machine

An ear-phone unit is available as an accessory.

With its use the recorder will periorm as a dictation

and transcription machine, Iimiting the sound to one

person.

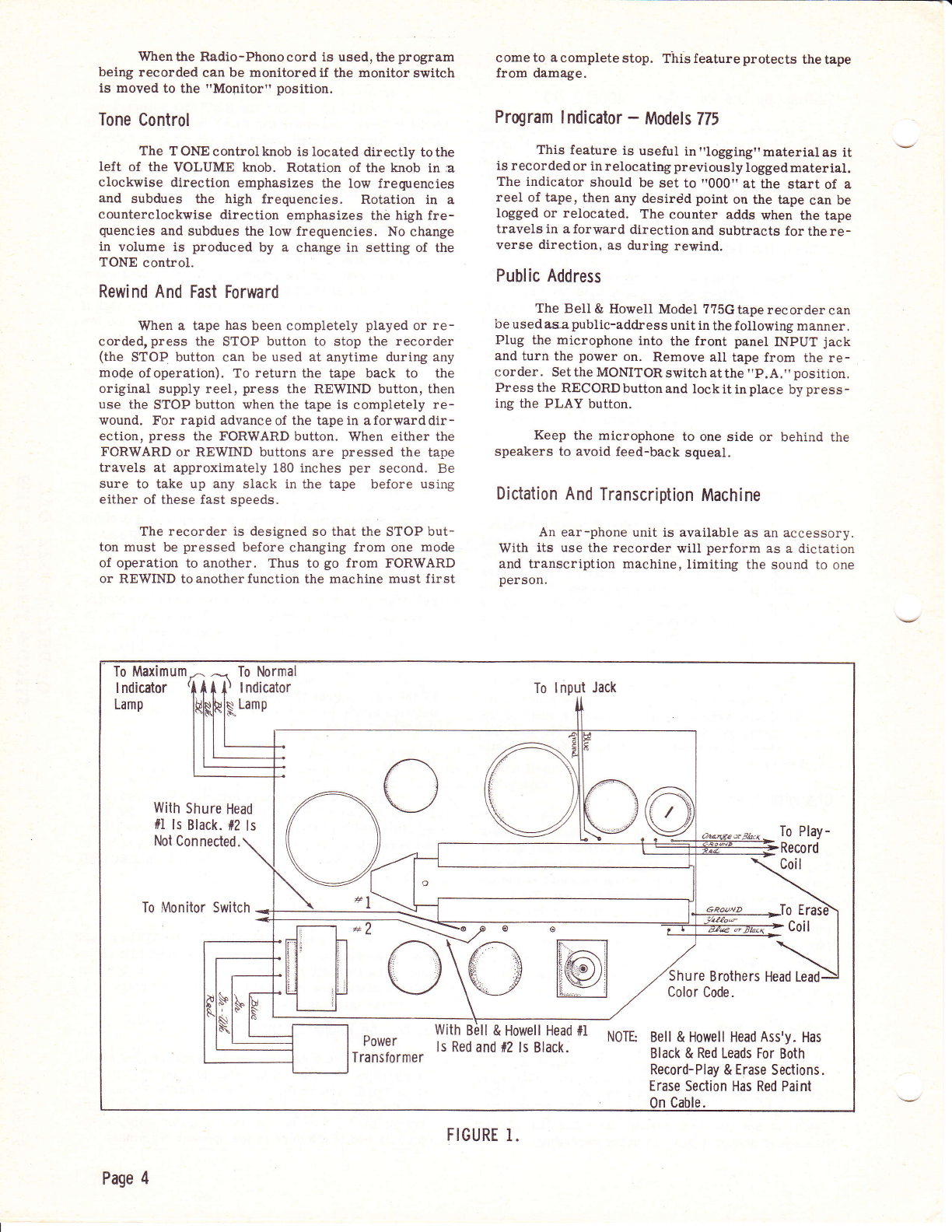

To Maximum

I ndicator

Lamp - To Normal

I I lndicator To I nput Jack

With Bell & Howell Head #I

ls Red and #2 ls Black.

To Play-

Record

Coil

Shure Brothers Head Lead

Color Code.

N0TE Bell & Howell Head Ass'y. Has

Black & Red Leads For Both

Record-Play & Erase Sections.

Erase Section Has Red Paint

Cable.

Lamp

With Shure Head

#l ls Black. #2 ls

Not Connected.

To Moniior Switch

Power

Transforme r

o\o

Page 4

FIGURE I.

-\

FLAY- RITSRT SWIT*FI ATTUAT Iru# t IT{K

5W tT*t.t

@ truTrRL$fiK MuTtrus srrurT*il@

FIGURE 2

D I SASSEMBLY I NSTRUCT IONS

EE

\ITil N

\-= :

e; b

\II

\II L

(lO )

P€ i

rm n

\FI

\F I

;r3 l

oo )

j.e 7

oF !

lnn

To Test 0r Replace Tubes

Remove the bottom grille assembly, held in place

by 4 Phillips headscrews. The two longer screws are

used for that side of the grille which has the name plate.

To Remove Amplifier And Tape Mechanism

From Case

1. Remove the two reel spindles held in place

by Phillips head machine screws and flat washers.

2. Remove PAUSE, VOLUME, and TONE control

knobs from their shafts.

3. Remove the top plate assembly (5) secured

in place by 4 Phillips head machine screws. This will

give access tothe magnetic head, Pressure padassem-

bly, idler drive wheels, upper linkage parts, Veeder

Root counter assembly, and level indicating lamps.

4. Remove the plastic carrying handle, secured

in place by two screws. On early models, screws are

accessible from under side of the handle.

5. Place the recorder in its upright position and

remove the two plastic feet, secured in place by the

Phillips head machine screws at the back of the case.

Remove the bottom grille as described under TO TEST

CR REPLACE TUBES.

6. Remove the two Phillips head screws aeces-

sible through the openings in the channel metal support

f or the plastic handle.

7. Withdraw the mechanism assembly from the

case, being caqeful not to damage the speaker cones.

Removal 0f Amplifier Assembly

1. Disconnect all plug-in leads shown in Fig. l.

NOTE: Refer to Figure 2 for location of items

mentioned below.

2. Disconnect the slide switch wire link from

the slide switch by first loosening the 3/9" switch

position adjustment nut.

3. Unsolder the leads to the on-off switch and

the interlock muting switch (M2 Fig. 2).

4. Unscrew the volume and tone control locking

nuts.

-rl

O

r

(3

fnj

nt

chl

1

)

7

1

)

\

Page 5

A P}..IOTOFACT "EXPLODED' VIEW

l'{oward \7. Samr & Co., lnc. 1959

F -- Page 6

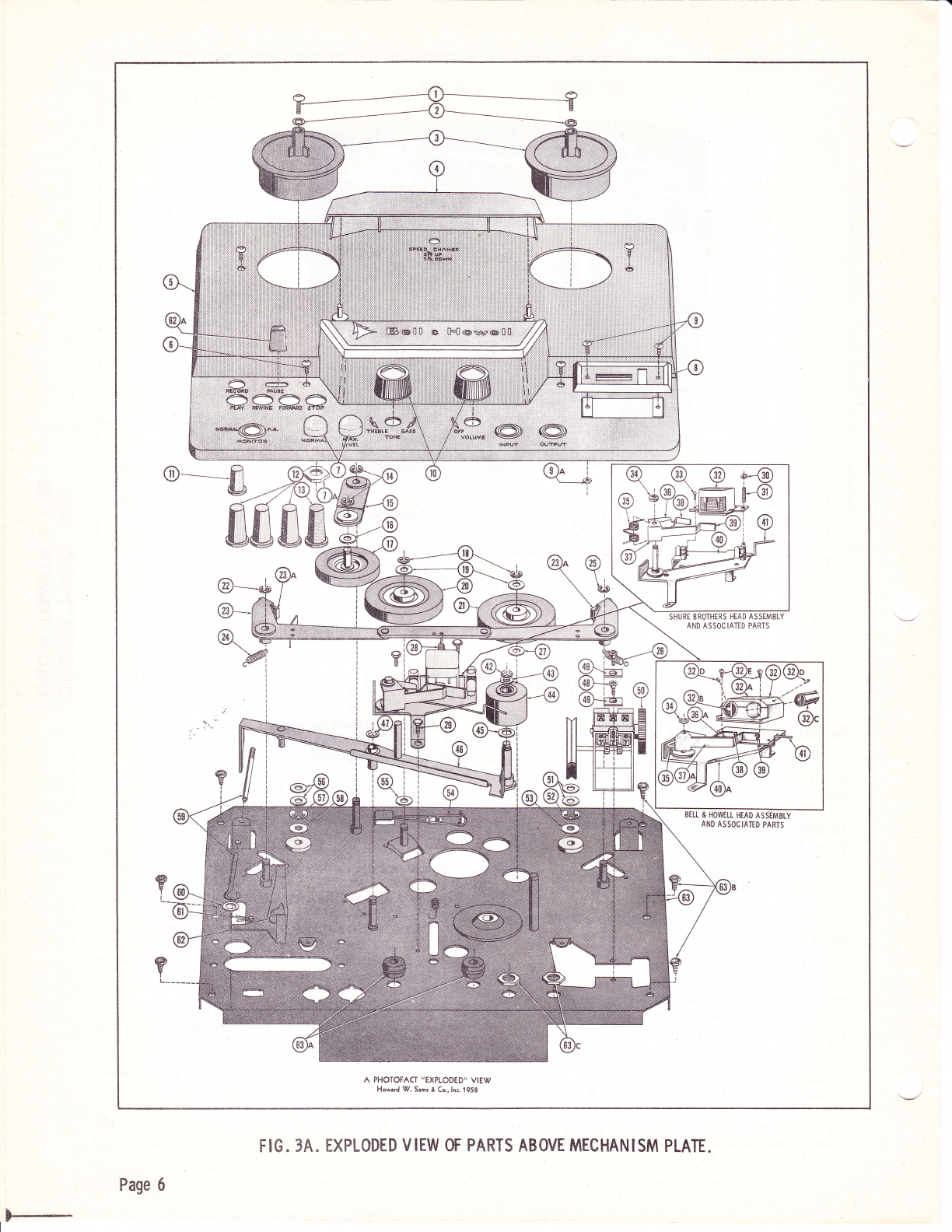

F$G. 3A" HXPLCSED VIEW OF PARTS ABOVE MECHANISM PLATE"

w

\ lil

\i=

9;

\I

\'&

Hg

dm

\F

\F

gr\ 3

oo

Ltt

oF

ta

-?l

O

l-

(3

m

n

6

Page 7

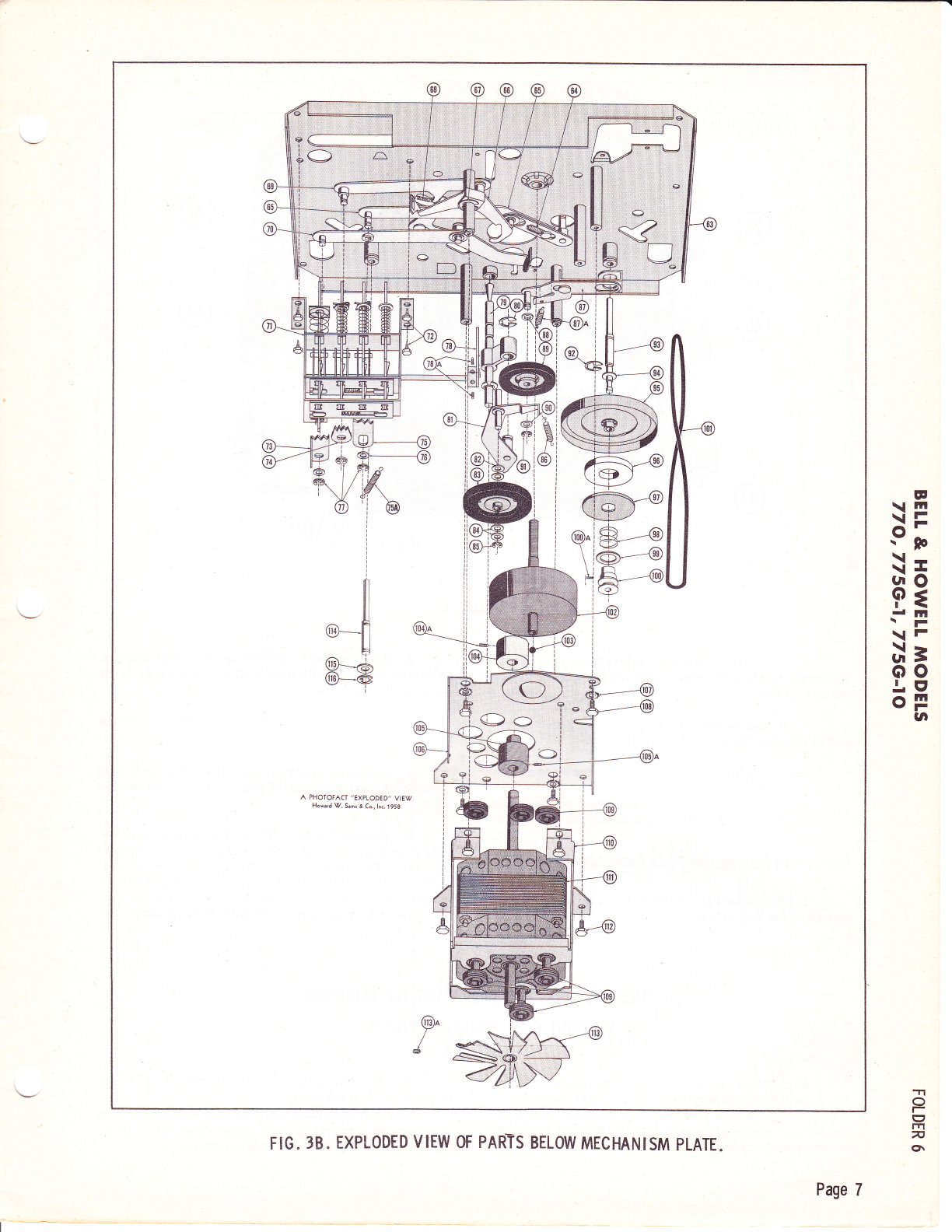

F IG. 38 " EXPI-ODED V IEW OF PARTS BELOW MECHAN ISM PLATE.

5. Remove the six 1/4" self tapping screws and

flatwashers alongthe bottomand top edgeof theprint-

ed circuit board.

6. Withdraw the amplifier assembly,usingcare

not to damage the printed circuit board.

NOTE: After reassembly adjust the slide switch

position and securethe adjustment with the 3/8"

nut so that the slide switch makes proper contacts

when changing from record to play back position.

Removal 0f Mechanism Plate Assembly

1. Disconnect the drive motor (111) Ieads by re-

moval of the solderless connectors.

INSTRUCTIONS FOR

W ITHOUT CASE

In order to operate the unit when removed from

the case it is necessary to close the interlock switch.

Use a wedge to hold the swttch in a closed position.

Be sure to restore the interlock to normal condition

before reassembling the recorder.

Page 8

FIGURE 4

OPERATING THE RECORDER

WH ILE SERV IC ING

2. Remove the input, output jack and monitor

switch locking nutswhich hold thesecomponents tothe

main mechanism piate.

3. Remove the two indicator lamp assemblies

from the main mechanism pldte.

4. Disconnect the two cables of the magnetic head

assembly from the amplifier and free these cables from

their cable clamps.

5. Remove the six 5f16" self tapping screws that

hold the main mechanism plate to each speaker mount-

ing plate. The main mechanism platecannow bewith-

drawn,and the cirive motor,clutch assembly,and push

button control switches from the linkage system may

be inspected, cleaned, and adjusted if necessary.

The speaker cones should beprotected bycovers

of cardboard on masking tape.

The unit should be operated in anuprightposition

or otherwise supported in such manner that the ventilat-

ing fan is not obstructed during operation.

INTRODUCTION

E

\m

\itr

9;

\-

\I

Hg

I ltl

\r

\F

d=

oo

.|E'

OF

la

Troubles that may be encountered are arranged

in mechanical and electrical groupings, depending upon

origin. Due tothe fact thatsomedefects inreproduced

sound are actually of mechanical origin, troubles such

as "Wow" or "Flutter" and off pitch conditions are

listed as mechanical troubles.

Wherever reference is made to the use of lubri-

cants, apply only enough lubricant to coat the moving

surfaces. AII excess lubricant should be removed.

MECHAN ICAL TROU BLE CHART

SYMPTOM POSSIBLE CAUSE REMEDY

N,cisy push button operation. Lack of lubrication. Apply Belt & Howell # Spec. 1543 oil (Hodson

Gear OiI) to neoprene pads on push button

bhafts.

Vibration ncjise emanating

from case when in fast forward

or rewind position.

Top plate assembly seated im -

properly. Remove top plate assembly (5 l.ig. 3A) and

bend the front end of top plate down slightly so

when secured in place the front edge will seat

against the tape recorder bottom case assem-

blv.

Volume or tone controls bind

and are difficult to turn. Printed circuit assembly not

centered.

Lack of lubrication or "tacky"

condition of rubber grommets.

Reposition assembly, align shafts intorubber

grommets

Check condition of rubber grommets where

tone and volume control shafts pass through

main mechanism plate. Lubricate rubber

grommets with DOW-Corning 200-350CS fluid

silicon grease.

Clicking noise when recorder

is in fast forward or rewind. Check Veeder Root counter for loose springs

or lackof lubrication. If necessary, lubricate

gear teeth with DOW- Corning 200- 350CS fluid

silicon grease.

TI

o

I

1T'l

v

o\

Damaged Veeder Root counter.

Page 9

FIGURE 6

MECHAN ICAL TROUBLE CHART (Conti nued)

SYMPTOM POSSIBLE CAUSE REMEDY

Case upper lid assembly witl

not lock properly. Alignmentof locking prongs in-

coruect. Bend the two locking prongs riveted to the

upper lid assembly approximately ten degrees

inward and to the right or left as required tcr

make proper contact with the lock catches in

the lower case assembly.

Speed change shaft binding. Lack of lubrication. Apply lubricant, BeII & Howell Spec. #1i44

(Hodson non-melting white lubricant) to speed

change shaft.

Drive erratic on both speeds. Position of drive pulley (105 Fig.

3-B) incorrect. Check position of drive pulley on drive motor.

Loosen Allen screw and position bottom of

drive pulley to distance of .218 to top of motor

shell.

Thumping or scraping noise

when in forward or rewind

position.

Position of forward and rewind

pulley (104 Fig.3-B) incorrect. If position of forward andrewind putley is too

high on its shaft, it will scrape the underside

of the top plate assembly; if position of pu.lley

is too low, the Allen screw opening in the

pulley wiII strike against the rubber molded

wheel. Readjust as necessary.

Take up reel doesn't revolve in

play or record position. Take-up idler spring (87A Fig.

3-B) off or broken.

OiI on take up idler rim (gb Fig.

6).

Clutch slipping on clutch wheel

assembly.

Replace.

Moisten cloth in alcohol and clean surface of

rubber rim.

Reposition elutch pulley (100 Fig. 6)on shaft

and tighten Allen screw.

Take up reel does not revolve

in fast forward position. OiI on rim of fast forward idler

wheel (21 Fig. ).

Fast forward Iever spring (75A

Flg. 6) off or broken.

Moisten cloth in alcohol and clean surface of

rubber ri m.

Replace.

Page I0

MECHANICAL TROUBLE CHART (CONti NUEd}

SYMPTOM POSSIBLE CAUSE REMEDY

Fast forward idler spring (64

Fic. 3-B) off or broken. Replace.

Supply reel does not revolve in

rewind position. OiI on rewind idler wheel (1? fig.

4) or rewind drive wheel (20).

Rewindidler spring (68 Fig. 3-g'1

off or broken.

Moisten clothin alcohol andclean surfaces of

rubber rims of (1?) and (20).

Replace.

Reels do not stop when stop

button is depressed. Brake actuating spring (28 Fig.

3-,A) off or broken.

Brake lining worn.

Brake lever (?8 Fig. 6)loose on

shaft.

Replace.

Replace. (See Adjustments & Tests.)

Reposition brake lever (?B) and tighten AIIen

screws,

Counter mechanism does not

operate. Defective counter

Counter belt (101

broken.

(50 Fig. 3-A).

Fig. 7) off or

Check gear teeth incounter lor damage. Re-

place if necessary,

Replace.

Wow; flutter or chirps. Improper pressure between

capstan (102 Fig. 4) and pres-

sure roller (44).

Excessive takeuP tension.

Counter (50 Fig. ?)binding.

Dirty pressure pads (38 Fig. 3A)

Pressure roller (44 Fig. 3A)

binding on shaft or damaged.

Scored flywheel shaft (102 Fig.

4) or flywheel shaft bearings.

Worn idler wheel assembly (83

Fig. 3-B).

Bent fan blades (113 Fig. 5) or

bent motor shaft.

See Adjustments & Tests.

See Adjustments & Tests.

Check for chips or dirtingears and for scored

shaft. Cleanand lubricate. UseDow-Corning

200-350CS fluid silicon grease.

Saturate with alcohol. Brush contact gurfaces

in direction of normal tape travel,

Remove roller and clean bearing with pipe

cleaner dampened with alcohol. Clean roller

stud, if scored, polishwithcrocus cloth. Apply

a light coating of Hodson 2-4?8 non-melting

grease to the stud before reassembling.

If shaft is only lightly scored, polish with

crocus cloth. WARNING: DO NOT USE

EMORY CLOTH. If bearings are scored,

drill out rivets, remove bearings and replace

them.

Some dents in the drtving surface can be

ironed out by pressing the flat side of a screw

driver blade against the tire,while the wheel

is revolving. If tire is nicked or torn, replace

the wheel assembly. Apply a light coating of

Hodson 2-4?8 non-melting grease tothe stud,

before reassembling.

Place fan (hub up) on a flat surface. The ends

of all blades shouldcontact the surface. If any

blades are out of alignment by more than

0.015", reshape those blades. If motor sha"ft

is bent, replace the motor.

E

\E

9;

\-

\I

sio

P{

.-F

\F

Or\ 3

oo

Lg

oF

UI

Pitch of sound, from pre-

recorded tape is low. Capstan drive mechanism is

slipping. Remove top panel (5 Fig.3A). Dampen a pipe

cleaner with alcohol and clean aII driving

surfaces. NOTE: All driving surfaces can

bereached thru holes inthe mechanism plate

T1

o

I

ta1

n

cn

Page ll

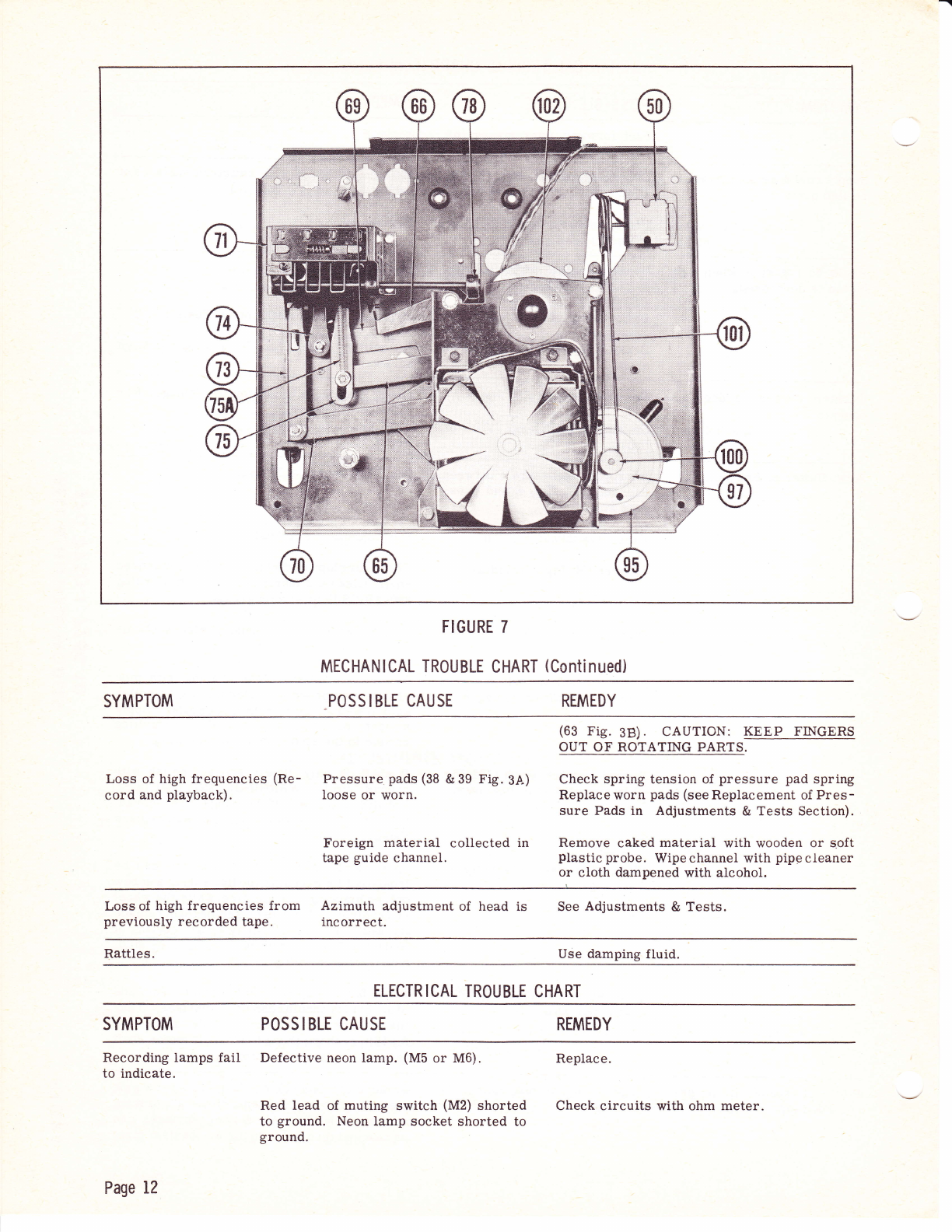

FIGURE 7

MECHANICAL TROUBLE CHART (Continued)

SYMPTOM POSS IBLE CAUSE REMEDY

(63 Fig. 38) . CAUTION: KEEP FINGERS

OUT OF ROTATING PARTS.

Loss of high frequencies (Re- Pressure pads (38 &39 Fig.3A) Check spring tension of pressure pad spring

cord and playback). Ioose or worn. Replace worn pads (see Replacement of Pres-

sure Pads in Adjustments & Tests Section).

Foreign material collected in Remove caked material with wooden or s.oft

tape guide channel. plastic probe. Wipechannel with pipecleaner

or cloth dampened with alcohol.

Lossof high frequencies from Azimuth adjustment of head is See Adjustments & Tests.

previously recorded tape. incorrect.

Rattles. Use damping fluid.

ELECTR ICAL TROUBLE CHART

SYMPTOM POS S I BLE CAU SE REMEDY

Recording lamps fail Defective neon lamp. (M5 or MG). Replace.

to indicate.

Red lead of muting switch (M2) shorted Check circuits with ohm meter.

to ground. Neon lamp socket shorted to

ground.

Page 12

EI-ICTRICAL TR0UBLE CHART (Continued)

SYMPTOM POSSIBLE CAUSE REMEDY

Cold solder connection to record-play-

back switch (M1). Reheat solder connection.

Motorboating. l2A)K7 tube defective or not fully seated

in socket. Check and replace as necessary.

Right speaker dead. Left speaker lead shorted to ground. Make visual check.

Distortion. Black Iead of speaker harness loose.

Defective 12AT? or 6CM6 tube.

Defective record level neon Iamp.

Hum control (R3) center rotating section

shorted to ground. Resistance of center

section to ground should be 2?0 ohms.

Resistor R16 (22K ohm in plate circuit

of 12AT?) open.

Make visual check.

Test and replace if necessary.

Test and replace if necessary.

Check with ohm meter.

Check with ohmmeter.

Low Output. Recording level too low.

Record current too low.

Foreign material on tape guide

or head.

Worn head pads or insufficient

pressure.

See Power Output test under Adjustments &

Tests. Check microphone.

See Adjustments & Tests.

Remove.

See "Loss of High Frequencies".

E

\ Itl

\itr

9;

\-

\I

F3

d lfl

\F

\F

d=

oo

.!. I

oF

(a

Low Output and Distortion. No bias or low bias. Oscillator coil open. Shorted

Record-Play srvitch (M-1) not

Check bias. (See Adjustments &

Remove.

erase head.

functioning.

Tests).

Foreign material on tape guide

or head.

Poor Iow frequency Defective magnetic head assembly.

response. Replace.

Low sound output. Tone control (R2) shorted togroundatthe

capacitor network C12 and C13. Check with ohmmeter.

6X4 rectifier plates

red hot. RedB leads oi power transformer shorted

to ground.

B+ filter capacitor shorted.

Check with ohmmeter.

Check sections A and B of filter capacitor C1

and replace if necessary.

Hum. Open hum adjusting control (R3).

Printed circuit wiring from output trans -

former frame to filter capacitor open.

Cold solder connection of capacitor C4,

.1 mfd (in input circuit) .

Cold solder connection of output trans-

former frame.

Cold solder connection of rectifier tube

retaining spring where attached to power

transformer shell.

Replace.

Check with ohmmeter.

Reheat the solder connections.

Reheat the solder connection.

Reheat the solder connection. O

E2

la1

n

o\

Page 13

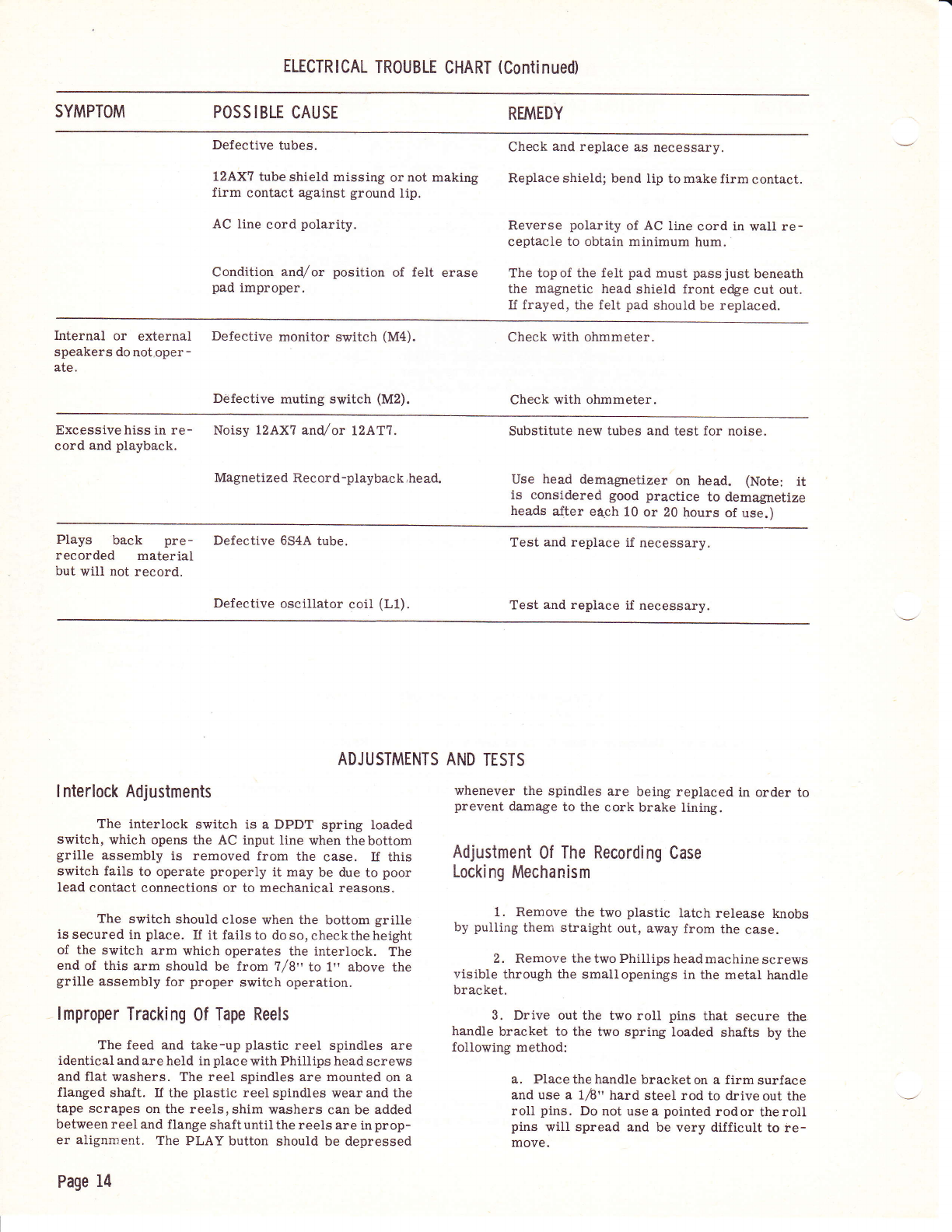

ELECTRICAL TROUBLE CHART (Continued}

SYMPTOM POSSIBLE CAUSE REMEDY

Defective tubes.

lzA)K'l tube shield missing or not making

firm contact against ground lip.

AC line cord polarity.

Condition and,/or position of felt erase

pad improper.

Check and replace as necessary.

Replace shield; bend Iip to make firm contact.

Reverse polarity of AC line cord in wall re-

ceptacle to obtain minimum hum.

The top of the felt pad must pass just beneath

the magnetic head shield front edge cut out.

If frayed, the felt pad should be replaced.

Internal or external

speakers do not.oper -

ate.

Defective monitor switch (M4).

D6fective muting switch (M2).

Check with ohmmeter.

Check with ohmmeter.

Excessive hiss in re-

cord and playback. Noisy 12AX? and,/or l2ATl .

Magnetized Rec or d -playback,head.

Substitute new tubes and test for noise.

Use head demagnetizer on head. (Note: it

is considered good practice to demagnetize

heads after e4ch 10 or 20 hours of use.)

Plays back pre-

recorded material

but will not record.

Defective 654.A tube.

Defective oscillator coil (L1).

Test and replace if necessary.

Test and replace if necessary.

ADJUSTMENTS

lnterlock Adjustments

The interlock switch is a DPDT spring loaded

switch, which opens the AC input line when thebottom

grille assembly is removed from the case. If this

switch fails to operate properly it may be due to poor

lead contact connections or to mechanical reasons.

The switch should close when the bottom grille

issecured in place. If it failsto doso,checktheheight

of the switch arm which operates the interlock, The

end of this arm should be from 7/8,'to 1" above the

grille assembly for proper srritch operation.

lmproper Tracking 0f Tape Reels

The feed and take-up plastic reel spindles are

identical and are held in place with PhiUips head screws

and flat washers. The reel spindles are mounted on a

flanged shaft. If the plastic reel spindles wear and the

tape scrapes on the reels, shim washers can be added

between reel and flange shaft until the reels are in prop-

er alignment. The PLAY button should be depressed

Page 14

AND TESTS

whenever the spindles are being replaced in order to

prevent damage to the cork brake lining.

Adjustment 0f The Recording Gase

Locking Mechanism

1. Remove the two plastic latch release knobs

by pulling them straight out, away from the case.

2. Remove the two Phillips head machine screws

visible through the smallopenings in the metal handle

bracket.

3. Drive out the two roII pins that secure the

handle bracket to the two spring loaded shafts by the

following method:

a. Place the handle bracket on a lirm surface

and use a 178" hard steel rod to drive out the

roll pins. Do not usea pointed rodor theroll

pins will spread and be very difficult to re-

move.

b. Remove the cover from the locking mec-

hanismr and inspect the linkage for freedom

of movement. If lubrication is required use

Bell & HoweII Spec. #1544 (Hodson Non-

Melting White Lubricant).

Replacement 0f Brake Linings

If damage or vt/ear makes it necessary to replace

t}te brake liningg scrape the old Iining from the metal

surface. Apply Ambroid liquid cement (Mfd. by Am-

broid Company, Boston, Mass.) to the metal surfaces

and set the new cork linings in place.

Replacement 0f Pressure Pads

Worn pressure pads may cause loss of volume

and a falling off of higher frequencies. The two pres-

sure pads are identical. To replace, serape off the oid

pads and affix the new pads with Ambroid liquid cement.

Pressure Roller Against Capstan

Connect an inch-ounce scale to end of presbure

arm assembly (46 Fig. 4). PulI the pressure roller

free from thecapstan. If reading is less than 16 in.-o2.,

bend the spring (41) in order to increase pressure.

Take Up Tension Adjustment

Place an empty ?" reel on the take up spindle.

Attach a short loop of string to the outside reel edge.

Connect a gram scale, Chatillon horizontal type (with

a minimum reading of 60 grams) to the string. HoId

the scale parallel to the recorder and at right angles

to the take up spindle. Depress the "play" button and

note the reading. If the reading is over or below the

tolerance listed herein, remove the mechanism from

the case assembly as described under "Disassembly

Instructions".

Next remove the back mechanism plate secured

in place by the six Phillips head sheet metal screws.

Disengage the counter drive belt from the clutch pulley

(100 fig. 5B). Remove the pulley secured by a8/36

x 3/t6" set screw. The tension spring (98 Fig.38) and

felt lining (96 Fig. 38) can now be slipped off the take

up spindle (93 Fig.3B). If the reading was over 60

grams, the felt should be saturated in a solution com-

posed of one part Standard Oil Company (New Jersey)

turbine oil #31 and 15 parts carbon tetrachloride.

After saturation allow the felt to dry for 30 minutes

before reassembly of the clutch. If the reading was

Iess than 30 grams, replace the tension spring and,/ar

felt as required.

After reassembly engage the counter drive belt

properly in order that the counter "counts" up when

the "play" or "forward" button is depressed.

Recheck the tape recorder for proper operation

after service has been completed.

Azimuth Adjustments

Thread recorder with azimuth test tape of 1.0

mil. wavelength. (Available from Toogood Recording

Company., 221 N. LaSalIe Street, Chicago, Ill.) Turn

volume control to "ON". While recorder is warming

up, connect an AC voltmeter (0-b volt range) to a

standard phone plug and drop the plug into the "Output"

jack. (Do not insert plug all the way into the jack, or

the speakers will be disconnected).

Place the speed change shaft (79 Fig. 4) in the

7 l/2 I.P.S. position and proceed as follows:

Shure Head

Start recorder (Play) and adjust volume control

to produce a voltmeter reading of approx. 1 volt. Ro-

tate azimuth adjusting screw (33 FiS.3A) and observe

meter reading. Adjust for maximum output.

Bell & Howell Head

Loosen head locking setscrew (32D Fig. 3A).

Grasp the fin at the rear of the head with long-nose

pliers br tweezers and rotate the head to obtain maxi-

mum output. Hold head in position, while tighting the

locking setscrew.

Power Output

Make .a test recording of a 400 cycle or 1000

cycle tone at the level where the "Distort" lamp flickers

very faintly on the Model ??5 or where the "Record"

lamp flashes strongly on the Model ??0. Connect an

AC voltmeter, oscilloscope and 6 ohm 5 watt resistor

across a standard phone plug and insert plug into the

"Output" jack. Depress "Play" button, adjust volume

control and observe distortion, note output. Output

voltage should be at least 3.5 volts (5% harmonic dis-

tortion Ievel).

Signal To Noise Ratio

Make a test recording of a 1000 cycle tone at

7 l/2 lrP.S., set oscillator level low enough so that

"Volume" control knob can be turned to atleast 3/4

open position. Disconnect oscillator and rewind ab6ut

12 of recorded tape (donot touchvolumecontrol). Re-

record over last l/2 of tapewithoutany signal. Rewind

all of tape. Connect 6 ohm 5 watt resistor andVTVM

across a phone plug and insert plug in "Output" jack.

Depress "PIay" button and adjust volume control to

produce an output of 1 volt. When re-recorded (erased)

section of tape reaches head, output should drop at

least 36 DB.

Erase And Record Currents

Shure Head

Insert a 10 ohm non-inductive resistor in series

with the ground return lead (black or orange) from the

record-play head. Connect a V.T.V.M. across the re-

sistor. Depress the "Record" button. Set the volume

control at its lowest level and read the bias current.

Bias current should produc e a voltage reading of 0.01 1 -

0.016 volts.

Remove 654A tube, connect an audio oscillator

(set at 1000 C.P.S.) to the input of the recorder and

adjustoscillator input sothat "Distort" lamp will flash

when volume control is 3/4 open.

IE

\lrll

\=

9;

\-

\I

$3

dln

\F

\F

il=

oo

.!. El

oF

vl

-1

o

|-

U

7

o\

Page 15

(o

I

o

o

\r

l4l t!

>g >H

Pe 33

(\ (/) F.(/l

IJ

(J

E

o

tt

>'

o

\o.

(\T

!z

o

o-

F

=

o

@@

\Z

C\I

c!

@

(tt

F

z.

l4J

=

J

E

o

,/*

@

@

+!Jr F'

co -E

@'=

\Z

c

C\f

(\!

o@

@FT

Lix

E\O

@

-N

=k

r! 6{

<F ao

@

-t

lrJ

a

o

=

z. >.

o=

oo

lrl -

(,=

JN

*a

X,I

=2.

o

O

J

E

lrj

rJ\

I

l4l

z

o@

'@5s

iir''

@

^N

=t

*S

e

)>

=6

;E

L) e4

!o

=o-

a>

qd

t3z

uJ-

EZ

l=

5F

a- (/l

\.,

F

:

tal

I

v

z. att

o

:. Zo

-a oB

3 6 k!

!

'<, sF h I

dff(e 23

z=:-,-.d

=7.2? ; E

v;-F *a

sx=E 2;

2 *&,2. { 'o

LL

ze . a

r!>ci6 qt r

EgHu ,-*

d:F==

= =.n.tt

t/)o<< .i

Ea== P

i4, I

<=+l;l

tt,

(9

z.

o

lrl,

G,

r4J

(J

z.

F

V,

a

lrj

&,

b

9";J

E .39- .,q

O no c-o :i

E PTEEE

r -id.!R

.=

5 = 9 E €= ; E

su.EsSq.E-e

-c s= c- J o=

E E:3*E F i

=€ !e;E; R

E= E H= E F g

€I !EE s9s

E g r H.EE i:E

p rE€ =El;

FsE€g:;E

EEg A =.=E E

3?,Hg.5E E=

-j c.; ,ti s .i .o

ul

z

&

trl

\6

E,F

o<

tr. (J

.J

EI

J<

oc,

Eo

fg

ui

6>

o

\Z

c

t\

st

N-

@

@

@tF

V,

c

LN

cis

-r--Jl,'

I

I

I

@

T--

I

I

I

=l

HS

T

@tE

c.l E

BB,.

d CJN

o5F

<=

(9:c b-

zc) o

-5 I

3i !r,

E l--^rff-l1, e

o{ @ '' ,------.,

s =a

-:.5 \9

-tf.]5, *

ARE

lgl--{f

\c@

R

x@5 l: It'

-.1

p=l

=3t

6l

-F9{

z.z I

ool

f-

!Z

(-)

o:r

*E

z=^

FI

z.i

rd!

=!

(9!

UI

vtl

-t

c|l

FI

=!

Wri

oAl I

it

N

(J

l!

O

z.

o

F

O

z.

D

-

o

F

o\

cc

o

oo

o

c

o

oc

o

a

I

o- o

o

!n

c

o

o

n(J

zc)

z.

C

;Y,

o

F\

v.

olZ

6 <\l

NN r

c

o

F-

GI c)

z.

z.

=

\Z

o

N

o-

\z

o

€\Z

o\z

ct

-t !z

( T

GI c

a

(\J

o

oo

oc

ac

o

o(J

z.

o

o

fn o

oo

o

(Y\

G

o

oc

o

o

(Yl

o

c

o

oY,

o

t\ v

GI

Rl c

(f

o

gr

t\

ir c

o()

zc

o

oo

\o (J

z.

\Z

o

6

*v

oc

o

o

o

+(-)

zc

C:'

n

t&

cr

tr

t\

x

(\I

t\

F

(\r \o

=

c)

\o rq

a,fl

\o

F

(9

-l

x

\o

=

lrl

Fir rn

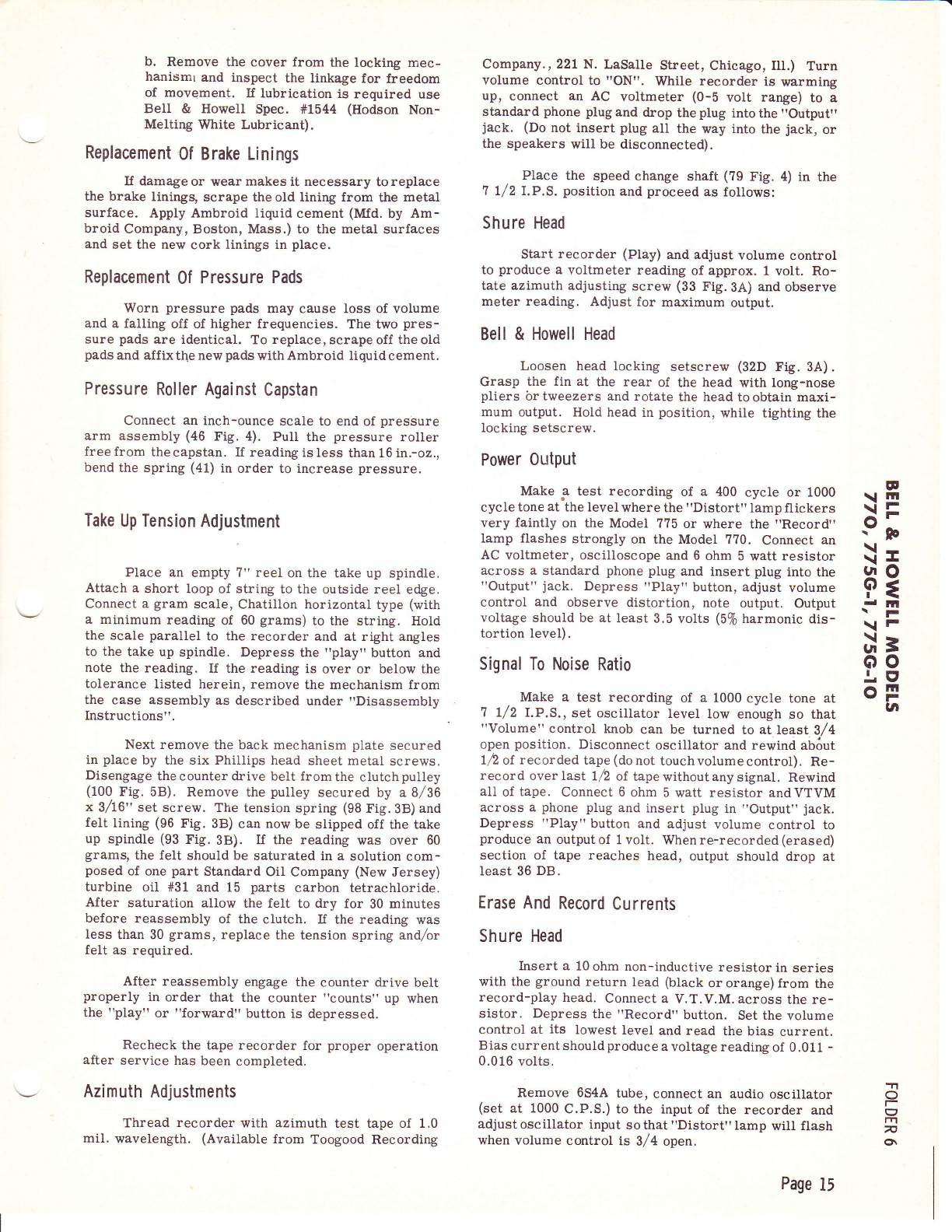

SCHEMATIC OF 77A, 775G-1 AND 775G-IO AMPLIFIERS.

Page t6

=

EI

I

o

o

l-

I

ra

I

rn

tn

I

I

(,

v,

J

o

&

F

z

o

U

g

AFg

=5rh

Ft-!

rh{hh

+) li CL

hF-

geE

EEE

E!q5

(JYo.

E Ad R

F a'* I

ut q 9n

E Et.=

- t.

5 ts d>

FR >.9 B

o o-co

o€d

H .$ eu

E 3 rar'= E

E i-.v> g

Ozrsl!iO

l- =oc?ua

s\ e .T^r

or^ o(d)ar

(,)= (a; (n

:.i:E: F

FsFEF;

€E-€-d h

FF.dg

Eqeot>

gE= B= I

+s+ B+ H

lo trro.!lo c

l- .d t- lrJ t- d

F-€r Hr-rC

sS!;.eH

o5q)(l)(D5

E:E FEx

> u : E>2,

oo@o@o

o

O. t;

x!

Lf,

oo

bA E

;o

;(J

V,E.:

C,.E E

esE

E Y

f\J

rc

(J ET

<r;

t3g

e€E

OL

ALO

il:I

X;E

lJ- c E

.! .s

5)j

,atr

go\

o:'

>.=

tJ

'uo

oo.

o.o

o9

L)

vt

c,

o

=

I

G

(J

(J

-

F

J

o

c,

F

u

IJJ

J

ItJ

tn

Z2

o=

r-

E;

r\_

4 -v,

(J.,'

ni

AU

ot

Zs

hz

=9

tllvt

blrt

uq

4

.n

o

F

E'

lrt

v

o

ts

q)

b0

o

cd

cl

(.)

I

o'

z

i

v)

tll

o

z

z

o

J

.n

z

E

a

o

F

o

F{

Fa

F

.;

op

g

i Hg

o oa

o

z

tll

=

ur

()

J

A

tlt

e,

Et

==

o

,Z

EF

g

<ct

a/tt L

Or-

E. d,

do-

ao

<ct

<z

g.F

a- d.

z<

u.l o-

(J

o)

Fci

O-

L

€iv

-r<

EA

n

Eor

:i tt{

K9

oo

FF

@

o

o

6l

o

t-

lt/)

IF

IF

t<

gl3

k l*-

c, l.ng

tvr.L

l--{

ilN -.

v3tse

odoo

o tsoo

lr?raloN

Fi Jtr*-

tr dd

R- R

6lca 6t

rv zz z

S SSSoo$SoSoSS

c0 @ 6D O {r,< c\ O E- <{ CO ot CO @ \i @ c\l O) .(l| O 6a

o) o o) cD o o) o) o) or o) o) co co o) o) o) o 6) o! o) o)

t- € t- t- F t- t- E- t- c0 t- t- t- t- F I- @ F t- t- t-

dr-addHdtlFlFt Fad- -id

ooooooooooooooooooooo

t- E- I-, r- t- r- t- t- t- r- F t- r- t- E- t- F r- F F r-

o

z

UI

=

u,l

Ez

:3

o

ca

:F+RqRqnqs$ $q Hnqsq

gHHgH*Hg6RH HH #gHgH

t- t5 '<

n +, i Kor c\ 6l

Ea q EEE E q H

OC) O UF]O O O O

<A p <o<

6l

ctN

Fa

o:r

Htqagf?aana as

*BHEHHHHHEH HH

T?qT H BqF?

eAOCItoAOAO

aanoaooao

a- .. 3 qe$ $^ HF* a

z? ? I *,2*, *,? 95? q

Ra I I SH$ FR asa R

Am Fq O o{AA AQ E:A ca

5e

>.-

9E

ur{

<o-

l^oo

I :<aOOOcrF- 61 crlQ -t-R

lO ;<=OOO=r{iaNO c\IOOO)<OXX

i5 :E XRs 5 E???F3?R5R ERX=

F

o

:

A.

s

o:r $,., co F oo o, I = E 3 g I I = 99 R R S R

Oc)OOOC)UOOOOOOOO(JOOOUO

o

z

llj

=

llJ

U

o-

Iu

e,

Hct

oL

SE

o.<

art G

**

$cD

co co

(9 c0

6lN

trE

3:

9p

3f

oci

2z

{r-

r, &,

rs

a_d

oz

*=

-ls ci

frggz

4ia

8ds

5e

>.-

9E

ur{

<a-

o

tct

,ra Z-

caE

Ef

nO-

o@

@c0 -

oo

l- C-

0

z

F

ooo oo

l()rt!lt?oolJ"

r$ 6'A N Cra 6a C\

4o-

U^o oo^

H6o<,<rH

-{ l.$ a r-{

{.r

UJ:

l-z SEU*no

OU

o

LU

o

z

UJ

o- t-t

#E

llJ

./,

f9k

oq)

O;i

n6

.i c)

nfi

a-e sf ro

3n

lrJ

o

z

UJ

G

F{iF

ssx

ur

v,

:) rb;

EEg

'ci 9'.A

F€;

o_ 6

klt{ 5

Fi d61 6a

PAGE 17

F

o

o

=

e

=

at

f

o

!.rJ

z

J

lrJ

g

E

-

c

IE

5

b

E

I

c6

o

I

(^ -.

e.a

f:

Ft

ru9

Z-o

E:

<^o

9: o

05f

o3

i! '6

zfr

d.5

<€

(Jeo

c

o

T

o

E

o

€

=

^

-o

o

3

tr

-

c

o

(J

Y

la

z

o

-

l-

4

I

c,

L'

la

IlI

o

o

z

F

ln

-

J

I,|

F

4

4

t!I

e,

vt

6

I

f

L

f

o

o

6

D

s

c,

trl

=

c,

o

vt

z

4

e,

tll

=

o

a

5S e,

6= lJ

*i =

EE d,

d6*9 o

c -o: r

:EEe (n

8EX* z

?€.t E

Hgle C.

.e;3: F

E.F F F

ngv==

.io.dd

s P F:.-.

r!!lx

s F ESB

;4+sg

i:>=5

!o

t

tr

a-

IE

o

L'

la

z

o

-

l-

*p

49

96

la6

PH

trl

a

z

F

ln

-

J

I,l

F

4

4

z

o

6TF F

c* 6 6

H 6! !

f @: ! o

;p> z F

i:.

: "---8 s: S

;9- p d ,

-i o x o e^

' dZ t5€F

^d_

I4 Y X - > > >D 6

e y 3 a 6 qi, -6 -d - !

i3af;i;€isi:

o

z

t6o6oo

;oN+$

:

z)

c. "a q q

666;!=iAiZZ

cCcra t 5dd6 d

KVIAOTqAOUEE

o

z

at

F

o

F

d

=",".4 -

a E a-l

iaFtr 6F d

H >q!* I

g!.qzg 5

i€."iS !

, *.Y

6 -i:J E

b .gi F;; a

O::H UqH

d>t6>22

B2

=o

6

z

EE

pl

>>!E

E, >>E> >E

o

z

s

fiz

d

EZ

9E

€d

6Z

et

=d

la

:

,q

fr: J

o

ziR

aq

jo

F

o

F

z

{

)

od

TE

o< )

gz

6<

)

-z )

d

:t d

Ee

;<

i4

;1,

E

24

z

o

{

o

z

F

o

o@

Ed

3z

i4

a:RgSHSegREgResR

666o-H

roooooooooodddd

o

zFv^ v - $C

4ENo6^dvY6V O9u9

;s"i5FERsR35EEEil

5:

P;. o:NoscoF

{NNNNNNNNN6d--

EE&E&EddCdddcd

o

F

z

:

UE

€

6

OF

;<

o

z

o@@

=

I

tz

54

rq BE$g$ESEHSEgEE$

FFFFFFFFFFFFFFF

zI

giHHHgEgExFHxE:

So

FZ ncEi(EEA,EE,AEAAA?

PAGE 18

Adjust volume control so that "Normal" lamp

flashes, voltage across resistor should be 0.00033 -

0.0004? volts. Advance volume control until "Distort"

lampflashes; voltage should be 0.00065 - 0.00095 volts.

NOTE: If V.T.V.M. wiII notindicate these lowvoltageg

connect an oscilloscope in place 6f the meter and adjust

Vertical gain of scope to produce a patternof suitable

amplitude; transfer scope leads to the low (10 ohm)

section of a 1000/1 voltage divider, bridge complete

divider with V.T.V.M. and oscillator. Adjustoutput of

oscillator to produce the same scope deflection -

voltage produced by record current rvill be approx.

1/1000 of meter reading.

Replace 654,{ tube in socket and insert a 1 ohm

non-inductive resistor in series with the ground return

(blue or black) lead from the erase head. Bridge re-

sistor with a V.T.V.M. Depress "Record" button and

measure the erase current. Current should produce a

voltage of 0.04 volts minimum.

Bell & Howell Head

Use the same procedures as for Shure heads

except insert 100 ohm non-inductive resistor in place

of 10 ohm resistor. Bias current will produce a volt-

age of 0.013 - 0.018 volts. "Normal"Iamp will flashat

0.0025 - 0.0035 volts. "Distort" Iamp will flash at

0.0052 - 0.0068 volts. "Record Level" lamp on Model

?70 will flash at 0.0036 - 0.005 volts.

Erase current will produce a voltage of 0.0042

volts across a 1 ohm resistor.

PARTS LIST

The following pages list, by part number and name, parts of the

Tape Recorders covered in this manual. To help make positive identi-

ficationof parts when ordering replacements, order by part number and

model number and give serial number of Recorder.

The "Usable On Code" eolumn refers to the model or models in

which each part is used. Wherever "ALL" appears in this column, that

particular part is used in all three models covered by this manual.

Otherwise, the code is as follows:

??5-G-1 Shure Head Model - Code A

??5-G-10 Bell & Howell Head Model - Code B

110 Bell & Howell Head Model - Code C

E

\rll

\itr

9;

\-

\I

Fg

I lfl

\F

\F

gr\ 3

oo

I9

oF

UI

-1

O

t-

I

rrl

n

o\

MECHANICAL PARTS LIST

Usable

on

Code.

?00245

700? 16

800423

800?95

0?6343

076344

70Q245

8005?4

?004?7

800573

700245

?00550

?01508

800440

800439

Screw, 4 - 40 x 1,/4 Truss Head Phillips

Washer, .116 x .281 x .020

Spindle, ReeI

Cover Ass'y., Removable

Top Plate Assembly

Top Plate Assembly

Screw, 4 - 40 x 1,/4 Truss Hd. (Attaching Parts)

Cap, Neon Plastic

Nut, Hex., 9/16 - 2? (Attaching Part)

Escutcheon, Counter

Screw, 4 - 40 x 1/4 Truss Hd. (Attaching Parts)

Nut, Tinnerman (Attach. Parts)

Knob, Tone & Volume

Button, Record

Button, Push

5A-1

,, -2

tr -3

,, -4

tt -5

rt -5

tt -6

,, .-7

tt -?A

rt -8

tt -9

" -gA

" -10

" -11

,, -L2

ALL

ALL

ALL

ALL

AB

c

ALL

ALL

ALL

AB

AB

AB

ALL

ALL

ALL

Page 19

MECHANICAL PARTS LIST (Cont.)

Fig. &

Index

No.

Part

No. Description

Usable

on

Code.

5A-13

" -14

il -15

" -16

" -17

" -18

" -19

" -20

" -21

,, -22

" -23

'r -23

" -23.A

,, -24

" -25

,, -26

,, -21

" -28

" -29

" -30

" -31

" -32

" -32

" -32A

" -328

" -32C

" r32D

" -32E

" -33

" -34

" -35

" -36

" -36A

rt -3?

" -3?A

" -38

" -39

" -40

" -40A

,t -4L

,, -42

" -43

,, -44

r' -45

r' -46

" -46

,, -41

5A-48

r -49

" -50

" -51

,, -52

" -53

" -54

" -55

" -56

" -57

" -58

" -59

" -60

" -61

r -62

" -62A

800441

700890

0?6191

700?9?

0?6183

?00890

?0079?

0?6180

0?6239

?00890

0?6190

076402

8004?8

800536

?00890

800536

?00?9?

8005?2

700343

?0089?

800546

0?619s

0?641 5

800645

0761?8

0?6179

700440

?00188

?00183

?00890

800023

0162L2

076273

076232

076214

800564

800564

0?6 194

016272

8004?6

?00890

?00806

800? 14

?0080?

076185

0?6326

?00890

?00088

800599

0?6261

700797

700889

?00?98

80058?

?00?9?

?00?97

?00889

700?98

80060?

?00?9?

?00553

800560

0?6265

Button, Stbp

"E" Rin6i, Retaining .18?

Rewind Idler Arm Assembly

Washer, .191 x ?/16 Fibre

Idler, Second Rewind

"Et'Ring, .18?

Washer, .191 x ?/16 Fibre

Idler Wheel, Rewind Drive

Idler Wheel, Fast Forward

"E" Ring, .18?

Brake Assembly

Brake Assembly

Brake Lining

Spring, Rrake

ttE" Ring, .18?

Spring, Brake

Washer, .191 x ?/16 Fibre

Spring, Brake Actuating

Screw, #6 x l/4 Hex. Hd. Sht. Metal

"E" Ring, .43? Shaft

Spring, Azimuth

Azimuth Plate (Record & Erase Head)

Erase & Record Head Assembly (Bell & Howell)

Base Housing

Erase Head Assembly (Bell & HoweII)

Record Head Assembly (8ell & Howell)

Set Screw (Attaching Part)

Screw, 6 - 32 x l/4 Fil, Hd. Phil. Mach. (Attaching Part)

Screw, 4 - 40 x g/g rit. Hd. Phil. Mach.

t'Et'Ring, ,18?

Spring, Torsion

Arm & Pad Assembly, Erase

Arm & Pad Assembly, Erase

Alm & Pad Assembly, Recotd & Play

Arm & Pad Assembly, Record & Play

Pad, Pressure

Pad, Pressure

Head Mtg. Bracket Assembly

Head Mtg. Bracket Assembly

Spring, Pressure RoIIer

"Et'Ring, .18?

Washer, Nylon, .191 x .3?5 x .015

Pressure Roller

Washer, Nylon, .25? x .437 x .015

Pressure Roller Lever Assembly

Pressure RoIIer Lever Assembly

"E" Ring, .187

Screw, FIat Hd. ,4 - 40 x l/4

Clips, Counter Mounting

Counter Assembly

Washer, .191 x 7/16 Fibre

"E" Ring. .250

Washer, .265 x t/2 x .030 Fibre

Spring, Speed Change Shaft

Washer, .191 x ?/16 Fibre

Washer, .191 x ?/16 Fibre

"E" Ring, .250

Washer, .265 x I/2 x .030 Fibre

Link, Remote Control

Washer, .191 x ?/16 Fibre

Pin, Cotter L/16 x 3/8

Lever, Pause

Knob, Pause

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

AB

c

ALL

ALL

ALL

ALL

ALL

ALL

ALL

A

A

A

BC

BC

BC

BC

BC

BC

A

ALL

ALL

A

BC

A

BC

ALL

ALL

A

BC

ALL

ALL

ALL

ALL

ALL

AB

c

ALL

AB

AB

AB

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

AB

AB

AB

AB

AB

Page 20

This manual suits for next models

2

Popular Measuring Instrument manuals by other brands

Rohde & Schwarz

Rohde & Schwarz FSB operating manual

Siemens

Siemens Sitrans F Series operating instructions

Parker

Parker ServiceJunior SCJN Series Operation manual

MKS

MKS Granville-Phillips Mini-Convectron 275... quick start guide

PCB Piezotronics

PCB Piezotronics IMI SENSORS 607A12 Installation and operating manual

Levitronix

Levitronix PuraLev i30SU user manual

Minebea Intec

Minebea Intec Weight indicator Puro operating instructions

AEMC

AEMC CA7027 user manual

Veolia

Veolia Sievers TOC-R3 installation guide

JensPrima

JensPrima innoCon 6800D operating instructions

socomec

socomec COUNTIS ECi2 operating instructions

Brooks Instrument

Brooks Instrument VersaTorr BVT125 Installation & operation manual