Belshaw Brothers 618L User manual

Item Number / Serial Number are listed on a data tag attached to the equipment.

This manual should only be used with the Item Number(s) shown above.

SUPPORT

The #1 Source for Donut and Bakery Equipment www.belshaw.com

USA/Canada 1-800-578-2547

International (+1) 206-322-5474

Email service@belshaw.com

Web www.belshaw.com

SERIAL NUMBER

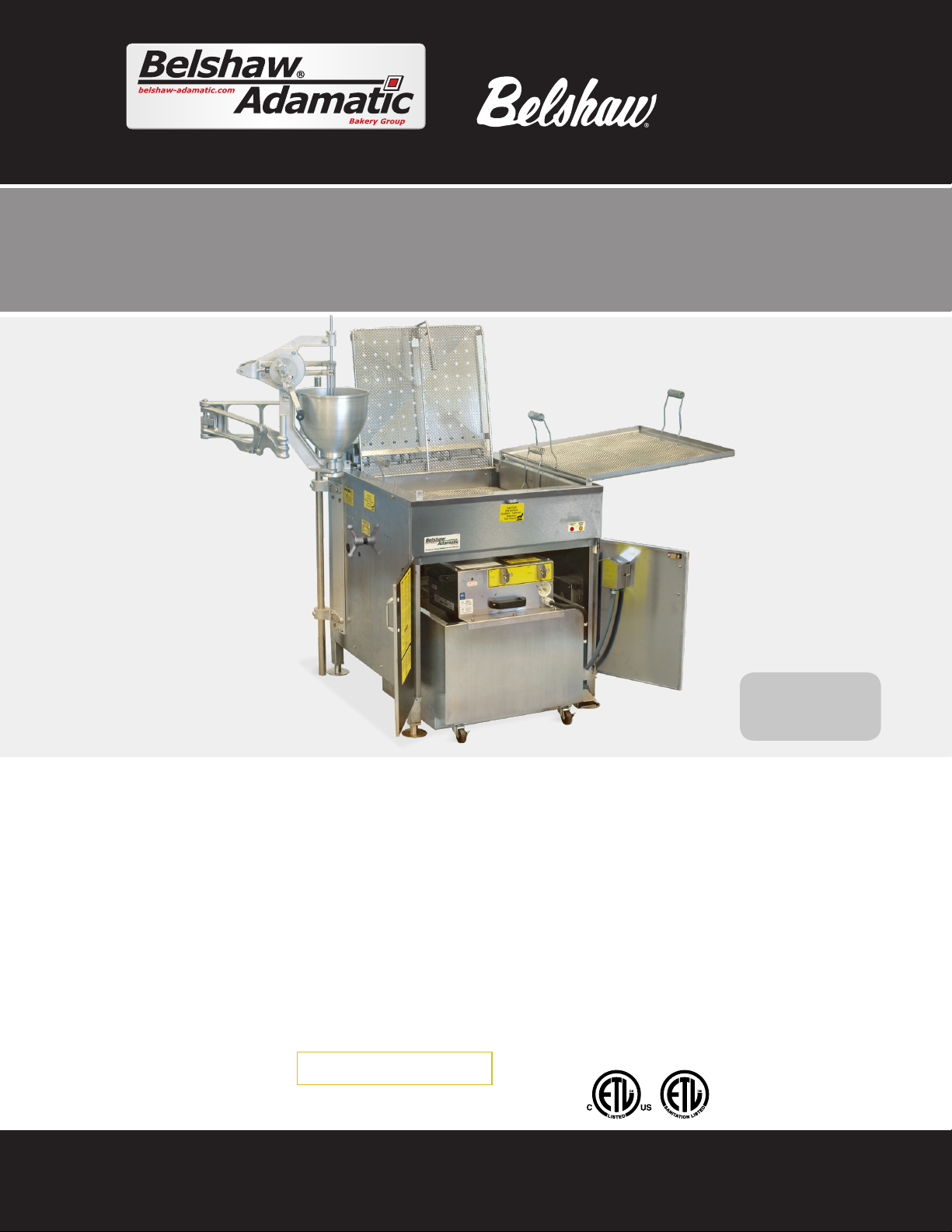

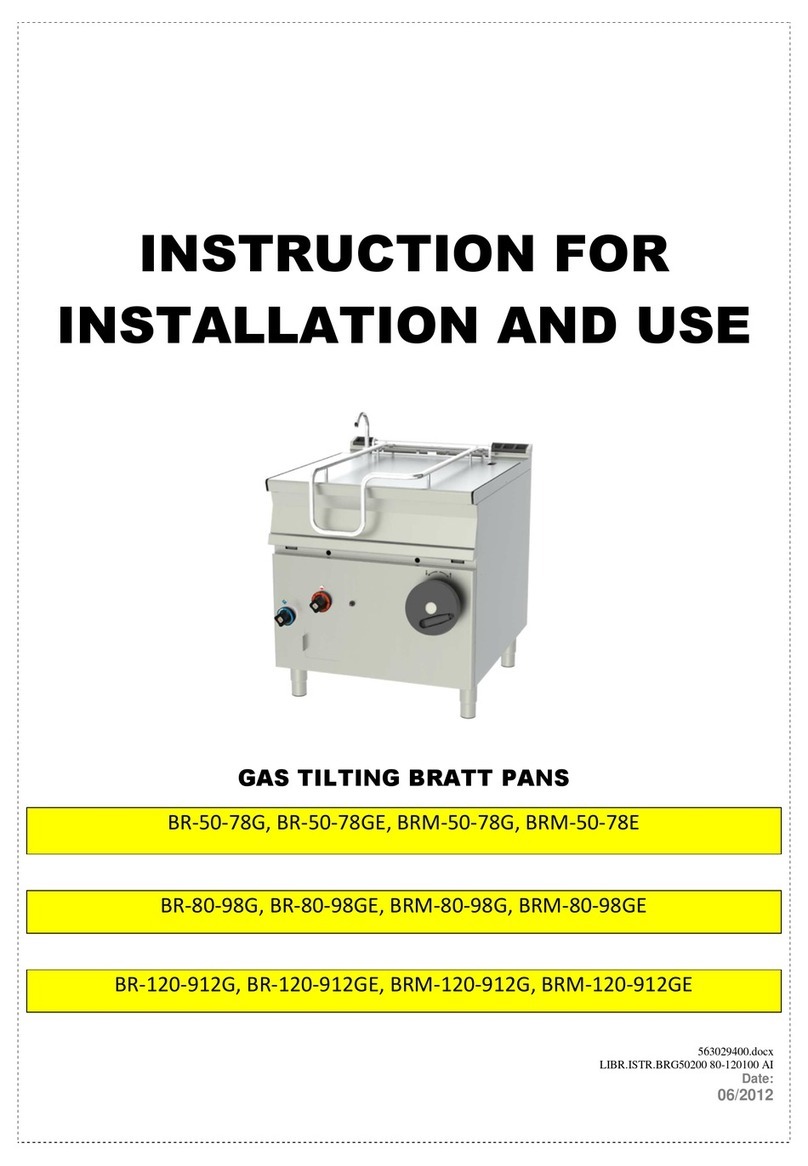

618L • 624

Donut Fryer • Electric

Belshaw 624 Fryer

with Type B Depositor,

Submerger and EZMelt

Melter-Filter.

ITEM NUMBERS

21254-10 618L, 18” x 26”, 208-240V/50-60Hz/1-Phase

21257-10 624, 24” x 24”, 208-240V/50-60Hz/1-Phase

21256-10 618L, 18” x 26”, 208-240V/50-60Hz/3-Phase

21259-10 624, 24” x 24”, 208-240V/50-60Hz/3-Phase

OPERATOR'S MANUAL

TECHNICAL SUPPLEMENT

PARTS AND ELECTRICAL DIAGRAMS

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

2 MN-0019EN Operator’s Manual 618L, 624, and 634 Fryers

EQUIPMENT RECORD

Please provide the information below when you correspond with Belshaw about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ____________________________________________________________________

Serial number

IN CASE OF DAMAGE TO EQUIPMENT

In case of damage to the equipment upon delivery, follow these steps immediately.

1. Inform the freight carrier. The phone number will be on the shipping receipt or label.

2. Take photographs of the equipment, both inside and outside the box or crate.

3. Do not throw away any packaging.

4. Report the damage to the distributor (or other party) from whom you bought the equipment.

5. Email your photos to the distributor (or other party) AND to Belshaw Customer Service at

service@belshaw.com. Include a Belshaw Order Number in your communications. Your Order

Number will begin with “CO…, followed by 6 digits) and should be marked on the box or crate.

IN CASE OF MISSING ITEMS

1. If possible, note the missing items on the delivery receipt of the freight carrier.

2. Take photographs of the entire shipment.

3. Follow steps 2 – 5 above.

MN-0019EN 031819

Belshaw Adamatic Bakery Group

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Email: service@belshaw.com • http://www.belshaw.com

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L, 624, and 634 Fryers Operator’s Manual MN-0019EN 3

Contents

Sections

1 Operation 5

2 Cleaning 7

Cleaning the Exterior Surfaces 7

Cleaning the Frying Screen 7

Cleaning the Kettle 7

Removing the Shortening 7

Washing 8

Rinsing 9

Drying 9

3 Donut-Making Helps 10

Tips on Making Quality Cake Donuts 10

Calculating Correct Water Temperature 11

Ratios of Plunger Sizes to Donut Weights 11

Temperature Conversion 11

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

4 MN-0019EN Operator’s Manual 618L, 624, and 634 Fryers

Preface

The 618L, 624, and 634 Electric Fryers are

designed to fry cake and yeast-raised donut

products. Each must be bolted to a flat, dry

floor. The operator should stand opposite the

heater head.

The operator must work safely at all times and

read this manual and follow its instructions and

warnings. A thorough understanding of how to

install, maintain, and safely operate the fryer will

prevent production delays and injuries.

Heed the following warnings and all other

warnings that appear in this manual:

•Make sure the machine is bolted securely

to the floor. Doing so will prevent the

machine from moving, tipping, or

falling, which could cause serious injury.

•To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

•Never let water and hot shortening come

in contact with each other. Moisture

causes hot shortening to spatter, which

may cause serious burns.

•Do not overfill the kettle with

shortening. If shortening overflows the

kettle, it could cause serious burns or

could cause someone to slip on the floor

and be seriously injured.

•Hot shortening can cause serious burns.

Make sure that the system and the

shortening are cool before attempting

any cleaning, adjustment, disassembly,

or repair.

•To avoid electrocution or other injury,

unplug the machine before attempting

any cleaning, adjustment, disassembly,

or repair.

•Be careful never to get shortening, water,

or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

•To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

•To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

•Make sure that all electrical cords are

routed so that no one will trip over them.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L, 624, and 634 Fryers Operator’s Manual MN-0019EN 5

1 Operation

Above: OMRON Digital Temperature Controller

READ EACH STEP COMPLETELY

BEFORE DOING WHAT IT TELLS

YOU TO DO.

1. Make sure the drain is closed. The drain

handle is at the side of the fryer (usually the

left side).

2. Put enough shortening in the kettle to

completely cover the heating elements,

thermocouple, and high-temperature limit

control probe. Use one of these 3 methods:

3. If you have a Belshaw EZMelt shortening

melter-filter, warm the shortening and then

transfer it to the kettle. (Refer to the EZMelt

operator’s manual).

WARNING

Hot shortening causes severe burns.

4. Melt shortening in a pan on the stove and

pour it into the kettle.

5. Put solid shortening manually into the kettle.

Pack it tightly around the heating elements,

thermocouple, and high-temperature limit

control probe.

WARNING

Cover the heating elements completely! If

you put solid shortening, do not leave any

air spaces. Any air can cause the

shortening to overheat and catch on fire.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

6 MN-0019EN Operator’s Manual 618L, 624, and 634 Fryers

6. When the elements have been completely

covered with shortening, move the on/off

switch to the ON position.

7. The “Power On” pilot light on the front of the

fryer will light up.

FOR THE NEXT STEPS, SEE THE

DIAGRAM OF THE DIGITAL

TEMPERATURE CONTROLLER ON THE

PREVIOUS PAGE

To adjust the target temperature (marked SV on

the controller), push the up and down arrows at

the bottom right.

1. Set the Digital Temperature Controller target

temperature to 250°F/121°C.

2. The “Heating” pilot light on the front of the

fryer will light up, indicating that the

shortening has not yet reached the selected

temperature.

3. Continue adding shortening to the kettle until

it reaches the proper depth for frying. Use

one of the 3 methods below. For safety

reasons, we recommend the first method, and

discourage you from using any other method.

4. Use a Belshaw EZMelt to melt shortening

and transfer it to the kettle. See the EZMelt

manual.

5. Melt shortening in a pan on the stove and

pour it into the kettle.

6. Very carefully, put solid shortening into the

kettle.

WARNING

To avoid serious burns, be very careful not

to splatter hot shortening when you add

shortening to the kettle.

Shortening expands as it increases in

temperature. Put shortening in the kettle

gradually. Let the shortening in the kettle heat

up before you add more.

7. After all of the shortening has melted, set the

digital temperature controller to the desired

frying temperature.

8. The “Heating” pilot light will go out if the

high temperature limit control breaks the

circuit.

9. Wait for the shortening to reach the desired

temperature.

WARNING

To avoid serious burns, when the fryer is

operating, do not any part of the fryer that

is in contact with hot shortening.

Note: The fryer will automatically shut

off the elements if temperature is too

high. To restart, wait for the shortening to

cool, then push the red reset button

inside the door.

10. If you are frying cake donuts, move the

depositor into place over the fryer. Refer to

the depositor manual for complete

installation and operation instructions.

CAUTION

To avoid damaging the machine, do not

operate the conveyor until all the

shortening has melted.

11. Continue supplying shortening to the kettle

as required. Keep the kettle filled up to the

“Oil Level” marks on the side.

12. When you have finished using the fryer,

move the on/off switch to the OFF position.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L, 624, and 634 Fryers Operator’s Manual MN-0019EN 7

2 Cleaning

For your safety, observe the following warnings

throughout the entire cleaning process.

WARNING

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor can

cause serious injury or loss of life.

WARNING

To avoid electrocuting yourself or

damaging the machine, never allow water,

steam, shortening, cleaning solution, or any

other liquid to enter the electrical box or

the heater head.

WARNING

To avoid being burned in an explosion,

never use any flammable materials for

cleaning.

Cleaning the Exterior

Surfaces

1. Clean the polished and painted surfaces of

the fryer with a soft, damp cloth. Use a non-

abrasive cleaner to remove any

discoloration.

2. Polish these surfaces with a soft, dry cloth.

Cleaning the Frying Screen

1. In a sink or a dishwasher, wash the frying

screen using warm water and mild detergent.

Do not use an abrasive cleaner or scraper.

2. Rinse the frying screen in clear water.

3. Dry the frying screen thoroughly, using a

soft cloth, before using it again.

WARNING

Dry the frying screen thoroughly.

Moisture causes hot shortening to spatter,

which may cause serious injury.

4. Check the frying screen to make sure no

metal is flaking off of it. If the screen is

flaking, replace it immediately, so you do

not get metal particles in your product.

Cleaning the Kettle

There are four basic steps to cleaning the kettle:

removing the shortening, washing, rinsing, and

drying. You must perform all four steps and

perform them in the order listed.

Removing the Shortening

WARNING

To avoid being burned or electrocuted,

disconnect the fryer from the power source

before cleaning it.

1. Disconnect the machine from the power

source.

2. Let the shortening cool to 100°F/38°C.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

8 MN-0019EN Operator’s Manual 618L, 624, and 634 Fryers

3. Place a Belshaw Shortening Filter or a large

metal container under the drain valve of the

fryer.

WARNING

Do not use a plastic container. If the

shortening is not cool enough, the container

will melt, possibly causing you to be

burned, and causing shortening to get on

the floor.

4. Open the drain valve by turning the drain

valve extension knob on the side of the fryer

cabinet. Allow all the shortening to drain

into the Shortening Filter or metal container.

5. If you are using a metal container, watch it

to make sure the shortening does not

overflow. If the container becomes full,

close the drain valve, put another metal

container under the drain valve, and open the

drain valve again.

WARNING

Do not allow the shortening to overflow the

containers. Shortening will get on the

floor, and if the shortening is not cool

enough, you may be burned.

WARNING

Thoroughly clean and dry the floor if

shortening is spilled. Shortening on the

floor can cause serious injury or loss of life.

6. If you have drained the shortening into a

metal container and you wish to re-use the

shortening, set the container of shortening

aside. Place another suitable container

under the drain valve.

7. Brush accumulated crumbs from the heating

elements. Accumulated crumbs causes

corrosion and poor heat recovery.

8. Tilt the heater head assembly out of the fryer

and lock it in place.

9. Using a non-abrasive, non-metallic spatula,

scrape the sediment and any remaining

shortening through the drain valve.

10. Close the drain valve.

Washing

1. Carefully pour hot water into the kettle, up

to the normal level of the shortening. Add

trisodium phosphate (TSP) or another

appropriate cleaner.

2. Scrub the inside of the kettle. Do not use

any abrasive cleaners or scrapers.

WARNING

To avoid being burned, be very careful as

you work with hot cleaning solution. Never

put your hands in the solution. Wear

gloves and long sleeves in case any solution

splashes.

3. Allow the cleaning solution to cool to

100°F/38°C.

4. Place a large metal container under the drain

valve.

WARNING

Do not use a plastic container. If the

cleaning solution is not cool enough, the

container will melt; possibly causing you to

be burned, and causing cleaning solution to

get on the floor.

5. Open the drain valve and allow the cleaning

solution to drain into the container.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L, 624, and 634 Fryers Operator’s Manual MN-0019EN 9

6. Watch the container to make sure the

cleaning solution does not overflow. If the

container becomes full, close the drain

valve, put another large metal container

under the drain valve, and open the drain

valve again.

WARNING

Do not allow the cleaning solution to

overflow the container. Cleaning solution

will get on the floor, and if the solution is

not cool enough, you may be burned.

7. When the draining is complete, close the

drain valve.

8. Carefully carry the container(s) to the sink

and slowly pour the solution into the sink.

WARNING

Thoroughly clean and dry the floor if

cleaning solution is spilled. Liquid on the

floor can cause serious injury or loss of life.

Rinsing

1. Carefully pour clean, hot water into the

kettle, up to the normal level of the

shortening. If the cleaner you have used

requires that you add a neutralizer, do so

now.

2. Allow the water to sit for 5-10 minutes.

Then allow it to cool to 100°F/38°C.

3. Place a large metal container under the drain

valve.

WARNING

Do not use a plastic container. If the water

is not cool enough, the container will melt,

possibly causing you to be burned, and

causing cleaning solution to get on the

floor.

4. Open the drain valve and allow the water to

drain into the container.

5. Watch the container to make sure the water

does not overflow the container. If the

container becomes full, close the drain

valve, put another large metal container

under the drain valve, and open the drain

valve again.

WARNING

Do not allow the water to overflow the

container. Water will get on the floor, and

if the water is not cool enough, you may be

burned.

6. When the draining is complete, close the

drain valve.

7. Carefully carry the container(s) to the sink

and slowly pour the water into the sink.

WARNING

Thoroughly clean and dry the floor if water

is spilled. Water on the floor can cause

serious injury or loss of life.

Drying

Dry the kettle, drain valve and burner tubes

thoroughly, using a soft cloth. Make sure no

water is in the drain or drain tube.

WARNING

Dry all parts of the fryer thoroughly.

Failure to dry the fryer and kettle

completely will cause an eruption.

Shortening will overflow the sides of the

fryer and may result in fire, injury, or

death.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

10 MN-0019EN Operator’s Manual 618L, 624, and 634 Fryers

3 Donut-Making Helps

Tips on Making Quality

Cake Donuts

•Use the correct batter temperature.

In general, the correct batter temperature is

75°-80°F/24°-27°C. Check the mix

manufacturer’s instructions, as the

recommended temperature range may vary.

If the batter is too warm, the donuts will lack

volume and may “ring out” or be misshapen.

If the batter is too cold, the donuts will stay

under the shortening too long, fry too

slowly, and crack open or ball up. They

may also absorb excess shortening and lose

volume.

•Use the correct floor time.

A floor time of 10 minutes between mixing

and cutting allows the baking powder to

react with the water. This helps the donuts

attain the proper volume the proper level of

shortening penetration.

If the floor time exceeds 30 minutes, the mix

will gas off, the donuts will lose volume and

shape and will absorb too much shortening.

•Use the correct frying temperature.

The correct shortening temperature for

frying is 370°-380°F/188°-193°C.

If the shortening is too hot, the donuts will

fry too quickly on the outside and will lose

volume. The donuts may also become dense

inside.

If the shortening is too cold, the donuts will

spread too rapidly, will form large rings, will

tend to crack open, will be too light in

appearance, and will absorb too much

shortening.

•Maintain the proper shortening level. We

recommend a distance of 1 1/4” between the

depositor and the shortening.

If the shortening is too deep, the donuts may

not turn over when they reach the turner,

causing them to cook unevenly.

If the shortening is too shallow (too far

below the depositor), the donuts may not

drop flat, may turn over while submerging

and surfacing, and may become irregular,

cracked, or rough-crusted.

•Ensure that the donuts absorb the right

amount of shortening.

Donuts should absorb 1-1/2 to 3 oz/42 to 85

g of shortening per dozen, depending on

their weight. You can achieve proper

absorption by following tips 1-3.

•If the donuts do not absorb enough

shortening, they will not keep well.

If they absorb too much shortening, they will

lose volume and may become misshapen. If

this happens, follow tips 1-3, mix the batter

a little longer than usual, turn the donuts as

soon as they become golden brown, and turn

the donuts only once.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L, 624, and 634 Fryers Operator’s Manual MN-0019EN 11

Calculating Correct Water

Temperature

The following is an example of how to calculate

the correct water temperature to use. You must

use your own room temperature, dry mix

temperature, desired batter temperature, and, if

you are making yeast-raised donuts, estimated

temperature increase during mixing.

Cake Donuts Yeast-Raised Donuts

°F

°C

°F

°C

Room temperature

72

22.2

72

22.2

Dry mix temperature

+70

+21.1

+70

+21.1

Total A

142

43.3

142

43.3

Desired batter temperature

75

23.9

80

26.7

x3

x3

x3

x3

Total B

225

71.7

240

80.1

Total B

225

71.7

240

80.1

-Total A

-142

-43.3

-142

-43.3

Desired water temp. for cake donuts

83°F

28.4°C

98

36.8

↓

↓

Figure from above

98

36.8

Temperature increase during mixing (average: 30°F/17°C)

-30

-17

Desired water temperature for yeast-raised donuts

68°F

19.8°C

Ratios of Plunger Sizes to

Donut Weights

The weights given are for donuts without icings

or other toppings. They are provided for

reference only, as weights vary according to the

density of the batter.

Plunger Size Donut Weight per

Dozen

1”

5-8 oz/142-227 g

1 5/8”

14-17 oz/397-482 g

1 3/4”

16-20 oz/454-567 g

1 7/8”

19-24 oz/539-680 g

2"

22-27 oz/624-765 g

Temperature Conversion

To convert temperatures from Fahrenheit to

Celsius, subtract 32 from °F and divide the result

by 1.8. For example, 212°F-32/1.8 = 100°C.

To convert temperatures from Celsius to

Fahrenheit, multiply °C by 1.8 and add 32 to the

result. For example, (100°C x 1.8) + 32 = 212°F.

°

F

°

C

°

F

°

C

55

12.8

340

171.1

60

15.6

345

173.9

65

18.3

350

176.7

70

21.2

355

179.4

75

23.9

360

182.2

80

26.7

365

185.0

325

162.8

370

187.8

330

165.6

375

190.6

335

168.3

380

193.3

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L | 624 Fryers Technical Supplement MN-0019EN 13

Electric Fryer

618L | 624

Technical Supplement

Belshaw Adamatic Bakery Group

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • 800-578-2547

Email: service@belshaw.com • http://www.belshaw.com

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

14 MN-0019EN Technical Supplement 618L | 624 Fryers

EQUIPMENT RECORD

Please provide the information below when you correspond with Belshaw about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ____________________________________________________________________

Serial number

IN CASE OF DAMAGE TO EQUIPMENT

In case of damage to the equipment upon delivery, follow these steps immediately.

1. Inform the freight carrier. The phone number will be on the shipping receipt or label.

2. Take photographs of the equipment, both inside and outside the box or crate.

3. Do not throw away any packaging.

4. Report the damage to the distributor (or other party) from whom you bought the equipment.

5. Email your photos to the distributor (or other party) AND to Belshaw Customer Service at

service@belshaw.com. Include a Belshaw Order Number in your communications. Your Order

Number has 6 digits and should be marked on the box or crate.

IN CASE OF MISSING ITEMS

1. If possible, note the missing items on the delivery receipt of the freight carrier.

2. Take photographs of the entire shipment.

3. Follow steps 2 – 5 above.

MN-1128EN 031819

Belshaw Adamatic Bakery Group

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (+1)206-322-5474 • 1-800-BELSHAW • 800-578-2547

Email: service@belshaw.com • http://www.belshaw.com

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L | 624 Fryers Technical Supplement MN-0019EN 15

Contents

Technical Supplement

Before you start 16

17

17

17

17

18

18

19

20

1Installation

Unpacking the Fryer

Initial Cleaning

Installing the Fryer

Moving the Fryer

Mounting the Drain Tray

Assembling the Frying Screen Handles

2Troubleshooting

3Temperature Controller

4 Diagrams and Parts Lists

23

27

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

16 MN-0019EN Technical Supplement 618L | 624 Fryers

Before you start

The 618L, 624, and 634 Electric Fryers are

designed to fry cake and yeast-raised donut

products. Each must be bolted to a flat, dry

floor. The operator should stand opposite the

heater head.

The operator must work safely at all times and

read this manual and follow its instructions and

warnings. A thorough understanding of how to

install, maintain, and safely operate the fryer will

prevent production delays and injuries.

Heed the following warnings and all other

warnings that appear in this manual:

•Make sure the machine is bolted securely

to the floor. Doing so will prevent the

machine from moving, tipping, or

falling, which could cause serious injury.

•To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

•Never let water and hot shortening come

in contact with each other. Moisture

causes hot shortening to spatter, which

may cause serious burns.

•Do not overfill the kettle with

shortening. If shortening overflows the

kettle, it could cause serious burns or

could cause someone to slip on the floor

and be seriously injured.

•Hot shortening can cause serious burns.

Make sure that the system and the

shortening are cool before attempting

any cleaning, adjustment, disassembly,

or repair.

•To avoid electrocution or other injury,

unplug the machine before attempting

any cleaning, adjustment, disassembly,

or repair.

•Be careful never to get shortening, water,

or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

•To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

•To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

•Make sure that all electrical cords are

routed so that no one will trip over them.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L | 624 Fryers Technical Supplement MN-0019EN 17

1 Installation

Unpacking the Fryer

1. Use a fork lift to transport the shipping crate

to the work station.

2. Break down the shipping crate.

3. Remove all the packing materials from the

fryer. These include foam, tape, brown

paper, plastic, and white protective coating.

4. Position the fryer to allow sufficient space

on either end of the machine for any

equipment you plan to use with it.

Initial Cleaning

Clean your fryer before using it. Wipe the inside

of the kettle with a soft, damp cloth. Dry the

kettle thoroughly.

WARNING

To avoid electrocuting yourself or

damaging the machine, never allow water,

steam, cleaning solution, or other liquid to

enter the heater head or the electrical box.

WARNING

Never let water and hot shortening come in

contact with each other. Moisture causes

hot shortening to spatter, which may cause

serious injury. Prior to use, make sure the

kettle and any other parts you have washed

are dry.

Installing the Fryer

1. Make sure the power requirements of the

machine, found on the data plate on the back

of the heater head assembly, match your

power source.

2. Using a fork lift or pallet jack, lift the fryer

cabinet and screw each leg in as far as it will

go.

3. Set the fryer cabinet on a flat, dry floor.

4. Level the fryer. Follow these steps:

a. Check to see if the fryer is level. To do

so, place a level across the top of the

fryer cabinet.

b. If the fryer is not level, lift the fryer

using a fork lift or pallet jack, and turn

the legs to adjust them.

c. Using the fork lift or pallet jack, lower

the fryer to the floor. Be sure that all the

legs rest on the floor when the fryer is

level.

5. Bolt the fryer to the floor. The foot of each

leg has two holes in it for this purpose.

WARNING

To avoid serious burns, other injury, or

death, make sure the fryer is securely

fastened to the floor so it will not tip or fall

over.

9. Connect the fryer to a properly grounded

power source.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

18 MN-0019EN Technical Supplement 618L | 624 Fryers

Moving the Fryer

If you ever want to move the fryer to a different

workstation, follow this procedure:

1. Turn off the fryer and disconnect it from the

power source.

2. Allow the machine and the shortening to

cool.

WARNING

Do not touch hot shortening. It can cause

serious burns.

3. Remove the shortening from the fryer as

explained in “Removing the Shortening” in

Section 3.

WARNING

To avoid burns, falls, other injury, or

death, never attempt to move the fryer

when it has shortening or other liquid in it.

WARNING

Thoroughly clean and dry the floor if

shortening is spilled. Materials on the floor

can cause people to slip or fall, resulting in

serious injury or loss of life.

4. Remove the bolts that secure the fryer to the

floor.

5. Using a fork lift, transport the machine to

the new workstation.

6. Level the fryer, bolt it to the floor, and

connect it to the power source, as explained

in “Installing the Fryer” above.

Mounting the Drain Tray

The drain tray is mounted on the right side of the

fryer in the factory. To move the drain tray on

the left side, see the diagram below and follow

these steps.

1. Remove the acorn nut from the back side of

the drain tray hinge shaft (Diagram )

2. Slide the drain tray hinge shaft out of the

drain tray mounting brackets (Diagram )

3. Lift off the drain tray.

4. Remove the two drain tray support brackets

that are mounted on the right side of the

cabinet (Diagram )

5. Install the drain tray support brackets on the

left side of the cabinet. Each bracket is held

in place by two hex-head machine screws,

two hex nuts, two internal tooth lock

washers, and two flat washers. Tighten all of

these securely.

6. Put the drain tray in place on the left side of

the fryer. The holes on the drain tray should

line up with the holes in the mounting

brackets on the left side.

7. Slide the drain tray hinge shaft through the

holes in the mounting brackets and the drain

tray.

8. Tighten the acorn nut (removed in step 1) on

the end of the drain tray hinge shaft.

9. Lift the drain tray support rod (Diagram )

so it is held in place by the support brackets

installed on the left side in Step 5.

Belshaw Adamatic Bakery Group •service@belshaw.com •800-578-2547 • (+1)206-322-5474

618L | 624 Fryers Technical Supplement MN-0019EN 19

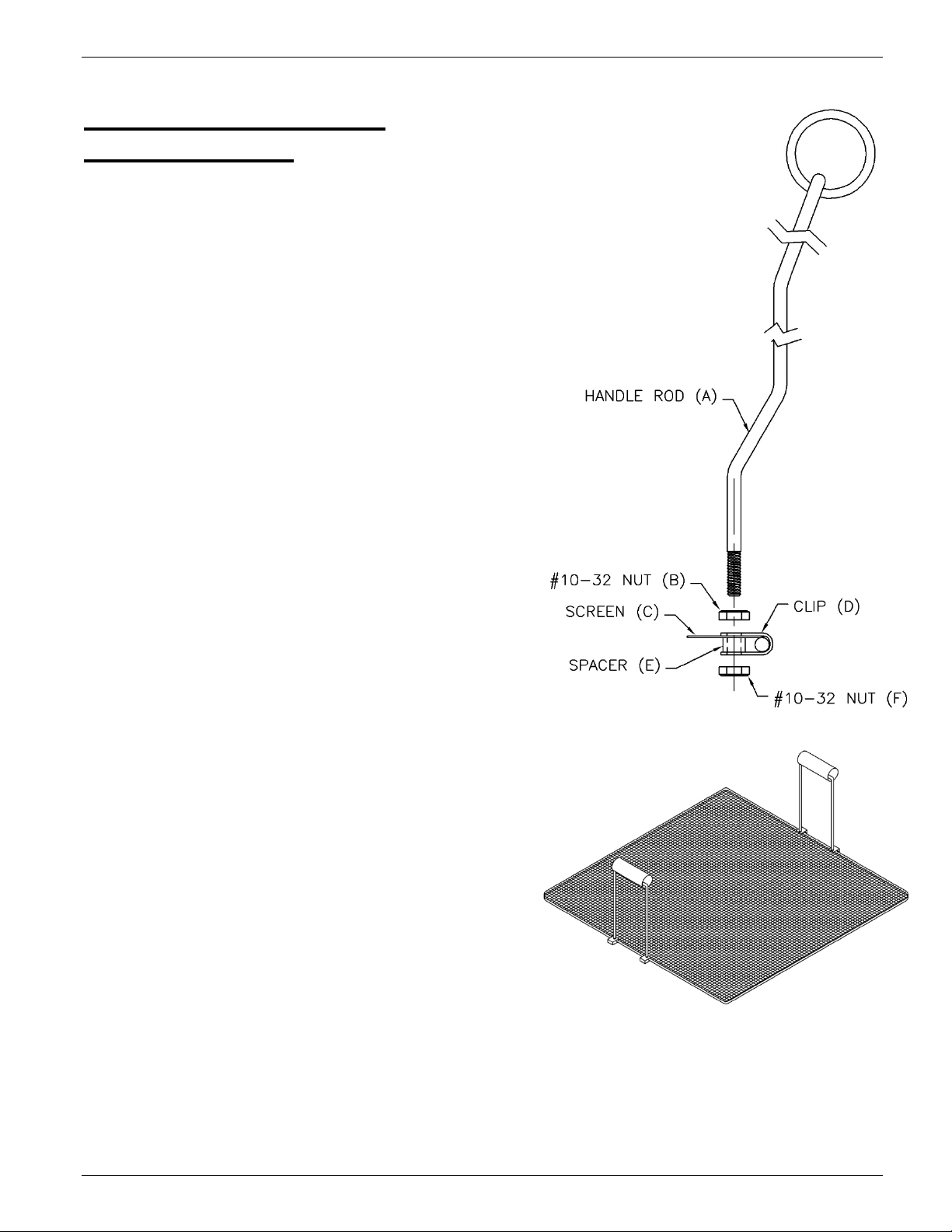

Assembling the Frying

Screen Handles

(Be aware that you may be using detachable

handles rather than fixed handles, particularly

when making raised donuts using screens which

are placed inside a proofer. In this case, your

handles should NOT be attached to screens.)

Frying Screens come with handles and hardware

unassembled. When assembled the location of

the handles should be as follows:

•For Model 618L and 718L Fryers, center the

handles along the long sides of the screen.

•For Models 624 and 724, center the handles

along any opposing sides of the screen.

•For Models 634 and 734, center the handles

along the short sides of the screen.

To assemble Frying Screens, refer to Figure 1

opposite.

1. Install #10-32 Nuts (B) on threaded handle

rods (A).

2. Locate clips (D) on the screen (C). Center the

handles as listed above for each type of fryer.

3. Insert threaded end of handle (A) with handle

to outside as shown, making sure that the

spacer (E) is in place.

4. Install #10-32 nuts (F) flush onto threaded

end of handle (A)

5. Tighten #10-32 Nuts (B) locking handle

assembly to screen.

(Above: Figure 1)

Other manuals for 618L

1

This manual suits for next models

5

Table of contents

Other Belshaw Brothers Fryer manuals

Popular Fryer manuals by other brands

Minca

Minca EC22AA operating instructions

Tecnoinox

Tecnoinox FRS35G7 Installation

Lotus cooker

Lotus cooker BR-50-78G Instructions for installation and use

Henny Penny

Henny Penny COMPUTRON 7000 500 Service manual

Sunbeam

Sunbeam Classic FP5500P Instruction/recipe booklet

Brinkmann

Brinkmann 815-4005 SERIES owner's manual