5

Allaciamento del tubo di alimentazione gas ............................................................................................................. 73

Allacciamento alla rete idrica ..................................................................................................................74

Trasformazione ad altri tipi di gas...........................................................................................................74

Istruzioni di uso ............................................................................................................................................................. 76

Sistema di ribaltamento della vasca .......................................................................................................77

Dimensional drawings with connection points BR 80 – 98 (Fig.1) ....................................................................... 80

Dimensional drawings with connection points BR 120 – 912 (Fig. 1a) ................................................................ 81

Controlling (Fig. 2) ........................................................................................................................................................ 81

Gas valve, nozzles and burners (Fig. 3) ................................................................................................................... 82

Pilot burner (Fig. 4) ...................................................................................................................................................... 82

Positions gas valve control knob (Fig. 6) .................................................................................................................. 83

Gas valve (Fig. 5) ......................................................................................................................................................... 84

Wiring diagram (Fig. 7) ................................................................................................................................................ 85

Declaration de conformidad con las normas ............................................................................................................ 88

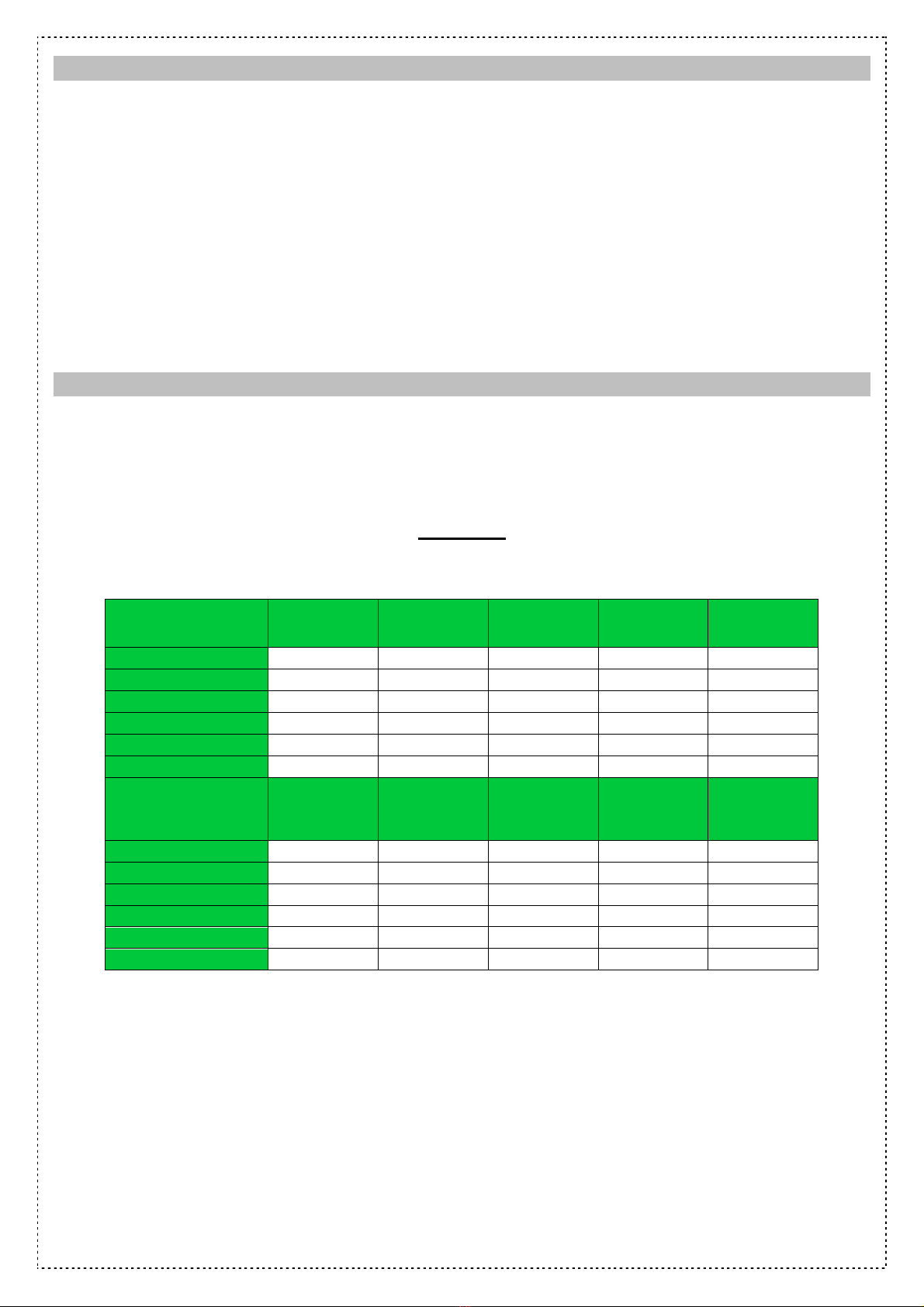

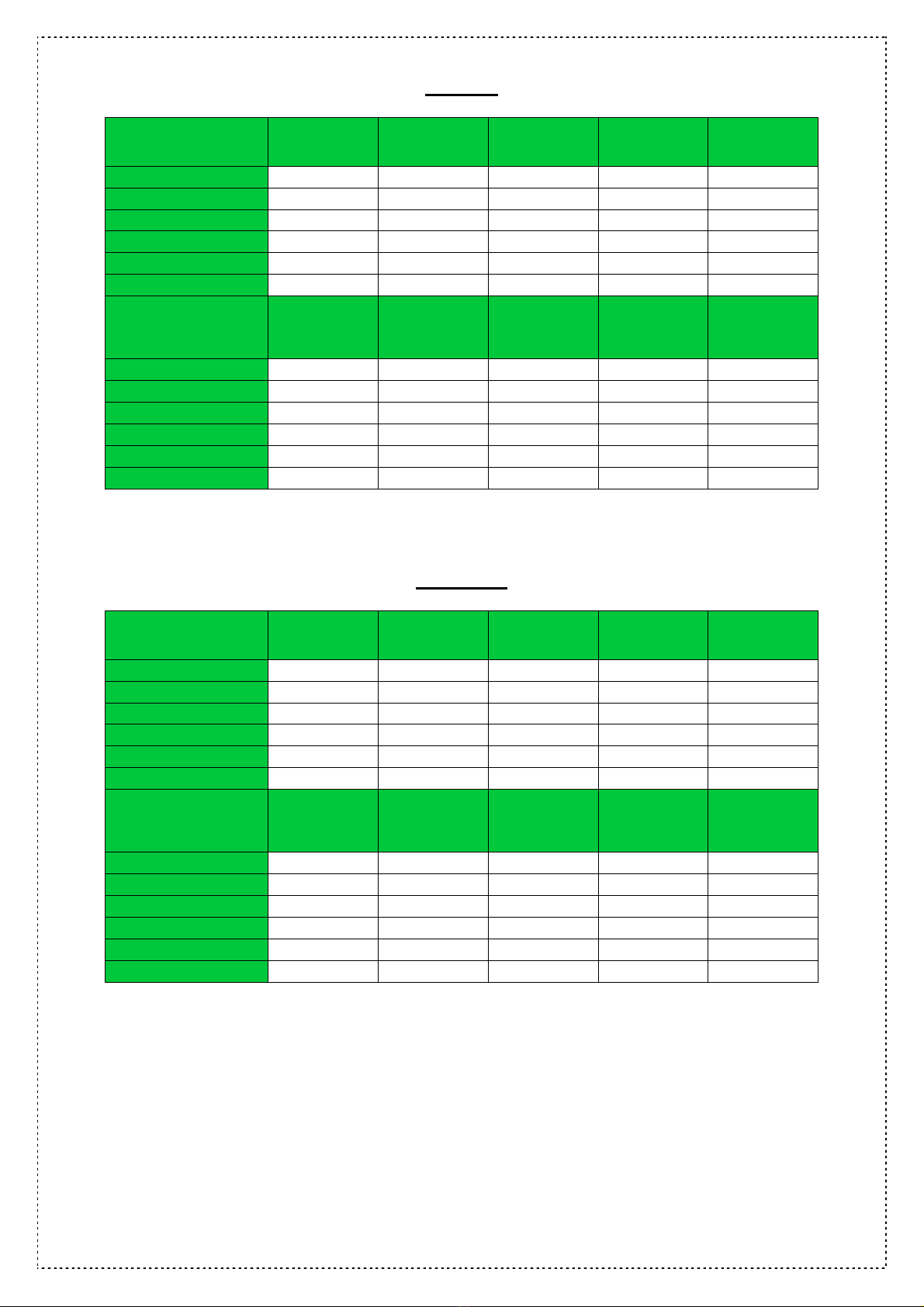

Datos tecnicos .............................................................................................................................................................. 88

Informaciones básicas sobre las sartenes basculantes ......................................................................................... 90

Control del envoltorio y del aparato ........................................................................................................................... 90

Instrucciones generales .............................................................................................................................................. 90

Instalacion ..................................................................................................................................................................... 91

Instrucciones técnicas para la instalación y regulación ................................................................................. 91

Importante: ................................................................................................................................................................... 91

Ubicación ....................................................................................................................................................................... 91

Realización de la evacuación de humos del aparato tipo A (fig. 8) ..................................................................... 92

Medidas de seguridad el aspecto de proteccion contra incendios de acuerdo a la norma EN 061008 art. 12-

2 ...................................................................................................................................................................................... 92

Conexión de la manguera conectora de gas ........................................................................................................... 93

Conexión del agua ....................................................................................................................................................... 94

Medidas para el cambio e instalación a otro tipo de gas. ...................................................................................... 94

Instrucciones de uso .................................................................................................................................................... 96