Benchcrafted Swing Away Seat Instruction sheet

BENCHCRAFTED

•

SWING AWAY SEAT

Assembly & Installation Guidelines

version March 2019

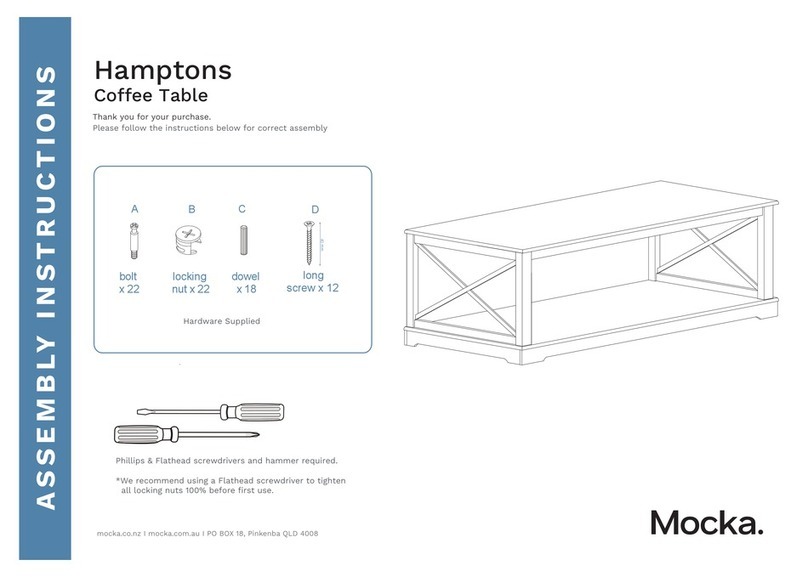

Package contents pictured

Not pictured:

•round head wood screws (3)

•optional oak seat

Not included:

• mounting fasteners

USE AND FUNCTION

Thanks for purchasing the Benchcrafted Swing Away Seat. Originally designed for use on

woodworking benches and shop furniture, the seat can be used in a wide variety of ap-

plications like restaurants, kitchens, craft rooms, garages, and the like.

The seat itself is quite simple. It pivots a bit more than 180 degrees so you can swing

the seat under a table top when not in use, and also allow some range of movement

while seated. The castings are powder-coated cast iron and require no maintenance

other than a wipe down with a soft cloth when they become dusty. The seat can be used

outdoors, but being made of iron, any exposed areas or worn areas (like the bosses the

mount rides on and the steel pivot pins) will eventually rust. That’s not to say the seat

will become non-functional, just be aware of a visual change once exposed to the ele-

ments. A little oil under the heads of the pivot pins will help keep the mount swinging

free.

WEIGHT CAPACITY

The iron and steel components are overbuilt and will support even the largest humans.

There is no weight limit. The mechanical connection with your bench or table is another

matter, and again, up to the nal installer.

BALANCE

If you’re mounting the seat to a freestanding table or bench with straight legs, and the

bench doesn’t weigh a lot, you may nd it easy to tip the bench over once you put your

body weight on the seat. Again, this depends on the weight of the bench or table, the

weight of the sitter, the table’s leg arrangement, and the sitter’s body position relative

to the seat and table. If your table has a base where the legs or feet extend past the

top (in eect, going under the seat as in a trestle table) you’ll have some extra support

underneath and will nd the arrangement more stable. Also, if the sitter is positioned so

the mount is between their legs, or to the side of either leg, the balance will change. If

you nd your arrangement unstable, you may need to add weight to your bench or fas-

ten it to the ground. Also keep in mind if you’re mounting more than one seat to a struc-

ture, and two people sit down on the same side of the bench, you may get some tipping.

OVERHANG

The seat can be mounted to a table or bench who’s top is ush, or protruding from the

leg on which the seat is mounted. For woodworking benches, you’ll want to mount the

bracket on the side of the leg, so as to not interrupt the front plane of the bench. Mount

it as close to the front of the bench as you can, but again, on the side of the leg. This

places the top of your bench away from your torso to allow free movement when work-

ing from a seated position. For other applications, like writing, typing or eating, the top

of the table can be closer to your torso, so you can mount the bracket further in from

the edge of the top, or to a leg or surface that’s recessed from the edge of the top.

How a range of overhang amounts aects the sitter’s relationship with the table top

HEIGHT

To get a feel for the ideal height to mount the seat, you can temporarily clamp the

bracket to your bench or table leg to test dierent heights. 20” is a good starting point

for average people. The top of the bracket is about 1” below the nal height of a 1” thick

wood seat. So if you want your nal height to be 20”, mount the bracket so the top of

the casting is 19” o the oor. For bars or higher applications, you may want to install a

footrest for support.

MOUNTING THE SWING AWAY SEAT BRACKET

DISCLAIMER

Benchcrafted will not be held responsible for your mounting situation or dam-

age or injury incurred as a result of faulty mounting of the Swing Away Seat.

The installer is entirely responsible for the outcome of each mounting situation.

Because of the wide variety of mounting situations, we don’t include any mounting fas-

teners with the seat. Here are some guidelines to help you choose fasteners.

For mounting to hardwoods at least 3” thick (like a workbench leg) you can use good

quality 1/2” lag bolts (sometimes called lag screws.) Good quality means deep and sharp

threads. Some of the big box stores carry really lousy quality bolts with shallow, blunt

threads. Don’t use these! If you’re mounting to softwood like pine or r, you’ll want at

least 4” of thread engagement in the material, so 5” lag bolts.

If your mounting surface is thinner than what we describe above, it’s best to use a 1/2”

machine bolt, nut and lock washer for maximum strength. Place the bolt head on the

bracket side and the nut and washer on the opposite side of the mounting surface.

When mounting the bracket, orient it

so the thicker bosses (which bear the

weight of the sitter) are on the bottom.

You can use any standard hex head fastener to mount the seat, but we like the look of

the square head lags and bolts in the black nish available from www.blacksmithbolt.

com. We have no aliation with the company, but we’ve been happy customers for a

number of years. Your local hardware store will most likely have the fasteners you need.

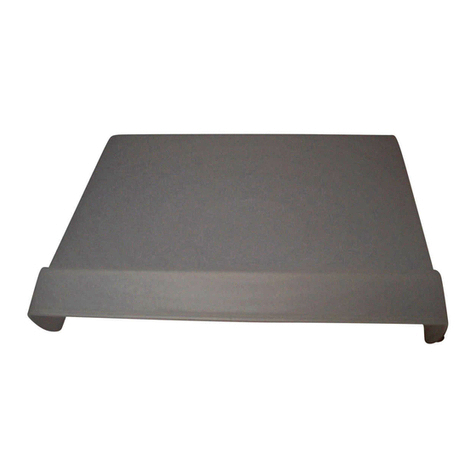

ASSEMBLE THE WOOD SEAT

Once the bracket is attached to your structure you can join the mount to the bracket.

Before you do that you should attach the wood seat. If you’re making your own wood

seat, the dimensions are 7/8” thick (but not less) x 11” diameter at least (a little larger is

ne.) You’ll need to attach the support bar to the mount before attaching the wood seat.

Two 5/16” machine screws are provided for attaching the support bar. See illustration

below.

Three wood screws are included for attaching the wood seat. Grain direction relative to

the iron components is not critical, but make sure you select a straight grained board for

the seat itself. When attaching the seat, make sure you position it so the edge of the seat

lands on the rectangular boss in the middle of the mount. This ensures good support for

the entire diameter of the seat.

JOIN THE MOUNT TO THE BRACKET

Marrying the two heavy parts is easy. Place the mount into the bracket (between the two

sets of bosses) and line up the holes, just like a door hinge. Drop one of the pivot pins

in from above in the top hole in the bracket, then follow up with the lower one. The pins

stay in position with gravity alone. If you nd them dicult to insert, check for a build-

up of powder coating in the holes. If you nd some, run a ½” twist drill bit (slowly now)

or le through the holes to clean them up. You can put a few drops of oil or light grease

inside the holes before assembly if you like. But it’s easy enough to disassemble later for

cleaning and lubrication too. To do that, just take the weight o the mount by lifting up

on the wood seat, and then the pivot pins should be easy to lift out of their holes. The

seat should pivot smoothly and freely once mounted and installed.

As with all Benchcrafted products, feel free to contact us for technical help should you

All dimensions are nominal

Table of contents

Other Benchcrafted Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Kettler

Kettler PP756-ANTH Assembly instructions

Coaster

Coaster Ricardo 190821 Assembly instructions

Furniture of America

Furniture of America Radnor CM4536C Assembly instructions

Forte

Forte CALPE CLPK21 Assembling Instruction

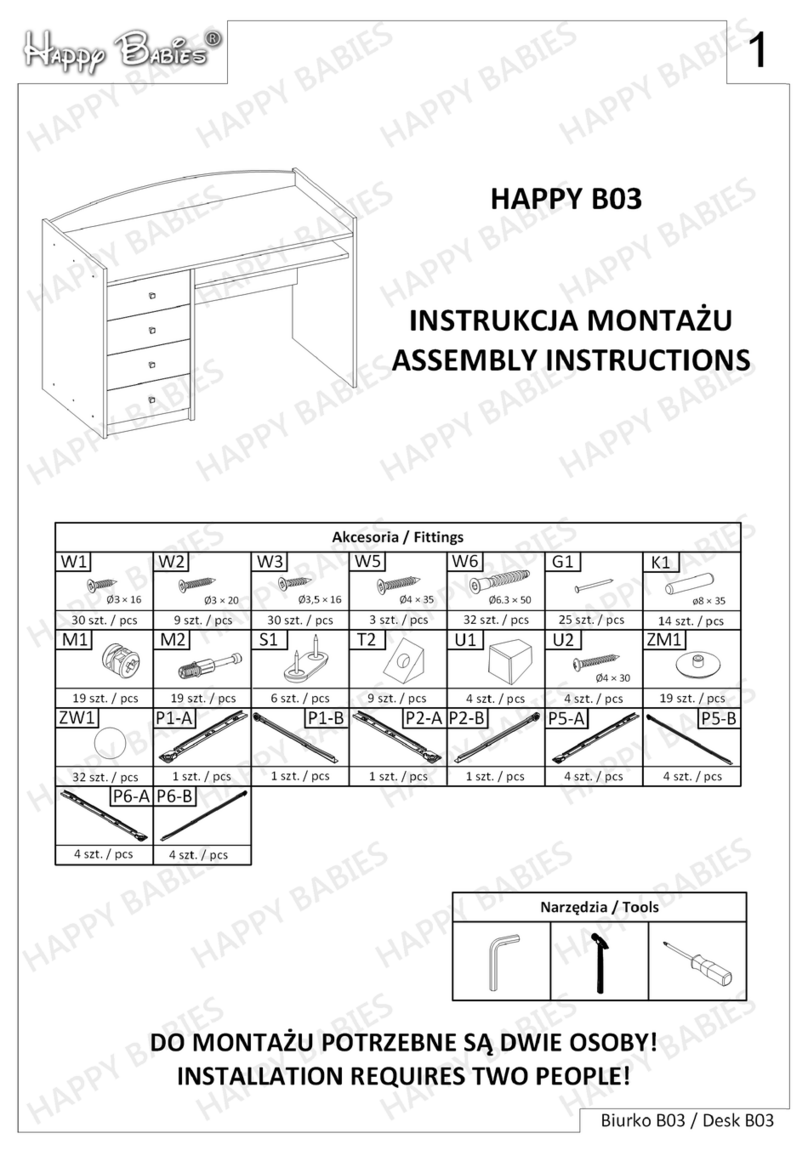

Happy Babies

Happy Babies HAPPY B03 user manual

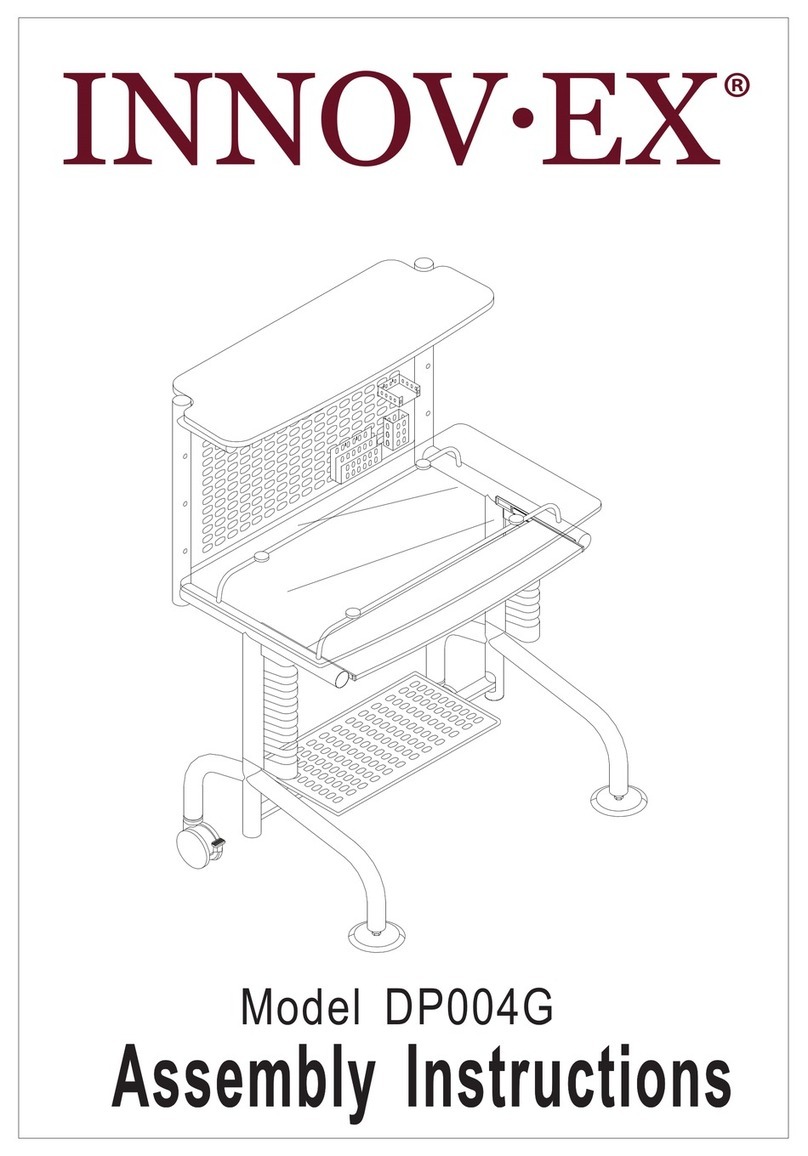

Innovex

Innovex DP004G Assembly instructions

Tarrington House

Tarrington House 221-0811 quick start guide

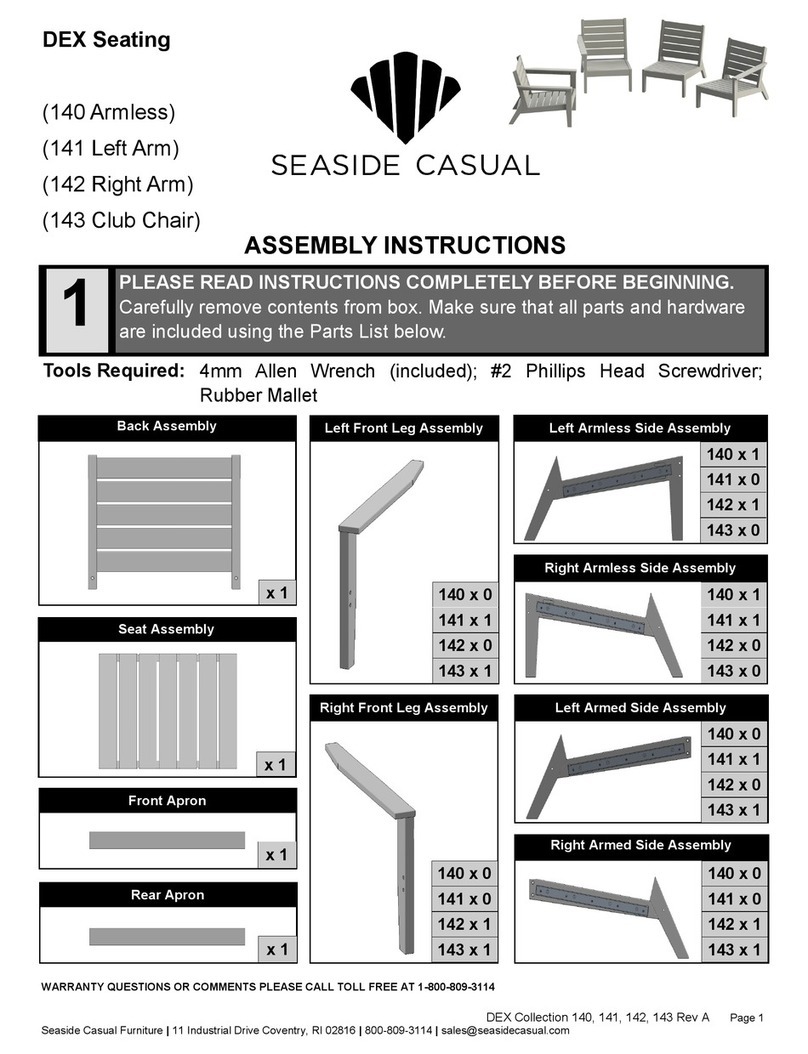

Seaside Casual

Seaside Casual DEX 140 Assembly instructions

IKEA

IKEA EXPEDIT COFFEE TABLE SQUARE instructions

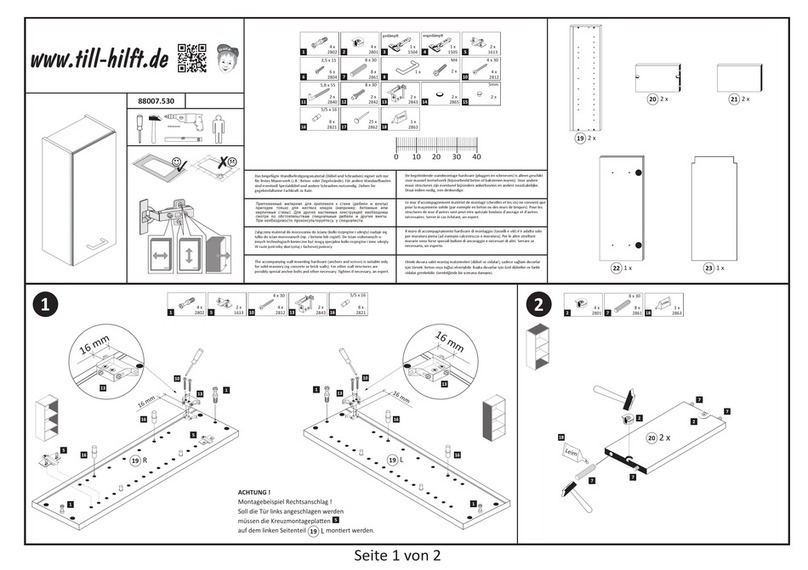

Till-Hilft

Till-Hilft 88007.530 Assembly instructions

KI

KI Intellect Book Box Assembly instructions

Dorel Home Products

Dorel Home Products 4540049QE manual