Benchmark BAKER ATLAS 5715XA User manual

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 1 of 39

OPERATIONS AND MAINTENANCE MANUAL

WINCH OPERATORS PANEL

BAKER ATLAS 5715XA PANEL

F140529000

Kerr p/n AMS4A040

TABLE OF CONTENTS

SECTION DESCRIPTION

1.0 GENERAL DESCRIPTION

2.0 DETAILED DESCRIPTION OF FEATURES

3.0 MENUOPERATINGINSTRUCTIONS

OPENHOLEMODE

4.0 MENUOPERATINGINSTRUCTIONS

CASED HOLE MODE

5.0 SYSTEM OPERATING INSTRUCTIONS

6.0 DRAWINGS, SETUP PROCEDURES AND

PARTS LISTS

7.0 INSTALLINGNEWSOFTWARE

8.0 CABLE DRAWINGS

9.0 CETESTCERTIFICATES

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 2 of 39

1.0 INTRODUCTION

1.1 GENERAL DESCRIPTION

This panel is designed to acquire and display depth, tension, and magnetic

mark data from a wireline logging winch unit. The panel provides the

operator a means to set and make adjustments to the data as necessary.

Depth is displayed from data provided from an encoder mounted on a

measuring device. The encoder quadrature pulses are passed through to

the acquisition system. The tension data is provided by a load pin and is

also passed through to the acquisition system.

The panel can be set in either open hole logging or cased hole logging

modes. This is done by installing jumper J3 on the main processor board

for cased hole mode or removing the jumper for open hole mode.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 3 of 39

1.2 FEATURES AND SPECIFICATIONS

-- Digital displays for depth, line speed, tension and magnetic marks (or CCL offset)

-- Analog incremental tension meter, 4 inch (108 mm) dia., 270 degree

-- Differential or Incremental tension zero push button switch

-- Excessive tension alarm setting allows operator to set tension alarm to a

predetermined value. Contact closure is provided for winch shutdown

-- Zero Depth button - sets depth to 0. Depressing button again resets depth to

previous setting. Only works when line speed is zero

-- Approaching surface alarm

-- Depth adjust up or down switches. Only works when winch is stopped

-- Load cell zero & calibrate controls. Only works when there is no load on cable

-- Depth & tension saved in non-volatile memory at power loss

-- Outputs for Magnetic Marks, Tension and Encoder to interface to an acquisition

system.

-- RS485 Interface for additional control and data outputs.

-- Can be set to display either English or Metric units.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 4 of 39

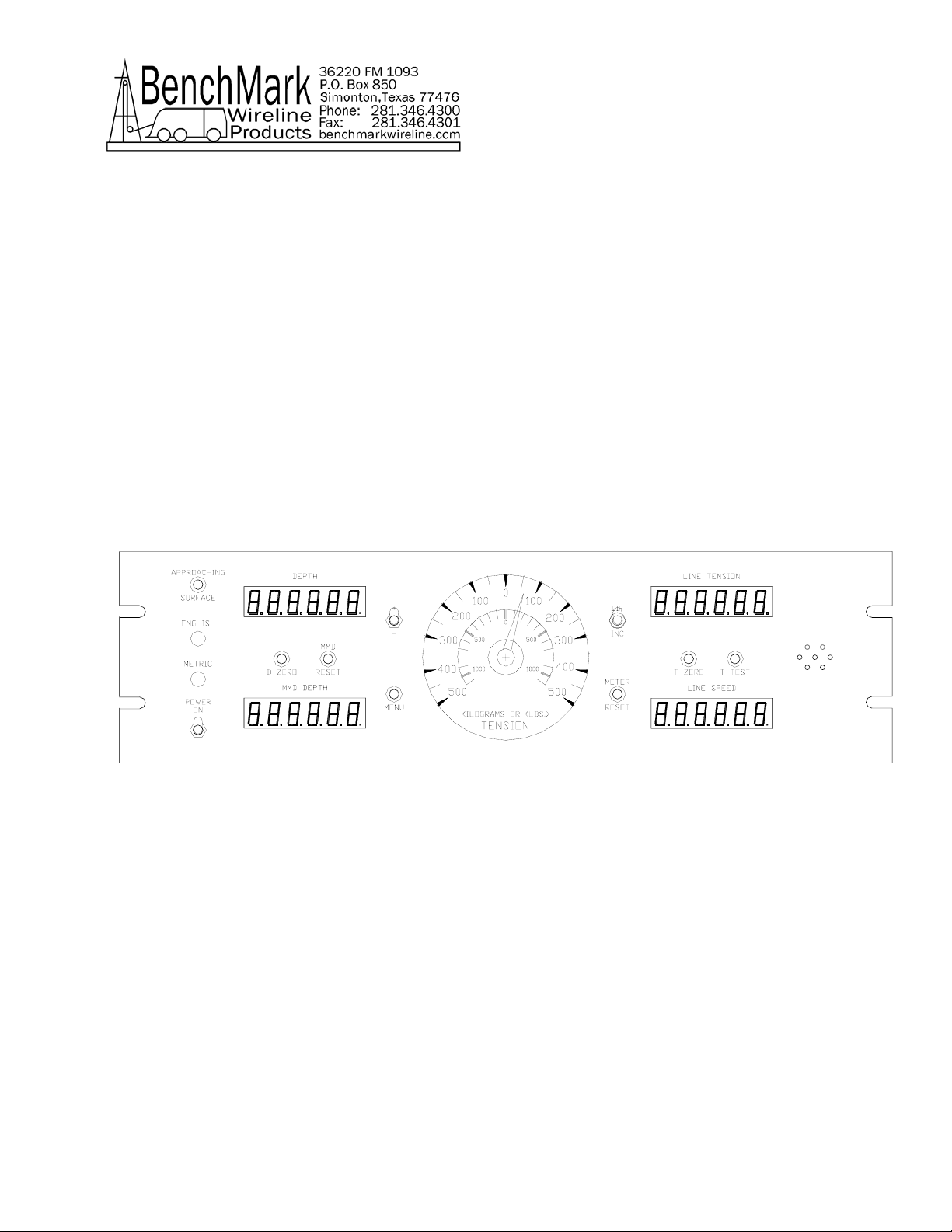

2.0 DETAILED DESCRIPTION OF FEATURES

2.1 FRONT PANEL

2.1.1 ANALOG TENSION METER

This meter displays either differential or incremental tension. This

provides a more visual display of tension change.

2.1.2 INCREMENTAL/TOTAL TENSION SWITCH

This switch will change the analog meter from Incremental tension to

Differential tension.

Incremental tension provides a high resolution tension scale. It must

be periodically reset as tension increases or decreases to keep it

from pegging out.

Differential tension provides a delta tension reading. The meter will

slowly reset itself to 0 so the reset switch is not necessary.

2.1.3 METER RESET SWITCH

This switch will reset the meter to the 0 (center) position.

2.1.4 DEPTH DISPLAY

This meter provides a digital display of depth.

2.1.5 LINE TENSION DISPLAY

This meter provides a digital display of total line tension.

2.1.6 LINE SPEED DISPLAY

This meter provides a digital display of line speed.

2.1.7 MAGNETIC MARK DISPLAY

This meter provides a digital display of the depth where the last

mark was detected. It is also used as a CCL offset display when the

panel is configured for cased hole operations (MODE 3).

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 5 of 39

2.1.8 MAGNETIC MARK RESET

Pressing the MMD reset button clears the last mark setting. The

next mark detected will be used to set the window for any

subsequent marks.

2.1.9 ZERO DEPTH

Pressing this button will reset the depth to 0. Depressing the button

again will reset the depth to the previous setting. The Zero Depth

button will only work when the line speed is zero (i.e. winch not

moving).

2.1.10 MENU

Pressing this button will activate the menu software. The software

feature to be set will be displayed on the DEPTH display. The

features can be toggled through by pressing the menu button until

the desired feature is displayed.

2.1.11 + / - SWITCH

This switch is used for different functions. It is used to change the

depth setting in either an up or down direction. The winch must be

stopped before the depth can be set. In menu mode (see section

3.0) the switch is used to set menu parameters.

2.1.12 APPROACHING SURFACE LED AND ALARM

This LED is lit and an audible alarm is sounded when the depth is

less than 100' (30 m). This is a warning to the hoist operator that

they are approaching surface and should take care to get the

equipment safely out of the well. When the LED is depressed, the

alarm will stop but the LED will continue to blink. Once the depth

reading is greater than 100' (30 m), both the alarm and the LED will

turn off.

2.1.13 ENGLISH / METRIC UNITS

These LEDs will indicate if the panel is in English or metric mode. If

the depth is set to English, the English LED will be lit. If the depth is

set to Metric the Metric LED will be lit. The tension can be set to

English (LBS) or Metric (KG) but it will not light the LED.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 6 of 39

2.1.14 T-ZERO SWITCH

Use this switch to set the tension to 0 at the start of a logging run.

This will zero out the tension circuit. The line should be slack

through the head at this time.

2.1.15 T-TEST SWITCH

Press T-TEST and verify that the panel tension reads 20000 lbs

(MODE 5) or 5000 lbs (MODE 3). Verify tension is being properly

recorded on acquisition system.

2.2 REAR PANEL

2.2.1 12 – 24 VDC

This connector supplies dc power for the panel operation (9 VDC

min, 30 VDC max). The panel can operate on either 12 or 24 vdc

(12 vdc is U.S. truck standard voltage, 24vdc is European truck

standard voltage). Pin A is positive, pin B is negative.

2.2.2 OVER TENSION CONTACT

This connector provides a connection to the overtension circuit

relay. When an overtension condition is active, the two pins are

connected together. In normal position the two pins are open. This

feature can be used to interface to the winch unit control system to

provide automatic hoist shutdown at an overtension condition.

2.2.3 SIGNAL INPUT

Encoder, tension, and magnetic mark signals and power are passed

through this connector to/from the sensors on the measuring head.

2.2.4 SIGNAL OUTPUT

Encoder, tension, and magnetic mark signals, processed and some

unprocessed are passed through this connector to the acquisition

system.

2.2.3 RS485 SERIAL INTERFACE

This connector provides an RS485 interface from the panel to the

acquisition system. Connectors are provided for both RS485 in and

out.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 7 of 39

2.3 JUMPER SETTINGS

A row of jumpers are located on the internal processor board to set the

panel in different configurations.

J1 on = DEPTH IN METERS

J1 off = DEPTH IN FEET

J2 on = TENSION IN KG

J2 off = TENSION IN POUNDS

J3 on = CASED HOLE MODE (AM3K + CASE OR HOIST)

J3 off = OPEN HOLE MODE (AM5K + FOCUS)

J4 off = Rev D or earlier PC board

J4 on = Rev E PC board

J5 on = FOCUS mode

J5 off = AM5K standalone mode

J1 and J2 are only in affect when J5 is off

2.3.3 PROCESSOR REBOOT

In the event of a panel "lock up" or other malfunction, the processor

in the panel can be rebooted by turning off the panel, depressing the

T-ZERO and T-TEST buttons simultaneously then turn the power

back on while the buttons are depressed.

When the panel is rebooted, all the menu settings will be returned to

the factory default settings.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 8 of 39

3.0 MENU COMMANDS – OPEN HOLE MODE

This panel has internal software which allows it to be set for various

configurations. To change the settings, press the MENU button. The feature to be

set will be displayed on the DEPTH display. Press the MENU button again until

the feature you want to set is displayed.

In this mode (open hole) the panel is configured to work with the AM5K measuring

head and the Baker Atlas FOCUS acquisition system.

Jumper J3 must be removed to put the system in this mode (refer to section 2.3).

The parameters for each feature will be displayed on the LINE TENSION display.

Press the +/- switch to cycle through all the available parameters. When the

value you want to select is displayed, press the MENU button. ACCEPT will then

be displayed. Press + for yes, - for no.

Following is a listing of all the available settings.

3.1 CABLE SIZE

Functionality:Cable size selection automatically sets load pin angle setting

for the selected cable size.

If other is selected, the LCA value needs to be entered. This

value is based on the bend angle of the cable over the

tension wheel. This value is empirically derived and must be

furnished by the measuring head manufacturer (Kerr

Measurement Systems Inc.). Contact Kerr with the line

specifications.

Procedure: Use +/- switch to select cable size.

Indication: CABLE will be displayed on the DEPTH display and the

selections will be displayed on the LINE TENSION display.

Cable Size Values available

7-32

9-32

5-16

3-8

7-16

15-32

SLAM

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 9 of 39

S-SLAM

Other

Default value is 7-16

If OTHER is selected, two additional options are available.

LCA and WHLCIR.

LCA (Load Cell Angle). This setting allows for the use of a

sheave mounted load cell. The angle of the cable exiting the

sheave should be entered. Typically for a load cell mounted

above the top sheave the LCA would be 0. For a load cell

mounted to the bottom sheave the LCA would be 90 (90

degrees). Default value is 0.

WHLCIR (Wheel Circumference). This value is set to the

circumference of the measuring wheel to ensure the depth is

measured correctly. Default value is 2.0 ft.

3.2 TEN ALARM

Functionality:When preset tension value is reached, alarm sounds and

tension display flashes value

Procedure: Use +/- switch to set the tension alarm setting.

Indication: TALARM will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Selection: Each cable size will have a corresponding Tension Alarm

setting. Only the setting for the cable size selected (see

menu option 1) can be adjusted.

Default Values

7-32 1500

9-32 2400

5-16 2400

3-8 2400

7-16 2400

15-32 2400

SLAM 2400

S-SLAM 2400

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 10 of 39

3.3 TENSION SHUTDOWN

Functionality:When value is reached, alarm sounds, tension display flashes

value, and tension contact closure switch is closed. This can

be used to provide a signal to automatically stop the winch.

Procedure: Use +/- switch to set tension shutdown setting

Indication: TSHTDN will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Selection: Each cable size will have a corresponding Tension Alarm

setting. Only the setting for the cable size selected can be

adjusted.

Default Values

7-32 2000

9-32 3000

5-16 3500

3-8 3500

7-16 3500

15-32 3500

SLAM 3500

S-SLAM 3500

Note: The RESET or Approaching Surface button needs to be

depressed before the winch shutdown relay will de-energize.

3.4 DELTA TENSION ALARM

Functionality:When the delta tension setting is reached the alarm sounds.

In incremental mode, you must periodically press meter reset

or this alarm will sound when the tension reaches the set

value. In differential mode, the meter will reset itself and the

alarm will only sound on a quick change of tension.

Procedure: Use +/- switch to set the Delta Tension setting.

Indication: DT-TEN will be displayed on the DEPTH display and the

value being set will be displayed on the TENSION display as

it is being adjusted.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 11 of 39

3.5 DELTA TENSION SHUTDOWN

Functionality:When value is reached, alarm sounds, tension display flashes

value, and tension contact closure switch is closed. This can

be used to provide a signal to automatically stop the winch.

Procedure: Use +/- switch to set tension shutdown setting

Indication: DTSHDN will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Note: This parameter is derived from the reading on the analog

meter. If the DTSHDN value is set to 500 then whenever the

tension reading on the meter is greater than 500 the winch

shutdown relay will be activated.

Note: The RESET or Approaching Surface button needs to be

depressed before the winch shutdown relay will de-energize.

3.6 DEPTH ADJUST (Shim)

Functionality:The shim amount selected will automatically be added or

subtracted from the depth input.

Procedure: Use +/- switch to set the shim setting.

Indication: DP-ADJ will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set. The values are feet / thousand.

Default value is 0.

3.7 DEPTH ALARM

Functionality:When Alarm depth value is reached, the alarm will sound and

LED will flash. Pressing the LED will turn off alarm but the

light will continue to flash.

Procedure: Use +/- switch to set the depth alarm value.

Indication: DALARM will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Default value is 100’

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 12 of 39

3.8 MMD

Functionality:The MMD window determines when the next mark can be

detected. The cable must travel at least the distance of the

value set before a mark can be detected. Marks can only be

detected if they occur within this window. I.E. If the window

is set for 95', the cable must travel 95' from the last mark

before a new mark can be detected.

Procedure: Use +/- switch to change MMD window value.

Indication: MMD will be displayed on the DEPTH display and the window

value will be displayed on the TENSION display as it is being

set.

Pressing the MMD reset button clears the last mark setting.

Default value is 5’

3.9 MMD DETECT

Functionality:If STRONG is selected, only marks greater than 4 gauss will

be detected. If ALL is detected, any mark stronger than .3

gauss will be detected.

Procedure: Use +/- switch to toggle MMD detect value from STRONG to

ALL.

Indication: DETECT will be displayed on the DEPTH display and either

STRONG or ALL will be displayed on the TENSION display.

3.10 ENCODER

Functionality:The value selected will automatically be used as the encoder

input pulses per revolution (PPR) setting.

Procedure: Use +/- switch to set the ENCODER Pulse Per Revolution

setting.

Indication: ENCODR will be displayed on the DEPTH display and the

value will be displayed on the TENSION display.

Selection: 1200 (600 ppf or 1968 ppm)

780 (390 ppf or 1280 ppm)

512 (256 ppf or 1680 ppm)

Default value is 1200.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 13 of 39

3.11 ENCODER DIRECTION

Functionality:The value selected will toggle the encoder direction between

UP and Down.

Procedure: Use +/- switch to set the ENCODER direction setting.

Indication: ENCDIR will be displayed on the DEPTH display and either

UP or DN value will be displayed on the TENSION display.

Default value is UP.

3.12 ENG – MET UNITS

Functionality:The depth and tension values will be displayed in the units

selected.

Procedure: Use +/- switch to set the MEASUREMENT UNITS setting.

Indication: UNITS will be displayed on the DEPTH display. The

selection can be toggled through any combination of English

or Metric units. The selection will be displayed on the

TENSION display. The ENGLISH (green) LED display will be

lit when FT – LBS is selected and the METRIC (red) LED will

be lit when in any of the other modes.

Selection:

FT - LBS

FT-KG

MT - LBS

MT-KG

Default value is FT – KG

3.13 MMD PLAYBACK

Functionality:The depth of the first 25 detected marks is stored in memory

and can be played back.

Procedure: Use +/- switch to toggle through all of the marks that have

been detected. This starts from the last mark detected.

Pressing depth 0 will clear all the stored marks.

Indication: MMD DP will be displayed on the DEPTH display and the

mark depth will be displayed on the TENSION display.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 14 of 39

4.0 MENU COMMANDS – CASED HOLE MODE

In this mode (cased hole) the panel is configured to work with the AM3K

measuring head and the Baker Atlas CASE and HOIST acquisition systems.

Jumper J3 must be installed to put the system in this mode (refer to section 2.3).

4.1 LOGGING SYSTEM TYPE

Functionality:This setting determines the encoder pulse rate that will be

output to the acquisition system. The tension scale will also

be determined by this setting.

Procedure: Use +/- switch to select Logging System type.

Indication: LOGSYS will be displayed on the DEPTH display. and either

CASE or HOIST will be displayed on the TENSION display.

CASE:

Encoder output: 256 pulses per foot

Tension: 1.5vdc = 20,000 lbs

HOIST:

Encoder output: 600 pulses per foot

Tension: 5vdc = 10,000 lbs

Note: Use the 4-20ma output signal for tension to the HOIST

system. Install a 250 ohm resistor across the 4-20ma output

to get the 0 – 5vdc voltage drop required.

4.2 CABLE SIZE

Functionality:Cable size selection automatically sets load pin angle setting

for the selected cable size. Wheel size is also automatically

set for the selected cable size.

If other is selected, the LCA value needs to be entered. This

value is based on the bend angle of the cable over the

tension wheel. This value is empirically derived and must be

furnished by the measuring head manufacturer (Kerr

Measurement Systems Inc.). Contact Kerr with the line

specifications.

Procedure: Use +/- switch to select cable size.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 15 of 39

Indication: CABLE will be displayed on the DEPTH display and the

selections will be displayed on the LINE TENSION display.

Cable Size Values available

7-32

9-32

5-16 (Default setting)

3-8

Other

4.3 TENSION ALARM

Functionality:When preset tension value is reached, alarm sounds and

tension display flashes value

Procedure: Use +/- switch to set the tension alarm setting.

Indication: TALARM will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Selection: Each cable size will have a corresponding Tension Alarm

setting. Only the setting for the cable size selected (see

menu option 2) can be adjusted.

Default Values

7-32 1500

9-32 2400

5-16 2400

3-8 2400

4.4 DELTA TENSION ALARM

Functionality:When the delta tension setting is reached the alarm sounds.

In incremental mode, you must periodically press meter reset

or this alarm will sound when the tension reaches the set

value. In differential mode, the meter will reset itself and the

alarm will only sound on a quick change of tension.

Procedure: Use +/- switch to set the Delta Tension setting.

Indication: DT-TEN will be displayed on the DEPTH display and the

value being set will be displayed on the TENSION display as

it is being adjusted.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 16 of 39

4.5 TENSION SHUTDOWN

This value is added to the DTALRM or the TALRM settings to determine

when the shutdown relay is activated.

Example:

If the TNALRM is set to 4000 and the TSHTDN is set to 500, the ALARM

will sound when tension reaches 4000lbs and the OT contacts will close

when tension reaches 4500lbs

If the Tension Alarm is set to 2000 and the Shutdown is set to 150 then the

winch shutdown will occur at 2150 lbs.

Procedure: Use +/- switch to set tension shutdown setting

Indication: TSHTDN will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Selection: Each cable size will have a corresponding Tension Alarm

setting. Only the setting for the cable size selected can be

adjusted.

Note: The RESET or Approaching Surface button needs to be

depressed before the winch shutdown relay will de-energize.

4.6 DEPTH ALARM

Functionality:When Alarm depth value is reached, the alarm will sound and

LED will flash. Pressing the LED will turn off alarm but the

light will continue to flash.

Procedure: Use +/- switch to set the depth alarm value.

Indication: DALARM will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set.

Factory default value is 100’

4.7 CCL OFFSET

Functionality:The CCL depth will be displayed on the CCL DEPTH meter.

This makes it easier to monitor CCL depth in addition to

bottom of tool depth.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 17 of 39

Procedure: Use +/- switch to set the CCL offset depth

Indication: CCL will be displayed on the DEPTH display and the value

will be displayed on the TENSION display as it is being set.

4.8 DEPTH ADJUST (Shim)

Functionality:The shim amount selected will automatically be added or

subtracted from the depth input.

Procedure: Use +/- switch to set the shim setting.

Indication: DP-ADJ will be displayed on the DEPTH display and the

value will be displayed on the TENSION display as it is being

set. The values are feet / thousand.

Factory default value is 0.

4.9 ENCODER

Functionality:The value selected will automatically be used as the encoder

input pulses per revolution (PPR) setting.

Procedure: Use +/- switch to set the ENCODER Pulse Per Revolution

setting.

Indication: ENCODR will be displayed on the DEPTH display and the

value will be displayed on the TENSION display.

Selection: 1200 (600 ppf or 1968 ppm)

780 (390 ppf or 1280 ppm)

512 (256 ppf or 1680 ppm)

Default value is 1200.

4.10 ENCODER DIRECTION

Functionality:The value selected will toggle the encoder direction between

UP and Down.

Procedure: Use +/- switch to set the ENCODER direction setting.

Indication: ENCDIR will be displayed on the DEPTH display and either

UP or DN value will be displayed on the TENSION display.

Default value is UP.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 18 of 39

5.0 SYSTEM OPERATING INSTRUCTIONS

5.1 Power up panel and verify it is working properly.

5.2 Verify the panel is configured to match the system (head type, Acquisition

System, encoder, etc.)

5.3 Set up acquisition system:

5.4 Press T-Zero and verify that panel tension reads 0. Verify tension is

recorded on acquisition system.

5.5 Set line size to match cable size installed in head (refer to section 3).

5.6 Set Tension Alarm and the Tension Shutdown values.

5.7 Set depth adjust value.

5.8 Install cable in measuring head and lay it slack on the ground.

5.9 Press T-Zero to zero the tension value.

5.10 Press T-Test and verify that panel tension reads 5000 (mode 3) or 20000

(mode 5). Verify tension is being properly recorded on acquisition system.

5.11 Pull tool to depth 0 position. Press D-Zero and verify that panel depth

reads 0. Set acquisition system depth to 0 at this time.

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 19 of 39

6.0 DRAWINGS AND PARTS LISTS

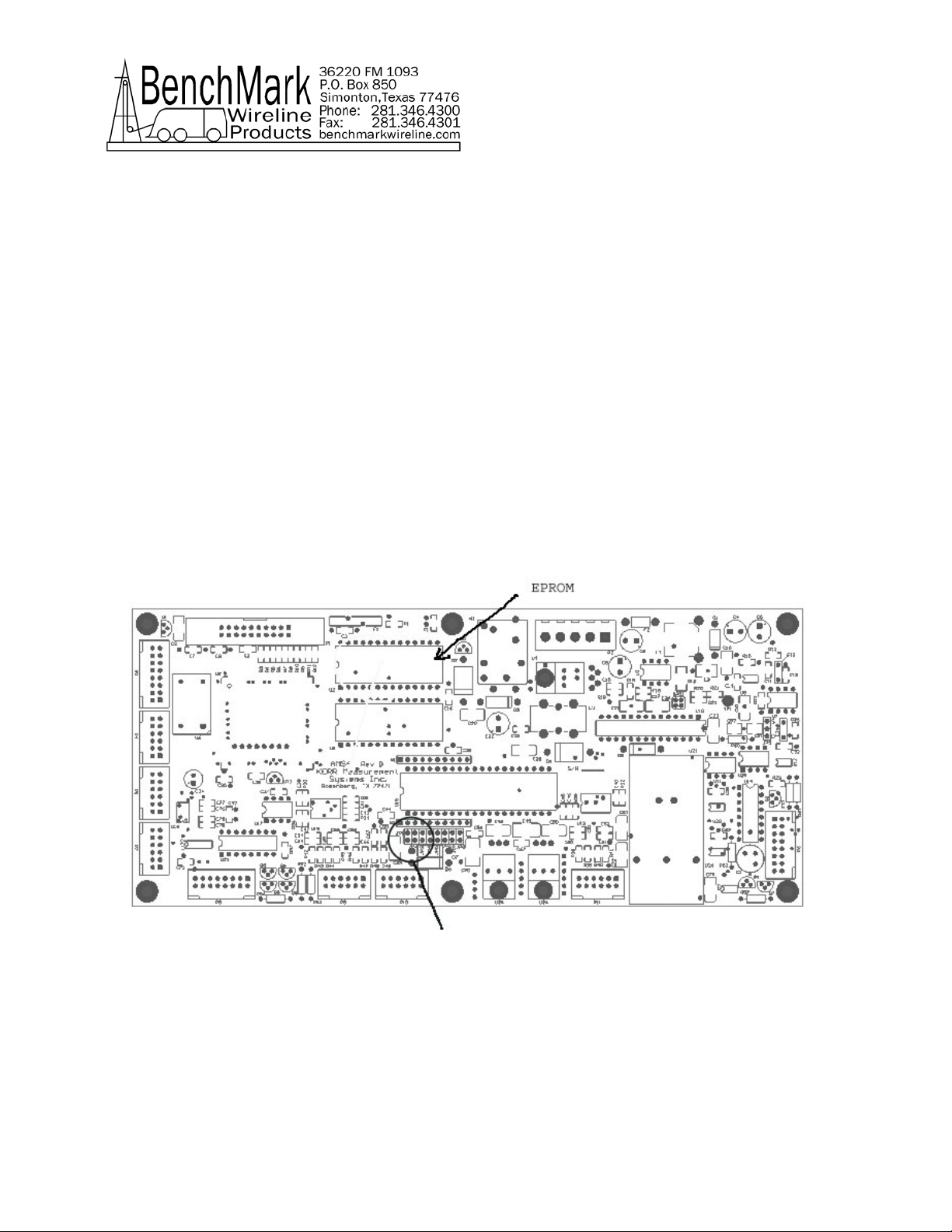

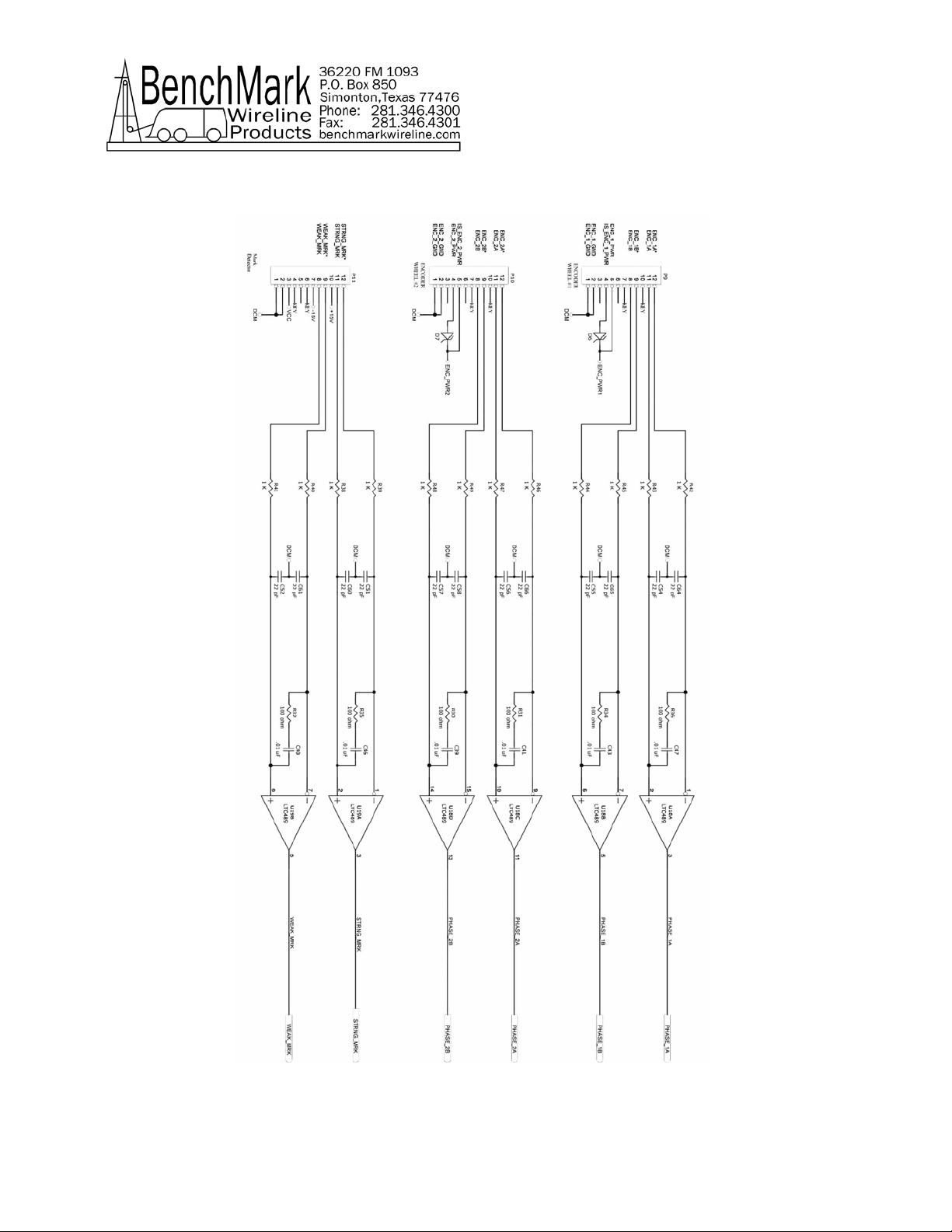

6.1 Main Processor Board

AMS4A040 PANEL USER MANUAL Rev H Nov 2006 Page 20 of 39

6.1.1 ENCODER AND MMD INPUTS

This manual suits for next models

2

Table of contents

Popular Automobile Accessories manuals by other brands

Hayman Reese

Hayman Reese 03371RW installation instructions

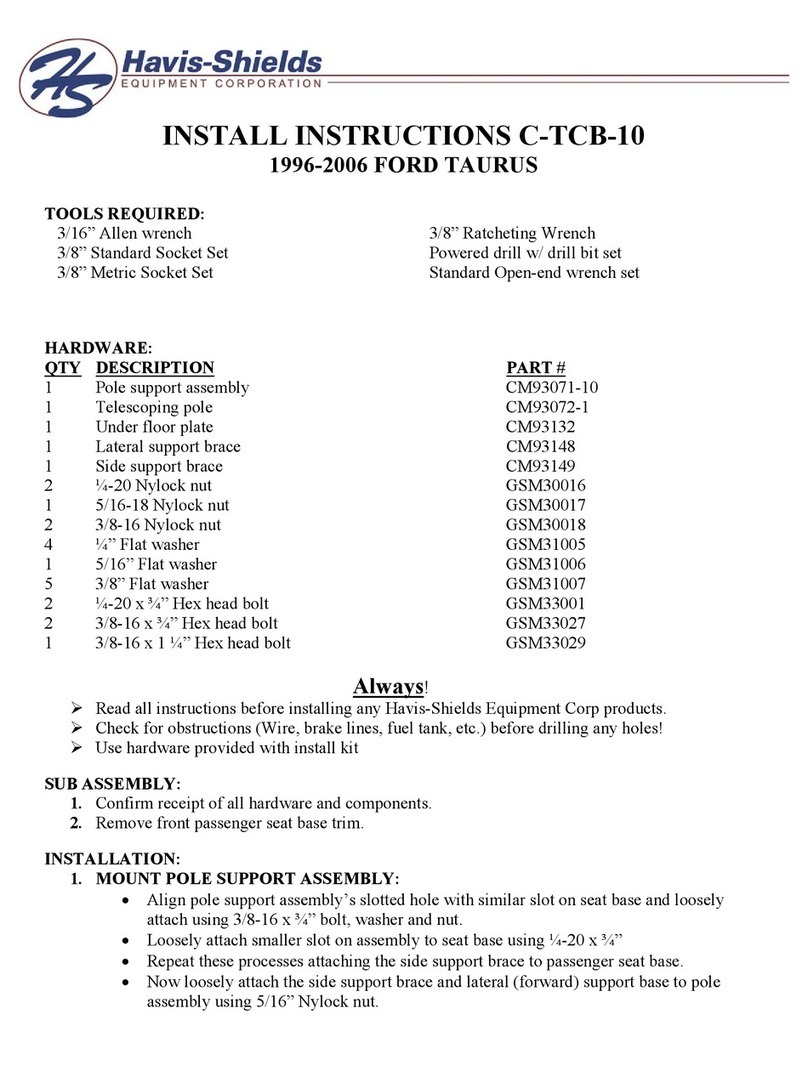

Havis-Shields

Havis-Shields 1996-2006 Ford Taurus C-TCB-10 Install instructions

benbat

benbat Oly BM 701 Instructions for use

Federal Signal Corporation

Federal Signal Corporation Legend LGD Installation, operation and service manual

Z Automotive

Z Automotive Double Bypass installation instructions

Edge

Edge CS2 Quick install guide