Benchmark 1239-301 User manual

20V MAX BRUSHLESS

1/2" IMPACT WRENCH

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

3042597

JD509820

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

Maximum initial battery voltage (measured without a load)

is 20 volts. Nominal voltage is 18 volts.

5 Year Limited Warranty

3 Year Limited Warranty on Battery and Charger

1

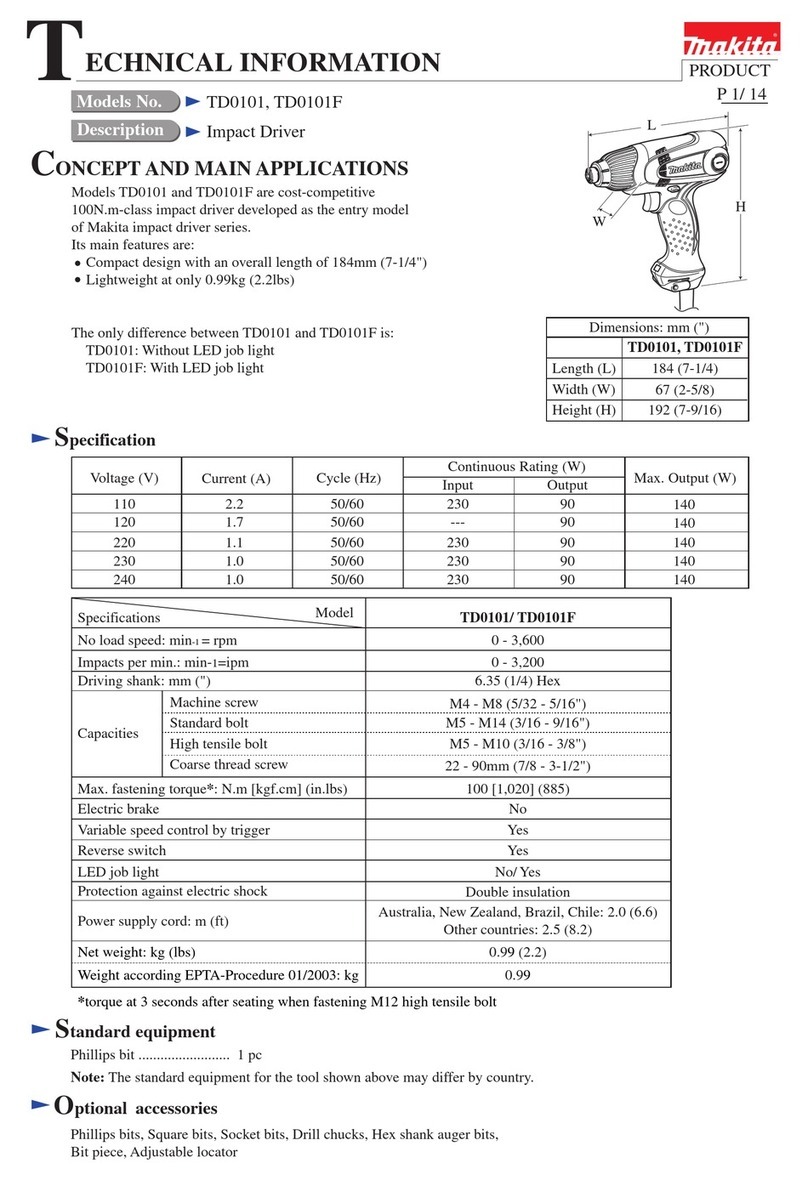

PRODUCT SPECIFICATIONS

20V MAX BRUSHLESS 1/2" IMPACT DRILL

Volts 20V

Variable Two Speeds 0–2200/0-2700 RPM (no load)

2 Variable Impact Speeds 0–2600/0-3000 BPM

Torque 380 ft/lbs.

Square Drive 1/2”

Weight 4.6 lbs. (2.08kg) with battery

Battery 20V 4Ah Li-ion (Maximum charged

battery voltage, measured without load,

is 20V with a nominal value of 18V)

Replacement Battery 5350-011 (4Ah) Charge time –

up to 120 minutes

Replacement Charger Assembly 5350-010 (2.4A) up to 120 minutes

charge time

NEED ASSISTANCE?

Call us on our toll-free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package

2

20V MAX BRUSHLESS 1/2" IMPACT WRENCH 1239-301

TABLE OF CONTENTS

Product Specifications .................................................................................. 1

Table of Contents .......................................................................................... 2

General Safety Instructions ........................................................................... 3

Eye, Ear & Lung Protection ............................................................................ 3

Electrical Safety ............................................................................................ 4

Power Tool Safety .......................................................................................... 4

Work Area Safety .......................................................................................... 4

Electrical Safety ............................................................................................ 4

Personal Safety ............................................................................................. 5

Power Tool Use and Care ............................................................................... 5

Specific impact wrench safety rules .............................................................. 6-7

Battery Pack Recycling ................................................................................. 8

Symbols ........................................................................................................ 9

20v Max Brushless 2vsr Impact Wrench.......................................................10

Assembly and Operation .............................................................................. 11

Checking the Battery Charge Status ............................................................ 11

Checking the Battery Pack .......................................................................... 11

Installing a Battery in the Impact Wrench .................................................... 12

Installing Impact Sockets ............................................................................. 13

Forward/Reverse Button............................................................................... 14

Variable Speed Trigger Switch...................................................................... 14

Speed and Auto-Stop Control ...................................................................... 15

Removing Fasteners .................................................................................... 15

Maintenance ............................................................................................... 16

General ....................................................................................................... 16

Lubrication .................................................................................................. 17

Lithium-ion Battery Performance ................................................................. 17

Lithium-ion Battery Maintenance ................................................................. 17

Battery Pack Removal and Preparation for Recycling.................................... 17

Exploded View ............................................................................................ 18

Parts List .................................................................................................... 19

Warranty ..................................................................................................... 20

3

GENERAL SAFETY INSTRUCTIONS

WARNING: Before using this tool or any of its accessories, read this manual

and follow all Safety Rules and Operating Instructions. The important precautions,

safeguards and instructions appearing in this manual are not meant to cover all

possible situations. It must be understood that common sense and caution are

factors which cannot be built into the product.

EYE, EAR & LUNG PROTECTION

SYMBOL MEANING

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CSA Z94.3 or

ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage.

Prescription eyeglasses ARE NOT a replacement for proper eye protection.

The usage of a safety standard compliant face shield placed over proper

safety glasses or goggles can reduce the risk of facial injury.

Non-compliant eyewear can cause serious injury if broken during the

operation of a power tool.

Use hearing protection, particularly during extended periods of operation

of the tool, or if the operation is noisy.

WEAR A DUST MASK THAT IS DESIGNED TO BE

USED WHEN OPERATING A POWER TOOL IN A

DUSTY ENVIRONMENT.

Dust that is created by power sanding, sawing, grinding, drilling, and other

construction activities may contain chemicals that are known to cause

cancer, birth defects,

or other genetic abnormalities. These chemicals include:

• Lead from lead-based paints

• Crystalline silica from bricks, cement, and other

masonry products

• Arsenic and chromium from chemically treated lumber

The level of risk from exposure to these chemicals varies, according to how

often this type of work is performed. In order to reduce exposure to these

chemicals, work in a

well-ventilated area, and use approved safety equipment, such as a dust mask

that is specifically designed to filter

out microscopic particles.

TO AVOID ELECTRICAL HAZARDS,

FIRE HAZARDS OR DAMAGE TO THE TOOL,

USE PROPER CIRCUIT PROTECTION.

This tool is wired at the factory for 120 V AC operation. It must beconnected

to a 120 V AC, 15 A circuit that is protected by a time-delayedfuse or circuit

breaker. To avoid shock or fire, replace power cordimmediately if it is worn, cut

or damaged in any way.

4

WARNING: Ventilation openings in batteries and chargers must always

be open to allow cooling air to circulate freely. Air vents that are blocked,

restricted or covered may result in the battery or charger overheating.

Overheating may lead to damage to the tool or cause a fire, resulting in

possible serious injury.

POWER TOOL SAFETY

WARNING: Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

Double insulated tools are equipped with a polarized plug (one blade is wider

than the other). This plug will only fit into a polarized plug one way.

If the plug does not fit into the outlet properly, reverse the plug. If it still does

not fit, contact a qualified electrician to install a polarized outlet. Do not alter

the plug in any way. Double insulation eliminates the need for the three-pronged

grounded power cord and grounded power supply system.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body

is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Do not use the power cord to carry the tool or to pull the

plug out of the outlet. Keep the power cord away from heat, oil, sharp edges,

and moving parts. Replace a damaged power cord immediately. A damaged power

cord increases the risk of electric shock.

When operating a power tool outdoors, use an outdoor-rated extension cord

type “W-A” or “W”. These cords are rated for outdoor use and they reduce the

risk of electric shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

5

tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

Avoid accidental start-ups. Verify that the switch is in the OFF position before

plugging in the tool. Carrying a power tool with a finger on the switch or plugging in

a tool that has the switch in the ON position invites accidents.

Remove adjusting keys and wrenches before turning the tool ON. A wrench or key

that is left attached to a rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance allows the operator to maintain better control of the tool in unexpected

situations.

Use safety equipment. Always wear eye protection.

Use a dust mask, non-skid safety shoes, a hardhat, or hearing protection when

appropriate.

POWER TOOL USE AND CARE

Use clamps or another practical means to secure and support the workpiece

to a stable platform. Holding the work in a hand or against the body is not stable

and may lead to loss of control.

Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the outlet before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures reduce the risk

of accidental start-ups.

6

When power tools are not in use, store them out of the reach of children or

untrained persons. Tools are dangerous in the hands of untrained users.

Maintain power tools with care. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less likely to bind, and are

easier to control.

Inspect the tool for misalignment or binding of moving parts, broken parts,

If it is

damaged, have the tool serviced before using it. Many accidents are caused by

poorly maintained tools.

Use only accessories that are recommended by the manufacturer for this

model. Accessories that are suitable for one tool may become hazardous when

used with another tool.

Tools servicing must be performed by qualified personnel. Service or

maintenance performed by non-qualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow the instructions

in the Maintenance section of this Manual. The use of unauthorized parts or failure

to follow the instructions in the Maintenance section of this Manual may create a

risk of electric shock or injury.

WARNING: Know your impact wrench. Do not plug in the charger or install

the battery in the tool until you have read and understand this Instruction

Manual. Learn the tool’s applications and limitations, as well as the specific

potential hazards related to this tool. Following this rule will reduce the risk of

electric shock, fire, or serious injury.

Always wear eye protection. Any power tool can throw foreign objects into

your eyes and cause permanent eye damage. ALWAYS wear safety goggles

(not glasses) that comply with ANSI safety standard Z87.1. Everyday glasses

have only impact resistant lenses. They ARE NOT safety glasses.

WARNING: Glasses or goggles not in compliance with ANSI Z87.1 could

cause serious injury when they break.

WARNING: Always use a safety shield, hearing protection and dust mask

when drilling concrete.

Use only impact sockets and accessories that are designed for use with an impact

wrench. Do not use chrome plated sockets and accessories. Chrome plated sockets

and accessories are designed for hand use only and MUST NOT be used with an

impact wrench. They may shatter and possibly cause serious injury.

Before each use, check the impact sockets and accessories for excessive wear or

cracks. Worn or damaged sockets or accessories may shatter and possibly cause

of the impact wrench.

Never use the impact wrench as a torque wrench. Always use a torque wrench to

adjust the fastener to the specified torque.

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

SERVICE

SPECIFIC IMPACT WRENCH SAFETY RULES

7

Keep the impact wrench handle and body clean and free of oil and grease. Always

use a clean dry cloth when cleaning. Do not use solvents, brake fluid, gasoline or

other petroleum products to clean the tool. They will damage the tool.

Do not wear neckties or loose clothing.

When wearing gloves, they must be tight fitting and slip resistant type. Leather

Always use two hands when operating the impact wrench. Use one hand on the

handle and the other on the front of the tool body.

Never place your hand so it is touching the socket or accessory when the tool is

turned ON. Your hand could be seriously injured.

Always remove the plug from the power source before installing or removing any

socket or accessory.

Be ready for components to shift when removing any fastener. The speed of the

fastener removal could cause unexpected shifting of the components.

WARNING: Only use the charger supplied with this tool to charge the

battery.

Do not store or carry a battery in a manner in which metal objects could contact the

exposed metal end. Do not place a battery in aprons, pockets, drawers, etc. with

loose nails, screws, keys etc. The battery could short circuit causing a fire, personal

injury or damage to the battery.

Never attempt to open the battery for any reason. If the housing of the battery

breaks or cracks, immediately discontinue use and do not recharge.

Do not charge the battery if it is wet or shows any evidence of corrosion.

A small leakage from the battery may occur under extreme usage, charging or

temperature conditions. This does not indicate a failure. However, if the outer seal

is broken and this leakage gets on your skin, follow these steps:

1. Wash immediately with soap and water.

2. Neutralize with a mild acid, such as lemon juice or vinegar.

3. If liquid gets into your eyes, flush immediately with clean water for a minimum

of 10 minutes and seek medical attention.

NOTE: The battery liquid is slightly acidic.

Do not incinerate the battery. It can explode in a fire.

Do not use an extension cord. Plug the charger cord directly into an electrical outlet.

Use the charger only in a standard 120V, 60 Hz electrical outlet.

Do not use the charger in wet or damp conditions. It is intended for indoor use only.

Do not use the charger near sinks or tubs. Do not immerse the charger in water.

Do not allow the cord to hang over the edge of a table or counter or touch hot

surfaces. The charger should be placed away from sinks and hot surfaces.

Do not operate charger if the cord or plug is damaged. Replace the damaged cord

and plug immediately.

8

Do not operate the charger if it has received a sharp blow, been dropped or

otherwise damaged in any way. Have a qualified technician examine the charger

and repair it if necessary. Do not disassemble the charger.

Do NOT charge the batteries when the work area or the battery temperature is at or

below 0° C (32° F) or above 45° C (113° F).

Unplug the charger when not in use and before cleaning or maintenance.

BATTERY PACK RECYCLING

To preserve our natural resources, please recycle or dispose of

batteries properly.

The batteries charged by this charger may contain chemicals

and metals that are harmful to the environment. Never dispose of

re-chargeable batteries in your normal household garbage or in

landfill sites as they will add to the pollution of the environment.

Consult your local waste authority for information regarding additional available

recycling and disposal options.

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

9

SYMBOLS

WARNING: Some of the following symbols may appear on the impact wrench

Study these symbols and learn their meaning. Proper interpretation of these

VVOLTS Three-phase alternating current

with neutral

AAmperes Direct current

Hz Hertz noNo load speed

WWatts Alternating or direct current

kW Kilowatts Class II construction

ųF Microfarads Splash-proof construction

LLiters Watertight construction

kg Kilograms Protective grounding at grounding

terminal, Class I tools

HHours .../min Revolutions or reciprocations per

minute

N/cm2Newtons per

square centimeter ØDiameter

Pa Pascals 0

OPM Oscillations per minute Arrow

MIN Minutes Warning symbol

SSeconds Wear your safety glasses

Alternating current Wear a dust mask

Three-phase alternating

current Wear hearing protection

3042597

JD509820

This symbol designates that this tool is listed with Canadian and U.S.

requirements by ETL Testing Laboratories, Inc.

Conforms to UL Std. 60745-1 and 60745-2-11.

Certified to CAN/CSA Std. C22.2 No. 60745-1 and 60745-2-11.

10

20V MAX BRUSHLESS 20V MAX 2VSR

IMPACT WRENCH

Battery charger

5350-010

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

½" Square

Drive

Forward / Reverse

Switch

Air

Vent

Variable Speed

Trigger

Battery

5350-023

Handle

Speed Selector

Buttons

Air Vents

Red LED

Green LED

11

ASSEMBLY AND OPERATION

CHECKING THE BATTERY CHARGE STATUS

The level of charge remaining in the battery can be checked by using the battery

LED power indicator that is contained on the end of the battery.

NOTE: The battery charge remaining may be checked while the battery is installed

in the tool with the ON/OFF switch turned OFF. It may also be checked while the

battery is removed from the tool. DO NOT check the battery charge remaining while

the battery is in the charger. You will get a false reading and you may also damage

the battery status system.

1. Press and hold the battery status button located on the end of the battery.

2. One or more of the Four LED lights in the LED window will come ON to indicate

the amount of charge that is remaining in the battery as follows:

Charge Level

Indicator

Amount of Charge

Remaining

0 -

10%

10 -

25%

25 -

50%

50 -

75%

75 -

100%

3. Release the battery status button to turn the LED’s OFF.

CHECKING THE BATTERY PACK

1. Place the battery charger (1) in a dry location near a 110–120V 60 Hz electrical

outlet (Fig. 1).

2. Plug the battery charger into the outlet and make sure the green LED indicator

light (5) comes ON. If it does not, refer to the chart (Fig. 2) to identify the

problem.

3. Turn the battery (2) upside down and slide it onto the charger. NOTE: Make sure

the grooves (3) in the sides of the battery slide over the matching tabs on the

charger (4) until the battery latch “clicks” into place.

FIG. 1

4 2 3

5 6 1

12

NOTE: a) When the charger is plugged into the wall receptacle and NO battery is on

the charger, the green indicator light (5) will turn ON indicating the charger is “live”.

b) When a discharged battery is installed on the charger, the green indicator light

will turn OFF and the red indicator light (6) will FLASH. The flashing red indicator

light indicates the battery is being charged.

c) If the red indicator light does not come ON, check to make sure battery pack is

slid fully onto the charger and the electrical outlet is working properly.

d) See Fig. 2 at right for other indicator light functions.

e) A discharged battery pack should be fully charged in up to 120 minutes.

f) It is normal for the battery charger to hum and be warm to the touch during

operation.

g) If the battery pack does not charge properly, check to make sure the electrical

outlet is “live”.

h) Do NOT charge batteries when the work area or the battery temperature is at or

below 5°C (41° F) or above 40°C (105° F).

Green Light Red Light Battery Inserted

Into Charger

Charging Status

ON OFF ON Charger connected to power

supply

OFF Flashing YES Battery being charged

ON OFF YES Battery fully charged

OFF ON YES Battery defective or bad contact

ON ON YES Battery too hot or too cold to

be charged

FIG. 2

INSTALLING A BATTERY IN THE IMPACT WRENCH

1. Remove the discharged battery (1) from the impact wrench by pressing downward

on the battery release button (2) and sliding the battery backward until it is removed

from the drill handle (3) (Fig. 3).

2. Slide the fully charged battery onto the matching keys (4) in the impact wrench

handle where the discharged battery has been removed.

NOTE: Make sure the slots in the battery are fully engaged with the mounting keys

in the handle handle. The battery release button will “click” into place when the

battery is fully installed.

WARNING: Do not immerse the battery pack in water. Sudden cooling could

cause a hot battery to explode or leak.

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

13

FIG. 3

INSTALLING IMPACT SOCKETS

WARNING: Use only impact sockets and accessories that are designed for use

with an impact wrench. Do not use chrome plated sockets and accessories. Chrome

plated sockets and accessories are designed for hand use only and MUST NOT be

used with an impact wrench. They may shatter and possibly cause serious injury.

WARNING: Always remove the battery from the tool before changing any

sockets, bits or accessories. You may injure your hand if the tool is started

accidentally.

To install a socket, press the square portion of the socket (1) onto the square drive

(2) of the impact wrench (Fig. 4).

1 2 3

FIG. 4

NOTE: Slide the socket fully onto the square drive so the socket retainer (3) will

hold the socket firmly in place

1

2

4 3

14

FORWARD/REVERSE BUTTON

This impact wrench is equipped with a forward/reverse button (1) (Fig. 5).

1. To operate the impact wrench in the reverse direction, press the forward/reverse

button to the RIGHT. This direction of rotation will loosen the fastener.

2. To operate the impact wrench in the forward direction, press the forward/reverse

button to the LEFT. This direction of rotation will tighten the fastener.

NOTE: Never press the forward/reverse button while the impact wrench it turned

ON. Damage to the tool will result.

VARIABLE SPEED TRIGGER SWITCH

This impact wrench is equipped with a variable speed ON/OFF trigger switch.

1. To start the impact wrench, gently squeeze the trigger switch (2) (Fig. 6).

NOTE: The impact wrench will turn at its slowest speed when the trigger switch is

depressed slightly. The impact wrench will turn at its fastest speed when the trigger

switch is fully depressed.

2. To stop the impact wrench, release the trigger switch.

NOTE: Never allow your hand to cover the air vents of the impact wrench. Running

the tool at slow speeds will cause it to heat up. If the tool gets warm while running

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

FIG. 5

at slow speeds, stop and allow it to cool.

FIG. 6

2

15

SPEED AND AUTO-STOP CONTROL

(Located on tool foot)

Push the selection button when the tool is in forward for low or high speeds. Push to

select the auto-stop feature when the tool is in reverse.

Speed Direction Lights Application

Low Forward On Low torque and finish work such

as plastic trim or installation

High Forward On Higher torque such as driving

self-tapping screws

Reverse Auto-Stop Reverse On To loosen screws or bolts

WARNING: For safety reasons, the operator must read the sections of this

Owner’s Manual entitled “GENERAL SAFETY WARNINGS”, “POWER TOOL

SAFETY”, “SPECIFIC SAFETY RULES”, “BATTERY AND CHARGER SAFETY”

and “SYMBOLS” before using this impact wrench.

Verify the following every time the impact wrench is used:

1. Safety glasses and hearing protection are being worn.

2. Socket or accessory is “impact wrench” rated.

3. Socket or accessory is in good condition.

Failure to observe these safety rules will significantly increase the risk of injury.

REMOVING FASTENERS

One of the most common uses for the impact wrench is to remove car wheel nuts

for rotating the tires. Car wheel nut removal is used for illustrative purposes.

DANGER: BEFORE ATTEMPTING TO REMOVE A CAR WHEEL, MAKE

SURE ALL JACKING, WHEEL BLOCKING AND WHEEL REMOVAL SAFETY

PROCEDURES ILLUSTRATED IN THE OWNER’S MANUAL FOR YOUR

CAR ARE FOLLOWED EXACTLY. FAILURE TO FOLLOW THOSE SAFETY

INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

1. Install the correct size of impact socket on the impact wrench.

2. Set the forward/reverse button to the RIGHT for removing fasteners.

3. Insert the battery in the tool.

4. Grasp the impact wrench handle (1) with one hand and the front housing of the

impact wrench (2) with the other hand (Fig. 7).

5. Place impact socket (3) onto the wheel nut.

NOTE: Make sure the socket is fully engaged with the nut to avoid potentially

damaging the socket or the wheel nut.

6. While holding the tool level with the ground and with a firm grasp, squeeze the

trigger switch (4).

16

When removing fasteners, do not allow the impact wrench to operate more than

15 seconds unless the fastener begins to turn. If the fastener fails to turn within

15 seconds, reverse the direction of rotation and operate the impact wrench in a

forward direction on the fastener for a few seconds. Now switch back to reverse

direction and remove the fastener. This procedure will usually break loose seized

or “frozen” fasteners.

FIG. 7

WARNING: Operating the impact wrench for more that 15 seconds at a time

on a seized or “frozen” fastener will place severe stress on the impact wrench and

cause damage. It may also break the fastner.

MAINTENANCE

GENERAL

WARNING: When servicing, use only identical replacement parts. The use

of any other part may create a hazard or cause product damage.

DO NOT use solvents when cleaning plastic parts. Plastics are susceptible to

damage from various types of commercial solvents and may be damaged by their

use. Use a clean cloth to remove dirt, dust, oil, grease etc.

WARNING: DO NOT allow brake fluids, gasoline, petroleum-based

products, penetrating oils, etc. to come into contact with plastic parts.

They contain chemicals that can damage, weaken, or destroy plastic.

DO NOT abuse power tools. Abusive practices can damage the tool and

the workpiece.

WARNING: DO NOT attempt to modify tools or create accessories.

Any such alteration or modification is misuse and could result in a hazardous

condition leading to possible serious injury. It will also void the warranty.

1239-301

20V MAX BRUSHLESS 1/2" IMPACT WRENCH

3 2 4 1

17

LUBRICATION

lubricant for the life of the unit under normal conditions. Therefore, no further

lubrication is required.

LITHIUM-ION BATTERY PERFORMANCE

Lithium-ion rechargeable batteries generally provide superior performance to

nickel-cadmium batteries when used in power tools.

• Faster charges

• Longer battery life

• More power

• Lighter weight

Lithium-ion batteries perform best and deliver peak output power at room

temperature (20° C or 68° F). When operated in lower temperatures, the battery

output will be reduced and it will NOT function below –20° C (-4° F). The output

power will increase as the heat generated by the battery during use increases the

internal temperature of the battery. The result is increased power as the tool is used.

LITHIUM-ION BATTERY MAINTENANCE

Lithium-ion batteries share many characteristics with nickel-cadmium batteries.

The major characteristic that is NOT shared with nickel-cadmium batteries is that

Lithium-ion batteries do not have a “memory” and do not require to be completely

discharged periodically. It is recommended that you charge your Lithium-ion

batteries after each use so they will be fully charged when needed.

NOTE: A fully charged battery will lose about 2% of its charge per month

during storage.

BATTERY PACK REMOVAL AND PREPARATION FOR RECYCLING

To preserve our natural resources, please recycle or dispose of batteries properly.

The batteries supplied with this tool may contain chemicals and metals that are

harmful to the environment. Never dispose of rechargeable batteries in your normal

household garbage or land fill sites because they will add to the pollution of the

environment.

Consult your local waste authority for information regarding available recycling and

disposal options.

WARNING: If the battery pack has been removed from the tool, cover the

terminals of the battery pack with electrical tape or heavy-duty adhesive

tape. Never touch both terminals with metal objects or body parts, because a

short circuit may result. Keep away from children. Do not attempt to destroy

or disassemble battery pack or remove any of its components. Rechargeable

batteries must be recycled or disposed of properly. Failure to comply with

these warnings could result in fire and serious injury.

18

EXPLODED VIEW

1239-301

20V MAX BRUSHLESS 20V MAX 2VSR IMPACT WRENCH

19

PARTS LIST

Always order by part number.

KEY # PART # PART NAME / QUANTITY KEY # PART # PART NAME / QUANTITY

14030090006

Inner Six Angles /4

22 2010180050 Motor Gear /1

24040030003 Spring Washer /6 23 3140020130 Type O Sealing Ring /1

34040010011 Washer /4 24 4020010015 M5x10 /2

43140100012 Rubber Sleeve /1 25 3140020108 Rubber Column /1

52020050080 Aluminum Armet /1 26 2020010028 Gear Box /1

63140020017 Type O Sealing Ring /1 27 1030240002

Motor

/1

72010080012 Shaft Coat /1 28 3010020033 Enclosure /2

82030020034 Washer #1 /1 29 1060050017 Switch /1

92040050021 Outer Shaft /1 30 3120030129 Direction Setting Button /1

10 4080070001 Ball /2 31 2030100064 Holder /1

11 2040200009 Washer #2 /1 32 4020010027 M3x6 /1

12 4080040001

Torque Spring

/24 33 2020180005 Cooling Aluminum Parts /1

13 2030020035 Inner Shaft /1 34 3150170016 Conducting Plate /1

14 2050060178 Planetary Gear /1 35 4030010106 St3.9x19 /6

15 2040050022 Inner Shaft /1 36

16 2010010027 Planetary Gear /3 37

2030100070 Hook /1

17 4110050003 Pin 6x15.5 /3 38

4020010031

M3x10

/1

18 2030020229 Washer #3 /1 39

4040080003

External Serrated Lock Washer /1

19 4010010084 Bearing 6002rs /1 40

4060010003

Hex Nut M3

/2

20 4100010014 Inner Clip /1

1290090046

Battery Pack

/1

21 2010090083 Ring Gear /1

WARNING: When servicing, use only original equipment replacement parts.

The use of any other parts may create a safety hazard or cause damage to the tool.

Any attempt to repair or replace electrical parts on this tool may create a safety

hazard unless repairs are performed by a qualified technician. For more information,

call the Toll-free Helpline, at 1-866-349-8665.

Table of contents

Other Benchmark Impact Driver manuals

Popular Impact Driver manuals by other brands

OEM Tools

OEM Tools 25811 Operating instructions and parts manual

PROPOINT

PROPOINT 8972440 user manual

Central Pneumatic

Central Pneumatic 69576 Owner's manual & safety instructions

Aircat

Aircat 1320 Operating instruction

MasterForce

MasterForce 241-0418 Operator's manual

Deltafox

Deltafox DP-EIW 4533 Translation of the original instructions for use