Benchmark 1282-721 User manual

5 Year Limited Warranty

READALLINSTRUCTIONSBEFOREFIRSTUSE.KEEPTHISMANUALFORFUTUREREFERENCE.KEEPAWAYFROMCHILDREN.

WEAREARPROTECTION

WEARAFACEMASK

WEARCSAAPPROVEDEYEPROTECTION

1

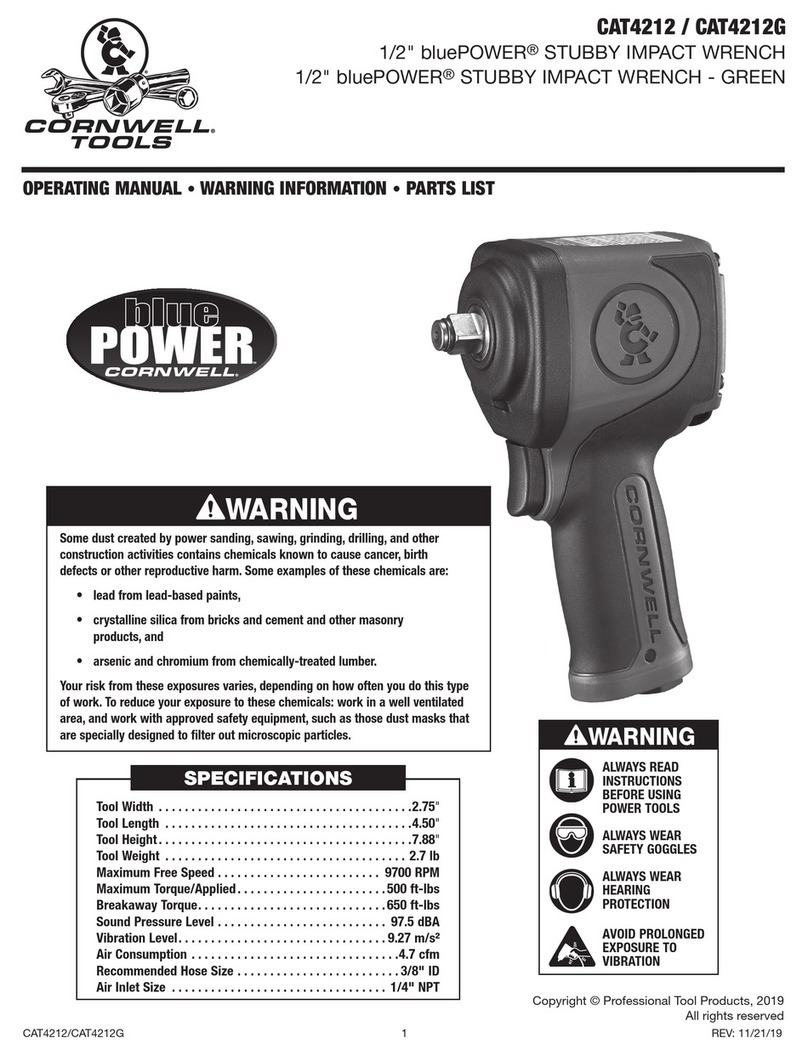

PRODUCTSPECIFICATIONS

1/2"DRIVEPNEUMATICIMPACTWRENCH

Drive

1/2"(13MM)

MaxDrivespeed

7,500RPM

MaximumTorque

740ft.Lbs.

MaxPSI

120PSI

AverageAirConsumption

3.7CFM@90PSI

Workingpressure

90PSI

Airinlet

1/4”NPT

RecommendedHose

3/8”

Weight

4.6lb(2.1kg)

•Pleasenote(wherethe¼”NPTconnecterisnotalreadyinstalledonthetool)yourtoolmaybeshippedwithablackplasticcapinstalledintheairinlet.Prythecapoutpriortoinstallingthe¼”NPTconnector.NEEDASSISTANCE?Callusonourtoll-freecustomersupportline:1-866-349-8665(MondaythroughFriday9am–5pmEasternStandardTime)TechnicalquestionsReplacementpartsPartsmissingfrompackage

NOTE

these instructions pertain to the tool only. Please refer to

your compressors operator’s manual and follow the manufactures

instructions.

1282-721

1/2"PNEUMATICIMPACTWRENCH

2

TABLEOFCONTENTSProductSpecifications.............................................................................................. 1TableofContents....................................................................................................... 2SafetyGuidelines....................................................................................................3-5Symbols...................................................................................................................... 6ToolSpecificWarnings.............................................................................................. 7Knowyour1/2"DrivepneumaticimpactWrench.................................................. 8AssemblyandOperating..................................................................................... 9-13Maintenance...................................................................................................... 14-16ExplodedView.......................................................................................................... 17PartsList............................................................................................................ 18-19Warranty................................................................................................................... 20

3

SAFETYGUIDELINESWARNING:ThismanualcontainsinformationthatrelatestoPROTECTINGPERSONALSAFETYandPREVENTINGEQUIPMENTPROBLEMS.Itisveryimportanttoreadthismanualcarefullyandunderstanditthoroughlybeforeusingtheproduct.Thesymbolslistedbelowareusedtoindicatethisinformation.DANGER!Potentialhazardthatwillresultinseriousinjuryorlossoflife.WARNING!Potentialhazardthatcouldresultinseriousinjuryorlossoflife.CAUTION!Potentialhazardthatmayresultinmoderateinjuryordamagetoequipment.Note-Theword"Note"isusedtoinformthereaderofsomethinghe/sheneedstoknowaboutthetool.PERSONALSAFETYTheseprecautionsareintendedforthepersonalsafetyoftheuserandothersworkingwiththeuser.Pleasetaketimetoreadandunderstandthem.

1282-721

1/2"PNEUMATICIMPACTWRENCH

4

Donotuseoxygenoranyothercombustibleorbottledgastopowerair-poweredtools.Failuretoobservethiswarningcancauseexplosionandseriouspersonalinjuryordeath.Useonlythecompressedairtopowertheair-poweredtools.Useaminimumof25’(7.6m)ofhosetoconnectthetooltothecompressor.Failuretocomplywillresultinseriousinjuryorlossoflife.

Riskofelectricshock:Donotexposeacompressortorain.Storeitindoors.Disconnectthecompressorfrompowersourcebeforeservicing.Compressormustbegrounded.Donotusegroundingadaptors.

Riskofpersonalinjury:Donotdirectcompressedairfromtheairhosetowardstheuserorotherpersonnel.

Riskforinhalation:Neverdirectlyinhaletheairproducedbythecompressor.

Riskofbursting:Donotadjustthepressureswitchorsafetyvalveforanyreason.Theyhavebeenpresetatthefactoryforthiscompressor’smaximumpressureTamperingwiththepressureswitchorthesafetyvalvemaycausepersonalinjuryorpropertydamage.

Riskofburns.Thepumpandthemanifoldgeneratehightemperatures.Inordertoavoidburnsorotherinjuries,donottouchthepump,themanifold,orthetransfertubewhilethecompressorisrunning.Allowthepartstocooldownbeforehandlingorservicing.Keepchildrenawayfromthecompressoratalltimes.

Riskofbursting:Makesuretheregulatorisadjustedsothatthecompressoroutletpressureissetlowerthanthemaximumoperatingpressureofthetool.Beforestartingthecompressor,pulltheringonthesafetyvalvetomakesurethevalvemovesfreely.Drainwaterfromtankaftereachuse.Donotweldorrepairtank.Relieveallpressureinthehosebeforeremovingorattachingaccessories.

Oxygen

nydrogen

Combustible

explosive

SYMBOLMEANING

5

DANGER!Keepchildrenawayfromtheworkarea.Donotallowchildrentohandlepowertools.Donotusethistoolinthepresenceofflammableliquidsorgases.Sparksthatarecreatedduringusemayignitegases.Keepairhoseawayfromheat,oil,andsharpedges.Checkairhoseforwearbeforeeachuseandensurethatallconnectionsareproper.Alwaysensurethattheworkpieceisfirmlysecuredleavingbothhandsfreetocontrolthetool.Alwaysensurethatthetoolhasstoppedbeforeputtingitdownafteruse,forsafetypurposesandtopreventpossibledamagetothetool/user.Keepproperfootingatalltimesinordertoensurecorrectbalance.WARNING!DonotallowunskilledoruntrainedindividualstooperatetheGravityFeedSprayGun.Locatethecompressorinawell-ventilatedareaforcooling,andaminimumof12”(31cm)awayfromthenearestwall.Protecttheairhoseandthepowercordfromdamageandpuncture.Inspectthemforweakorwornspotseveryweekandreplacethemifnecessary.Alwayswearhearingprotectionwhenusingtheaircompressor.Failuretodosomayresultinhearingloss.Donotcarrythecompressorwhileitisrunning.Donotoperatethecompressorifitisnotinastableposition.Donotoperatethecompressoronarooftoporanelevatedpositionthatcouldallowtheunittofallorbetippedover.*Alwaysreplaceadamagedgaugebeforeoperatingtheunitagain.*Donotconnectthetooltoasourceofcompressedairwithanoutletpressuregreaterthan120PSI.CAUTION!AlwaysensurethatthetoolhasstoppedbeforedisconnectingtheairsupplyDonotwearwatches,rings,bracelets,orlooseclothingwhenusinganyair-poweredtool

Donotoverloadthetool.Allowthetooltooperateatitsoptimumspeedformaximumefficiency.

Donotuseatoolthatisleakingair,thathasmissingordamagedparts,orthatrequiresrepairs.VerifythatallscrewsaresecurelytightenedForoptimalsafetyandtoolperformance,inspectthetoolbeforeeveryusage,inordertoensurefreemovementofthetrigger,safetymechanisms,andsprings.Alwayskeepyourairtoolcleanandlubricated.Dailylubricationisessentialtoavoidinternalcorrosionandpossiblefailures.Ensurethefloorisnotslipperyandwearnon-slipshoes.Floorsshouldbekeptcleanandclear.Alwaysfollowallworkshopsafetyrules,regulations,andconditionswhenusingthetoolandkeeptheworkareaclean.Carrythetoolbythehandleonly,keepingfingersawayfromthetrigger.Donotcarrythetoolbythehose,magazine,oranyotherparts.Donotusethetoolnearorbelowfreezingpoint,asdoingsomaycausetoolfailure.Donotstorethetoolinafreezingenvironmenttopreventiceformationonthetoolsoperatingvalves,asdoingsomaycausetoolfailure.Handlingandstorageofoil:Usewithadequateventilation.Avoidcontactofoilwitheyes,skin,andclothing.Avoidbreathingsprayormist.Storeinatightlyclosedcontainerinacool,dry,well-ventilatedareafreefromIncompatiblesubstances.Trippinghazard.Theairhosemaybecomeatrippinghazardwhenitisplacedintheworkarea.Usecarewhenwalkingintheworkarea.

1282-721

1/2"PNEUMATICIMPACTWRENCH

6

CAUTION!

Disconnecttoolfromtheairsupplyandturnoffthecompressor

beforeperforminganymaintenanceorchangingaccessories,whenclearingajammedfastener,whenthetoolisnotinuse,whenitisbeinghandedtoanotherperson,andwhenitisleftunattended.Failuretocomplymayresultinmoderateinjuryordamagetoequipment.

Usesafetygogglesandearprotection

:Wearsafetyglasseswithsideshieldswhenoperatingthetool/compressorandverifythatothersintheworkareaarealsowearingsafetyglasses.SafetyglassesmustconformtoAmericanNationalStandardsInstitute(ANSIZ87.1)requirementsandmustprovideprotectionfromflyingparticlesfromthefrontandthesides.

Air-poweredtoolsareloud,andthesoundcancausehearingdamage.Alwayswearearprotectiontopreventhearingdamageandloss.Failuretocomplymayresultinmoderateinjury.

Note:Recycle unwanted materials rather than disposing of them as waste. Sort the tools,

hoses, and packaging in specific categories and take to the local recycling center or

dispose of in an environmentally safe way.

SYMBOLS

WARNING:

Someofthefollowingsymbolsmayappearonthetool.Studythesesymbolsandlearntheirmeaning.ProperinterpretationofthesesymbolswillallowformoreefficientandsaferoperationThistool.

SYMBOLS

Read operator s manual: To reduce the risk of injury,

user must read and understand operator s manual

before using this product.

Risk to hearing :

using this tool.

In hearing loss.

Always wear ear protection when

Failure t o d o s o m a y r e s u l t

Eye protection: Always wear safety goggles, safety

glasses with side shields, or a full-face shield when

operating this product.

7

TOOLSPECIFICWARNINGS

•

Avoiddirectcontactwithaccessoryandworksurfaceduringandafterworkastheybecomeheatedandsharp.Wearsafetyglovestoprotecthands.

•

Operatorsmustbephysicallyabletohandlethebulk,weight,andpoweroftool.Donotforcethetool.

•

Repetitiveworkmotionsandexposuretovibrationcanbeharmfultohandsandarms.Ifnumbness,tingling,painorwhiteningoftheskinoccurs,stopusingthetool.

•

Stayclearofthehammerwhileinoperation.Flyingobjectscancausesevereinjury.

•

Avoid“free-running”.Thisoccurswhenthetoolisnotinpropercontactwiththework,eitherslidingofforbreakingthroughthinconcreteorrock.

•

Selectthecorrectshankandretainerforthetoolbeingused.

•

Neverusedullaccessoriesastheyrequireexcessiveworkpressureandcanbreak.

•

Maintainabalancedbodypositionandsecurefootingatalltimes.

•

Beawareofhiddenhazardsthatmayexistwhereyouareworking,suchaselectricwiresetc.

•

Thistoolisnotintendedforuseinanexplosiveatmosphere.

Alwaysensurethataccessoriessuchasimpactsockets

are

speciallydesignedforusewiththe1/2"drivepneumaticimpact

wrench.

•

Alsoensuretheyaresecuredandcorrectlyfastened

beforeconnectingthetooltotheairsupply.

•

Donotusethe1/2"drivepneumaticimpactwrenchforanytask

otherthanthatitisdesignedtoperform.

•

Donotusethe1/2"drivepneumaticimpactwrenchunlessyou

havebeeninstructedhowtodoso.

1282-721

1/2"PNEUMATICIMPACTWRENCH

8

KNOWYOUR1/2"DRIVEPNEUMATICIMPACTWRENCH

No.

Description

No.

Description

1

1/2"Squaredrivehead

4

Trigger

2

Airinletplug

5

Forward/reverseSwitch

3

Airdeflector

9

ASSEMBLYANDOPERATINGThe1/2"pneumaticimpactwrenchhasacompositebodytoreducestrain.Thewrenchdeliversupto740ft.lbs.oftorquetogettoughfasteningjobsdonefast.Thisimpactwrenchisdesignedforremovingandinstallingbolts,e.g.,automotivelugnutsontires,andforgeneralassemblywork.COMPATIBLECOMPRESSORSGUIDELINESFORPROPERUSEANDOPERATIONBesuretouseaproperaircompressorwithair-poweredtools.Thecompressorshouldbeabletosupplyaminimalairdeliveryof3.7CFM@90PSItoensurethecompressorcanruncontinuouslywiththetool.

AirCompressorSizeandPower

2HP

21/2HP

3+HP

5-6Gallons

Light-dutyandIntermittentuse

Light-dutyandIntermittentuse

Medium-dutyandIntermittentuse

8-11Gallons

Light-dutyandIntermittentuse

Medium-dutyandIntermittentuse

Heavy-dutyandIntermittentuse

15+Gallons

Medium-dutyandIntermittentuse

Heavy-dutyandContinuoususe

Heavy-dutyandContinuoususe

1282-721

1/2"PNEUMATICIMPACTWRENCH

10

AIRSYSTEMAlwaysuseclean,dry,regulated,compressedairat5.2to6.2bar(75to90PSI)Donotexceedthemaximumorminimumpressures.Operatingthetoolatthewrongpressure(Toolowortoohigh)willcauseexcessivenoiseorrapidwearoftool.

No.

Description

No.

Description

1

1/2"DrivePneumaticImpactWrench

6

Regulator0-90PSI(0-6.2bar)

2

Quickconnector

7

Filter

3

Quickcoupler

8

Cut-offvalve

4

Airhose

9

Aircompressor

5

Lubricator

11

WARNING

Keephandsandotherpartsofthebodyawayfromtheworkareaswhenconnectingthetooltotheairsupply.Failuretocomplycouldleadtoseriousinjuryorlossoflife.Itisrecommendedthatafilter-regulator-lubricatorisusedandlocatedasclosetothetoolaspossible.Ifafilter-regulator-lubricatorisnotinstalled,placeupto6dropsofcompressoroilintotheNPTinletplugbeforeeachuse.Ifafilter-regulator-lubricatorisinstalled,keeptheairfilterclean.Adirtyfilterwillreducetheairpressuretothetool,whichwillcausereductioninpower,efficiency,andgeneralperformance.Foroptimalperformance,installaquickconnectortothetoolandaquickcoupleronthose,ifapplicable.Verifythatalloftheconnectionsintheairsupplysystemaresealedinordertopreventairfromleaking.Failuretocomplymayresultinmoderateinjuryordamagetoequipment.

Airtools

Readthisinstructionmanualthoroughlybeforeusingthetool.

Readallsafetyguidelines(seesection"safetyguidelines”)atthebeginningofthismanual.Alwaysinspecttheairtoolpriortoeachuseto

-

ensureproperuseofpowersource.

-

determinewhetherthetoolisinproperworkingorder.Onlyuseaccessorieswhicharespeciallydesignedforusewiththistool.Drainthecompressortankdaily.Waterintheairsupplylinewilldamagethetool.Cleantheairinletandthefilterweekly.Linepressureshouldbeincreasedtocompensateforunusuallylongairhoses.Thehosediametershouldbe3/8”.Donotusethetoolifitisnotinproperworkingorder.Donotuseoxygenoranyothercombustibleorbottledgastopowerthistool.Donotusethistoolinthepresenceofanyflammableliquidsorgases.Keephoseawayfromheat,oil,andsharpedges.Checkhoseforwearandtear,ensurethatallconnectionsaresecure.Failuretocomplycouldleadtoseriousinjuryorlossoflife.

1282-721

1/2"PNEUMATICIMPACTWRENCH

12

OperationWARNING!

Potentialhazardthatcouldresultinseriousinjuryorlossoflife.

•

UseonlythesocketsspecificallydesignedforthispneumaticImpactWrench.Failuretocomplytocomplymayresultinmoderateinjuryordamagetothetool.

1. VerifythattheairsupplyiscleanbeforeoperatingthepneumaticImpactWrench.2. Plugincompressor,turnitonandsetthepressureregulatorto90PSI,attachoneendoftheairhosetothecompressorandtheotherendoftheairhose(1)tothepneumaticImpactWrench(2)Useplumber’stapetopreventairleak.3. Placeandlockthesocket(1)overthesquaredrive(2)ofthepneumaticImpactWrench.4. Pressthetrigger(1)ofthetoolforrotatingoperation.5. Adjusttheregulatorknob(1)attherearendofthetooltocontrolthespeedoftheairflowandtoadjustthedirectionofrotation(Forwardandreverse).

13

After using the tool, disconnect the

air hose (1) from the tool (2)

Note

: When repair the tool, use hex key

to remove the screws if necessary.

Storage

If it is necessary to store the tool for an extended period of time, apply a generous amount of

lubrication before storing.

The tool should be allowed to run for approximately 30 seconds after lubricating, in order to

ensure that the lubrication is uniformly distributed throughout the tool.

1282-721

1/2"PNEUMATICIMPACTWRENCH

14

Maintenance

NOTE:Do not store the tool anywhere temperatures will fall below freezing.

DANGER!

Disconnect the tool from the air compressor before maintenance/service,

adjusting and when it is not in use.

Repairs must be performed by a qualified service technician only.

Failure to comply will lead to serious injury or loss of life.

MAINTENANCEREQUIRED

DESCRIPTION

TOOLSORMATERIALSREQUIRED

MAXIMUMSERVICEINTERVAL

Eachuseor

every2hrs.

Monthly

Asneeded

Generalinspection-freemovement

Trigger,spring,

None

X

In-depthinspection

Wornorbrokenparts

X

X

Replacewornorbrokenparts

X

Lubrication

Seebelow

Pneumatic

tooloil

X

Lubrication: If the tool and the

equipped with an in-line lubrication system, place

up to 6 drops of pneumatic tool oil into the air inlet

before each use or after every 2 hours of

continuous use, depending on the characteristics

of the workpiece.

Air-operated tools must be inspected periodically, and worn or broken parts must be replaced

in order to keep tools operating safely and efficiently.

Inspect and replace worn or damaged 0-rings, seals, etc. Tighten all screws and caps

frequently in order to help prevent personal injury.

Loss of power or erratic action may be due to the following

-

Excessive drain in the air line.

-

Moisture or restriction in the air pipe.

-

Incorrect size or type of hose connector. Check the air supply and follow instructions.

-

Grit or gum deposits in the Die Grinder may also reduce performance.

15

•Inspectthetrigger,thespring,andthesafetymechanismforfreemovementonaregularbasisinordertoensurethatthesafetysystemisfullyfunctional.•Veritythatnopartislooseormissingandthatnopartisstuckorjammed.

•

Disconnectthetoolfromtheairsupply,clean,andstoreitinasafe,dry,andchildprooflocation,whentoolisnotinuse.

•Whentemperaturesarebelowfreezing,keeptoolsaswarmaspossibleusinganysafe,convenientmethod.•Checktheairsupplyforcorrectsizeandtypeofhoseconnectors.Toavoidlossofpowerorerraticaction,ensurethatthereisnoadditionaldrainontheairlineandnomoistureorrestrictionintheairpipe.TroubleshootingDANGER!If any of the following symptoms appear while the tool is in use,

turn it off and disconnect it from the air supply immediately.

Failure to comply will lead to serious injury or loss of life.

Disconnect the tool from the air supply before making any adjustments.

Repairs must be performed by a qualified service technician only.

The following chart lists common issues and solutions. Please read it

carefully and follow all instructions carefully.

Problem

Possiblecauses

Solutions

Toolrunsatnormalspeedbutlosespowerunderload.

1.

Motorpartsarewornordamaged.

2.

Camclutchiswornorstuckduetolackoflubricant.

1.

Lubricateclutchhousing.

2.

Checkforexcessclutchoil.Clutchcasesshouldbehalf

filled,asoverfillingcancausedragonhigh-speedclutchparts.Atypicaloiled/lubricatedwrenchrequires1/2ounceofoil.Greaselubrication:Heatisgenerateddueto

insufficientgreaseinthechamber.

Severeoperatingconditionsmayrequirefrequentlubrication.

1282-721

1/2"PNEUMATICIMPACTWRENCH

16

Problem

Possiblecauses

Solutions

Toolrunsatlowspeed.Airflowsslightlyfromexhaust.

1.

Dirtparticlesarejammedinmotor.

2.

Powerregulatorisinclosedposition.

3.

Airflowisblockedbydirt.

1.

Checkifthereisblockageintheairinletandthefilter.

2.

Pourpneumatictooloilintotheairinletasperinstructions.

3.

Operatethetoolbyreversingtherotationinback-and-forthdirectioninshortduration.Repeattheabovestepsasneeded.

Toolstopsworking.Airflowsfreelyfromexhaust.

Oneormoremotorvanesgotstuckduetomaterialbuildup.

1.

Pourpneumatictooloilintotheairinlet.

2.

Operatethetoolbyreversingtherotationinback-and-forthdirectionsinshortduration(whereverapplicable).

3.

Tapmotorhousinggentlywithplasticmallet.

4.

Disconnecttheairsupplyandoperatethemotorbymanuallyrotatingthedriveshank(whereverapplicable).

Tooldoes

notshutoff.

ThrottlevalveO-ringsaredislodgedfrominletvalve.

ReplaceO-rings.

17

1282-721

1/2"PNEUMATICIMPACTWRENCH

EXPLODEDVIEW

1282-721

1/2"PNEUMATICIMPACTWRENCH

18

PARTSLIST

WARNINGWhenservicing,useonlyoriginalequipmentreplacementparts.Theuseofanyotherpartsmaycreateasafetyhazardorcausedamagetothetool.Anyattempttorepairorreplaceelectricalpartsonthistoolmaycreateasafetyhazardunlessrepairsareperformedbyaqualifiedtechnician.Formoreinformation,

calltheToll-freeHelpline,at1-866-349-8665.

AlwaysorderbyPARTNUMBER,notbykeynumber.

Key#

Part#

PartName

Qty

1

1282-721-001

Frontsleeve

1

2

1282-721-002

Frontsealwasher

1

3

1282-721-003

Bushing

1

4

1282-721-004

AnvilCollar

1

5

1282-721-005

O-ring7.5X1.8

1

6

1282-721-006

Transmissionshaft

1

7

1282-721-007

Hammerhouse

1

8

1282-721-008

Hammerpin

2

9

1282-721-009

Hammerblock

2

10

1282-721-010

Bearing16002ZZ

1

11

1282-721-011

Frontcover

1

12

1282-721-012

Rotor

1

13

1282-721-013

Blade

6

14

1282-721-014

Pin4*46

1

15

1282-721-015

Cylinder

6

16

1282-721-016

Backcover

1

17

1282-721-017

Bearing60012ZZ

1

18

1282-721-018

RetainingRing

1

19

1282-721-019

GunBody

1

20

1282-721-020

Backsealwasher

1

21

1282-721-021

O-ring52.7X1.8

1

22

1282-721-022

Rotarycontroller

1

23

1282-721-023

O-ring34X2.4

1

24

1282-721-024

Closurecover

1

25

1282-721-025

Spring

1

26

1282-721-026

SteelBallSpring

1

27

1282-721-027

HexScrewM5X88.5

4

28

1282-721-028

Pin2.5X23

1

29

1282-721-029

O-ring3X1

2

30

1282-721-030

Trigger

1

19

1282-721

1/2"PNEUMATICIMPACTWRENCH

Key#

Part#

PartName

Qty

31

1282-721-021

Pin2.5X30

1

32

1282-721-032

AirInletPlug

1

33

1282-721-033

SwitchPin

1

34

1282-721-034

Compressionspring

1

35

1282-721-035

Exhaustcover

1

36

1282-721-036

O-ring20.3X2.3

2

37

1282-721-037

Washer

1

38

1282-721-038

O-ring16X2.5

2

39

1282-721-039

AirConnector

1

Table of contents

Other Benchmark Impact Driver manuals