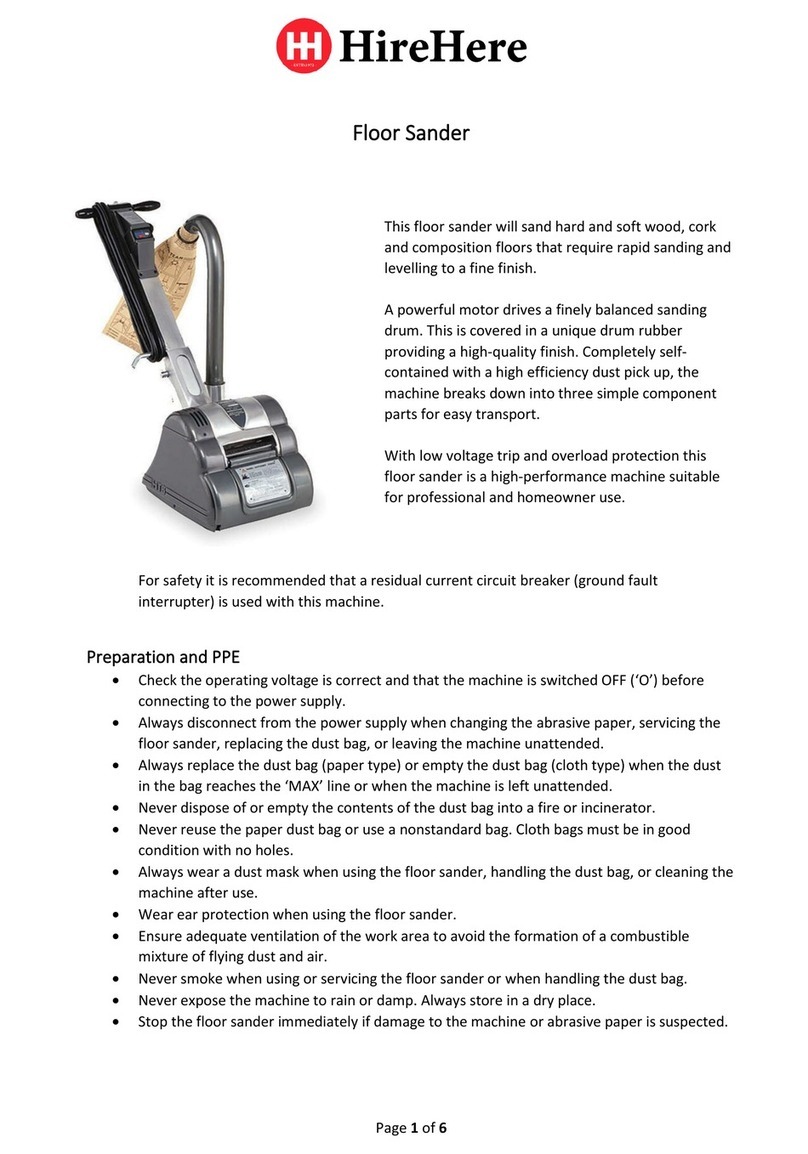

Benchmark 1262-000 User manual

5" RANDOM

ORBIT SANDER

5 year limited warranty on tool

JD2529U

1

PRODUCT SPECIFICATIONS

5" RANDOM ORBIT SANDER

Voltage 120V , 60 Hz AC

Amperes 2.5A

Speed 0-13000 min OPM (no load)

Sanding pad size: 5 inch (127 mm)

Sandpaper Attachment Hook & Loop

Weight 3.4 LB (1.53Kg)

NEED ASSISTANCE?

Call us on our toll-free customer support line:

1-866-349-8665

(Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package.

1262-000

5" RANDOM ORBIT SANDER

2

TABLE OF CONTENTS

Product specifications ................................................................................... 1

Table of contents ........................................................................................... 2

General safety warnings ............................................................................3 - 6

Specific safety rules for Random Orbit Sanders ............................................. 7

Guidelines for extension cords ....................................................................... 8

Symbols ........................................................................................................ 9

Know your sander ........................................................................................10

Assembly and operating ..........................................................................11 - 2

Maintenance ............................................................................................... 13

Exploded view ............................................................................................. 14

Parts list ..................................................................................................... 15

Warrant ....................................................................................................... 16

Save these instructions for reference

3

GENERAL SAFETY WARNINGS

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Before using this tool orany of itsaccessories, read this manual and follow

all Safety Rules and Operating Instructions. The important precautions, safeguards

and instructions appearing in this manual are not meant to cover all possible situations.

It must be understood that common sense and caution are factors which cannot

be built into the product.

EYE, EAR & LUNG PROTECTION

SYMBOL MEANING

ALWAYS WEAR EYE PROTECTION THAT CONFORMS

WITH CSA Z94.3 or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage.

Prescription eyeglasses ARE NOT a replacement for proper

eye protection. The usage of a safety standard compliant

face shield placed over proper safety glasses or goggles

can reduce the risk of facial injury.

Non-compliant eyewear can cause serious injury if broken

during the operation of a power tool.

Use hearing protection, particularly during extended periods

of operation of the tool, or if the operation is noisy.

WEAR A DUST MASK THAT IS DESIGNED TO BE

USED WHEN OPERATING A POWER TOOL IN A

DUSTY ENVIRONMENT.

Dust that is created by power sanding, sawing, grinding,

drilling, and other construction activities may contain

chemicals that are known to cause cancer, birth defects,

or other genetic abnormalities. These chemicals include:

• Lead from lead-based paints

• Crystalline silica from bricks, cement, and other

masonry products

• Arsenic and chromium from chemically treated lumber

The level of risk from exposure to these chemicals varies,

according to how often this type of work is performed. In

order to reduce exposure to these chemicals, work in a

well-ventilated area, and use approved safety equipment,

such as a dust mask that is specifically designed to filter

out microscopic particles.

4

1262-000

5" RANDOM ORBIT SANDER

ELECTRICAL SAFETY

WARNING

To avoid electrical hazards, fire hazards or damage to the tool, use proper

circuit protection.

This tool is wired at the factory for 120 V AC operation. It must be connected

to a 120 V AC, 15 A circuit that is protected by a time-delayed fuse or circuit

breaker. To avoid shock or fire, replace power cord immediately if it is worn,

cut or damaged in any way.

Save these instructions for reference.

5

WARNING

Read all safety warnings, instructions, illustrations and specifications provided

with this power tool. Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

Always use safety glasses, ear protection and a dust mask when operating the tool.

The term “power tool” in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operatinga power tool outdoors, usean extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in adamp location is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as a dust mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce personal injuries.

6

1262-000

5" RANDOM ORBIT SANDER

c)

connecting to power source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and

clothing away from moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become

complacent and ignore tool safety principles. A careless action can cause

severe injury within a fraction of a second.

4) Power tool use and care

a)

Do not force the powertool. Use the correct power tool for your application.The correct

power tool will do the job better and safer at the rate for which it was designed.

b)

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack,

if detachable, from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding

the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

5) Service

Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool

is maintained.

7

SPECIFIC SAFETY RULES FOR ROS

WARNING

Know your random orbit sander. Do not plug in the sander until you have read

and understand this Instruction Manual.

Learn the tool’s applications and limitations, as well as the specific potential

hazards related to this tool. Following this rule will reduce the risk of electric

shock, fire, or serious injury.

Always wear eye protection. Any power tool can throw foreign objects into your

eyes and cause permanent eye damage.

ALWAYS

Wear safety goggles (not glasses) that comply with ANSI Safety Standard Z87.1.

Everyday glasses have only impact resistant lenses. They ARE NOT safety glasses.

WARNING

Glasses or goggles not in compliance with ANSI Z87.1 could cause serious

injury when they break.

WARNING

Always use a dust mask when sanding.

WARNING

Always use hearing protection when sanding, particularly during extended

periods of operation.

WARNING

Always unplug the tool from the power source before changing the sandpaper

and when cleaning the tool.

Do not wear gloves, neckties or loose clothing.

Secure the workpiece. Use clamps or a vise to hold the work when practical.

It is safer than using your hand and it frees both hands to operate the tool.

Do not sand material too small to be securely held.

Make sure there are no nails or foreign objects in the part of the workpiece

to be sanded.

Always keep hands out of the path of the sanding pad. Avoid awkward hand posi-

tions where a sudden slip could cause your hand to move into the path

of the sanding pad.

To avoid injury from accidental starting, always remove the plug from the power

source before installing or removing sandpaper or the vacuum adaptor.

8

1262-000

5" RANDOM ORBIT SANDER

GUIDELINES FOR EXENSION CORDS

Make sure your extension cord is the proper size. When using an extension cord,

be sure to use one heavy enough to carry the current the tool will draw. An undersized

cord will cause a drop in line voltage resulting in loss of power and overheating.

The table below showsthe correct size to use according to cord length and

nameplate ampere rating. Ifin doubt, use the next heavier gauge.The smaller

the gauge number the heavier the cord.

Be sure your extension cord is properly wired and in good condition. Always replace

a damaged extension cord or have it repaired by a qualified electrician before

using it. Protect your extension cord from sharp objects, excessive heat and damp

or wet areas.

Use a separate electrical circuit for your power tools. This circuit must not

be less than 14 gauge wire and should be protected with either a 15A time delay

fuse or circuit breaker. Before connecting the power tool to the power source,

make sure the switch is in the OFF position and the power source is the same

as indicated on the nameplate. Running at lower voltage will damage the motor.

When operating a power tool outdoors, use an outdoor extension cord marked

“W-A” or “W”. These cords are rated for outdoor use and reduce the risk of electric

shock.

WARNING

Keep the extension cord clear of the working area. Position the cord so it will

not get caught on the workpiece, tools or any other obstructions while you are

working with the power tool.

WARNING

Repair or replace damaged or worn extension cords immediately.

Select the appropriate extension cord gauge and length using the chart below.

LENGTH OF EXTENSION CORD

110V-120V 25’(7.5 m) 50’ (15.25 m) 100’ (30.5 m) 150’ (45.7 m)

Amps AWG Wire Size

0-6 18 16 16 14

7-10 18 16 14 1 2

11-12 16 16 14 12

13-16 14 12 Not recommended

9

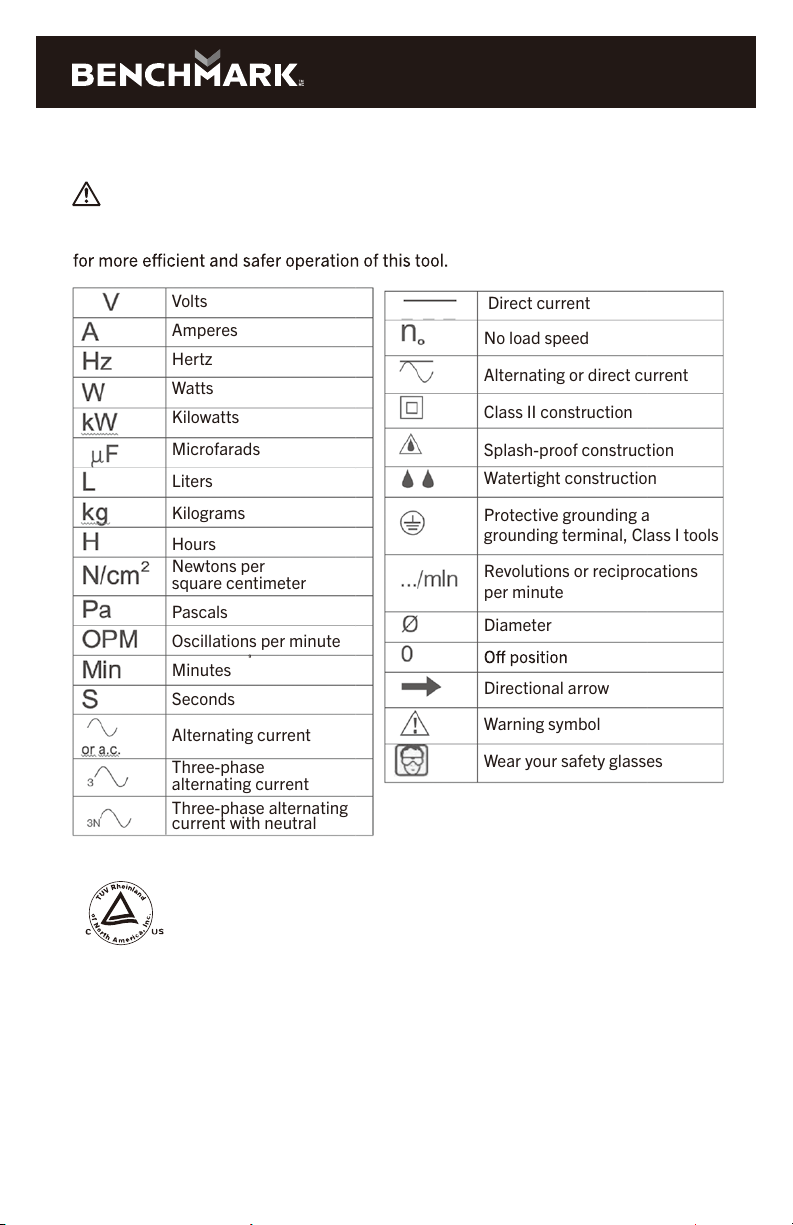

SYMBOLS

WARNING

Some of the following symbols may appear on the random orbit sander. Study these

symbols and learn their meaning. Proper interpretation of these symbols will allow

Volts

Amperes

Hertz

Watts

Kilowatts

Microfarads

Liters

Kilograms

Hours

Newtons per

square centimeter

Pascals

Oscillations per minute

Minutes

Seconds

Alternating current

Three-phase

alternating current

Three-phase alternating

current with neutral

Direct current

No load speed

Alternating or direct current

Class II construction

Splash-proof construction

Watertight construction

Protective grounding a

grounding terminal, Class I tools

Revolutions or reciprocations

per minute

Diameter

Directional arrow

Warning symbol

Wear your safety glasses

This symbol designates that this tool is listed with U.S. and

Canadian requirements by cTUVus Testing Laboratories, Inc.

UL62841-1,UL62841-2-4;

CSA C22.2#62841-1,CSA C22.2#62841-2-4 .

JD2529U

1262-000

5" RANDOM ORBIT SANDER

KNOW YOUR RANDOM ORBIT SANDER

1.

2.

Palm grip

3.

Sanding plate

4.

Dust bag

5.

Cooling vents

6.

Variable speed control dial

1

2

34

5

6

11

OPERATION AND ASSEMBLY

WARNING

Ensure tool is unplugged before making any adjustments

NOTE:

The drawings in the assembly and operating section of this manual may

INSTALLING A SANDING DISC

To install a sanding disc, firmly press the sanding disc (1) onto the hook and

loop pad (2) (Fig. 1).

NOTES:

a) Place the sanding disc so the holes in the disc line up with the matching holes

in the hook and loop pad.

b) Press the sanding disc firmly onto the hook & loop pad.

To remove the sanding disc (1), simply peel the disc away from the hook and

loop pad (2) (Fig. 2).

ON/OFF SWITCH

To turn the switch ON, press the left hand side of the switch (1) (Fig. 3).

To turn the switch OFF, press the right hand side of the switch (2).

CONNECTING THE DUST BAG ASSEMBLY TO THE SANDER

1. Slide the dust bag connector (1) into the dust port (2) in the rear of

the sander (Fig. 4).

2. When the dust bag connector is pressed fully into the dust port and mates

with the dust port keyway, ensure they “snap” into place.

CLEANING THE DUST BAG

Remove the dust bag assembly (1) from the dust port by carefully pulling it out

of the dust port (Fig. 5). Carefully shake the dust bag assembly with the end.

NOTE:

Make sure the dust bag tabs (3) mate with the dust port keyway (4).

When the dust bag connector is pressed fully into the dust port and mates with

the dust port keyway, ensure they “snap” into place.

Remove the dust bag assembly (1) from the dust port by carefully pulling it out

of the dust port (Fig. 5). Carefully shake the dust bag assembly with the end cap

opening (2) pointing downward to remove the sanding dust. Reinstall the dust bag

assembly as noted in Fig 4.

WARNING

For safety reasons, the operator must read the sections of this Owner’s Manual

entitled “General Safety Warnings”, “Power Tool Safety”, “Specific Safety Rules”,

“EXTENSION CORD SAFETY” and “Symbols” before using this sander.

12

1262-000

5" RANDOM ORBIT SANDER

Operation and Assembly – continued

VERIFY THE FOLLOWING EVERY TIME THE SANDER IS USED:

1. Sander cord is not damaged.

2. Sanding disc is in good condition and properly installed on the sander.

3. The workpiece is properly secured and free from any foreign objects.

4. Safety glasses, safety goggles, or face shield is being worn.

5. Hearing protection and dust mask are being worn.

NOTE:

Failure to adhere to these safety rules can greatly increase the chances

of serious injury.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

12

2

2

1

1

13

ASSEMBLING AND OPERATING

SANDING DISC SELECTION

Make sure you select the correct size and style of sanding disc for your sander.

The correct disc will:

• Have a diameter of 5"

• Have a row of eight 3/8" holes that match the hole pattern in the sander base.

• Have a backing for use with the hook & loop disc attachment system.

Selecting the correct grit and type of sandpaper is extremely important in achieving

a high-quality sanded finish. Aluminum oxide, silicon carbide and other synthetic

abrasives are best for power sanding. Natural abrasives such as flint and garnet

are too soft for economical use in power sanding.

In general, coarse grit will remove most material. Fine grit will produce the best

finish in all sanding operations. The condition of the surface to be sanded will

determine which grit will do the best job.

NOTE:

Where the sanding disc grits are shown numerically, higher numbers indicate

finer grit and lower numbers indicate coarser grit.

If the surface is rough, start with a coarse grit and sand until the surface is uniform.

Medium grit may then be used to remove scratches left by the coarser grit.

Fine grit should be used for finishing the surface.Always continue sanding with

each grit until the surface is uniform.

SANDING

Clamp or otherwisesecure your workpiece to prevent it from moving under

the sander while being sanded. Secure the workpiece in a vice if possible.

WARNING

Any unsecured workpiece could be thrown toward the operator causing injury.

Place the sander on the workpiece so the complete sanding disc surface is in

contact with the workpiece. Turn the sander ON by pressing on the left-hand side

of the ON/OFF switch. Move the sander slowly over the workpiece making successive

passes in parallel lines, circles or crosswise movements. Because the random

orbital motion of the sanding disc moves in tiny circles, it is not necessary to move

the sander with the grain or in the same direction for successive passes (Fig. 6).

CLEAN THE DUST BAG OFTEN

sanding dust.

DO NOT FORCE THE SANDER. The weight of the sander usually provides adequate

pressure. Let the sander and the sanding disc do the work. Applying added pressure

will slow the motor, increase the wear on the sandpaper and greatly reduce the

sander speed. Excessive pressure will overload the motor causing possible damage

from the motor overheating. It will also create an inferior finish on sanded work.

Any finish or resin on wood will soften from the frictional heat, causing sandpaper

to become clogged quickly. Do not sand in one spot too long as the sander’s rapid

action may remove too much material, making the surface uneven.

14

1262-000

5" RANDOM ORBIT SANDER

Clean the Dust Bag Often – Continued

Extended periods of sanding may tend to overheat the motor. If this occurs,

turn the sander OFF, wait until the sanding disc comes to a complete stop

and remove it from the workpiece. Check to make sure your hands have not

been covering the cooling vents. Let the motor cool before continuing the

sanding operation.

MAINTENANCE

WARNING

When servicing, use only identical replacement parts. The use of any other part

may create a hazard or cause product damage.

DO NOT use solvents when cleaning plastic parts. Plastics are susceptible to

damage from various types of commercial solvents and may be damaged by their

use. Use a clean cloth to remove dirt, dust, oil, grease etc.

WARNING

Do not allow brake fluids, gasoline, petroleum-based products, penetrating oils,

etc.to come into contact with plastic parts. They contain chemicals that can

damage, weaken or destroy plastic.

DO NOT abuse power tools. Abusive practices can damage the tool and the workpiece.

WARNING

DO NOT attempt to modify toolsor create accessories. Any such alteration

or modification is misuse andcould result in a hazardous conditionleading

to possible serious injury. It will also void the warranty.

Fig. 6

15

Maintenance – Continued

NOTE:

It has been found that electric tools are subjected to accelerated wear and possible

premature failure when they are used on fiberglass boats and sports cars, wallboard,

spackling compounds or plaster. The chips and grindings from these materials

are highly abrasive to electric tool parts such as bearings, brushes, commutators,

etc. Consequently, it is not recommendedthat this tool be used for extended

work on any fiberglassmaterial, wallboard, spackling compounds or plaster.

During any use on these materials it is extremely important that the tool is cleaned

frequently by blowing it out with an air jet.

WARNING

Always wear safety goggles or safety glasses with side shields during all sanding

operations. It is criticalthat you also wear safety goggles or safety glasses

with side shields and a dust mask while blowing dust out of the sanderwith

an air jet. Failure to take these safety precautions could result in permanent eye

or lung damage.

LUBRICATION

lubricant forthe life of the unit under normal conditions. Therefore, no further

lubrication is required.

1262-000

5" RANDOM ORBIT SANDER

EXPLODED VIEW

16

17

PARTS LIST

WARNING

When servicing, use only original equipment replacement parts. The use of any

other parts may create a safety hazard or cause damage to the sander.

Always order by PART NUMBER, not by key number.

Key # Part Name Part # Quantity

1 Housing 3011060039 1

2 PCB 1130010288 1

3 Carbon brush 1230010169 2

4 Switch 1061250004 1

5 Switch cover 3140080029 1

6 607-RS 4010010053 1

7 Screw ST3.9 x 14 4030010074 2

8 Screw ST3 9 x19 4030010106 10

9 Clamp 2030050002 1

10 Stator 1020060044 1

11 Brush holder 2030070014 2

12 Cord guard 3140010066 1

13 UL cord set 1190030078 1

14 Rotor 1010060044 1

15 6000-2RS (HCH 4010010054 1

16 Washer 2030020231 1

17 Fan 3150018887 1

18 Counter balance 2030020397 1

19 Eccentric 2010120030 1

20 Dust proof washer 2030170007 1

21 Bearing seat 2020130001 1

22 6002-2RS (HCH) 4010010084 1

23 Washer 2030020033 1

24 Screw M5X16 4020080004 1

25 Brake ring 3140050004 1

26 Plate 3150130172 1

27 Plate 1150020152 1

28 Screw M5X14 4020010081 4

29 Holder 3180040134 1

30 Dust bag 3180040130 1

18

1262-000

5" RANDOM ORBIT SANDER

WARRANTY

If this Benchmark tool fails due to a defect in material or workmanship within

five years from the date of purchase, return it to any Home Hardware store with

the original bill of sale for exchange. 3-year warranty for the battery and charger.

This warranty doesnot include expendableparts including but not limited

to blades, brushes, belts, light bulbs.

This warranty covers defects in material or workmanship only. It does not cover

normal wear and tear, failure due to abuse/misuse, or defects caused by careless

or accidental mishandling. If this Benchmark product is used for commercial

or rental purposes, this warranty does not apply.

Save these instructions for reference

NEED ASSISTANCE?

Call us on our toll-free customer support line:

1-866-349-8665

(Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package.

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

Made in China

1262-000

BENCHMARK TOOLS CANADA

ST. JACOBS, ONTARIO N0B 2N0

©2021 Home Hardware Stores Limited

TM

MC

CUSTOMER SERVICE/TECHSUPPORT

1-866-349-8665

* This BenchmarkTM product carries a five (5) year LIMITED warranty against defects

in workmanship and materials. See Owner’s Manual for full details.

5" RANDOM

ORBIT SANDER

JD2529U

Table of contents

Other Benchmark Sander manuals