Benchmark 1282 006 User manual

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

5 Year Limited Warranty

6" ORBITAL

PNEUMATIC SANDER

1

PRODUCT SPECIFICATIONS

6" ORBITAL PNEUMATIC SANDER

Sanding Pad 6" (150mm) hook & loop fastening system

Variable Free speed 0-12,000 OPM

Average Air consumption 4.5 cfm @ 90 PSI

Operating pressure 90 psi (6.3 bar)

1.8 lbs (0.8 kg)

Weight

Air inlet size 1/4”

Maximum air pressure 120 psi (8.3 bar)

Recommended hose size 3/8”

NEED ASSISTANCE?

Call us on our toll- free customer support line:

*Please note (where the ¼” NPT connecter is not already installed on the tool) your

tool may be shipped with a black plastic cap installed in the air inlet. Pry the cap

out prior to installing the ¼” NPT connector.

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

Note these instructions pertain to the tool only. Please refer to your

compressors operator manual and follow the manufacturers instructions.

• Technical questions

• Replacement parts

• Parts missing from package

1282 006

6" ORBITAL PNEUMATIC SANDER

2

TABLE OF CONTENTS

Product Specifications................................................................................... 1

Table of Contents........................................................................................... 2

Safety Guidelines ..................................................................................... 3-6

Symbols ....................................................................................................... 7

Tool Specific Warnings .................................................................................. 8

.................................................... 9

Know Your 6" Orbital Pneumatic Sander

..................................................................... 10-12

Assembly And Operating

Maintenance

Troubleshooting

Exploded View

....................................................................................... 13

Parts List .............................................................................................

............................................................................................

.................................................................................... 13-14

Warranty......................................................................................................

15

16-17

18

3

SAFETY GUIDELINES

DANGER! Potential hazard that will result in serious injury or loss of life.

WARNING:

WARNING! Potential hazard that could result in serious injury or loss of life.

CAUTION! Potential hazard that may result in moderate injury or damage to

equipment.

Note - The word " Note " is used to inform the reader of something he / she needs to

know about the tool.

This manual contains information that relates to PROTECTING PERSONAL SAFETY

and PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual

carefully and understand it thoroughly before using the product. The symbols listed

below are used to indicate this information.

These precautions are intended for the personal safety of the user and others working

with the user. Please take time to read and understand them.

PERSONAL SAFETY

Do not use oxygen or any other combustible or

bottled gas to power air-powered tools. Failure

to observe this warning can cause explosion

and serious personal injury or death.

Use only the compressed air to power the

air-powered tools. Use a minimum of 25’

(7.6 m) of hose to connect the tool to the

compressor. Failure to comply will result in

serious injury or loss of life.

•

Risk of electric shock: Do not expose a compressor to rain.

Store it indoors. Disconnect the compressor from power

source before servicing. Compressor must be grounded. Do

not use grounding adaptors.

•

Risk of personal injury: Do not direct compressed air from the

air hose towards the user or other personnel.

•

Oxygen

Hydrogen

Explosive

Combustible

SYMBOL MEANING

1282 006

6" ORBITAL PNEUMATIC SANDER

4

DANGER!

Keep children away from the work area. Do not allow children to handle

power tools.

Do not use this tool in the presence of flammable liquids or gases. Sparks

that are created during use may ignite gases.

Keep air hose away from heat, oil, and sharp edges. Check air hose for wear

before each use and ensure that all connections are proper.

Always ensure that the workpiece is firmly secured leaving both hands free

to control the tool.

Always ensure that the tool has stopped before putting it down after use, for

safety purposes and to prevent possible damage to the tool/user.

Keep proper footing at all times in order to ensure correct balance.

Always assume that the tool contains fasteners.

Do not point the tool toward yourself or anyone else.

•

•

•

•

•

•

•

•

Risk of inhalation: Never directly inhale the air produced by the

compressor.

•

Risk of bursting: Do not adjust the pressure switch or safety

valve for any reason. They have been preset at the factory for

this compressor’s maximum pressure Tampering with the

pressure switch or the safety valve may cause personal injury

or property damage.

•

Risk of burns. The pump and the manifold generate high

temperatures. In order to avoid burns or other injuries, do not

touch the pump, the manifold, or the transfer tube while the

compressor is running. Allow the parts to cool down before

handling or servicing. Keep children away from the compressor

at all times.

•

Risk of bursting: Make sure the regulator is

adjusted so that the compressor outlet

pressure is set lower than the maximum

operating pressure of the tool. Before

starting the compressor, pull the ring on the

safety valve to make sure the valve moves

freely. Drain water from tank after each use.

Do not weld or repair tank. Relieve all

pressure in the hose before removing or

attaching accessories.

•

SYMBOL MEANING

5

WARNING!

Do not allow unskilled or untrained individuals to operate the air tool.

Do not use the tool for any task other than that it is designed to perform.

Locate the compressor in a well-ventilated area for cooling, and a minimum

of 12” (31 cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture. Inspect

them for weak or worn spots every week and replace them if necessary.

Always wear hearing protection when using the air compressor. Failure to do

so may result in hearing loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or an elevated position that

could allow the unit to fall or be tipped over.

Always replace a damaged gauge before operating the unit again.

Do not connect the tool to a compressed air source with a pressure output

that is higher than 120psi.

•

•

•

•

•

•

•

•

•

•

CAUTION!

Always ensure that the tool has stopped before disconnecting the air supply.

Do not wear watches, rings, bracelets, or loose clothing when using any

air- powered tool.

Do not overload the tool. Allow the tool to operate at its optimum speed for

maximum eciency.

Do not use a tool that is leaking air, that has missing or damaged parts, or

that requires repairs. Verify that all screws are securely tightened.

For optimal safety and tool performance, inspect the tool before every usage,

in order to ensure free movement of the trigger, safety mechanisms, and

springs.

Always keep your air tool clean and lubricated. Daily lubrication is essential

to avoid internal corrosion and possible failures.

Ensure the floor is not slippery and wear non-slip shoes. Floors should be

kept clean and clear.

Always follow all workshop safety rules, regulations, and conditions when

using the tool and keep the work area clean.

Carry the tool by the handle only, keeping fingers away from the trigger. Do

not carry the tool by the hose, magazine, or any other parts.

Do not use the tool near or below freezing point, as doing so may cause tool

failure. Do not store the tool in a freezing environment to prevent ice

formation on the tools operating valves, as doing so may cause tool failure.

Handling and storage of oil: Use with adequate ventilation. Avoid contact of

oil with eyes, skin, and clothing. Avoid breathing spray or mist. Store in a

tightly closed container in a cool, dry, well-ventilated area free from

Incompatible substances.

Tripping hazard. The air hose may become a tripping hazard when it is

placed in the work area. Use care when walking in the work area.

•

•

•

•

•

•

•

•

•

•

•

•

1282 006

6" ORBITAL PNEUMATIC SANDER

6

CAUTION!

Disconnect tool from the air supply and turn o the

compressor before performing any maintenance or

changing accessories, when clearing a jammed

fastener, when the tool is not in use, when it is being

handed to another person, and when it is left

unattended. Failure to comply may result in moderate

injury or damage to equipment.

•

Use safety goggles and ear protection: Wear safety

glasses with side shields when operating the

tool/compressor and verify that others in the work

area are also wearing safety glasses. Safety glasses

must conform to American National Standards

Institute (ANSI Z87. 1) requirements and must

provide protection from flying particles from the front

and the sides.

Air-powered tools are loud, and the sound can cause hearing damage.

Always wear ear protection to prevent hearing damage and loss. Failure to

comply may result in moderate injury.

Note: Recycle unwanted materials rather than disposing of them as waste. Sort the

tools, hoses, and packaging in specific categories and take to the local recycling

centre or dispose of in an environmentally safe way.

•

7

1282 006

6" ORBITAL PNEUMATIC SANDER

8

TOOL SPECIFIC WARNINGS

WARNING! DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to the tool safety rules. If you use this

tool unsafely or incorrectly, you can suer serious personal injury.

Use the correct tool for the job. This tool was designed for a specific function.

Do not modify or alter this tool or use it for an unintended purpose.

Do not use the tool if any parts are damage broken or misplaced. Repair or

replace the parts.

Do not use any power tool with a malfunctioning power switch or control. A

power tool that fails to respond to the controls is dangerous and can cause an

injury. A qualified technician must repair and verify the power tool is

operating correctly before it can be used.

Never use a tool with a cracked or worn tool accessory. Change the tool

accessory before using it.

Do not cover the air vents.

Only use accessories that are specifically designed for use with the tool.

Ensure the accessory is tightly installed.

Only use an accessory that exceeds the speed rating (see Specifications).

Disconnect the power source before installing or servicing the tool.

Before using the tool on a workpiece, test the tool by running it at the highest

speed rating for at least 30 seconds in a safe position. Stop immediately if

there is any abnormal vibration or wobbling. Check the tool to determine the

cause.

Never force the tool. Excessive pressure could break the tool, resulting in

damage to your workpiece or serious personal injury. Excessive pressure is

the cause if your tool runs smoothly under no load, but roughly under load.

Keep hands and fingers away from the work area. Any part of the body

contacting the tool’s working parts could result in an injury.

Do not place the tool down until the tool’s accessory has stopped moving.

The accessory may catch the surface of work material and wrench itself free,

causing injury to the user or others in the work area.

Be aware of the rotation direction before starting the tool to reduce

hazardous situations due to unexpected rotation direction.

Never run the tool unless the abrasive pad is applied to the workpiece.

•

•

•

•

•

•

•

•

•

•

•

•

•

KNOW YOUR

6" ORBITAL PNEUMATIC SANDER

Hose and Dust bag port collar

ON/OFF trigger

9

Adapter

Hose Dust bag

Sanding pad

Compressor connection port

Speed control lever

AIR SYSTEM

Always use clean, dry, regulated, compressed air at 4.8 to 6.9 bar (70 to 100 PSI)

Do not exceed the maximum or minimum pressures. Operating the tool at the wrong

pressure (too low or too high) will cause excessive noise or rapid wear of tool.

1282 006

6" ORBITAL PNEUMATIC SANDER

10

ASSEMBLY AND OPERATING

No. Description No. Description

6" Orbital Pneumatic Sander

Quick connector

Quick coupler

Air hose

Lubricator

Regulator (0 to 8.5 bar)

Filter

Cut-o valve

Air compressor

1

2

3

4

5

6

7

8

9

Be sure to use a proper air compressor with air-powered tools. The compressor

should be able to supply a minimal air delivery of 4.56 CFM @ 90 PSI to ensure the

compressor can run continuously with the tool.

GUIDELINES FOR PROPER USE AND OPERATION

COMPATIBLE COMPRESSORS

Air Compressor

Size & Power

4 - 5 Gallons Light duty and

intermittent use

Light duty and

intermittent use

Light duty and

intermittent use

6 - 11 Gallons Light duty and

intermittent use

Medium duty and

intermittent use

Medium duty and

intermittent use

15+ Gallons Medium duty and

intermittent use

Heavy-duty and

continuous use

Heavy duty and

continuous use

1 1/2–2 HP 2 1/2 HP 3+ HP

11

INSTALLING AIR HOSE AND TOOL START UP

INSTALLING OR CHANGING SANDING DISCS (FIG. 1)

If a filter/regulator/lubricator is not installed on the air system, air operated tools

should be lubricated at with each use or after 2 hours work with 2 to 6 drops of oil,

depending on the work environment, directly through the male fitting in the tool

housing.

To attach a hook and loop sanding disc to your sander; turn over your sander so that

the backing pad is facing up. Push the paper on the sanding base ensuring it is stuck

to pad. To remove and replace, peel o and repeat process to install.

ON/OFF TRIGGER

To operate the tool, press the trigger located on the top of the tool.

To stop tool, release the trigger.

WARNING! Ensure you read, understand, and apply safety instructions before

use.

As a standard practice, drain water from the air compressor tank and air lines prior

to use each use (reference your compressor operators manual for detailed

instructions).

Remove cap and then install the 1/4" male connector into the air inlet port on the

tool.

Turn on the air compressor and allow it to build up pressure.

Adjust the air compressor’s regulator or the supply line regulator to 90PSI.

Connect compressor air hose to the 1/4" male connector installed on the sander.

Adjust the speed control switch on the tool to the desired variable speed.

Squeeze trigger gently. Start the sander at a slight angle to the work surface.

Move the sander slowly back and forth in wide overlapping areas. Let the sander

do the work. Do not put additional pressure on the sander.

This slows down the speed of the pad, reducing sanding eciency and puts

additional burden on the air tool motor.

When finishing sanding, lift sander o the work before releasing the trigger.

•

•

•

•

•

•

•

•

•

•

Fig 1

WARNING: Ensure the tool is disconnected from the air hose (compressor)

before making any adjustments or repairs to the tool.

1282 006

6" ORBITAL PNEUMATIC SANDER

12

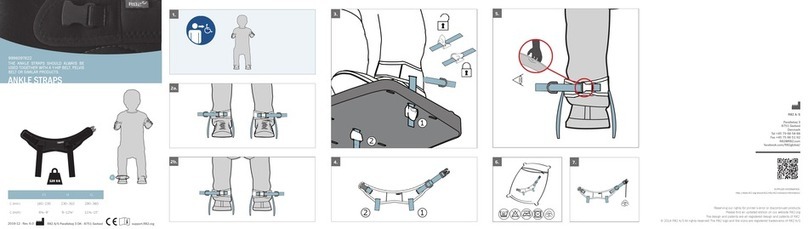

INSTALLING DUST HOSE AND DUST BAG (FIG.2).

Tie the dust bag to one end of the dust hose and then insert the other end of the

hose into the hose and dust bag port collar at the back of the sander. Turn the collar

clock-wise to lock hose into the tool. Turn the collar counter-clockwise to loosen

and remove the hose.

STORAGE

If it is necessary to store the tool for an extended period of time, apply a generous

amount of lubrication before storing. The tool should be allowed to run for

approximately 30 seconds after lubricating in order to ensure that the lubrication is

uniformly distributed throughout the tool.

OPERATING THE SPEED CONTROL LEVER

The speed control lever is located on the underside of the tool just below the ¼”

connector.

To increase speed pull lever up (away from body of tool). To decrease speed, push

the lever toward the body of the tool.

Locked pipe

Fig 2

13

WARNING:

NOTE: Do not store the tool anywhere temperatures will fall below freezing.

REMOVING AND REPLACING SANDING PAD

Disconnect tool from air supply before maintenance/service, adjusting, cleaning

jams, reloading and when not in use. Repairs must be performed by a qualified

service technician only. Failure to comply will lead to serious injury or loss of life.

WARNING: Ensure tool is disconnected from the air hose (Compressor) before

removing base from tool

MAINTENANCE

Lubricate the air sander daily with a few drops of air tool oil dripped into the air inlet

When not in use, disconnect from air supply, clean tool, and store in a safe, dry,

childproof location.

The following chart lists common operating system issues and solutions.

Please read it carefully and follow all instructions carefully.

Use the open wrench included with your tool and slide wrench between the sanding

pad and the base of the tool to engage the nut. Turn the wrench clock-wise while

holding the sanding pad (to stop it from turning). Continue turning wrench until the

sanding pad separates from the base of the tool. Reverse process to re-install

sanding pad on base.

Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect

size or type of hose connectors. To remedy check the air supply.

Grit or gum deposits in the tool may also reduce performance. If your model

has an air strainer (located in the area of the air inlet), remove the strainer, and

clean it.

Clean the tool after use. Do not use worn, or damaged tool.

Loss of power or erratic action may be due to the following:

•

•

•

WARNING:

If any of the following symptoms appear while the tool is in use, turn it o and

disconnect it from the air supply immediately. Failure to comply will lead to serious

injury or loss of life. Disconnect the tool from the air supply before making any

adjustments. Repairs must be performed by a qualified service technician only.

TROUBLE SHOOTING

a)

b)

1282 006

6" ORBITAL PNEUMATIC SANDER

14

PROBLEM POSSIBLE CAUSES REMEDIES

Tool runs at normal

speed but loses

under load

1. Motor parts worn.

2. Cam clutch worn or sticking

due to lack of lubricant.

1. Lubricating clutch housing.

2. Check for excess clutch oil. Clutch cases

need onlu be half full. Overfilling can cause

drag on high speed clutch parts, ie. a

typical oiled/lubricated wrench requires

1/2 ounce of oil. GREASE LUBRICATED:

NOTE: Heat usually indicates insucient

grease in chamber. Severe operating

conditions may require more frequent

lubrication.

Tool runs slowly.

Air flows slightly

from exhaust

1. Motor parts jammed with dirt

particles

2. Power regulator in closed

position

3. Air flow blocked by dirt.

1. Check air inlet filter for blockage.

2. Pour air tool lubricating oil into air inlet

as per instructions.

3. Operate tool in short bursts quickly

reversing rotation back and forth where

applicable.

4. Repeat above as needed. If this fails

return to service centre.

Tools will not run.

Air flows freely

from exhaust

1. One or more motor vanes

stuck due to material build up.

1. Pour air tool lubricating tool into air

inlet.

2. Operate tool in short bursts of forward

and/or reverse rotation where applicable.

3. Tap motor housing gently with plastic

mallet.

4.Disconnect supply. Free motor by

rotating drive shank manually where

applicable.

5. If tool remains jammed return to service

centre.

Tool will not shut

o

1. “O” rings throttle valve

dislodged from seat inlet valve.

1. Replace“O” ring or return to service

centre.

15

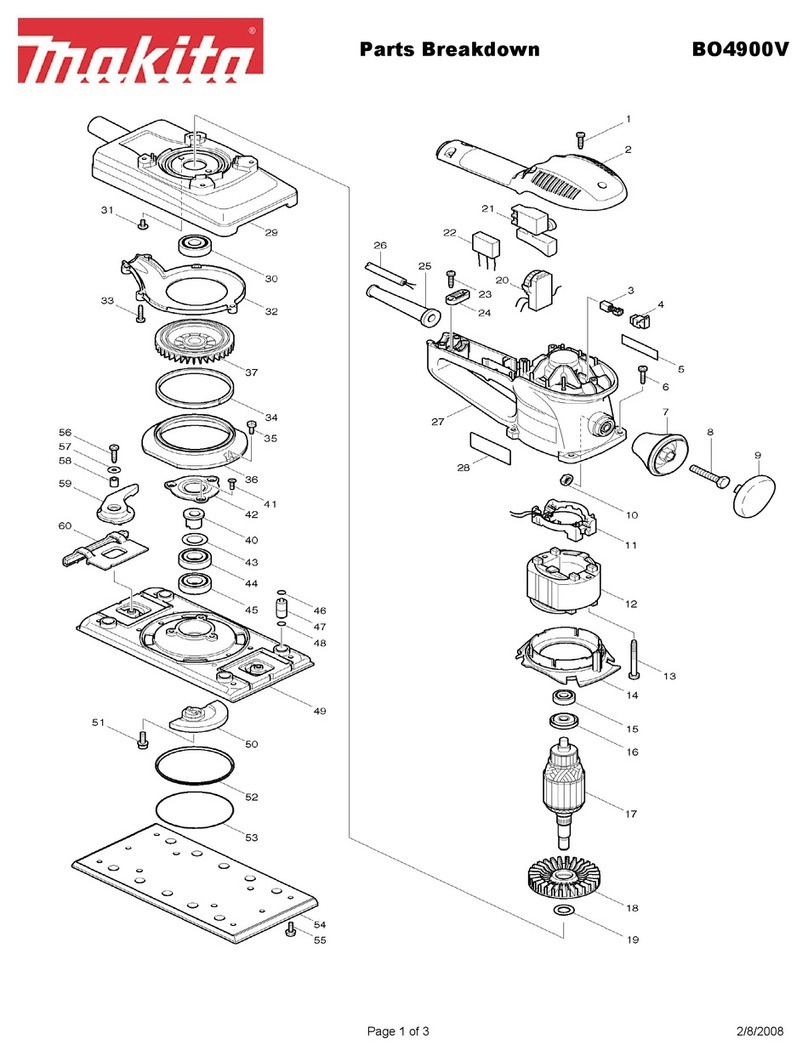

EXPLODED VIEW

16

1282 006

6" ORBITAL PNEUMATIC SANDER

PARTS LIST

WARNING: When servicing, use only original equipment replacement parts.

The use of any other parts may create a safety hazard or cause damage to the tool.

Any attempt to repair or replace electrical parts on this tool may create a safety

hazard unless repairs are performed by a qualified technician. For more information,

call the Toll-free Helpline, at 1-866-349-8665.

Always order by part number.

Key # Part # Part Name Quantity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

05.02.24.0006-01

03.02.02.055.016

03.02.02.002.011

03.02.02.055.020

03.05.02.011

03.02.02.057.002

03.02.01.027.023

03.02.02.032.001

03.05.01.188

03.05.02.117

03.02.02.055.014

03.02.01.059.020

03.02.02.002.016

03.05.04.151

03.05.01.256

03.02.02.055.002

03.02.02.055.005

03.05.02.051

03.05.03.047

03.02.02.056.005

03.02.02.055.013-05

03.02.02.055.001

03.05.04.046

03.02.02.055.004

03.05.01.067

03.02.02.056.003

03.02.02.056.001

03.02.02.056.002

03.02.02.056.004

Sanding pad

Main shaft

Retainer ring

Bearing washer

Bearing

Drive shaft

Woodru key

Lock ring

O-ring 37.5x3.55

Bearing 6001ZZ

Front cover

Rotor

Rotor blade

Pin 3x28

O-ring 6.7x1.8

Cylinder

Rear cover

Bearing 6000ZZ

Retainer ring 10

Protective shield

Housing

Housing sheath

Pin 3x20

Trigger

O-ring 14x1.6

Vacuum suction joint

Lock pipe

Vacuum suction straight pipe

Vacuum suction bend pipe

1

1

1

1

1

1

1

1

1

1

1

1

5

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

Key # Part # Part Name Quantity

30

31

32

33

34

35

36

37

38

39

03.02.02.055.007

03.02.02.055.010

03.02.02.055.009

03.05.01.043

03.02.02.055.008-01

03.05.01.197

03.02.02.055.006

03.05.01.284

03.02.02.055.011

03.02.02.055.021

Switch plug

Switch pin

Switch spring

O-ring 11.5x1.8

Air inlet

O-ring 4.2x1

Switch pole

O-ring 8.5x1.5

Adjust knob

Retainer ring 12

1

1

1

1

1

1

1

1

1

1

17

WARRANTY

BENCHMARK WARRANTY

If this Benchmark tool fails due to a defect in material or workmanship within five

years from the date of purchase, return it to any Home Hardware store with the

original bill of sale for exchange. 3-year warranty for the battery and charger. This

warranty does not include expendable parts including but not limited to blades,

brushes, belts, light bulbs. This warranty covers defects in material or workmanship

only. It does not cover normal wear and tear, failure due to abuse/misuse, or defects

caused by careless or accidental mishandling. If this Benchmark product is used for

commercial or rental purposes, this warranty does not apply.

1282 006

6" ORBITAL PNEUMATIC SANDER

18

6" ORBITAL

PNEUMATIC SANDER

*5 year limited warranty on tool

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

Made in China

1282 006

BENCHMARK TOOLS CANADA

ST. JACOBS, ONTARIO N0B 2N0

©2021 Home Hardware Stores Limited

TM

MC

CUSTOMER SERVICE/TECH SUPPORT

1-866-349-8665

* This BenchmarkTM product carries a five (5) year LIMITED warranty against defects

in workmanship and materials. The charger and batteries carry a three (3) year

LIMITED warranty. See Owner’s Manual for full details.

Table of contents

Other Benchmark Sander manuals

Popular Sander manuals by other brands

EXTOL PREMIUM

EXTOL PREMIUM 8891846 Translation of the original user manual

Bosch

Bosch Professional GSS 18V-13 Original instructions

Black & Decker

Black & Decker BDERO600 instruction manual

Westfalia

Westfalia 85 88 46 instruction manual

Etac

Etac R82 ANKLE STRAPS quick guide

Alto

Alto Classic 8 Operator's manual