Benchmark 1262-200 User manual

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

3042597

JD2442U

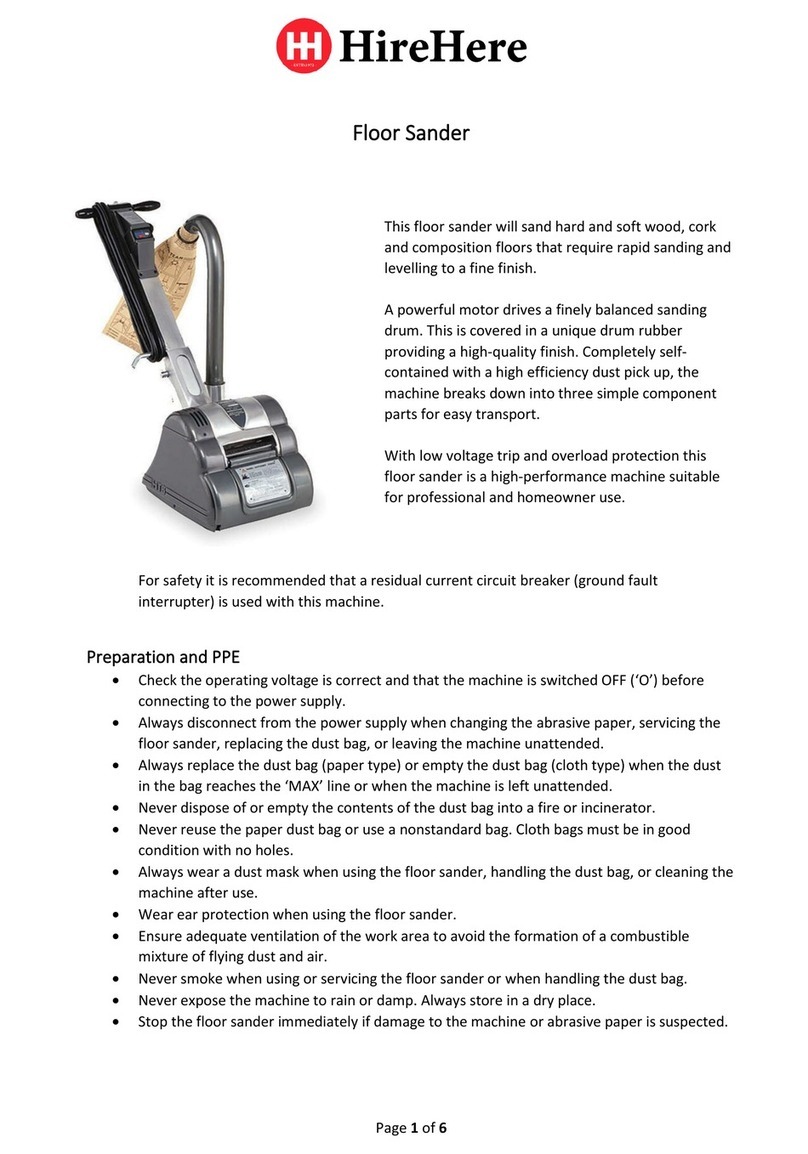

DETAIL SANDER

5 Year Limited Warranty on tool

1

PRODUCT SPECIFICATIONS

2A DETAIL SANDER

Rating: 120V, 60Hz, AC

Amperes: 2 Amp

Speed: 13,000 OPM (no load)

Sanding pad size: Detail sanding base:

5.8” x 5.8” x 3.3” (148 x 148 x 84 mm)

Detail sanding attachment:

3.5” x 3.5” x 3.5” (90 x 90 x 90 mm)

Finger sanding attachment:

3.6” x 1.2” (91 x 30 mm)

Tool weight: 2.6 lbs (1.17 kg)

NEED ASSISTANCE?

Call us on our toll-free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package

1262-200

DETAIL SANDER

2

TABLE OF CONTENTS

Product specifications ................................................................................... 1

Table of contents ........................................................................................... 2

General safety warnings ................................................................................. 3

Eye, ear & lung protection .............................................................................. 3

Electrical safety ............................................................................................ 4

Power tool safety............................................................................................ 4

General safety rules ....................................................................................... 4

Work area ...................................................................................................... 4

Electrical safety ............................................................................................. 5

Personal safety .............................................................................................. 5

Power tool use and care ................................................................................. 5

Service .......................................................................................................... 5

Specific safety rules....................................................................................... 6

Extension cord safety..................................................................................... 7

Symbols......................................................................................................... 8

Know your detail sander................................................................................. 9

Assembly and operating............................................................................... 10

Installing the dust box assembly................................................................... 11

Cleaning the dust box................................................................................... 11

Installing sandpaper .................................................................................... 11

Sandpaper selection and changing sanding plates........................................ 11

Fitting sanding sheets .................................................................................. 13

ON/OFF switch ............................................................................................ 13

Sanding ....................................................................................................... 13

Maintenance ............................................................................................... 14

Exploded view.............................................................................................. 15

Parts listing.................................................................................................. 16

Warranty...................................................................................................... 18

3

GENERAL SAFETY WARNINGS

WARNING:

Before using this tool or any of its accessories, read this manual and follow all Safety

Rules and Operating Instructions. The important precautions, safeguards and

instructions appearing in this manual are not meant to cover all possible situations.

It must be understood that common sense and caution are factors which cannot be

built into the product.

This instruction manual includes the following:

• General Safety Rules •Specific Safety Rules and Symbols

• Functional Description •Assembly

• Operation •Maintenance

• Accessories

SYMBOL MEANING

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CSA

Z94.3 or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage. Prescription

eyeglasses ARE NOT a replacement for proper eye protection.

Non-compliant eyewear can cause serious injury if broken during

the operation of a power tool.

Use hearing protection, particularly during extended periods of

operation of the tool, or if the operation is noisy.

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

Dust that is created by power sanding, sawing, grinding, drilling, and

other construction activities may contain chemicals that are known to

cause cancer, birth defects, or other genetic abnormalities.

These chemicals include:

• Lead from lead-based paints

• Crystalline silica from bricks, cement, and other masonry products

• Arsenic and chromium from chemically treated lumber.

The level of risk from exposure to these chemicals varies, according to

how often this type of work is performed. In order to reduce exposure

to these chemicals, work in a well-ventilated area, and use approved

safety equipment, such as a dust mask that is specifically designed to

filter out microscopic particles.

To avoid electrical hazards, fire hazards or damage to the tool,

use proper circuit protection.

This tool is wired at the factory for 120 Volts AC operation. It must be

connected to a 120 Volts AC, 15 Amps circuit that is protected by a

time-delayed fuse or circuit breaker. To avoid shock or fire, replace

power cord immediately if it is worn, cut or damaged in any way.

1262-200

DETAIL SANDER

4

GENERAL SAFETY RULES

WARNING: Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators.There is an increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of a ground fault circuit interrupter

(GFCI) protected supply.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol, or medication. A moment of inattention while operating power

tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

5

Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

If devices are provided for the dust extraction and collection, ensure these are

connected and properly used. Use of dust collection facilities can reduce dust-

related hazards.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which

it was designed.

Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts,

operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories, and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed.

could result in a hazardous situation.

SERVICE

Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

1262-200

DETAIL SANDER

6

SPECIFIC SAFETY RULES FOR DETAIL SANDER

WARNING: Know your detail sander. Do not plug in the sander until you have

read and understand this Instruction Manual. Learn the tool’s applications and

limitations, as well as the specific potential hazards related to this tool. Following

this rule will reduce the risk of electric shock, fire, or serious injury.

Always wear eye protection. Any power tool can throw foreign objects into

your eyes and cause permanent eye damage. ALWAYS wear safety goggles

(not glasses) that comply with

ANSI safety standard Z87.1. Everyday glasses have only impact resistant

lenses. They ARE NOT safety glasses.

WARNING: Glasses or goggles not in compliance with ANSI Z87.1

could cause serious injury when they break.

WARNING: Always use a dust mask when sanding.

WARNING: Always use hearing protection when sanding, particularly

during extended periods of operation.

WARNING: Always unplug the tool from the power source before

changing accessories, sandpaper and when cleaning the tool.

Do not wear gloves, neckties or loose clothing.

Secure the workpiece. Use clamps or a vice to hold the work when practical.

It is safer than using your hand and it frees both hands to operate the tool.

Do not sand material too small to be securely held.

Make sure there are no nails or foreign objects in the part of the workpiece

to be sanded.

Always keep hands out of the path of the sanding pad. Avoid awkward hand

positions where a sudden slip could cause your hand to move into the path

of the sanding pad.

To avoid injury from accidental starting, always remove the plug from the power

source before installing or removing dust box.

7

EXTENSION CORD SAFETY

Make sure your extension cord is the proper size.

When using an extension

cord, be sure to use one heavy enough to carry the current the tool will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The table below shows the correct size to use according to cord length

and nameplate ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number the heavier the cord.

Be sure your extension cord is properly wired and in good condition.

Always

replace a damaged extension cord or have it repaired by a qualified electrician

before using it. Protect your extension cord from sharp objects, excessive heat and

damp or wet areas.

Use a separate electrical circuit for your power tools.

This circuit must not be

less than 14 gauge wire and should be protected with either a 15A time delay fuse

or circuit breaker. Before connecting the power tool to the power source, make sure

the switch is in the OFF position and the power source is the same as indicated on

the nameplate. Running at lower voltage will damage the motor.

WARNING:

Repair or replace damaged or worn extension cords immediately.

Select the appropriate extension cord gauge

and length using the chart below.

When operating a power tool outdoors, use an outdoor extension cord marked

“W-A” or “W”. These cords are rated for outdoor use and reduce the risk of

electric shock.

WARNING:

Keep the extension cord clear of the working area. Position the cord so it will

not get caught on the workpiece, tools or any other obstructions while you are

working with the power tool.

MINIMUM GAUGE (AWG)

Amperage rating Total length

More than Not more

than

25' (7.5 m) 50' (15 m) 100' (30 m) 150' (45m)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Applicable

1262-200

DETAIL SANDER

8

SYMBOLS

WARNING: Some of the following symbols may appear on the sander. Study

these symbols and learn their meaning. Proper interpretation of these symbols will

V Volts n

~

Three-phase alternating

current with neutral

A Amperes Direct current

Hz Hertz noNo load speed

W Watts Alternating or direct current

kW Kilowatts Class II Construction

Microfarads Splash-proof construction

L Litres Watertight construction

kg Kilograms Protective grounding at

terminal, Class I tools

H Hours .../min Revolutions or reciprocations

per minute

N/cm² Newtons per square

centimetre Diameter

Pa Pascals 0

OPM Oscillation per minute Directional Arrow

Min Minutes Warning symbol

S Seconds Wear your safety glasses

~or AC Alternating current Wear a dust mask

~

Three-phase alternating

current Wear hearing protection

This symbol designates that this tool is listed with U.S. requirements by

ETL Testing Laboratories, Inc.

UL62841-1,UL62841-2-4;

CSA C22.2#62841-1,CSA C22.2#62841-2-4 .

3042597

JD2442U

9

KNOW YOUR DETAIL SANDER

Spindle locking button

Backing pad

ON/OFF switch

Palm grip

Cooling vents

Dust box

assembly

Dust box

filter vent

Cooling vents

work light

Hook & loop

fastening system

Finger & Delta

Attachments

1262-200

DETAIL SANDER

10

ASSEMBLY AND OPERATING

INSTALLING THE DUST BOX ASSEMBLY

1. Insert the dust box assembly (1)

onto the dust chute (2) (Fig. 1).

2. Push the dust box assembly fully

onto the dust chute.

NOTE: Remove and clean the dust

box assembly periodically to remove

accumulated dust from the dust box.

CLEANING THE DUST BOX

The dust box will collect much of the sanding dust that is generated during sanding

operations. As a result, it must be cleaned out periodically so the dust collection will

1. Grasp the sides of the dust box

(1) and pull it away from the rear

of the dust chute (2) (Fig. 2).

2. Insert a small flat blade

screwdriver at the front of the

dust box assembly (3) and

carefully pry the top of the dust

box (4) away from the bottom of

the dust box (5) (Fig. 3).

NOTE: It is best to perform this function either outside or over a trash can, as loose

dust will come out of the dust box very easily.

3. Shake all the dust out of the dust box.

4. Use a soft DRY brush to remove the dust from the

filter located inside the top of the dust box.

5. Once all the sanding dust is removed from the

dust box, press the upper and lower sections

together. They will “snap” into place when

properly assembled.

6. Reinstall the dust box onto the rear of the sander.

NOTE: Make sure the dust box assembly is fully

pushed onto the rear of the sander.

Fig. 1

Fig. 2

Fig. 3

11

INSTALLING SANDPAPER

WARNING: Unplug the sander from the

power source before installing or changing

the sandpaper.

1. Firmly press the sandpaper (1) onto the

hook & loop pad (2) (Fig. 4).

NOTES:

a) Place the sandpaper so the holes line

up with the matching holes in the hook

& loop pad.

b) Press the sandpaper firmly onto the

hook & loop pad.

2. To remove the sandpaper (1), simply peel

the sandpaper away from the hook & loop

pad (2) (Fig. 5).

SANDPAPER SELECTION

Make sure you select the correct size and style of sandpaper for your sander.

The correct sandpaper will:

• Fit onto the sanding pad with no overhang or exposed sanding pad

• Have 3/8" holes that match the hole pattern in the sander base

• Have a backing for use with the hook & loop disc attachment system.

Selecting the correct grit and type of sandpaper is extremely important in achieving

a high quality sanded finish. Aluminum oxide, silicon carbide and other synthetic

abrasives are best for power sanding. Natural abrasives such as flint and garnet are

too soft for economical use in power sanding.

In general, coarse grit will remove the most material and finer grit will produce the

best finish in all sanding operations. The condition of the surface to be sanded will

determine which grit will do the best job.

NOTE: Where the sandpaper grits are shown numerically, higher numbers indicate

finer grit and lower numbers indicate coarser grit.

If the surface is rough, start with a coarse grit and sand until the surface is uniform.

Medium grit may then be used to remove scratches left by the coarser grit. Fine grit

should be used for finishing the surface. Always continue sanding with each grit

until the surface is uniform.

CHANGING SANDING PLATES

CAUTION!

Unplug the tool before carrying out any maintenance or adjustments.

The multi sander is supplied with three interchangeable sanding plates.

• Detail sanding plate.

• Triangle sanding attachment.

• Finger sanding attachment.

Fig. 4

Fig. 5

1262-200

DETAIL SANDER

12

Proceed as follows to fit the required sanding plate/

attachment:

Remove the fitted sanding plate by removing the

mounting screw (A) using a Phillips screwdriver

(not supplied).

• Fit the required sanding plate/attachment to the

base of the machine.

• Secure the sanding plate/attachment by

replacing and tightening the mounting.

FITTING SANDING SHEETS

before attaching a new sanding sheet.

• The sanding sheet must fit the sanding plate and cannot overlap. If applicable

the holes punched in the sanding paper must line up with the holes in the

sanding plate in order for the dust extraction to

function properly.

• Never use the sander without a sanding sheet or

another consumable fitted.

WARNING: Always wear safety goggles or

safety glasses with side shields when operating

your sander. Failure to do so could result in

foreign objects being thrown into your eyes

resulting in possible serious eye damage.

Always wear an appropriate dust mask and

hearing protection when using your sander.

WARNING:

For safety reasons, the operator must read the sections of this Owner’s

Manual entitled "GENERAL SAFETY WARNINGS", "POWER TOOL

SAFETY", "SPECIFIC SAFETY RULES", "GUIDELINES FOR EXTENSION

CORDS" and "SYMBOLS" before using this compact detail sander.

Verify the following every time the compact detail sander is used:

1. Sander cord is not damaged.

2. Safety glasses and dust mask are being worn.

3. Hearing protection is being worn.

4. Sandpaper is the correct type for the job.

5. Sandpaper is in good condition and is properly installed.

Failure to observe these safety rules will significantly increase

the risk of injury.

13

ON/OFF SWITCH

To turn the sander ON, push the upper switch button

(1) until the sander starts. To turn the sander OFF,

press the lower switch button (2) (Fig. 6).

SANDING

Clamp or otherwise secure your workpiece to

prevent it from moving under the sander while

being sanded.

WARNING: An unsecured workpiece

could be thrown toward the

operator causing injury.

WARNING: Your sander should only

be turned ON when the entire surface

of the sanding pad is in contact with the

workpiece. Failure to follow this sanding

procedure could result in loose sandpaper

which could result in possible injury.

Place the sander on the workpiece so that the complete sandpaper surface is in

contact with the workpiece. Turn the sander ON by pressing on the upper ON/

OFF switch button. Move the sander slowly over workpiece making successive

passes in parallel lines, circles or crosswise

movements. Because the random orbital

motion of the sanding pad moves in tiny

circles, it is not necessary to move the

sander with the grain or in the same direction

for successive passes (Fig. 7).

NOTE: Hold the detail sander using the

grip on top of the sander. Be careful NOT to

cover the motor cooling vents (1) with your

hand (Fig. 8). Motor damage may occur from

overheating if the cooling vents are covered.

DO NOT FORCE THE SANDER. The weight of the sander usually provides

adequate pressure. Let the sander and the sandpaper do the work. Applying added

pressure will slow the motor, increase the wear on the sandpaper and greatly reduce

the sander speed. Motor damage may occur if excessive downward pressure is

applied. It will also create an inferior finish on sanded work. Any finish or resin on

wood will soften from the frictional heat, causing the sandpaper to become clogged

very quickly. Do not sand in one spot too long as the sander’s rapid action may

remove too much material, making the surface uneven.

Extended periods of sanding may cause the motor to run hot. If this occurs, turn the

sander OFF and wait until the sanding pad comes to a complete stop before lifting it

from the workpiece. While allowing the motor to cool down, brush, shake or vacuum

any dust accumulated in the vents before continuing the sanding operation.

Upon completion of the sanding operation, turn the sander OFF by pressing on the

lower ON/OFF switch button. Wait until the sanding pad comes to a complete stop

before removing it from the workpiece.

Fig. 6

Fig. 8

Fig. 7

1262-200

DETAIL SANDER

14

MAINTENANCE

GENERAL

WARNING: When servicing, use only identical replacement parts. The use

of any other part may create a hazard or cause product damage.

DO NOT use solvents when cleaning plastic parts. Plastics are susceptible to

damage from various types of commercial solvents and may be damaged by their

use. Use a clean cloth to remove dirt, dust, oil, grease, etc.

WARNING: Do not allow brake fluids, gasoline, petroleum-based products,

penetrating oils, etc. to come into contact with plastic parts. They contain

chemicals that can damage, weaken or destroy plastic.

DO NOT abuse power tools. Abusive practices can damage the tool and

the workpiece.

WARNING: DO NOT attempt to modify tools or create accessories.

Any such alteration or modification is misuse and could result in a hazardous

condition leading to possible serious injury. It will also void the warranty.

Remove accumulated dust and debris regularly using a soft DRY brush.

It has been found that electric tools are subjected to accelerated wear and

possible premature failure when they are used on fiberglass boats and sports

cars, wallboard, spackling compounds or plaster. The chips and grindings from

these materials are highly abrasive to electric tool parts such as bearings, brushes,

commutators, etc. Consequently, it is not recommended that this tool be used

for extended work on any fiberglass material, wallboard, spackling compounds or

plaster. During any use on these materials it is extremely important that the tool is

cleaned frequently by blowing it out with an air jet.

WARNING: Always wear safety goggles or safety glasses with side shields

during all sanding operations. It is critical that you also wear safety goggles or

safety glasses with side shields and a dust mask while blowing dust out of the

sander with an air jet. Failure to take these safety precautions could result in

permanent eye or lung damage.

LUBRICATION

high grade lubricant for the life of the unit under normal conditions. Therefore, no

further lubrication is required.

15

EXPLODED VIEW

1262-200

DETAIL SANDER

16

PARTS LIST

WARNING: When servicing, use only original equipment replacement parts.The

use of any other parts may create a safety hazard or cause damage to the sander.

Any attempt to repair or replace electrical parts on this sander may create a safety

hazard unless repairs are performed by a qualified technician.

For more information, call the Toll-free Helpline, at 1-866-349-8665

Monday – Friday from 9am to 5pm Eastern Standard Time.

Always order by PART NUMBER, not by key number.

Key # Part # Part Name Quantity

1 3011080036 Housing 1

2 1220050021 Led light assembly 1

3 1061250004 Switch 1

4 3140080044 Switch cover 1

5 4010010106 Bearing 627-2RS 1

6 1010080043 Rotor 1

7 4010010053 Bearing 607-2RS 1

8 1020080042 Stator 1

9 1130080024 Circuit board 1

10 3011080036 Housing 1

11 4030010106 Screw ST3.9x19 9

12 3140010074 Cord sleeve 1

13 1190030016 Ul plug and cord 1

14 3150010086 Fan 1

15 2030030201 Balance weight 1

16 2010130032 Eccentric 1

17 2030020300 Washer 1

18 4010010055 Bearing 6001-2RS 1

19 3180050003 Guide ring of dust 1

20 3180050023 Dust box cover 1

21 3190110005 Filter paper 1

22 3180060021 Filter paper pressure plate 1

23 3140020046 O ring 1

24 3180020038 Dust box 1

25 3150110006 Support bar I 1

26 3150110007 Support bar II 1

27 3190010026 Sealing ring 1

28 3150120091 Triangle liner 1

17

Key # Part # Part Name Quantity

29 4030010136 Screw ST2.9x9 4

30 3150120092 Triangle plate 1

31 4020010166 Screw M4x8 1

32 3190020062 Semicircle sponge plate 1

33 3190020063 Triangle sponge plate 1

34 3150120093 Finger plate 1

35 3190100017 Finger plate with hook and loop 1

36 3150120094 Long triangle plate 1

37 3190100018 Long triangle plate with hook and loop 1

1262-200

DETAIL SANDER

18

WARRANTY

BENCHMARK DETAIL SANDER

If this Benchmark Tool fails due to a defect in material or workmanship within 5

years from the date of purchase, return it to any Home Hardware store with the

warranty does not include expendable parts including but not limited to blades,

brushes, belts, light bulbs. This warranty covers defects in material or workmanship

commercial or rental purposes, this warranty does not apply.

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

3042597

JD2442U

Made in China

1262-200

BENCHMARK TOOLS CANADA

ST. JACOBS, ONTARIO N0B 2N0

©01 / 2021 Home Hardware Stores Limited

TM

MC

CUSTOMER SERVICE/TECH SUPPORT

1-866-349-8665

* This BenchmarkTM

DETAIL SANDER

5 Year Limited Warranty on tool

Table of contents

Other Benchmark Sander manuals