Benezan Electronics Beamicon2 IoExt1 User manual

Benezan Electronics

Hard- and software development

IoExt installation guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

Io-Ext1-Installation.docx22.09.2020

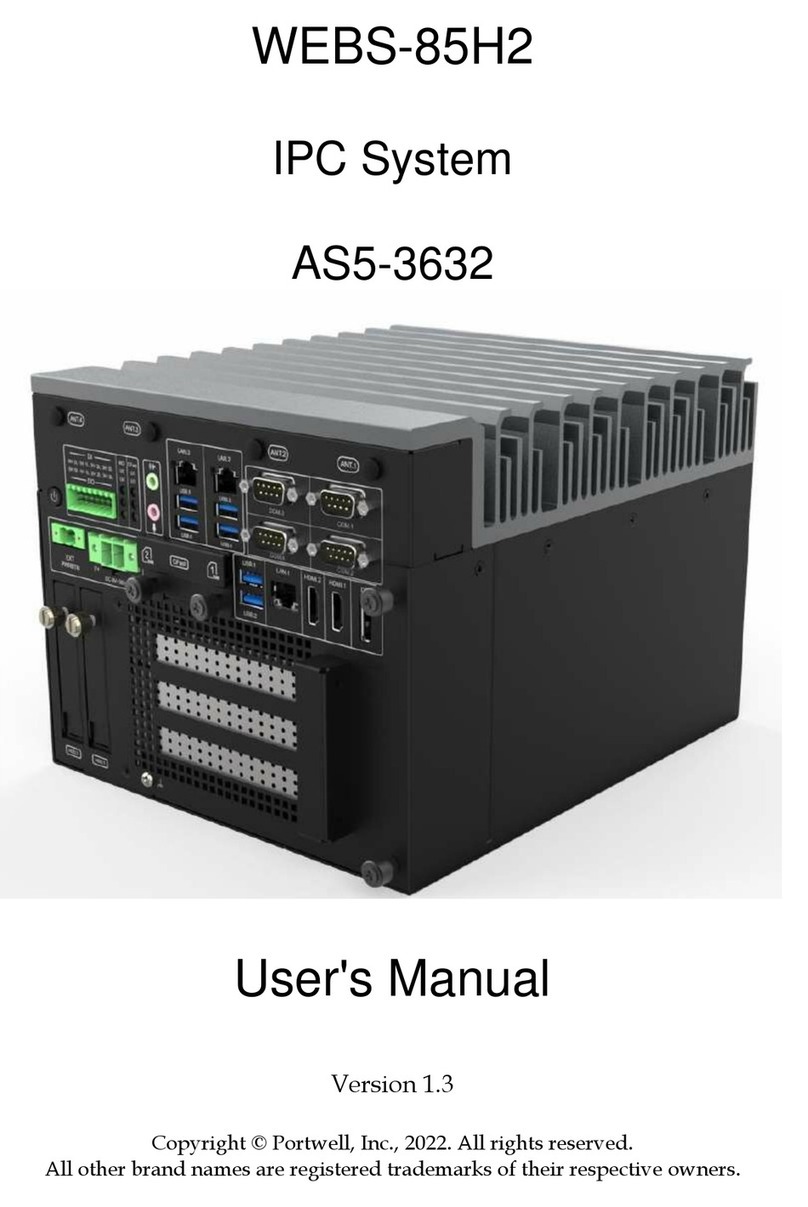

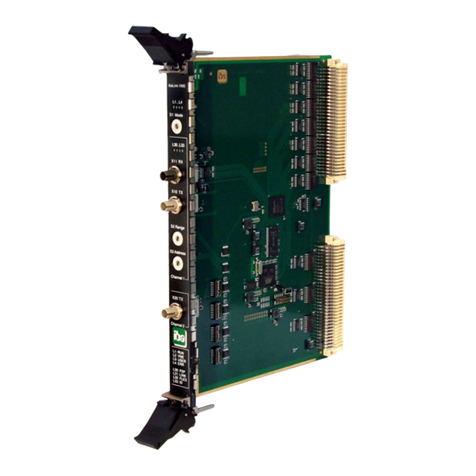

Beamicon2 IoExt1

Input/output extension for

CNC control with Ethernet interface

Installation manual

Version 1

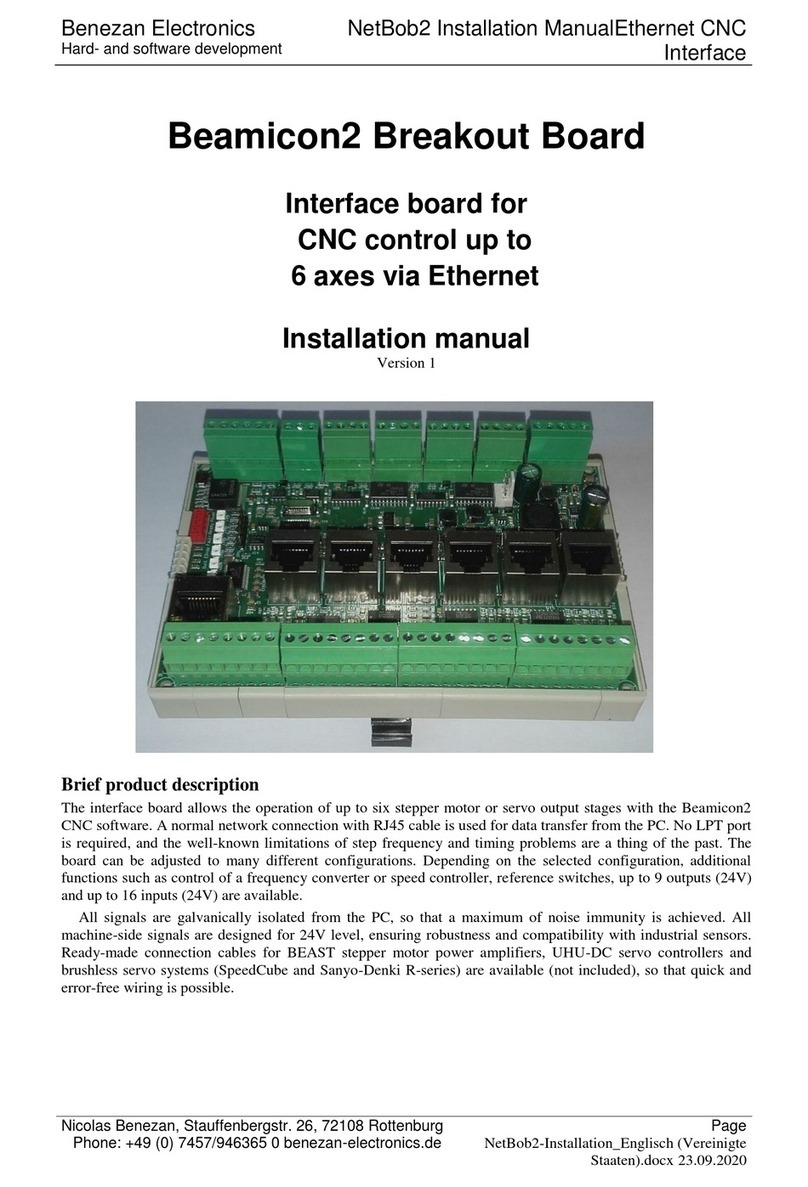

Brief product description

The IO Expansion provides additional digital inputs and outputs for the Beamicon2 CNC control. This means

that the number of available inputs and outputs is not limited to the limited number on the NetBOB or the

CncPod, but can be expanded practically at will.

The module has eight outputs and eight inputs with 24V level. Unused outputs can also be used as inputs, so

that up to 16 inputs are available alternatively. A normal network connection with RJ45 cable is used for data

transfer from the PC. A network switch is required to connect several modules to one PC. All signals are

galvanically isolated from the PC. All outputs and inputs are equipped with filters and protected against short-

circuit and polarity reversal, so that a maximum of interference immunity is achieved.

Benezan Electronics

Hard- and software development

IoExt installation guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

Io-Ext1-Installation.docx22.09.2020

Safety Instructions

The interface board may only be installed and put into operation by qualified personnel.

Please read the operating instructions carefully and follow all instructions exactly. Improper

installation or operation of the device can cause damage to the electronics or the machine and

can result in dangers to the health of the operating personnel.

Depending on the hazard potential of the machine, additional safety measures may be

required, such as door interlocks and standstill monitoring. As a rule, such safety functions

must be implemented purely electromechanically with external circuits (not included in the

scope of delivery) and must not depend solely on software and PC hardware. The system manufacturer, who

assembles the interface board and other components to form the overall system, and the system operator are

responsible for compliance with the legal regulations.

Connections

(All pins of the terminals are numbered

from left to right or from top to bottom)

Status LEDs

LED No.

Description

-

Outputs (X9 to X12, top)

-

Inputs (X1 to X8, bottom)

Network traffic

Network Carrier (connected)

Outputs (terminals above)

Pin No.

Assignment

1

0V Ground

2

Signal output (max. 250mA)

3

0V Ground

4

Signal output (max. 250mA)

Supply

voltage(terminal X13 right above)

Pin No.

Assignment

1

+24V output (max. 100mA)

2

Signal input

3

0V signal ground

Inputs (terminals below)

Functional description

No.

Description

1

Signal ground

2

+24V input (10..30V)

C

T

8

1

8

1

1

C

1

2

3

4

5

6

7

8

2

3

4

5

6

7

T

8

Benezan Electronics

Hard- and software development

IoExt installation guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

Io-Ext1-Installation.docx22.09.2020

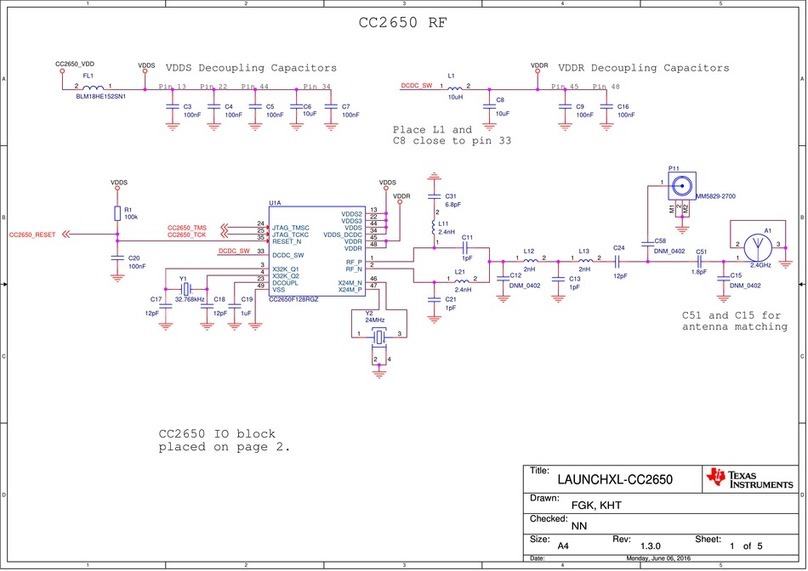

PC / network connection

The data transfer from the PC software to the CncPod is done via an Ethernet network connection (IEEE802.3

10BASE-T). The connection can be made with standard patch cables to the RJ45 socket ST1.

In contrast to similar products from competitors (e.g. Smoothstepper or Eding-CNC) no exclusive interface

has to be reserved on the PC, but the infrastructure of an existing network with switches can be used. There is

also no need to change IP addresses or otherwise interfere with the Windows Control Panel. The Beamicon2

software automatically detects all modules, even if it is connected "somewhere" in the network. Several modules

can be connected to a PC at the same time and can also be used simultaneously. To ensure reliable operation,

however, the following rules must be observed:

All modules must either be connected to the first switch after the PC, or a further switch may be added

if only devices of the machine are connected to the second switch, e.g. within the control cabinet of the

machine. All devices not involved in machine control (Internet router, printer, NAS, etc.) must be

connected to the first switch or to additional switches behind the first.

The transmission speed between the PC and the first switch must be higher than the maximum data rate

of any existing Internet routers (DSL modem etc.). For home networks with few PCs 100MBit is

recommended, for larger networks Gigabit-Ethernet.

Since no TCP/IP is used but a separate protocol, this cannot be forwarded by routers, external firewalls,

proxies, etc. Therefore only so-called "unmanaged switches" may be used between the control PC and

the CNC pod.

Switches must support Fast Forward and Store-and-Forward (virtually all modern switches meet this

criterion)

Hubs are also allowed for test purposes (listening with diagnostic tools on taps), but are not

recommended.

The data traffic of the machine controller must not be routed via slow (DSL modem) or unreliable

(wireless) connections (WLAN). All wireless interfaces are therefore intentionally hidden.

The network interface is galvanically isolated from the PC. Power-over-Ethernet (PoE) is not supported.

Power supply

The expansion module can be supplied with an operating voltage of 10 to 30V DC. The input is protected against

accidental reverse polarity. It is recommended to use a switching power supply with 24V, as most industrial

contactors, pneumatic valves and sensors are designed for this and can therefore be connected directly.

Connection of actuators

A total of 16 terminals (4 pluggable contact blocks with 4 connections each) are provided at the top of the

module for the connection of consumers. The connections with odd numbers 1, 3, 5 etc. are permanently

connected to ground. The actual outputs are the connections with even number 2, 4, 6 etc. The outputs are of the

PNP type, i.e. an activated output is connected to the supply voltage (24V), a deactivated one is high-impedance.

The outputs are protected against overvoltage by switching inductive loads and against short circuit. The

corresponding LED lights up when more than about 6V are applied to the output, i.e. when the output is either

switched on or a voltage is applied externally.

Connection of sensors

Each input has its own 3-pin terminal, where the supply voltage, the signal input and a ground connection is

available. This also allows a direct connection of inductive proximity switches without additional distribution

terminals. The inputs are intended for mechanical switches (normally closed or normally open) or for PNP type

sensors (switching to +). The corresponding LED lights up when more than about 6V are applied to the input.

Mechanical switches are connected with two wires to pin 1 (top) and pin 2 (middle). Inductive switches or

other electronic sensors are connected with three wires (brown=1, black=2, blue=3). If NPN types are to be used

(not recommended), an additional pull-down resistor of approx. 2.2kΩ must be connected between pins 1 and 2.

If the eight available inputs are not sufficient and not all outputs are used, outputs can also be used as inputs.

Thus, a total of up to 16 inputs are available. Since there are only two pins per input/output on the output

terminals, the supply voltage must be connected to a distribution terminal or directly to the power supply unit in

this case.

Benezan Electronics

Hard- and software development

IoExt installation guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

Io-Ext1-Installation.docx22.09.2020

Configuration

The assignment of the inputs and outputs is done in the Beamicon2 software. The installation and operation of

the software as well as the adjustment of the machine parameters is described in detail in the Beamicon2

software manuals. Therefore, only the special features of the expansion module will be discussed here.

After the first start, the module must first be connected. Open the hardware dialog by selecting this in the

menu under "Configuration -> Hardware". If several identical modules are connected, you may assign the

desired module with "Identify". In this case you

should remember the number of the module (8-digit

hexadecimal number, usually starting with "A3"),

because otherwise confusion could occur later when

assigning the individual inputs and outputs. Finally,

select the module and then click on "connect" and

"save".

To assign the signals, switch to the configuration

dialog (Menu -> Configuration -> Machine), and then

to the "Inputs/Outputs" page. You can now assign

existing signals (e.g. limit switches), or define new

ones (with "Add"), e.g. for your own macros.

The signals of the expansion module can be used

for (almost) any purpose, e.g

Relays or contactors for switching loads,

Pneumatic or hydraulic valves

Limit value/limit switches at the ends of the travel range of positioning axes,

"End position reached" switch on pneumatic cylinders

other sensors

However, there are the following restrictions:

The emergency stop input is assigned to a fixed input on the primary axis controller module (NetBob,

CncPod or TripleBeast)

Reference switches and tool length sensors, which have to achieve high precision in connection with

axis movements, cannot be placed on expansion modules because the propagation delay via the network

would result in a position deviation. These must be connected directly to the primary module.

Some outputs with special functions (PWM or analog output) can also only be assigned to certain pins

on the primary module.

Benezan Electronics

Hard- and software development

IoExt installation guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

Io-Ext1-Installation.docx22.09.2020

Technical data

Absolute limit values

The following parameters must not be exceeded under any circumstances to prevent damage to the device:

Parameters

min.

max.

Unit

Operating voltage

-40

+40

V

Storage temperature

-40

+70

°C

Operating temperature

0

+70

°C

Voltage at digital inputs

-40

+40

V

Voltage at digital outputs

-0.5

+40

V

Electrical connection values:

Parameters

min.

max.

Unit

Operating voltage (Vcc, nominal 24V)

+10

+30

V

Power consumption (without external consumers)

0.1

2

W

Ambient temperature

0

+50

°C

Level for logical 0 at inputs

-0.5

+5

V

Level for logical 1 at inputs

8.0

30

V

Current consumption at inputs at 24V

3

5

mA

Level for logical 0 at outputs

0

0.5

V

Level for logic 1 at outputs

Vcc-2

Vcc

V

Load current at outputs

0

250

mA

Switch-off energy with inductive load

0

3

mJ

Dimensions:

Description

Width

Length

Height

Unit

Dimension of the board without connector

56

62

8

mm

Dimensions with plug

56

82

22

mm

Other manuals for Beamicon2 IoExt1

1

Table of contents

Other Benezan Electronics Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Sun Microsystems

Sun Microsystems 2060 Hardware Engineering Manual

Radica Games

Radica Games DAVID-II 716 Operating and maintenance instruction manual

MSA

MSA ProtoCessor FPC-ED2 operating manual

Watercool

Watercool HEATKILLER GPU-X3 GTX 560 Assembly instructions

Creative

Creative EF0960 Safety & Regulatory Guide

Alphacool

Alphacool Cool Answer manual