Benford 2000 User manual

Benford Ltd., Central Boulevard, ProLogis Park, Coventry CV6 4BX, England

Tel.: +44 (0)2476 339400 - Fax: +44 (0)2476 339500

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer,birthdefects, andotherreproductiveharm

INSTRUCTION

2000 - 9000 (ITL)

Mechanical Drive Only

4.W.D Dumper Straight & Swing Skip

Publication No. B9507E-5 June 2004

iSafety Notes

June 2004 - 9507ES/5

General Safety Notes

LEFT and RIGHT HAND

All references in this manual to LEFT and

RIGHT are as viewed from the Operating

Position (Drivers Seat)

ii

Safety Notes

June 2004 - 9507ES/5

General Safety Notes

This Manual is Designed as a Guide to the Machines Controls and Maintenance

- IT IS NOT A TRAINING MANUAL

This manual must not be removed from the machine and

shouldbekeptinauseablecondition.Ifthemanualbecomes

unusable,newcopiesmaybeorderedfromthemanufacturer

by quoting the Publication Number.

ALLusersofthemachinemustbefullytrainedinitsoperation

andauthorisedtousethemachine.Consultthemanufacturer

or dealers for details of training courses.

Modifications to this machine and/or changes to the

specification which have not been approved by the factory,

willinvalidatethemachineswarrantyandpossiblyyourown

insurance cover.

Allthetimeyouareworkingonorwiththemachineyoumust

bethinkingwhathazardstheremaybeandhowtoavoidthem.

If you are unsure of anything concerning the machine or the

job - ASK.

DO NOT ASSUME ANYTHING

iii Safety Notes

June 2004 - 9507ES/5

WARNING

Observe the Following Points for Your Safety and Protection

Operatorsandmaintenance personnelmustalwayscomplywith thefollowingsafetyprecautions.These precautionsaregiven

hereforyoursafety.Reviewthemcarefullybeforeoperatingthemachineandbeforeperforminggeneralmaintenanceorrepairs.

Supervising personnel should develop additional precautions relating to the specific work area and local safety regulations.

zBefore operating the machine ensure you have had proper training and are fully conversant with the machine and

itsoperation-IfinDoubtASK!

zReadthisinstructionmanualcarefullybeforeoperatingthemachine.Ensurethisinstructionmanualiskeptwiththe

machineatall times and is in good condition - replace themanualimmediatelyif it becomes dirty, damaged or lost.

zDecals are fitted to the machine for safety purposes and MUST be replaced immediately if they are unreadable or

lost.Ifthemachine isrepairedandpartshave beenreplaced onwhichdecals werefixed ensurenewdecals arefitted

before the machine is put into service.

zAlwaysmakesurethereisadequateventilationaroundthemachine.Neverruntheengineinanenclosedareawithout

good ventilation or next to combustible materials.

zStop the engine before refuelling, if there is a spillage mop it up and do not start the engine until it is safe again.

zTheexhaustgetsextremelyhot.Donotplaceanythingontopofitandkeepallcombustiblematerialsclear.Donot

attempt any maintenance on a hot engine.

zBe familiar with all prohibited work areas such as excessive slopes and dangerous terrain conditions.

zCheck your local laws and regulations, the engine may require a spark arrester etc.

zDo not inspect or clean the machine with the engine running.

zBefore carrying out maintenance on the hydraulic system ensure the hydraulic fluid is cool and there is no residual

pressurein the hydraulic circuit-hydraulicfluidleakingunderpressurecanpenetratetheskin.

zMake sure you, and anyone else who uses the machine, have been trained to operate it safely.

zA hard hat, safety boots, safety glasses and reflective clothing must be worn at all times.

zEstablish a training programme for all operators to ensure safe operation.

zDo not operate the machine unless thoroughly trained and are physically and mentally fit.

zDo not operate the machine if it is damaged, improperly adjusted or not completely and correctly assembled.

zDo not operate the machine if you are unfit to do so because of alcohol or drugs etc.

zBefore performing any maintenance on the machine, place a warning tag on the machine to prevent accidental start-up.

Put the locking bar into position to prevent the front and rear chassis moving and creating a crushing zone.

zThe air taken in by the oil cooler fan, if fitted, must be free of dust and debris.

zEnsure the ROPS/FOPS is not damaged.

zWhen loading a dumper skip, no person should be on the machine.

zDo not carry passengers.

zKeep footplates and steps free from dirt, oil, snow, ice etc.

zCheck seat belts daily.

zDo not remove the radiator cap when the engine is hot. Do not add coolant to a hot engine.

zAlways park the machine safely on firm, level ground where it will not cause an obstruction or danger - chock the

wheelsifnecessary.DONOTLEAVETHEENGINERUNNINGorthestartkeyinthestartswitch.

zBefore taking the machine on public roads ensure the machine complies with all road traffic regulations and obey

alldrivinglaws.

zTyreChangesandrepairstoPuncturedTyresMUSTonlybecarriedoutbyfullytrainedOperativesusingthecorrect

equipment. The manufacturer of this machine recommends a competent firm is employed to carry out these tasks.

zIfthemachineshouldrollover,theOperatormustgripthesteeringwheelfirmlyallowingtheseatbelttorestrain

themintheseatuntilthemachinecomestorest.

General Safety Notes

iv

Safety Notes

June 2004 - 9507ES/5

General Safety Notes

Hydraulic Fluid

Fine jets of hydraulic fluid under pressure can penetrate the skin.

Donotuseyourfingerstocheckforsmallleaksorexposeuncovered

areas of your body to leaks.

Check for leaks using a piece of cardboard.

IfSkinisPenetratedwithHydraulicFluid,GetImmediateMedicalHelp

Fluid Levels

Ensure the Machine is on Level, Stable

Ground when Checking ALL Fluid Levels

Frozen Battery Electrolyte

Do Not Use a Machine with Frozen Battery Electrolyte

zBatteries with frozen electrolyte may explode if used or

charged.

zNever 'jump start' a machine with a frozen battery.

zTo help prevent freezing, keep the battery fully charged.

Fires

Do Not Use Water to Extinguish a Machine Fire

Usingwatertoextinguishanoilfirecouldspreadthefireorgiveyou

a shock from an electrical fire.

Use a carbon dioxide, dry chemical or foam extinguisher whilst

waiting for the fire brigade.

Keep the fire extinguisher safely and have it checked regularly.

Water Cooled Engines

Watercooledsystemsoperateunderpressuretoincreasetheboiling

point of the coolant. Therefore, the coolant temperature may be

greater than boiling water - 100ºC.

Never Maintain Cooling System when the Engine is HOT!

BEWARE

of Hydraulic Oil

Under Pressure

vSafety Notes

June 2004 - 9507ES/5

Lubricants

It is essential that anyone concerned with lubricants read and

understand the following text.

Hygiene

Lubricants are not a health risk when used correctly for their

intended purposes.

However, excessive or prolonged skin contact can remove the

natural fats from the skin, causing dryness and irritation.

Low viscosity oils are more likely to do this, therefore particular

careisnecessaryinhandlingusedoilswhichcanbedilutedwithfuel

contamination.

Whenever handling oil products, maintain good standards of care

plus personal and plant hygiene.

For details of these precautions we advise you to read the relevant

publications issued by your local health authority.

Storage

ALWAYS keep lubricants out of reach of children.

NEVER store lubricants in open or unlabelled containers.

Handling Oil

New Oil

There are no special precautions needed for the handling or use of

new oil other than the normal care and hygiene practices.

Old Oil

Usedenginecrankcaselubricantscontainharmfulcontaminants.In

laboratorytestsitwasshownusedpetrolengineoilscancauseskin

cancer.

Observe the following precautions.

A. Avoid prolonged,excessiveorrepeatedskin contact withused

engineoil.

B. Apply a barrier cream to the skin before handling used engine

oil.

C. Note the following when removing engine oil from the skin.

Wash skin thoroughly with soap and water. Using a nail brush

will help.

Use special hand cleansers to help clean dirty hands.

Never use petrol, diesel fuel or kerosene.

Avoid skin contact with oil soaked clothing.

Do not keep oily rags in pockets.

Wash dirty clothing before reuse.

Throw away oil soaked shoes.

First Aid - Oil

Swallowing

If oil is swallowed, do not induce vomiting.

GetMedicalAdvice

Old

In the case of excessive skin contact, wash with soap and water.

New

In the case of eye contact, flush with water for 15 minutes. If the

irritation persists, get medical attention.

Spillage

Absorbwithsandoralocallyapprovedbrandofabsorbentgranules.

Scrape up and dispose of in a chemical disposal area.

Fires

Extinguish with carbon dioxide, dry chemical or foam.

Lubricants - Health and Safety

vi

Safety Notes

June 2004 - 9507ES/5

WARNING

Observe the Following Points to Prevent Damage to the Machine

zAlwaysreplacehoses,couplersandotherpartswithpartssuppliedorrecommendedbyBenford-NEVERUSESPARE

PARTSOFINFERIORSPECIFICATION.

zNever allow unqualified people to perform repairs on the machine.

zNever overfill the engine oil or fuel tank.

zIfahosebursts,stop the engine immediately - ALWAYSreplacewithahoseofthecorrectspecification.

zDo not start the engine if you cannot see the hydraulic oil level in the sight gauge.

zFollow the engine starting instructions in this manual and on the machine.

zIfyou see oil leaking report it andgetit fixed immediately.

zMake sure the correct fuel, oils and grease is used.

zDo not operate the machine unless it is safe to do so. Remember to check for overhead obstructions while driving.

zNever use the machine for purposes other than those it was manufactured for.

zAlways ensure workmates are aware of your work plan.

zEnsure all tyres are serviceable before using the machine.

zNever cross inclines greater than those stated in this manual.

zNever drive the machine on to unstable ground or close to trenches, holes etc.

zDo not operate the machine if it is damaged, improperly adjusted or not completely and correctly assembled.

zEstablish a training programme for all operators to ensure safe operation.

SAFETY SYMBOLS

Safety symbols are used in these instructions to bring attention to actions that may cause personal injury or damage to

the equipment. Always observe these symbols, they are included for your safety and for the protection of the power unit.

Thissymbolidentifiesanactionthatrequiresparticularattentionand/orcare.

Thissymbolidentifiesanactionthatmaybedangerousifperformedincorrectly.

Thissymbolidentifiesatopicwherefurtherinformationisavailable.

Additional Safety and Warning Notes are Included in the Following Manual Pages

General Safety Notes

vii Safety Notes

June 2004 - 9507ES/5

Warning Transfers Used on the Dumper

General Safety Notes

Before operating the machine, Read and Understand the

Instruction Manual supplied with the machine

Refer to Manual Sections: Driving Controls, Operating

Instructions

Stay a safe distance away from the machine

Refer to Manual Sections: General Safety

Stay a safe distance from crushing zones

Refer to Manual Sections: General Safety

Always Use Seat Belt when Operating the Machine

Refer to Manual Sections: Seat Operating Instructions

For safe use of machines on gradients, see

instruction manual for skip uses

Refer to Manual Sections: Gradients

viii

Safety Notes

June 2004 - 9507ES/5

Warning Transfers - continued

Read the Instruction Manual before operating the machine and

ALWAYS remove the start key before performing ANY maintenance

Refer to Manual Sections: Delivery Checks, Maintenance Secure lifting cylinder with the locking device before

performing maintenance in the skip area

Refer to Manual Section: Skip Prop Instructions, Maintenance

Swing Skip control valve

Refer to Manual Sections: Operating

Instructions, Swing Skip Elevation and Slewing

Straight Skip control valve

Refer to Manual Sections: Operating

Instructions, Straight Skip Elevation

Do not ride on machine except in supplied seat and

never expose body to high pressure fluid leaks

Refer to Manual Section: Working on the Hydraulic

System, Maintenance

Engage the articulation lock before lifting machine

Refer to Manual Sections: Transportation - Crane

General Safety Notes

ix Safety Notes

June 2004 - 9507ES/5

Warning Transfers - continued

Engine noise level

Refer to Manual Section: Technical Specification, Noise Levels

Tyre Pressures

Refer to Manual Section: Technical Specification,

Tyre Specification/Capacity/Pressures/Wheel Torques

General Safety Notes

x

Safety Notes

June 2004 - 9507ES/5

General Safety Notes

Fatigue and finite life problems associated with

welded products such as ROLL OVER PROTECTIVE

STRUCTURES (ROPS).

Operational experience of ROPS indicates that equipment

of this type may become structurally inadequate and has

even failed during normal operations because users have

not inspected and maintained this equipment. Although

ROPS seem to be relatively maintenance-free, regular

periodic inspections to ensure ROPS are damage free and

thus capable of functioning in a rollover cannot be over

emphasized. Through periodic inspections, cracks, loose

bolts, damage, and other normal wear and tear related

problems can be eliminated before they become serious.

Proper inspection and maintenance procedures can

ensure that ROPS will perform the lifesaving function they

are designed for and expected to do.

Introduction

There are in-service factors which tend to degrade a ROPS/

FOPS systems energy absorbing or load carrying

capability.

A few of these factors are:

zStructural damage from vibrations and/or loadings

during some operations.

zA corrosive environment

zContinued use of the machine after rollover or accident

involving structural damage

zUnauthorized modification

zWorn or deteriorated isolation mounts

zBolt replacement with less than the correct grade or

neglect in maintaining proper bolt torque

zImproper installation

Any of these factors can cause an unsafe condition to exist

as well as exposing all concerned parties to liability

damages. The following guidelines will be helpful if

followed.

Attachments and/or Modifications

Generally ROPS/FOPS structures are not intended as

external load carrying members and must not be used to

mount attachments such as pull hooks, winches, side

booms, etc. without the manufacturers approval.

Non external load transmitting attachments such as

mirrors, fans, heaters, lights, etc. should be installed

following the manufactures guidelines. Typically these

attachments are located in non critical areas such as roof

sheets, enclosure sheet metal, or the middle portion of the

ROPS legs.

Modifications to basic design such as increasing canopy

height, or relocating ROPS legs should be avoided as

recertification is required.

Maintenance

Inspection - A scheduled, frequent visual check of mounting

hardware by operation or service personnel is recommended.

As most ROPS are different and function in different service

environments, no specific inspection interval can be

recommended. Inspection in conjunction with regular service

intervals is suggested. The inspection should check for:

zWorn, damaged or missing resilient mounts. Excessive

motion or rattling during operation are indications of a

problem. The mounts should be disassembled and

repaired if required.

zLoose, missing or damaged mounting hardware (bolts, nuts,

washers, etc.). Bolts should be checked for proper torque.

zCracks in ROPS/FOPS structure and mounting system.

The machine should be cleaned and disassembled as

necessary to allow inspection for cracks in the structure

and mounting system. Cracks are usually associated

with weld details and usually show as a line of rust

before it will be clear as a crack. Rust lines should be

taken as indications of cracks and verified by inspection

following the manufacturers procedures. Only some

cracks will badly affect the ROPS/FOPS function.

Cracks in enclosure sheet metal generally are not

structurally important. The manufacturer can identify

the appropriate measures. If in doubt, consult the

manufacturer.

zWater drainage paths. The check should verify clear

water drainage paths so that entrapped water will not

freeze and crack or deform the structure.

zCorrosion. Extensive paint peeling and rusting should

be noted and corrective action taken.

zSeat Belt. The presence and operability of a seat belt

should be noted. The belt should be clean,free of dirt

and grease and the latch should function smoothly.

zOther inspection. The structure should be inspected

following a rollover, collision or fire.

Repair

zReplace missing or damaged hardware with the

manufactures specified hardware. Re-torque all loose

threaded fasteners to the manufacturers specifications.

zReplace worn or damaged resilient mounts to prevent

further damage to the mounting surfaces and to prevent

more severe vibration problems.

zDetermine the repairability of cracks in ROPS/FOPS

structures on the basis of the crack details and effect on the

particular design. The manufacturer must be consulted at

this step. Some general rules which may be helpful are:

zEnclosure sheet metal cracks are repairable.

zSmall cracks may be repairable. Consult manufacturer.

zIf damaged by rollover, collision or fire consult manufacturer.

zIn all cases, when doubt exists; consult manufacturer.

Roll Over Protective Structures - ROPS

xi Safety Notes

June 2004 - 9507ES/5

Important Facts about Seat Belts

The potential exposure of this seat belt to severe environmental conditions make it crucial to inspect the seat belt system

regularly. It is recommended that the seat belt system is inspected at least once a year or more often if the vehicle is

exposed to severe environmental or vocational conditions, Any seat belt system that shows cuts, fraying, extreme or

unusual wear, significant discoloration due to UV exposure, dusty-dirty conditions, abrasion to the seat belt webbing, or

damage to the buckle, latch plate, retractor, hardware or any other obvious problem should be replaced immediately.

Once replacement of the seat belt has been determined, be certain that it Is only replaced with the original equipment

manufacturer recommended replacement seat belt. See your authorized spares and service centre for replacement. Your

restraint system has been developed and tested specifically for your machine.

If the inspection indicates that any part of the seat belt requires replacement, the entire belt must be replaced. It is vitally

important that all components be mounted back in the same position as the original components which were removed. This

will maintain the design integrity of the mounting points for the seat belt assembly.

Seat Belt Maintenance Guidelines

WARNING

zFailure to properly inspect and maintain a seat belt can cause serious injury or loss of life in the event of an accident.

zIt Is critical that any time the machine is involved in an accident, the entire seat belt system must be replaced.

zThe seat belt should be considered to have a finite life and must be replaced as needed throughout the life of the

machine. The belt must be inspected for needed maintenance at least once a year or more often if exposed to

severe environmental or vocational conditions.

zIf replacement of any part of the seat belt is indicated through maintenance guidelines below, the entire belt must

be replaced, both retractor and buckle side.

Maintenance Guidelines

The following maintenance guidelines detail how to

Inspect seat belt for “cuts, fraying, extreme or unusual

wear of the webbing, etc., and damage to the buckle,

retractor, hardware or other factors” which indicate that

seat belt replacement is necessary,

1 Check the webbing. Pull the webbing completely out of

the belt retractor and inspect the full length of the

webbing for cuts, wear, fraying, dirt and stiffness. If a

belt shows any cuts, fraying, extreme or unusual wear,

the system should be replaced.

2 Check the buckle and latch for proper operation and to

determine if latch plate is excessively worn, deformed

or buckle is damaged or casing broken.

3 Check retractor web storage device operation by

extending webbing to determine it locks properly and

that it spools out and retracts webbing properly.

4 Check web in areas exposed to ultraviolet rays from the

sun or extreme dust or dirt. If the original colour of the

web in these areas is extremely faded and/or the web

is packed with dirt, the physical strength of this web

may have deteriorated. If this condition exists replace

the system.

IMPORTANT

Follow Maintenance Guidelines 1-4 to properly

Inspect seat belt and tethers to determine if

replacement Is necessary.

June 2004 - 9507EI/5

1-1 2 to 9 Tonne Dumper Instruction Manual

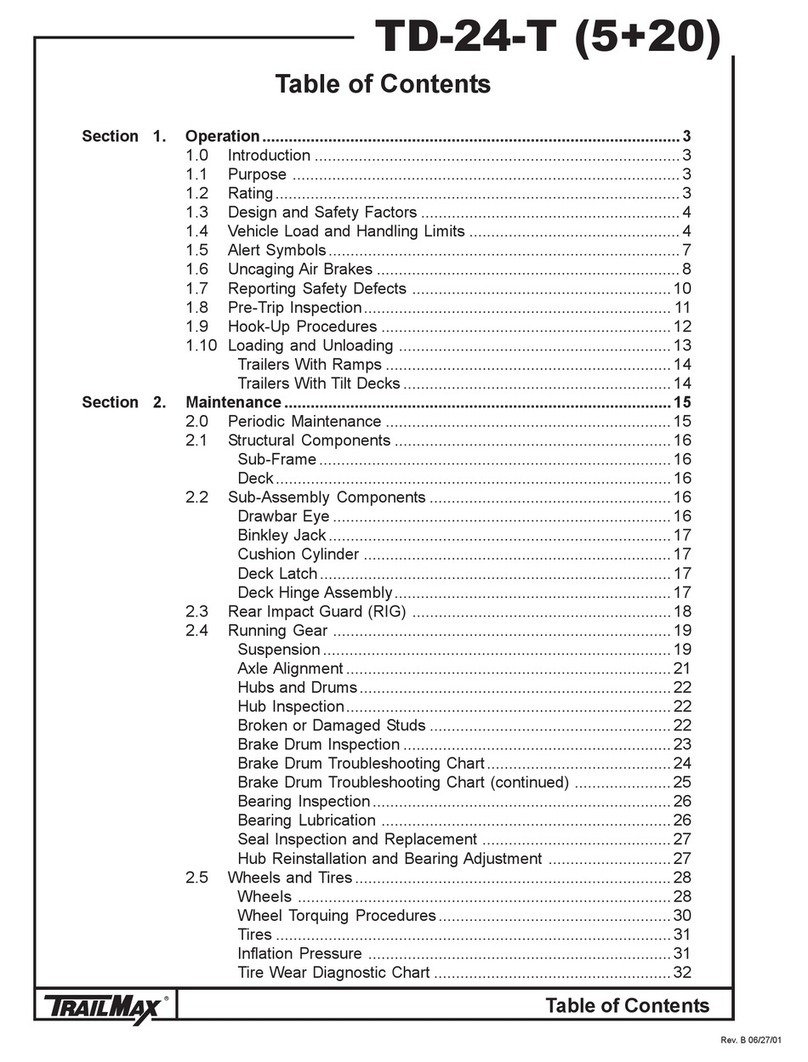

Contents

2 and 3 Tonne Dumpers - Straight Skip .................................................................................................................... 2

2, 3, 4, 5 and 6 Tonne Dumpers - Swing Skip ........................................................................................................... 3

4, 5, 6, 7 and 9 Tonne Dumpers - Straight Skip ........................................................................................................ 4

Introduction ............................................................................................................................................................... 5

General Description ................................................................................................................................................... 5

Safety ........................................................................................................................................................................ 6

Operational Safety Points .......................................................................................................................................... 6

Safe Operation Decals ............................................................................................................................................... 7

Delivery Checks ......................................................................................................................................................... 8

Transportation ........................................................................................................................................................... 8

Using Dumper as a Towing Vehicle ........................................................................................................................... 9

Towing - Torque Converters Models .......................................................................................................................... 9

Driving Controls ....................................................................................................................................................... 10

Steering Column Control Variations ........................................................................................................................ 11

Dashboard Controls - Machines Fitted with ITL Gearbox ........................................................................................ 12

Dashboard Controls - Machines Fitted with Turner Gearbox ................................................................................... 12

2000-3000 Dumpers Only ........................................................................................................................................ 13

Circuit Breakers ....................................................................................................................................................... 13

Audible Warnings .................................................................................................................................................... 13

Seat Operating Instructions ..................................................................................................................................... 14

Start Inhibitors - 2 and 3 Tonne Machines .............................................................................................................. 14

Start Inhibitors - 4, 5, 6, 7 and 9 Tonne Machines .................................................................................................. 14

Starting the Engine .................................................................................................................................................. 15

Stopping the Engine ................................................................................................................................................ 15

Using Clutch and Gearbox ....................................................................................................................................... 16

Torque Converter & Shuttle Gearbox ...................................................................................................................... 17

Steering ................................................................................................................................................................... 18

Stopping the Dumper .............................................................................................................................................. 19

Parking Brake .......................................................................................................................................................... 19

Handbrake Warning ................................................................................................................................................ 19

Gradients ................................................................................................................................................................. 20

Skip Uses ................................................................................................................................................................. 21

Swing Skip Elevation and Slewing .......................................................................................................................... 22

Anti Slew Skip Lock ................................................................................................................................................. 22

Straight Skip Elevation ............................................................................................................................................ 22

How the Hydraulics Function ................................................................................................................................... 23

Straight Skips .......................................................................................................................................................... 23

Swing Skips ............................................................................................................................................................. 25

ROPS - Rectangular Section 9000 Only .................................................................................................................. 25

ROPS - Round Section 2000 to 9000 ...................................................................................................................... 26

June 2004 - 9507EI/5

1-2

2 to 9 Tonne Dumper Instruction Manual

Machine Data

2 and 3 Tonne Dumpers - Straight Skip

Tow

Bracket

Skip Seat

Support

Engine

Canopy

Seat

Gear

Lever

Steering

Wheel

Handbrake &

Skip Control

Lever

Instruction

Manual Holder

Centre Pivot

Engine Stop

Lister Only

Propshaft

Propshaft Rear Axle

Front Axle

Battery

Steer Ram

Skip Pivot

Engine

Front Chassis

Skip Pivot

Transfer

Box

Accelerator

Pedal

Brake

Pedal

Brake

Master

Cylinder

Fuel Tank

Filler

Filler /

Dipstick

Gearbox

Rear Chassis

Hydraulic

Tank Filler

Clutch Pedal

Front Axle Filler

& Drain Plug

Skip Ram Rear Axle

Filler &

Drain Plugs

June 2004 - 9507EI/5

1-3 2 to 9 Tonne Dumper Instruction Manual

Machine Data

2, 3, 4, 5 and 6 Tonne Dumpers - Swing Skip

Battery

Steer Ram

Slew Ram

Skip Ram

Skip Pivot

Slew Ring

Engine

Front Chassis

Transfer

Box

Accelerator

Pedal

Brake

Pedal

Brake

Master

Cylinder

Fuel Tank

Filler

Filler /

Dipstick

Skip Pivot

Slew Ram

Clutch Pedal

(2 & 3 Tonne Only)

Gearbox

Rear Chassis

Hydraulic

Tank Filler

Front Axle Filler

& Drain Plug

Rear Axle

Filler &

Drain Plugs

Engine

Canopy

Gear

Lever

Steering

Wheel

Seat

Handbrake & Skip

Control Lever

Seat

Support

Tow

Bracket

Skip

Instruction

Manual Holder

Centre

Pivot Engine Stop

2-3 Tonne Lister

5-6 Tonne Deutz

Front Axle

Propshaft

Propshaft Rear Axle

June 2004 - 9507EI/5

1-4

2 to 9 Tonne Dumper Instruction Manual

Machine Data

4, 5, 6, 7 and 9 Tonne Dumpers - Straight Skip

Steering

Wheel

Handbrake & Skip

Control Lever

Seat

Gear

Lever

Seat

Support

Engine

Canopy

Tow

Bracket

Skip

Dashboard

Instruction

Manual Holder

Centre Pivot

Propshaft Propshaft Rear Axle

Front Axle

Engine Stop

2 & 3 Tonne Lister

5 & 6 Tonne Deutz

Steer

Ram

Rear Axle

Filler &

Drain Plugs

Battery

Skip Pivot

Skip Ram

Front Axle Filler

& Drain Plugs

Skip Ram

Skip Pivot

Fuel Tank

Filler

Gearbox

Transfer

Box

Engine

Accelerator

Pedal

Brake

Master

Cylinder

Filler / Dipstick

Front Chassis

Front

Axle

Brake

Pedal

Hydraulic

Tank Filler

Rear

Chassis

Battery Location

9000 Dumper

Only

June 2004 - 9507EI/5

1-5 2 to 9 Tonne Dumper Instruction Manual

Introduction

The range of 2 to 9 tonne payload site dumpers have been

designed to provide the greatest degree of component

standardisationpossible,thusprovidingtheuserwithsimplified

servicing requirements. It is for this reason that this handbook

coverstheentirerangeofdumpers,andusersofone,orallofthe

models will benefit from having a single source of information

for all the models in their fleet.

It must be noted, that the 4000 model included in this manual

is NOT the Hydrostatic Drive but the mechanical drive model

General Description

Skips

- Standard and Swing

All modelsintherangeare4wheeldrivedumpershavingaload

carryingskiplocatedoverthefrontaxle,andaheadofthedriver.

The2,3,4and6tonnemodelsareavailablewithaturntableskip

which rotates through 180º. The skip is mounted on a ball

bearing slew ring and is rotated by double hydraulic rams.

Engines

Enginesonallmachinesaremulti-cylinderdieselwhichtransmit

power to the wheels by means of mechanical gearboxes and

axles.

All machines are fitted with electric starting of the engine. A

separate key operated start switch is provided and is located

adjacent to the steering wheel. A battery isolator switch is

provided in the engine compartment.

Chassis

The chassis of the dumpers is of the two part articulating type

havingacentrepivotjointwhicharticulatesinbothvertical,and

horizontal planes.

Steering

Steering of the dumper is by an 'Orbitrol' hydrostatic steering

unit,poweringasingleramconnectingthefrontandrearchassis

units.

Transmission

The transmission of the dumpers comprise of heavy duty

constant mesh gearboxes with three forward and one reverse

gear on all models up to 3 tonne capacity. The 4, 5, 6, 7 and 9

tonnemodelshavetorqueconverterfourspeedshuttlegearboxes.

Braking

Thevehiclebrakingisprovidedbymeansoftotallyenclosedoil

immersed brakes located within the drive axles. These brakes

are self adjusting sintered multi-plate discs which are

hydraulically operated by means of single or tandem master

cylinders depending upon whether the dumper has 1 or 2 axle

braking.

In the case of two axle braking the tandem master cylinder

providesthefeatureoftotallyindependentfrontandrearsystems.

In the event of failure of one system, braking will still be

available on the alternative axle.

Electric System

All models are available with full lighting to comply with

British road traffic regulations. All models use a belt driven

alternator to charge the battery.

Machine Data

June 2004 - 9507EI/5

1-6

2 to 9 Tonne Dumper Instruction Manual

General Safety

Safety

These machines are designed to carry out the function of

transporting various free flowing materials. If used correctly

they will provide an effective and safe means of transportation

and meet the appropriate performance standards.

It is essential the machine Operator is an able bodied adult,

adequately trained in its safe operation. The Operator must

also be authorised to operate the machine and have sufficient

working knowledge of the machine to ensure it is in a full

and safe working condition before it is put to use

Operational Safety Points

Whenusingthismachine thefollowinglistof basicDo'sand

Don't's should be applied. This list is not necessarily a

completelist,butapplyingtheseruleswillgreatlyreducethe

possibility of an accident occurring.

Always

;Carry out a daily pre-start check of the machine.

;Ensure this Instruction Manual is placed in the special holder

behind the seat.

;Lookaround the machinebefore starting the engine -children

could be out of sight.

;Before starting the engine, ensure the transmission control

lever and/or gearlever is in the NEUTRAL position.

;Examine working area looking for possible dangers e.g.

trenches, confined areas, people working.

;Park the machine on safe, firm, level ground and remove the

start switch key.

;Clearaway obvious hazards and alwaysoperate with caution.

;Ensure you have a clear view when driving.

;Exercise great care when working on gradients - especially

when crossing.

;Whenrefuelling make surethe engine iscold and the machine

is in a well ventilated area, with the engine stopped. Use

clean fuel and container. Beware of naked flames, grinding

sparks etc.

;Winch or lift the machine from any situation where it cannot

extricate itself.

;Wear appropriate protective clothing :

Hard Hat ..................... at all times

Safety Boots ............... at all times

Safety Glasses ............ at all times

ReflectiveClothing ..... at all times

Gloves ........................ as conditions dictate

Ear Protectors ............. as conditions dictate

Respirator ................... in dusty conditions

;Wash and Clean machine at end of working day - Keep water

away from electrical components.

;Ensure drivers seat is correctly adjusted as described in the

Seat Operating section of this manual.

;Use footsteps and grabrails provided when getting on and

off the machine.

;Keep floorplate and steps free of mud, oil, debris etc.

;Use seatbelt when ROPS or FOPS is fitted.

;Reduce the payload if the materials are of a sticky non-

flowing nature.

;Ensure materials being tipped are of a free-flowing nature -

Swing skips only.

;Get off the machine whenever the skip is being loaded.

Never

:Attempt to ‘jump’ obstacles such as kerbs and manholes.

:Drive at speed over rough ground - drive slowly.

:Leave the machine unattended with the engine running, this

practiceis not onlydangerous but cancause premature engine

wear.

:Carry out maintenance unless engine is stopped and the start

key has been removed.

:Carry out maintenance unless the wheels are chocked and

the skip is propped.

:Tamper with any of the safety devices on the machine.

:Tighten or disconnect any hose whilst the engine is running.

:Attempt to start the engine from OFF the machine.

:Stand in the CRUSH area between front and rear frames

when the engine is running.

:Carry passengers.

:Use the machine as a towing vehicle.

:Allow the dumper to be loaded such that vision and safe

driving is impaired.

:Overload the dumper beyond its rated payload.

:Carry loads which extend over side of dumper - they create

instability and danger to pedestrians.

:Tip materials into a trench unless a banksman is employed

with a stop bar or baulk of timber, to prevent the dumper

getting too close to the edge and either falling in or causing

the trench sides to collapse.

:Drive the dumper with the skip elevated.

:Allow personnel to work under a raised skip if the skip props

are not in position.

June 2004 - 9507EI/5

1-7 2 to 9 Tonne Dumper Instruction Manual

General Safety

Safe Operation Decals

Themachinehasanumberofspecialdecalsfittedwhichdrawthe

users attention to various points of operation or safety.

Before Using the Machine

Read all the decals attached to the machine and fully

understand their meaning. If you don’t understand their

meaning contact your supervisor for clarification.

Condition of Decals

Ensurethe decals are alwaysclean and readable, replacewhen

necessary.

Spare decals are obtainable from the Manufacturers Spares

Department.

See SAFETY SECTION for Transfer Descriptions

This manual suits for next models

5

Table of contents