10. Elimination of disfunctions

No ignition:

- Check if the engine switches are (ON).

- Check if the fuel tap is (ON).

- Check spark plug and spark plug connector - if necessary replace the parts

Subfunction of fuel system

- Check if the tank is fueled

- Check if the fuel tap is (ON)

- Check function of fuel pump.

- Check the fuel line/hoses for leaks

Engine runs - but power is limited

- Check general function and adjustment of the gas cabling

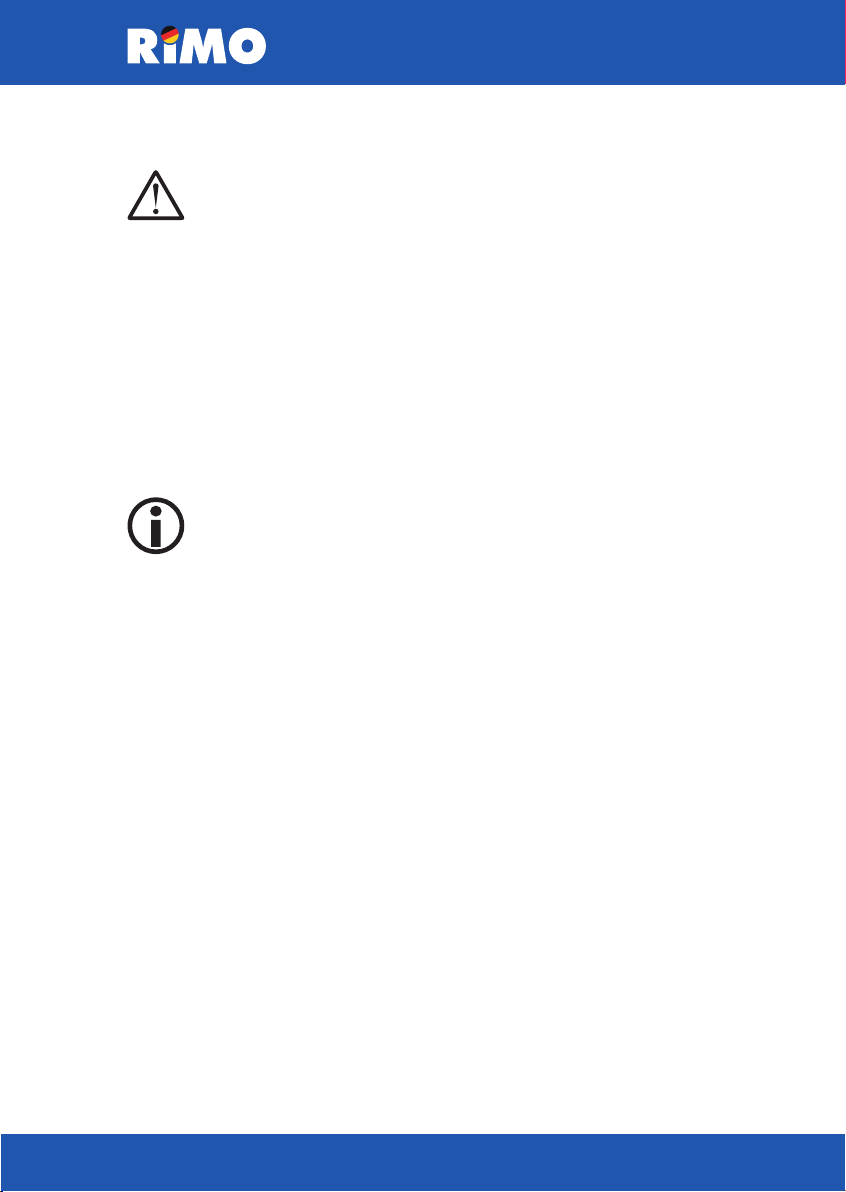

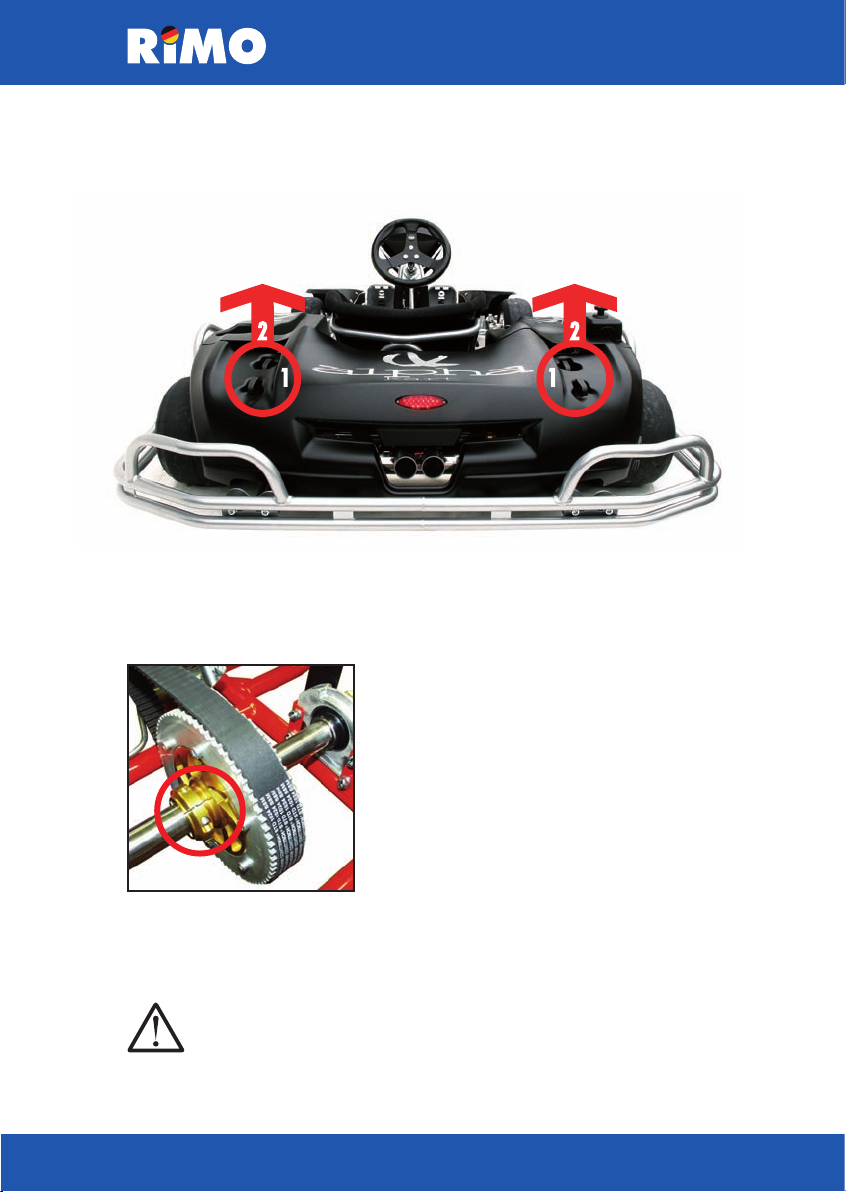

Unsatisfying brake deceleration

- Check the general function of the brake system

- Check the brake pads for abrasion and control the adjustment (see chapter 13.2 /13.3)

8

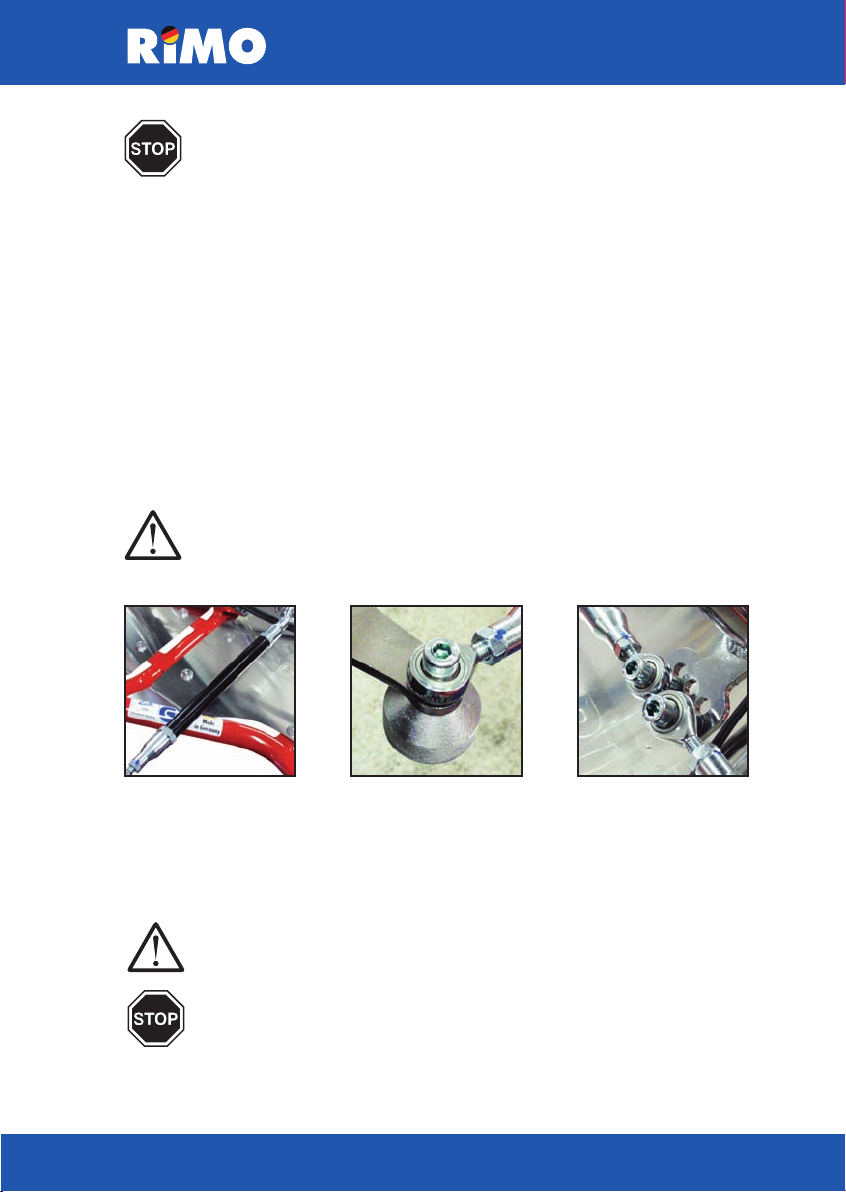

- untighten the bolts of the brake lever guidances to reach the brake pad

- untighten the bolts of the brake pad carriers to reach the brake pads

- replace the old brake pads against new and reassemble the brake in reverted order

8.7. Inspection an maintenance of the mechanical brake system

The vehicle has to decelerate undelayed during actuation of brake pedal.

The effective pedal way until begin of braking effect shouldn´t exceed 3cm.

In case of unsatisfying brake results go ahead as follows:

9. Cleaning instructions

RiMO recommends regularly cleaning of the vehicle.

Tip: Use a steam blaster or simple purifier and a cleaning rag.

Never use detergents which content thinners or acetone: these detergents could cause damages on

the powder coated surface of the vehicle.

In case of using a steam blaster take care not to hit carburetor, starter, bearings rear axle or stickers.