13

INTRODUCTION

Thank you for choosing our EVA 5 road gate.

All items included in Benincà’s wide product range stem

from twenty year of our experience in the sector of automatic

systems, always striving to nd new materials and advanced

technologies.

For this reason, nowadays we are able to offer you extremely

reliable products that, thanks to their power, efciency and

long-lasting features, entirely meet the end user’s require-

ments.

All our products are covered by a guarantee.

Furthermore, an R.C. insurance policy signed with a primary

insurance company, covers any injuries or damages caused

by manufacturing faults.

GENERAL INFORMATION

Of rugged construction, with an innovative and pleasant

design, the road barriers EVA are suited for intensive use

thanks to their 24VDC motor. This system is very easy to

install and adjust.

Equipped with an easy-to-use manual release, the barrier is

preset to assemble buffer batteries to allow its operation in

the event of power failure.

The arm in paint aluminium allows for the housing of any

accessories, as well as forewarning and safety devices. In

the event the arm hits an obstacle, an amperometric sensor

causes the movement reversion immediately.

The control unit is placed on the upper side of the barrier to

facilitate wire connections.

SPECIFICATION EVA 5

Power supply

Motor power supply

Power drawn

Current absorption

Torque

Jogging

Protection class

Operating temperature

Noise

Lubrication

Weight

230Vac 50Hz

24Vdc

120 W

4,6 A

130 Nm

Intensive use

IP54

-20°C / +70°C

<70 dB

Agip GR MU EP/2

55kg

OPENING SPEED

Motor power

supply

Opening time

(s)

Closing time

(s)

26 Vdc 3 4

23 Vdc 4 5

18 Vdc 5 6

The opening time of the road barrier changes according to the supply

voltage selected on the transformer of the control unit.

Times shown include braking.

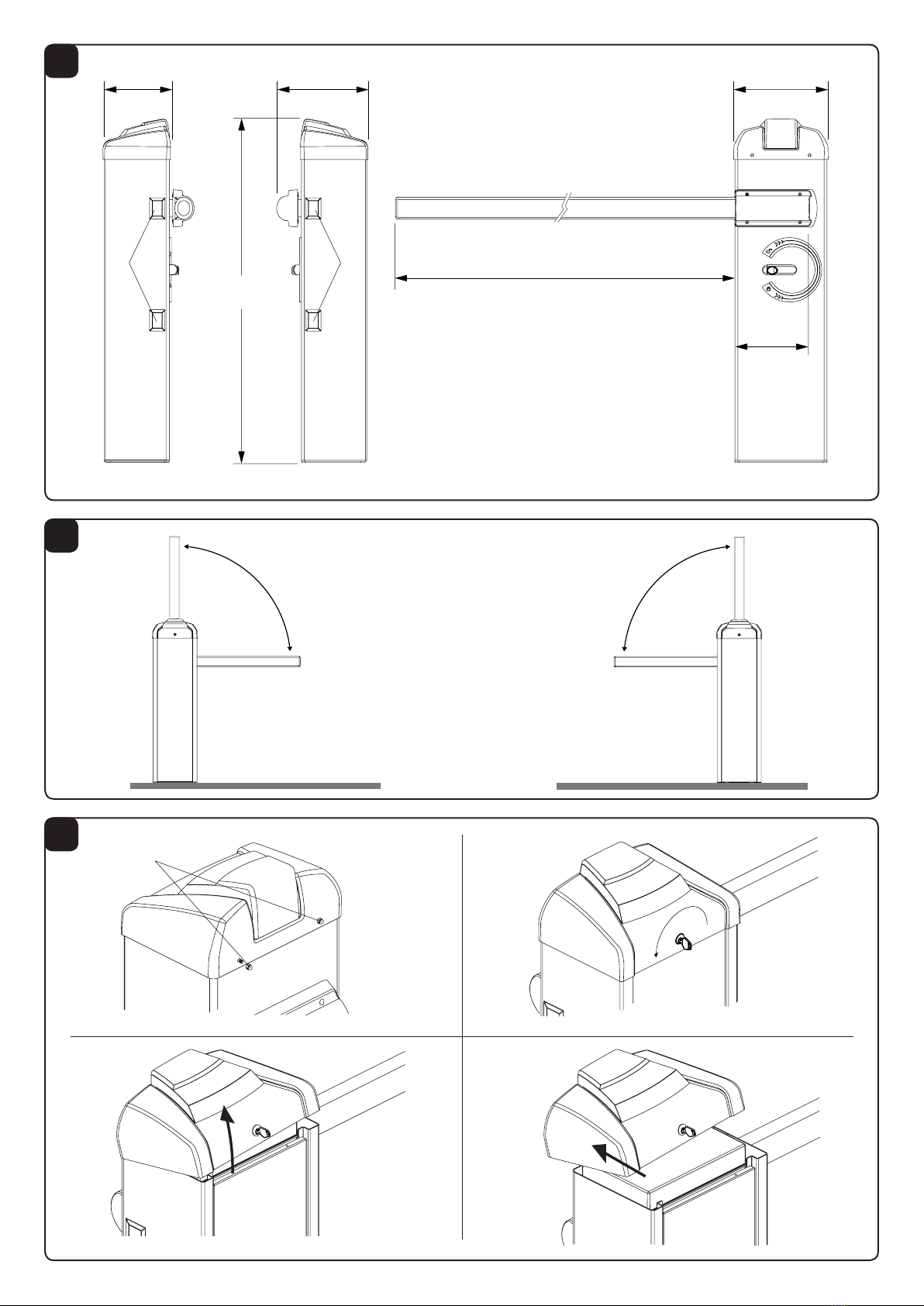

DIMENSIONS

FIG.1

Overall dimensions are expressed in mm.

The road barrier length ranges from 3m minimum to 5m

maximum.

As about 25cm are required to x a road barrier, a useful

opening of passage, ranging from 2.75m to 4.75, will be

available, as shown in Fig.1

Optional accessories can be tted onto be barrier (photo-

cells, selector, etc.). For assembly, apply the special covers

supplied (Rif. A).

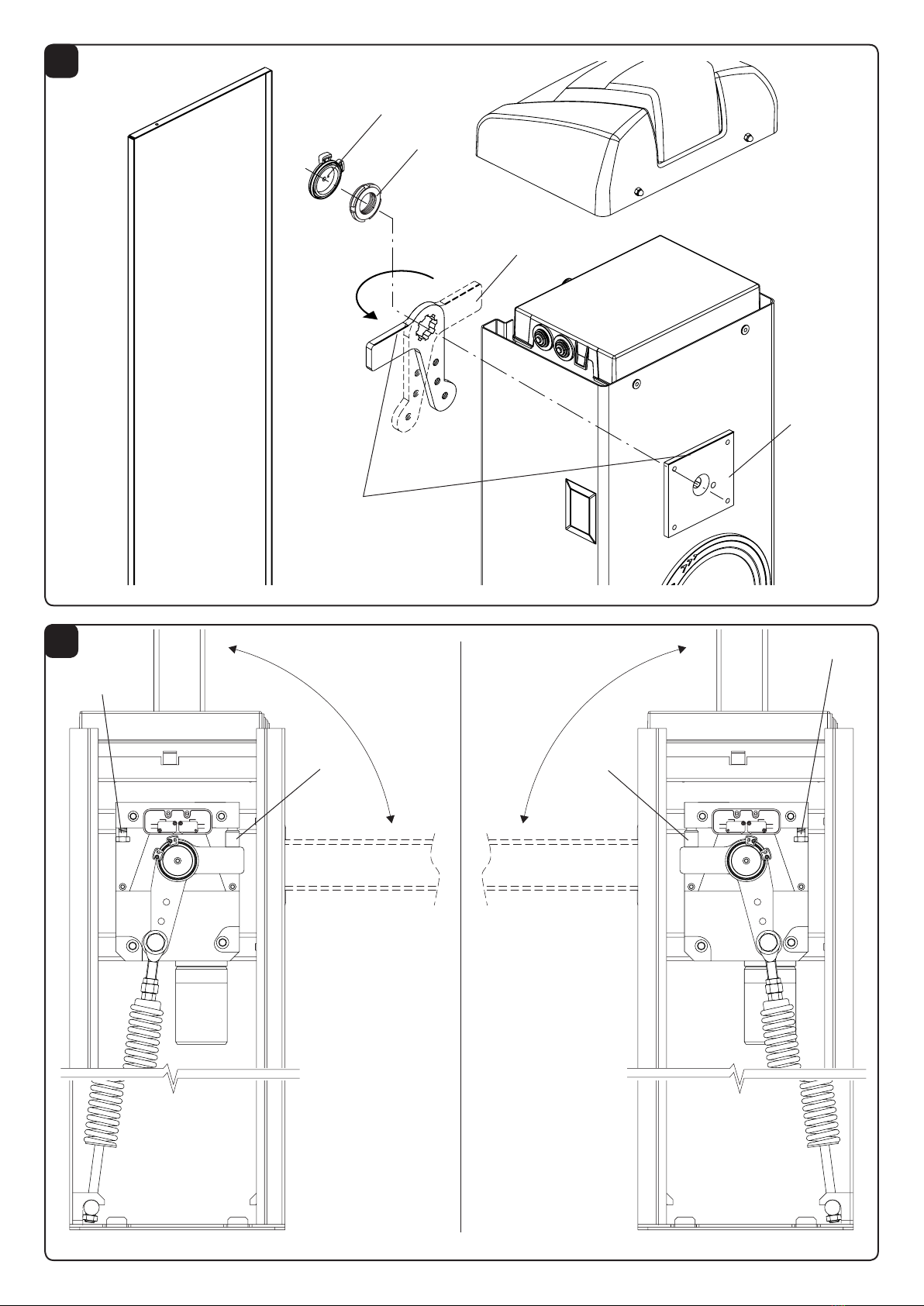

RIGHT/LEFT-HAND OPENING OF THE BARRIER

FIG.2

The EVA 5 road barrier is available in both right (EVA5-DX)

and left (EVA5-SX) models.

With reference to Fig.2, a right-hand opening road barrier is

a system which, seen from the door side, closes the right-

hand side of the passage. The left-hand opening is in the

opposite way.

As the opening side can be changed at any moment, it is

advisable to buy a type of road barrier which allows the ea-

siest and rapid installation.

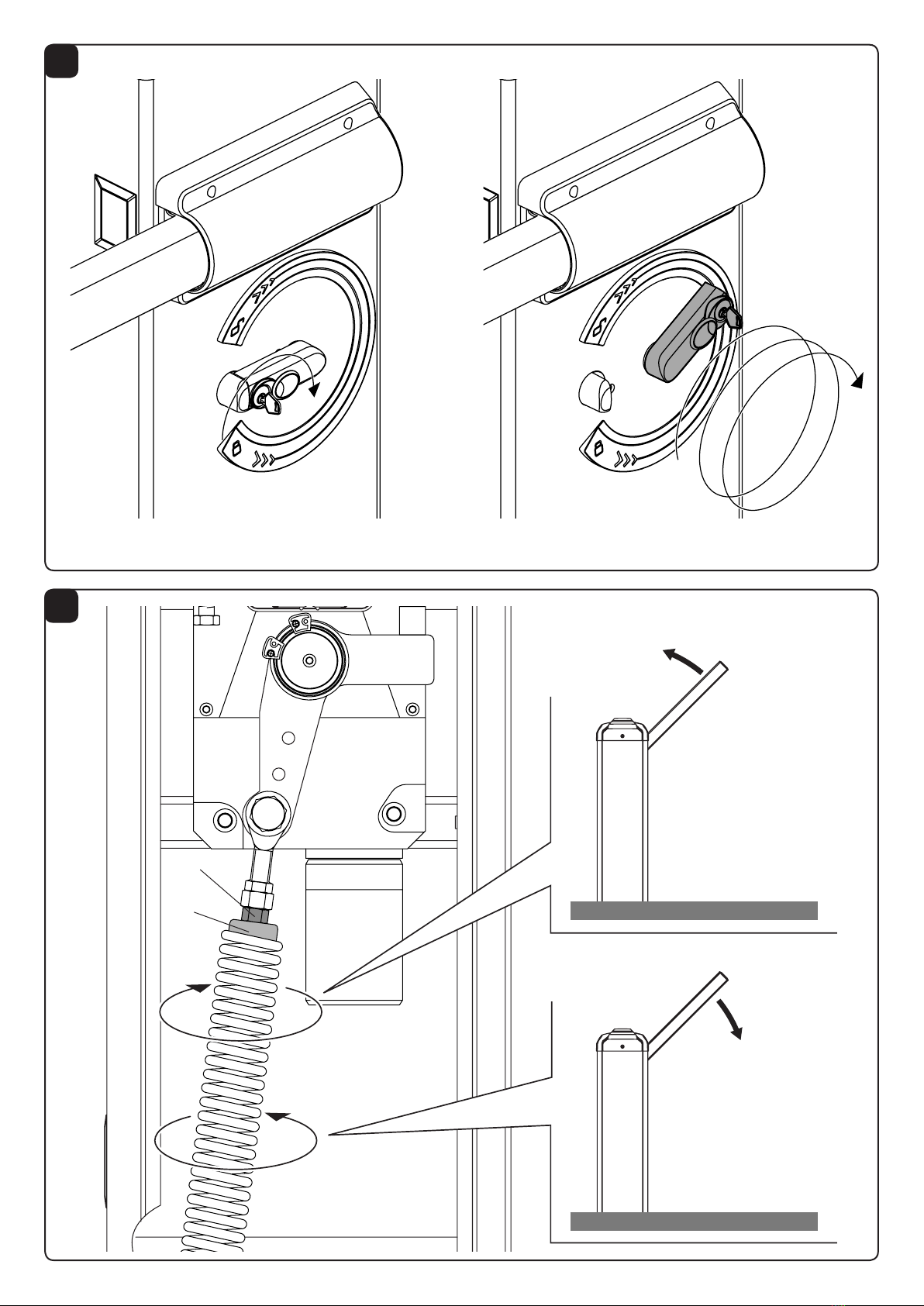

OPENING

FIG.3

The access to the electric and mechanical components of

the road barrier is protected by a lock with customized key.

Proceed as follows:

1 loosen the two nuts D

2 introduce the key in the lock on the side of the door and

turn it anti-clockwise

3 lift the front cover

4 remove the cover

By removing the front door it is now possible to reach both

the control unit, that is placed under the cover, and the

mechanical parts of the road barrier.

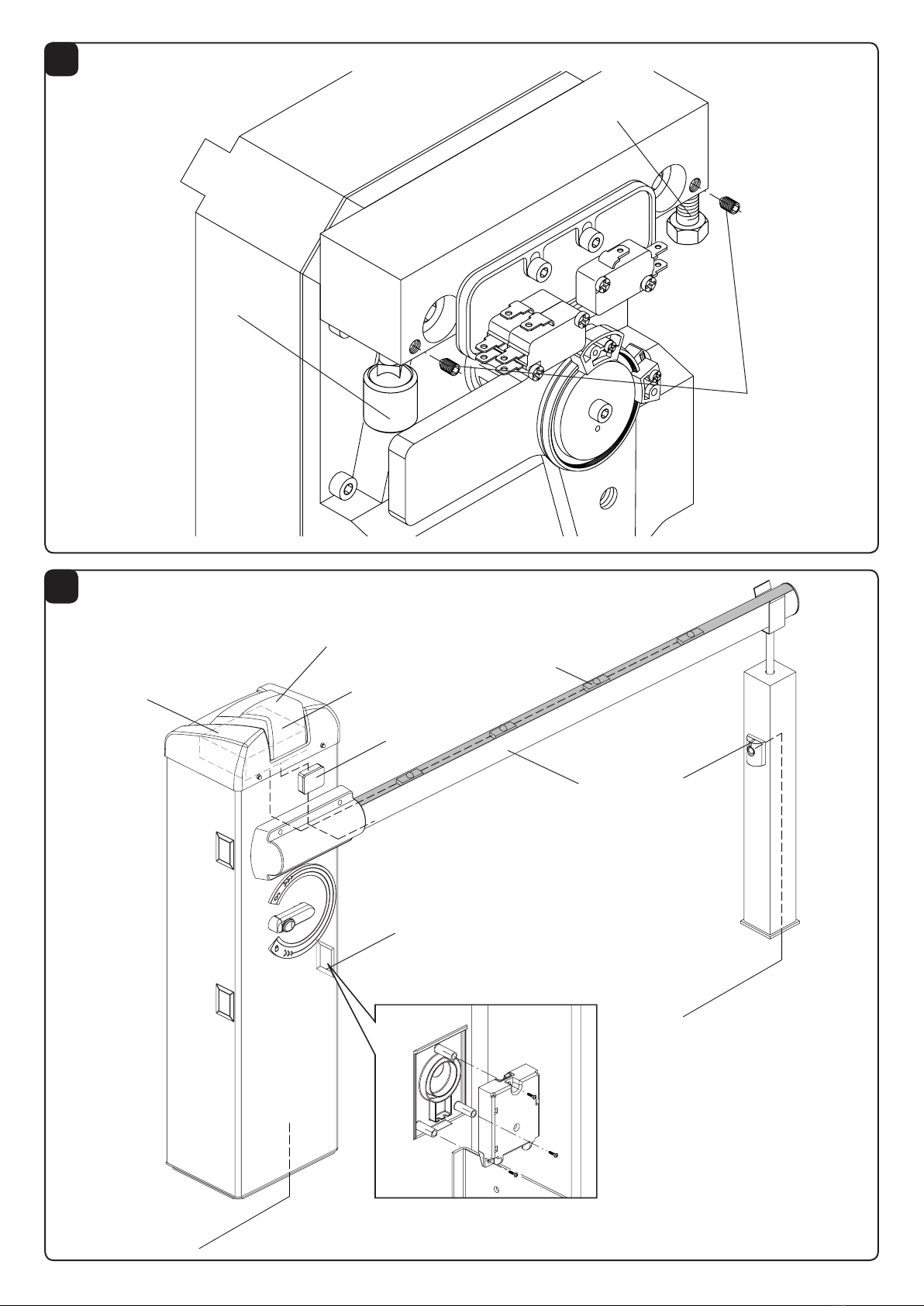

INSTALLATION OF THE FOUNDATION PLATE

FIG.4

After preparing the cable laying (mains power supply, acces-

sories, etc.), place the foundation plate keeping to dimensions

indicated.

Brackets to be cemented are supplied with the system (ref.

S). The brackets must be tted to the foundation plate by

means of 4 screws M12x50 (ref. V).

Check that the foundation plate is perfectly at (ref. L), then

x the road barrier by means of nuts D and corresponding

washers R.

POSITIONING OF THE SPRING

AND ACCESSORIES

FIG.5

According to the length of the beam and the type of accesso-

ries installed, before tensioning the spring, the correct point

to hook the spring to the lever must be selected.

The correct hooking point (“A”, “B” and “C”), must be se-

lected by taking account of table 1, according to the beam

length and the type of accessories to be installed.

HOW TO FIX THE BEAM

FIG.6

Any accessories for the beam (protection edges, lights, pneu-

matic safety edges, rack, etc. ) are installed before tting the

beam. See relevant instructions.

Fit the beam to plate P by using bracket S and both the 6

screws with the corresponding washers, and plate T.

Apply the removable plastic cover C.