Bennett T-75 Guide

Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456

USA 800-235-7618 ~ Outside USA 231-798-1310

sales@bennettpump.com ~ www.bennettpump.com

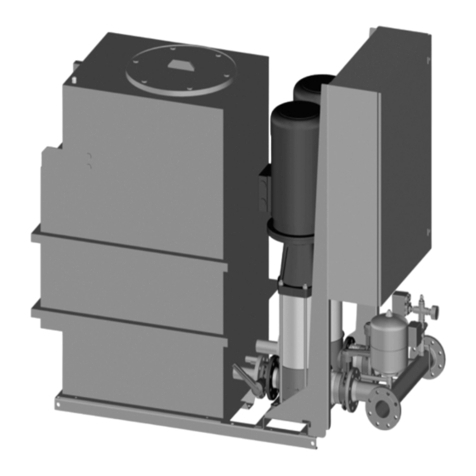

BENNETT T-75 HYDRAULIC PUMPING UNIT

T-75 Hydraulic Pumping Units

Operation, Service, & Parts Manual

107072 Rev G 10/26/18

Introduction / Operation / Troubleshooting / Parts

Only Trained Personnel May Work on This Equipment

READ THIS MANUAL

This manual has important information for safe installation and operation of this equipment. Read and understand this manual

before applying power. Keep this manual and tell all service personnel to read this manual. If you do not follow the instructions,

you can cause bodily injury, death, or damage to the equipment.

Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456

USA 800-235-7618 ~ Outside USA 231-798-1310

sales@bennettpump.com ~ www.bennettpump.com

The material included in this technical manual is accurate at the date of publication. The intent of this manual is to

assist. If further assistance is required, please contact the Bennett Technical Service Department at 1-800-423-6638.

Bennett Marketing Services can be contacted by mail, facsimile, telephone or e-mail at the locations specified below:

Bennett Pump Company

Marketing Services

1218 East Pontaluna Road

Spring Lake, MI 49456

Telephone from USA 1-800-235-7618

Telephone from outside USA 231-798-1310, Extension 287 or 269

Facsimile: 231-799-6200

Website: www.bennettpump.com

For new manuals, visit our web page at www.bennettpump.com

IMPORTANT

Examine the shipment immediately upon arrival to make certain there has been no damage or loss in transit.

Bennett Pump Company, as shipper, is not liable for the hazards of transportation. Please make damage

claims directly to the truck line.

Not all equipment covered in this manual is listed by Underwriters Laboratories.

APPROVALS & CERTIFICATES

U.L. Recognized Component / Certificate #20130326 – MH25908

Approved to comply with OIML R117 / Certificate #ZR 141/13-0092

Various other Weights & Measure Approvals and Safety Recognitions available, consult factory

Bennett Pump is an ISO 9001: 20015 Certified Company

Revision Level

Date

Description

A

-

Original Document

B

-

-

C

-

-

D

-

-

E

6/11/12

-

F

7/18/18

Updated Approvals & Certificates

Updated U.S. Technical Specifications and European Specifications

Updated Parts Lists

Added Spare Parts List

G

10/26/18

Added Air Eliminator Tube Caution Statement

Bennett T75 Operation, Service, & Parts Manual Table of Contents

1

TABLE OF CONTENTS

TABLE OF CONTENTS 1

SAFETY INFORMATION 3

General Information.......................................................................................................................................................................................................4

Hazardous locations ......................................................................................................................................................................................................4

Codes and Standards ....................................................................................................................................................................................................4

Unauthorized Alteration of Bennett Products....................................................................................................................................................4

Abbreviations and Acronyms.....................................................................................................................................................................................4

PRODUCT INTRODUCTION 5

Features & Construction..............................................................................................................................................................................................5

T75 Series Models...........................................................................................................................................................................................................5

Product Specifications ..................................................................................................................................................................................................5

Installation Piping for Type 75 Pump Dispenser ...............................................................................................................................................6

Pump Curves –U.S. Market ........................................................................................................................................................................................7

Pump Curve –European Market ..............................................................................................................................................................................7

Exterior Dimensions.......................................................................................................................................................................................................8

Inlet & Mounting Dimensions................................................................................................................................................................................ 10

OPERATION 13

Theory of Operation ................................................................................................................................................................................................... 15

TROUBLESHOOTING 17

Problem 1: The motor starts but the pump does not deliver fuel. ......................................................................................................... 17

Problem 2: The pump runs but delivery is slow.............................................................................................................................................. 17

Problem 3: Inaccurate delivery............................................................................................................................................................................... 18

Problem 4: Fuel runs out of vent tube when pump is operating. ........................................................................................................... 18

Problem 5: The computer jumps when the pump is turned on............................................................................................................... 18

PARTS 19

To Place an Order for Parts...................................................................................................................................................................................... 19

Model & Serial Plate Identification ...................................................................................................................................................................... 19

T75 Pumping Unit Assembly................................................................................................................................................................................... 20

Type 75 Pumping Unit Parts List ........................................................................................................................................................................... 21

Spare Parts Lists............................................................................................................................................................................................................ 22

Bennett T75 Operation, Service, & Parts Manual Table of Contents

2

Page Intentionally Left Blank

Bennett T75 Operation, Service, & Parts Manual Safety Information

3

SECTION 1: SAFETY INFORMATION

SAFETY INFORMATION

For safe installation of this equipment, read and understand all dangers, warnings, and cautionary information. Save this safety information in a

readily accessible location. Look for the following warnings throughout the manual:

Red and White “DANGER” means: If you do not follow the instructions, severe injury or death will occur.

Orange and Black “WARNING” means: If you do not follow the instructions, severe injury or death can occur.

Yellow and Black “CAUTION” means: If you do not follow the instructions, damage can occur to the dispenser.

Blue and White “IMPORTANT” means: Helpful tips and other recommendations on equipment installation, usage, and maintenance should

be observed.

DANGER PELIGRO DANGER

FIRE, EXPLOSION, INJURY, OR DEATH WILL OCCUR IF FUEL FILTERS ARE

CHANGED BY UNTRAINED PERSONNEL. MAKE SURE, ONLY TRAINED

PERSONNEL CHANGE FILTERS.

TO PREVENT INJURY TO YOU FROM VEHICLES AND ONLOOKERS,

ALWAYS PLACE A BARRIER AROUND THIS EQUIPMENT BEFORE

PERFORMING SERVICE OR MAINTENANCE.

GASOLINE AND FUEL ETHANOL IS FLAMMABLE. NO SMOKING OR

OPEN FLAME.

FUEL ETHANOL IS POISONOUS AND SHOULD NOT BE INGESTED.

DISCONNECT ALL POWER, RELIEVE PRESSURE TO THIS EQUIPMENT,

AND ASSOCIATED COMPRESSOR DURING INSTALLATION, SERVICE, OR

ANY MAINTENANCE I.E., CHANGING FILTERS.

WARNING ADVERTENCIA MISE EN GARDE

You must have training in the installation, service, or maintenance of

this equipment (dispenser, pump, console, control box, or submerged

pump) before working on it. Maintenance repairs must be done by

authorized personnel only. Warranty work may only be performed by

Bennett certified technicians.

To prevent electric shock, keep the electrical parts of the dispenser dry.

Electronic components are static sensitive. Use only proper static

precautions (e.g. static straps) before working on the equipment.

The emergency shut-off valve (also called the fire valve, shear valve, or

impact valve) must be closed when service or maintenance is performed

on this equipment.

You must have training in the operation and programming of this

dispenser before using it. READ THE OPERATORS MANUAL.

Make sure this equipment is correctly grounded. Failure to do will cause

injury or damage equipment or improper operation. Improper

grounding voids the warranty.

When anchoring the dispenser, always level the dispenser with shims

before bolting to the island. DO NOT shim the middle of base rails to

bolt down the dispenser.

CAUTION PRECAUCIÓN MISE EN GARDE

Do not drill holes in fuel dispensers. Holes can cause failure of the

electronic equipment. THE WARRANTY WILL BECOME VOID. Use only

adhesive backed sign mounting brackets.

IMPORTANT IMPORTANTE IMPORTANT

All trained technicians must work in accordance to all requirements,

standards, and guidelines specified by the suppliers Environmental

Standards® Health, Safety, Security & Environment (HSSE) policies.

Note: Bennett Pump highly recommends all technicians observe HSSE

policies defined by the supplier. Bennett Pump does not impose any

restrictions or additional requirements contained in Environmental

Standards® Health, Safety, Security & Environment (HSSE) policies.

!! READ AND UNDERSTAND ALL WARNING LABELS ATTACHED TO THE DISPENSER !!

Bennett T75 Operation, Service, & Parts Manual Safety Information

4

GENERAL INFORMATION

Read this manual carefully and read all tags/labels attached to the T75 Pumping Unit before starting any maintenance and/or service. A pumping

unit that is not properly maintained will not perform properly and will void the Bennett limited warranty.

Before installation, operation, maintenance and/or service ensure that protection against lighting strikes are in accordance with the American

Petroleum Institute Recommended Practice RP 2003, Protection Against Ignitions Arising out of Static, Lightening, and Stray Currents.

Service of the Bennett products and all accessories (e.g. Nozzles, Hoses, and Breakaways) must be performed by a technician who is trained in

accordance to all codes, requirements, standards, and regulations.

HAZARDOUS LOCATIONS

For safe operation, ensure that the dispenser is in a classified area as detailed below per NFPA 30, Flammable and Combustible Liquids Code and

NFPA 70, National Electric Code. For further information on the classification of locations for Fuel Dispensers, see NFPA 30, Flammable and

Combustible Liquids Code.

CODES AND STAND ARDS

Follow all local, state, federal requirements, and accordance’s for installation of all equipment. Note: Refer to Appendices for approval

documentation.

ANSI/UL79 Power-Operated Pumps for Petroleum Dispensing Products

API 2003 –Protection Against Ignitions Arising Out of Stray, Lightning, and Stray Currents

International Fire Code –2000 Edition

NFPA 30 –Flammable and Combustible Liquids Standard

NFPA 30A –Motor Fuel Dispensing Facilities and Repair Garages Standard

NFPA 70 –National Electric Code

OIML R117-1 Dynamic Measuring Systems For Liquids Other Than Water

PEI/RP100, Recommended Practices for Installation of Underground Liquid Storage Systems

PEI/RP200, Recommended Practices for Installation of Aboveground Liquid Storage Systems

UNAUTHORIZE D ALTERAT ION OF BENNETT PRODU CTS

DANGER: BEFORE PERFORMING ANY TYPE OF SERVICE TO THE DISPENSERS, BE SURE TO SHUT OFF ALL ELECTRICAL SUPPLIES AND

SECURE THEM IN THE OFF POSITION. CLOSE ALL VALVES IN INCOMING PIPING. MAINTENANCE MUST BE PERFORMED

BY TRAINED PERSONAL ONLY.

Bennett Pump Company products are designed to meet or exceed the standards of Underwriters Laboratories, Inc., Federal Communication

commission, and National Institute of Standards and Technology. Compliance with these standards protects the operator and the consumer from

personal injury and ensure an accurate delivery of product. Any deviation from the use of authorized replacement parts or alteration of a designed

product configuration may cause personal injury, death or the revocation of one or all of the above approvals.

Bennett Pump Company will not assume responsibility or liability for any consequential injury or damage caused by the unauthorized alteration of

its products.

ABBREVIATIONS AND AC RONYMS

Term

Description

AC

Alternating Current

API

America Petroleum Institute

DC

Direct Current

dB

Decibel

GPM

Gallons Per Minute

Hz

Hertz

kW

Kilowatt

LPM

Liters Per Minute

NEC

National Electrical Code

NFPA

National Fire Protection Agency

NPT

National Pipe Taper or National Pipe Thread

OEM

Original Equipment Manufacturer

PEI

Petroleum Equipment Institute

PSIG

Pounds per square inch gauge

THHN

Thermoplastic High Heat-resistant Nylon-coated

UL

Underwriters Laboratories, Inc.

VAC

Voltage Alternating Current

VDC

Voltage Direct Current

Bennett T75 Operation, Service, & Parts Manual Product Introduction

5

SECTION 2: PRODUCT INTRODUCTION

PRODUCT INTRODUCTION

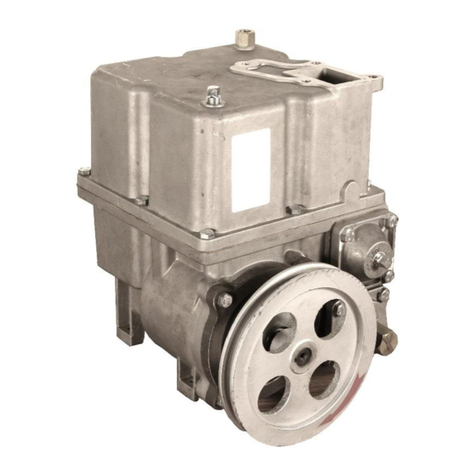

The Type 75 pumping unit is a rotary vane type, flammable-liquid pump. They are provided with an integral strainer, pressure relief valve, air

eliminator, and bypass valve, which is set to return liquid, under pressures exceeding 50 psi, to the suction side of the pump. For further

information, please contact the Bennett Technical Service Department at 1-800-423-6638.

FEATURE S & CONSTRUCTION

The T75 pumping unit is fully compatible with the SB-100 Meter, compact and lightweight unit built with the following functions.

Positive Displacement, Sliding Vane Design

Efficient & Low Power Consumption

Standard and High Displacement Flow Rate Models

Integrated & Approved Vortex Style Air Elimination Device

Self-Lubricating Bearings

Threaded test connections for field diagnostics

Internal Outlet Control Valve to Minimize Pressure Surges

Integral Filtration, selection of Micron ranges

Drain plug for servicing and filter replacement

Integrated pressure relief bypass valve (optional adjustable version)

Flanged outlet with direct SB100 Meter connection or 1 3/16” diameter Tube Style Outlet (30 mm)

Integrated Motor Mount Top Cover on Tube Outlet Versions

Flanged Bottom Inlet (Vertically Aligned 1-1/2” NPT) or 4 Bolt Filter Cover Side Inlet Mode

Patented internal design features to reduce the possibility of vapor lock

T75 SERIE S MODELS

Type 75D –Standard fuels and Gasoline/Ethanol blends with nominal ethanol concentrations up to 15%

Type 75A –For use with Gasoline/Ethanol blends with nominal ethanol concentrations up to 85%

PRODUCT SPECI FICATIONS

CAUTION: OPERATING THE REMOTE DISPENSER OR SUCTION PUMP AT VOLTAGES AT OR ABOVE THE REQUIRED 120/240VAC IS NOT

RECOMMENDED! FAILURE OR DAMAGE TO THE ELECTRONIC EQUIPMENT CAN OCCUR.

CAUTION: THE AIR ELIMINATOR (COPPER) TUBE MUST REMAIN OPEN TO THE ATMOSPHERE FOR PROPER VENTILATION.

DIMENSIONS

Flanged Outlet Style (Vertical) ...........................................................................................................................................................12 39/64” (320 mm)

Tubular Outlet Style (Vertical) ...............................................................................................................................................................11 5/8” (295 mm)

Flanged and Tabular Outlet Style (Horizontal) ........................................................................................................ 8-3/4” x 11-15/16”” (222 x 303 mm)

Flanged and Tabular Outlet Style (Depth) ............................................................................................................................... 11.15/16” (222 x 303 mm)

Weight...........................................................................................................................................................................................................36 lbs. (79kg)

U.S. SPECIFICATIONS

Power Requirements @ Maximum Flow & Pressure............................................................22 gpm (80 lpm) at 700 RPM with 3/4 HP Motor (0.55kW)

Maximum Flow Rate................................................................................................................................................................................24 gpm / 90 lpm

Noise Level ................................................................................................................................................................................................................ 72 dB

Maximum Operating Pressure..................................................................................................................................................................................50 psi

Maximum Motor Power Requirements ............................................................................................................................................1200 watts / 1.2 kW

Bypass Pressure ................................................................................................................................................................................................ Adjustable

Minimum Dry Suction............................................................................................................................................................................................ 8 in HG

Minimum Wet Suction......................................................................................................................................................................................... 21 in HG

Micron Filter ()...........................................................................................................................................................................................................N/A

Air Elimination ................................................................................................................................................According to OIML, CEE 77.313 Regulation

Pump Curve............................................................................................................................................................................................. Refer to Figure 2

Bennett T75 Operation, Service, & Parts Manual Product Introduction

6

EUROPEAN SPEC IFICATI O NS

Power Requirements @ Maximum Flow & Pressure............................................................... 22 gpm (80 lpm) at 700 RPM with 1 HP Motor (0.75kW)

Maximum Flow Rate............................................................................................................................................................................................80 L/min

Noise Level ................................................................................................................................................................................................................ 72 dB

Maximum Operating Pressure................................................................................................................................................................................3.5 bar

Minimum Pressure..................................................................................................................................................................................................0.7 bar

Maximum Motor Power Requirements ............................................................................................................................................1200 watts / 1.2 kW

Bypass Pressure ................................................................................................................................................................................................ Adjustable

Minimum Dry Suction............................................................................................................................................................................................ 400 mb

Minimum Wet Suction........................................................................................................................................................................................... 700 mb

Micron Filter ()................................................................................................................................................ 10, 35, 70 according to conditions of use

Air Elimination ................................................................................................................................................According to OIML, CEE 77.313 Regulation

Pump Curve............................................................................................................................................................................................. Refer to Figure 3

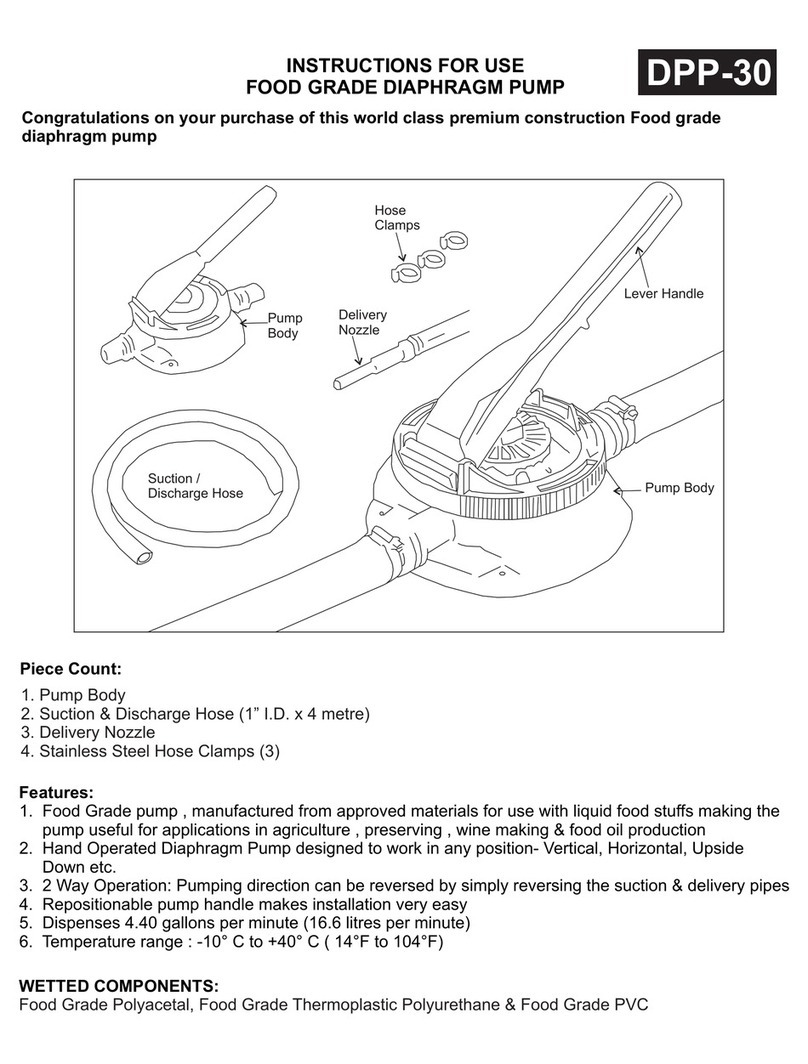

INSTALLATION PIPING FOR T YPE 75 PUMP DISPENSER

Refer to the PEI/RP100, Recommended Practices for Installation of Underground Liquid Storage Systems, PEI/RP200, Recommended Practices for

Installation of Aboveground Liquid Storage Systems, and all local, state, federal requirements, and accordance’s prior to any installation of all

equipment.

CAUTION: THE AIR ELIMINATOR (COPPER) TUBE MUST REMAIN OPEN TO THE ATMOSPHERE FOR PROPER VENTILATION.

To obtain maximum flow rates on a self-contained pump, follow these guidelines.

1. The total length of horizontal piping between the pump and tank must be no longer than 60 feet.

2. Static lift on self-contained units must not exceed 10 feet (vertical distance between product level in the storage tank and the center of

the pumping unit).

3. Use new 1-1/2” galvanized or approved non-metallic pipe for 10-15 GPM pumps. Use new 2” galvanized or approved non-metallic pipe

for 20-24 GPM pumps.

FLEXIBLE CONNECTOR

OR

SWING JOINT (INTERNATIONAL USE)

FIGURE 1

Bennett T75 Operation, Service, & Parts Manual Product Introduction

7

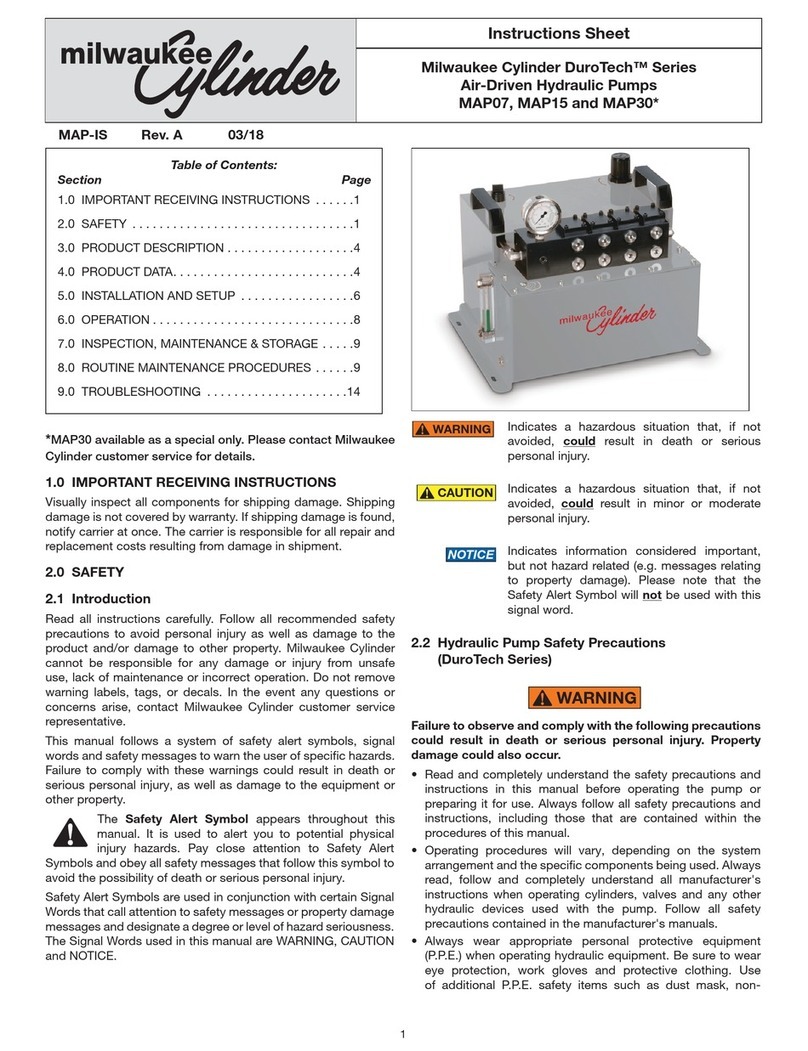

PUMP CURVES –U.S. MARKET

PUMP CURVE –EUROPEAN MARKET

T-75 Pump (3/4 hp) Performance

U.S. Market

0

5

10

15

20

25

30

35

0 5 10 15 20 25

Flow Rate (gpm)

Pump Pressure (psi)

Pump Speed

700 rpm

Test Conditions:

1. Tested on Stoddard Solvent

* 30 SSU Viscosity

* 0.78 Specific Gravity

2. 12 inches Hg operating vacuum

3. Fixed bypass cover

FIGURE 2

FIGURE 3

Bennett T75 Operation, Service, & Parts Manual Product Introduction

8

EXTERIOR DIMENSIONS

FLANGED - FRONT VIEW

2.69” [68 mm]

FLANGED OUTLET- BOTTOM VIEW

12.6” [320 mm]

1.63”

[40mm]

FIGURE 4

FLANGED OUTLET- TOP VIEW

FLANGED OUTLET- BACK VIEW

8.74” [222 mm]

FLANGED OUTLET- SIDE VIEW

11.9”[303 mm]

Bennett T75 Operation, Service, & Parts Manual Product Introduction

9

TUBE OUTLET - BOTTOM VIEW

1.63”

[40mm]

TUBE - FRONT VIEW

11.6” [295 mm]

11.9”[303 mm]

2.69”[68 mm]

11.9”[303 mm]

TUBE OUTLET- BACK VIEW

TUBE OUTLET- TOP VIEW

TUBE OUTLET- SIDE VIEW

FIGURE 5

Bennett T75 Operation, Service, & Parts Manual Product Introduction

10

INLET & MO UNTING DIMENSIONS

When installing units that contain a high alcohol product (e.g. E100). Confirm that the plumbing is designed to handle an alternative fuel. For multi-

hose units, piping must align with the footprint.

Alternative fuels, such as E25, E85, and other ethanol blends, may require special piping materials or components. Consult the piping manufacturer

to determine if the piping material, fittings, and connectors are compatible with the alcohol-blended fluid being used.

METER FLA NGE OUTLET OPTION

FIGURE 6

Bennett T75 Operation, Service, & Parts Manual Product Introduction

11

TUBULAR O UTLET / MOTO R MOUNT OPTION

FIGURE 7

Bennett T75 Operation, Service, & Parts Manual Product Introduction

12

SIDE INLET OPTION

FIGURE 8

INLET CENTER

Bennett T75 Operation, Service, & Parts Manual Operation

13

SECTION 3: OPERATION

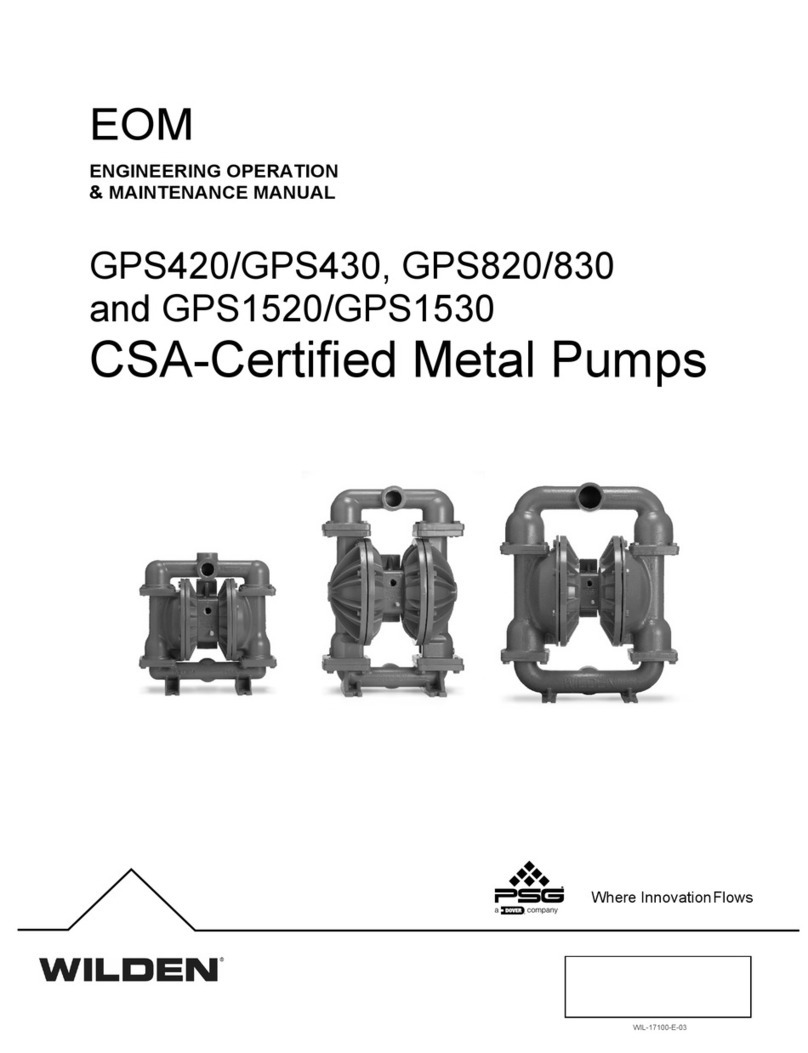

OPERATION

The following section describes each of the main components of the T75 pumping unit and the interface characteristics at each component. Refer

to the diagram on the next page for item locations. For any questions, please contact Bennett Technical Support at 1-800-423-6638.

The pump assembly has the following main components: (See Figure 9 for numbers in parenthesis.)

Body (1)

The inlet is designed to accept a triangular inlet flange with a 3-hole bolt pattern.

Cover (2)

The Flanged Outlet is used for direct meter mounting

The Tubular Outlet is used for remote meter mounting (as shown on page 6)

Filter (3) located in the horizontal position. Note: The filter cover includes a pipe plug to drain the pump.

An optional Inlet Check Valve (19) is available to hold product in the suction line when the pump is turned off. It maintains a vacuum

in the line preventing fuel from leaking through a loose joint into the ground.

Rotating Pump (4) with Radial Carbon Blades

The Throwout Rings (5) maintain contact of the blades to the stator.

The Stator (6) turns clockwise and is tightly fitted in the pump body.

The Rotor (7) is made of cast iron with a chrome-plated shaft.

The Self-Lubricated Bearings (21) are used to prevent seizure when tank is pumped dry.

The Cover (8), also of cast iron, encapsulates the rotor and the stator.

An Air Elimination Assembly (9),a patented fully static device, uses a vortex effect.

The insert (10) starts spinning the fluid.

The foam and the air pass through the Tube (11) and evacuated through the Orifice (12).

A Drain Line Eliminator (13) or atmospheric chamber of 1.2-gallon (4.5 liter) capacity.

The Float Valve Assembly (14) provides for the recovery of liquid from the chamber, while air is evacuated through the Vent Tube

(15).

A Non-Return Float (20) seals the atmospheric chamber when the pump is turned off to prevent flooding and spilling out onto the

driveway.

A Bypass Valve (16) is used to limit the maximum working pressure.

Its cover includes a device to adjust the bypass pressure (optional in USA)

A Control Valve Assembly (17) assures that all downstream hydraulic components are filled with liquid. This valve has a Relief Valve (18)

to relieve excess pressure.

NOTE: A diaphragm operated preset valve is available as an option.

Bennett T75 Operation, Service, & Parts Manual Operation

14

FIGURE 9

Bennett T75 Operation, Service, & Parts Manual Operation

15

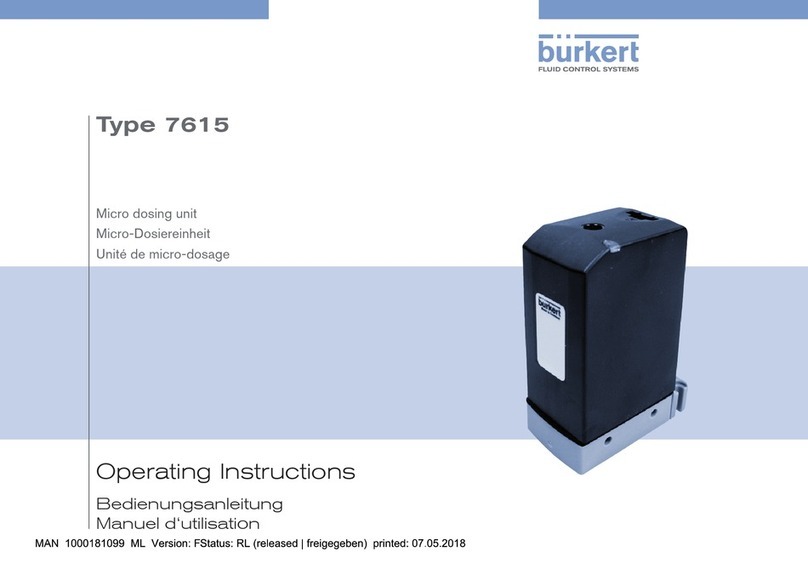

THEORY OF OPERATION

See Figure 10 for numbers in parenthesis.

The product is drawn from the underground storage tank through the strainer screen of Filter (1).

The Rotary Vane Pumping Unit (2) pressurizes the fluid.

Product enters the centrifugal Air Separator Assembly (3). Any air present is forced out the air tube along with a small amount of liquid

into the Atmospheric Chamber (4).

Product collected in the atmospheric chamber is returned to the pump intake across the non-return float when the liquid level in the

chamber lifts the float and valve assembly from its Seat (5). Any air is then vented to the atmosphere through the vent tube.

Air free product leaving the air separator opens the Control Valve (6) and is pumped to the meter. The control valve includes a built-in

Relief Valve (7) which relieves excess pressure caused by hot weather expansion.

Product passes through the meter where it is accurately measured, then through the hose and nozzle into the vehicle being fueled.

Whenever the nozzle is not fully opened, some liquid is relieved into the pump intake through the Bypass Valve (8).

FIGURE 10

Bennett T75 Operation, Service, & Parts Manual Operation

16

FIGURE 11

Bennett T75 Operation, Service, & Parts Manual Troubleshooting

17

SECTION 4: TROUBLESHOOTING

TROUBLESHOOTING

This section provides basic troubleshooting. It is not a substitute for technical training. Improper handling of equipment and/or improperly

performing the included procedures could damage your DISPENSER! Use the table in each section to determine the cause and solution. For any

additional questions, please contact Bennett Technical Support at 1-800-423-6638.

PROBLEM 1: THE MOTOR ST ARTS BUT THE PUMP DOES NOT DELIVER FUEL.

Refer to the table below for a description of various causes of the problem and the solution.

Cause

Solution

The fuel supply is below the suction stub in the storage

tank.

Fill the storage tank.

The vent pipe is plugged in the storage tank.

Clean the vent pipe.

The strainer screen or filter assembly has an obstruction.

Remove obstructions from the screen or filter assembly.

The bypass valve is not seating properly due to the wear

or obstruction.

Check the valve for an obstruction causing the valve to stay open, and/or replace

the bypass valve.

The v-belt is loose or broken.

Adjust or replace the v-belt.

There is an obstruction in the atmospheric float valve.

Clean the float and valve area. Check for swelling and binding in the linkage.

The pump is out of prime. All fuel drained out of suction

line due to fault line check or foot valve.

Check for a faulty foot valve in the storage tank or a faulty check valve in the

suction line.

The suction line is leaking.

Start the pump and open the nozzle. If bursts of air are felt while holding a finger

on the vent tube, the suction line is damaged. Repair or replace.

The intake line, foot valve, angle check valve, or vertical

check valve has an obstruction.

Connect a vacuum gauge to the ¼” plug on the filter cover. Turn the pump on and

open the nozzle. A reading of 15 or more inches of mercury with no flow indicates

a complete blockage in the suction line. Clean the line or replace.

The suction stub in the storage tank is on the bottom of

the tank.

Make sure there is a three-inch clearance.

The control valve has an obstruction.

Clean the control valve. It must slide freely in the valve cavity.

The nozzle is not working.

Replace the nozzle.

*Two pumps are connected to one storage tank with one

suction line. There is a faulty check vale in one of the

supply lines.

* Not recommended

Disconnect the vent tube on the idle pump. Install a short copper tube. Place the

end of the copper tube in a container of liquid. If the liquid is drawn out of the

container when the opposite pump is operated with an open nozzle, the line

check valve is faulty. Replace the check valve.

PROBLEM 2: THE PUMP RUNS BUT DELIVERY IS SLOW.

Refer to the table below for a description of various causes of the problem and the solution.

Cause

Solution

The fuel supply level is low.

Fill the storage tank.

The storage tank vent pipe is partially obstructed.

Clean the vent pipe.

The strainer screen is partially plugged.

Remove obstructions from the screen or filter assembly

The pump bypass valve is not seated properly.

Remove and clean the strainer screen.

The V-Belt is loose.

Adjust the V-Belt

The motor voltage is too low.

Check the power supply voltage. Check for too many pieces of equipment on one

electrical line.

A blade or blades in the pump are worn or broken.

Check the blades and replace if necessary.

An automatic nozzle has been installed.

Delivery speed will be reduced by 10-25%. If maximum speed is desired, replace

with a manual nozzle.

The motor is defective.

Inspect the motor for loose connections. If no loose connections are found, the

motor is defective. Repair or replace.

There is a slow leak in the suction line.

Start the pump and open the nozzle. If bursts of air are felt while holding a finger

on the vent tube, the suction line is damaged. Repair or replace.

The suction line is obstructed or the foot valve, angle, or

vertical check valve is partially stuck and will not open

fully.

Connect a vacuum gauge to the ¼’plug on the filter cover. Turn the pump on and

open the nozzle. A reading of 11 to 14 inches of mercury indicates a partial

obstruction in the suction line. Clean or replace the suction line components.

The pump control valve is partially stuck and will not

open fully.

Remove the valve and clean thoroughly.

The nozzle check valve is sticking.

Clean or replace the nozzle check valve.

The hose is defective (Flattened)

Replace the hose.

Bennett T75 Operation, Service, & Parts Manual Troubleshooting

18

PROBLEM 3: INACCURATE DELIVERY

Refer to the table below for a description of various causes of the problem and the solution.

Cause

Solution

Control valve stuck open.

Remove the 4-bolt control valve cover and free control valve.

Vent tube from air eliminator to atmosphere plugged.

Clear any obstructions.

PROBLEM 4: FUEL RUNS OUT OF VENT TUBE WH EN P U MP IS OPERATING.

Refer to the table below for a description of various causes of the problem and the solution.

Cause

Solution

Float valve stuck in a closed position.

Clean the float and valve area. Check for swelling and binding in the linkage.

Flooded suction chamber. Direction flow valve missing.

Storage tank level must be lower than pumping unit. Make sure 2 or more

pumps are not using the same suction line.

PROBLEM 5: THE COMPUTER JUMPS WHEN THE PUMP IS TURNED O N.

Refer to the table below for a description of various causes of the problem and the solution.

Cause

Solution

Control valve not seated properly

Remove valve cover and inspect for dirt or nicks in the O-Ring.

The Expansion Relief Dill Valve in control valve is stuck open.

Remove and inspect for foreign matter. Pull spring-loaded seat for better

view. Reinstall.

Table of contents

Other Bennett Water Pump manuals

Popular Water Pump manuals by other brands

Lancaster

Lancaster X99M33 Installation operation & maintenance

Witt

Witt hrp 5040 Installation and operating instructions

Liberty Pumps

Liberty Pumps 404 installation manual

Burkert

Burkert 7615 operating instructions

Honeywell

Honeywell CBU145-50A-042 instructions

Profactor

Profactor PF PU 1051 instruction manual