WIL-17100-E-03 17

CSA-Certified Pumps

SECTION 6

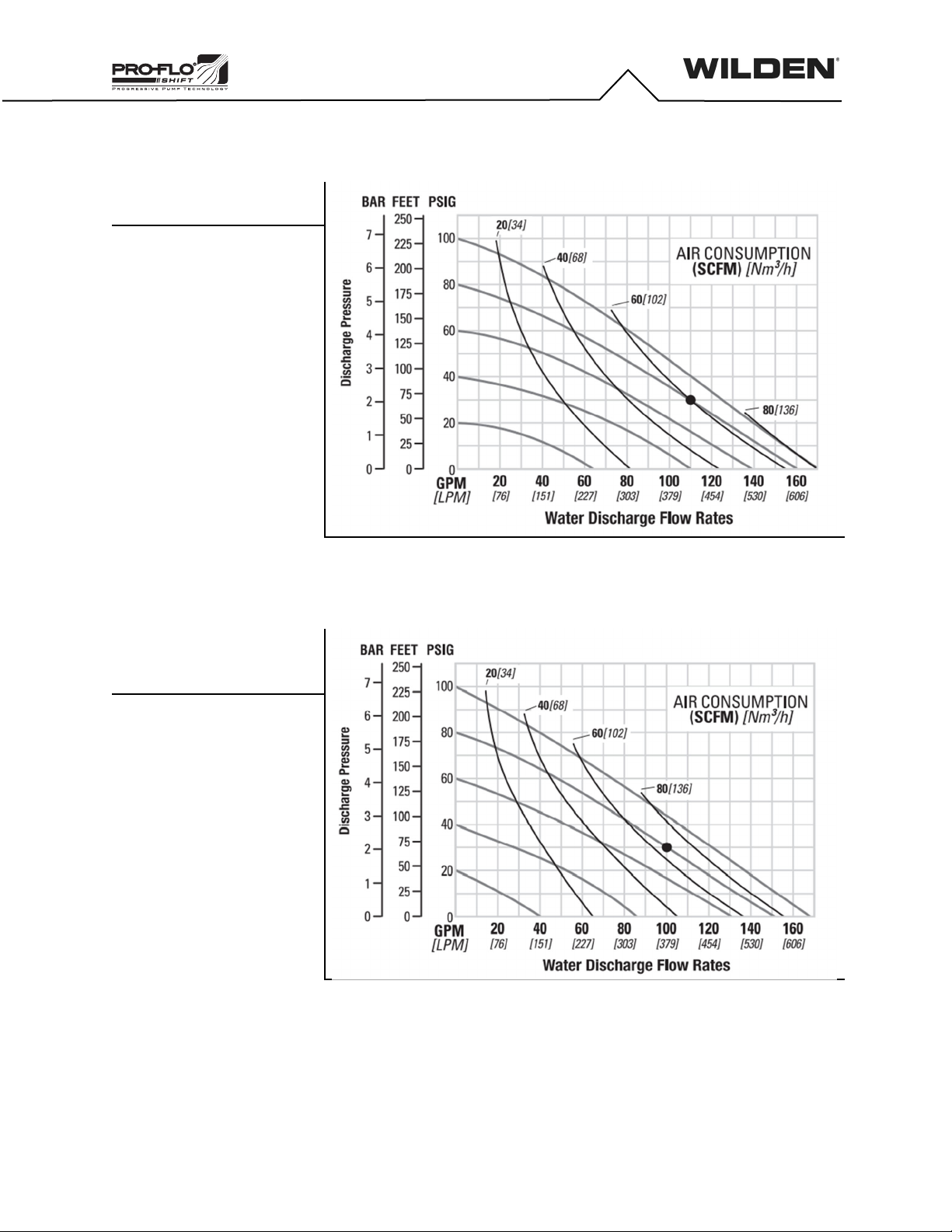

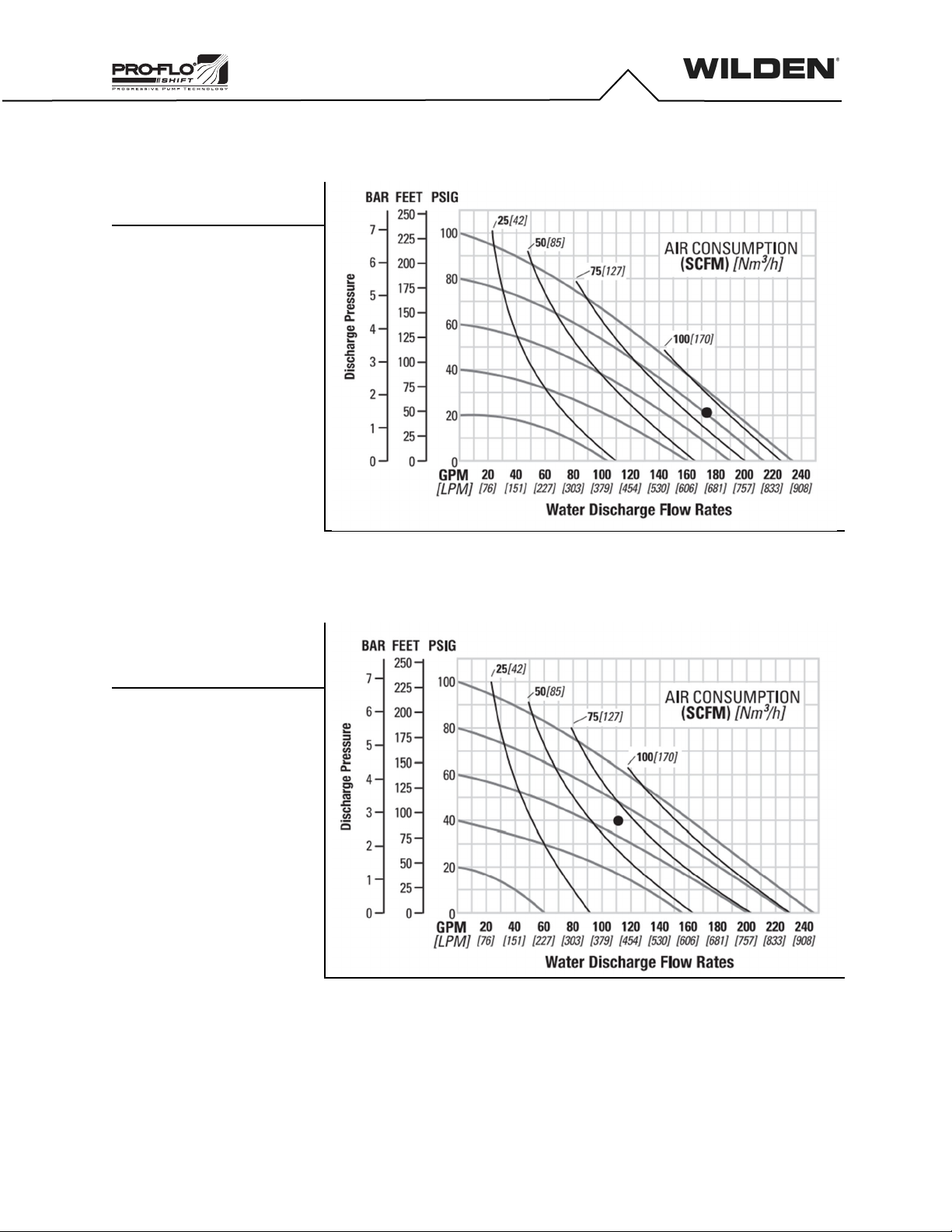

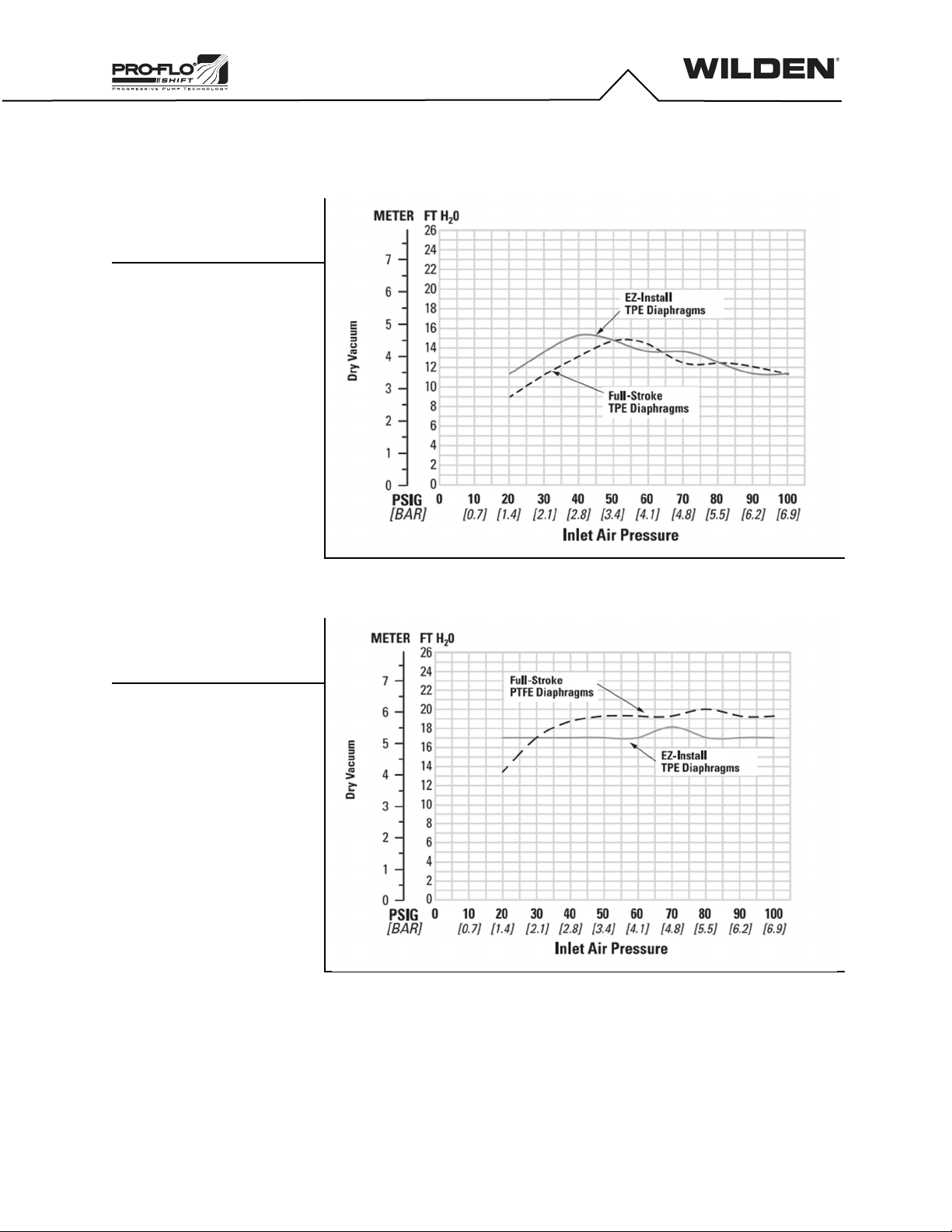

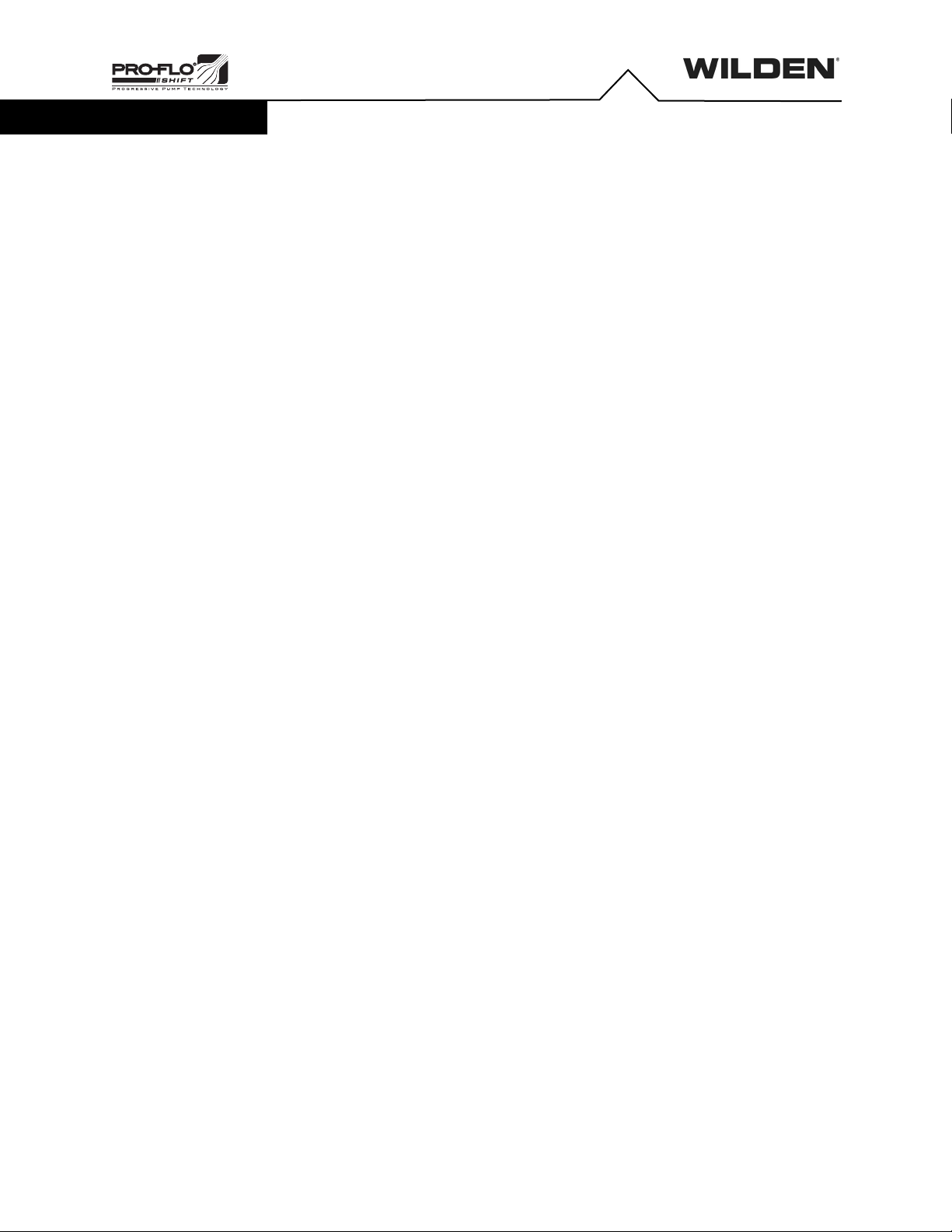

Prior to pump installation, ensure that the flow and suction lift

requirements are within the pump model’s capabilities. Refer to the

Section 5, Performance of the Engineering, Operation and Maintenance

(EOM) Manual for specific flow and suction-lift capabilities.

Before installation confirm that the pump materials of construction are

compatible with pumping application. Refer to the Wilden Chemical

Resistance Guide for assistance with wetted path and elastomer options.

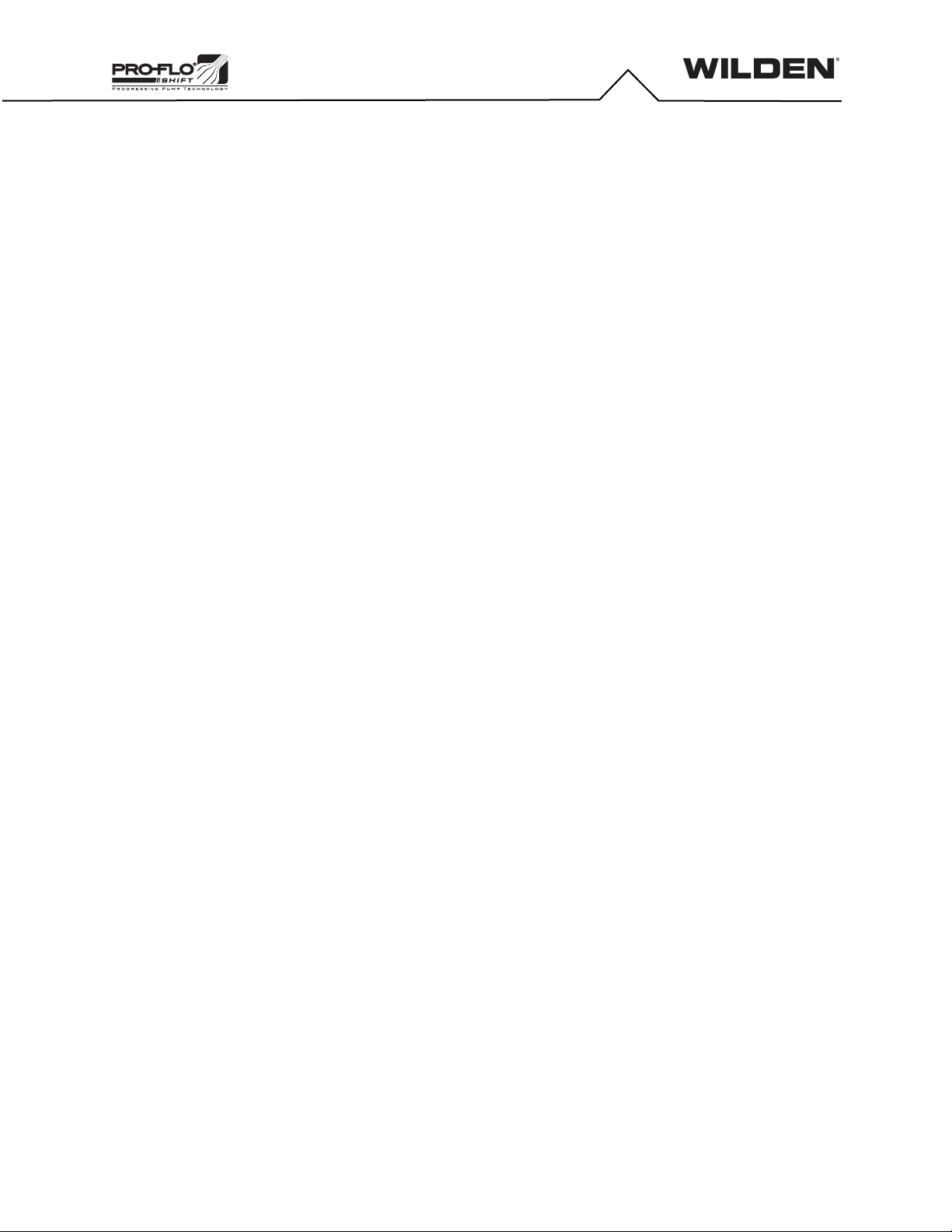

Piping

The pump should be located so that the length and complexity of the

suction and discharge piping is minimized. Unnecessary elbows, bends

and fittings can increase friction losses and should be avoided.

Pipe sizes should be selected to keep friction losses within practical limits.

The suction pipe diameter should be equivalent or larger than the

diameter of the suction inlet on your Wilden pump. The suction hose must

be non-collapsible, reinforced type as these pumps are capable of pulling

a high vacuum. Discharge piping should also be the equivalent or larger

than the diameter of the pump discharge to help reduce friction losses.

All piping should be supported independently of the pump. In addition, the

piping should be correctly aligned with the inlet and discharge connection

of the pump to avoid placing stress on the pump fittings. Flexible hose can

be installed to aid in absorbing the forces created by the natural

reciprocating action of the pump and will also assist in minimizing pump

vibration.

Gas Supply

The pump should have a supply line large enough (a 3/4” supply line is

recommended for 1-1/2” and larger pumps) to supply the volume of air

necessary to achieve the desired pumping rate. Gas pressure to the pump

should be controlled by a pressure-regulating valve and should not

exceed a maximum of 6.9 bar (100 psig). It is suggested that a needle

valve be placed in the supply line to control the flow of gas to the pump.

For best results, a 5μ(micron) filter should be installed before the gas inlet

of the pump to eliminate the majority of compressed gas line

contaminants.

Type of Gas

Sweet gas is required for natural gaspowered pumps. Please consult the

factory if considering using sour gas as levels of hydrogen sulfide (H2S)

may cause unacceptable corrosion and chemical attack.

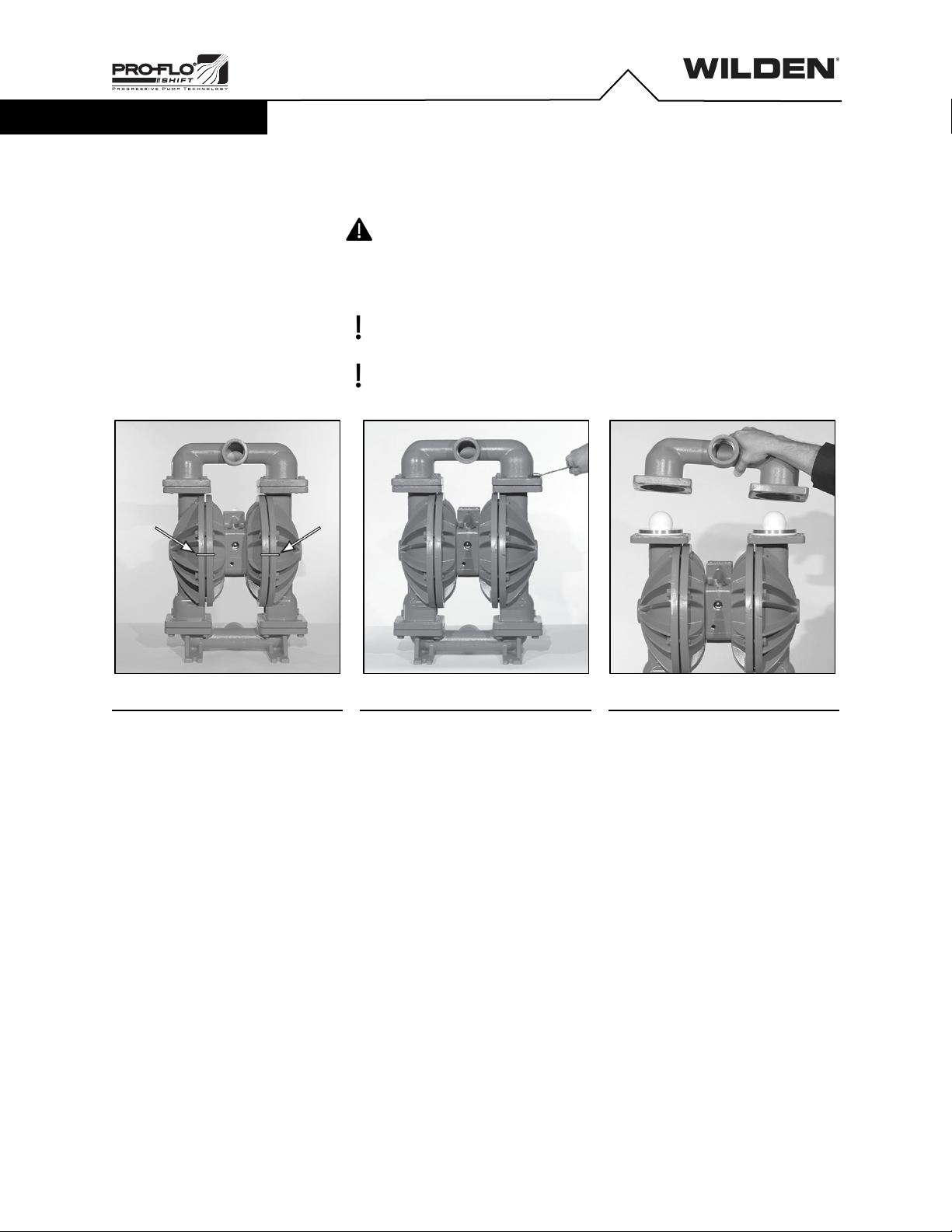

Pump Mounting and Installation

For simple installation and removal of the pump shut-off valves should be

installed in the inlet and discharge plumbing. If the pump is to be mounted

in a fixed location, a mounting pad placed between the pump and the

foundation will assist in minimizing pump vibration. If quick-closing valves

are installed at any point in the discharge system, or if pulsation within a

system becomes a problem, a surge suppressor should be installed to

protect the pump, piping and gauges from surges and water hammer.

Solids Passage

All Wilden pumps are capable of passing solids. A strainer should be used

at the inlet of the pump to ensure that the pump’s rated solids capabilities

are not exceeded. Refer to the Section 5 of this EOM manual for specific

solids-passage capabilities.

Flooded Suction

Pumps in service with a positive suction head are most efficient when the

inlet pressure is limited to 0.5–0.7 bar (7–10 psig). Premature diaphragm

failure may occur if positive suction is 0.7 bar (10 psig) or higher.

Suction Lift

When used in self-priming applications, it is critical that all fittings and

connections are airtight, or a reduction or loss of pump suction capability

will result.

Gas Outlet

All CSA-certified pumps are fitted with the single point exhaust option so

that all exhaust gases are routed through the muffler plate exhaust port.

The gas outlet must be recaptured or vented to a safe location in

accordance with locally, nationally and/or industry recognized codes.

Grounding

Pumps and accessories must be electrically grounded to a proper

grounding point to prevent an accumulation of electro-static charge when

used in potentially explosive areas. CSA-certified pumps come with a

grounding strap and are fitted with a grounding screw for the purpose of

electrically grounding the pump. Periodic inspection of the ground

connection should be performed to ensure the equipment is properly

grounded. Refer to the Wilden CE Safety Supplement and Safety Manual

for additional ATEX-certified pump considerations.

Functional Testing

1. Tighten all hardware prior to initial start-up. Refer to Section 7,

Reassembly Hints & Tips in the EOM manual for torque

specifications.

2. Prior to pump installation connect compressed gas line [do not

exceed rated pressure of 6.9 bar (100 psig)] to gas inlet of pump to

ensure that pump cycles consistently.

3. Cycle pump for 2-3 minutes.

4. After pump installation, check piping connections for leaks.

Pump Operation

1. To avoid damage to the pump new installations should be checked

for any debris in tank or piping system.

2. Once installation is complete, pump operation can be started.

Confirm the shut-off valves in the inlet and discharge plumbing are

open. Do not exceed the pump’s maximum rated pressure of 6.9

bar (100 psig). A pressure regulating valve and needle valve can be

used to adjust the speed of the pump.

3. Retighten all exposed fasteners after two (2) hours of operation.

Refer to Section 7, Reassembly Hints & Tips in the EOM manual for

torque specifications.

Emergency Shut-Down Procedure

In the case of an emergency situation, the pump should be stopped

immediately. To stop the pump’s operation, close the gas shut–off valve

(user-supplied). A properly functioning valve will cut-off the gas supply,

stopping the pump. The shut-off valve should be located far enough away

from the pumping equipment such that it can be reached safely in an

emergency situation. In the event of pump or diaphragm failure, close

shut-off valves at the inlet and discharge of pump to eliminate the

possibility of medium leakage. In the event of a power failure, the gas

shut-off valve should be closed, if restarting of the pump is not desirable

once power is regained.

Refer to the Wilden CE Safety Supplement, Safety Manual and EOM

Manual for additional information.

SUGGESTED INSTALLATION, OPERATION, MAINTENANCE

AND TROUBLESHOOTING