BENSON HEATING RS/UHA2 50 Manual

Gas room sealed unit heaters 2 stage

TECHNICAL INFORMATION ASSEMBLY

INSTRUCTIONS, USE AND MAINTENANCE

RS/UHA-2

BENSON HEATING

LUDLOW ROAD

KNIGHTON

POWYS

LD7 1LP

MAY 2003 Benson Heating is a divison of

Benson Climate Systems Ltd

COMPLIANCE NOTICES

The Benson RS/UHA2 range of warm air heaters detailed herewith are manufactured for Benson Heating within the

parameters of ISO 9002.

The Benson RS/UHA2 Range has been independently tested and assessed, and has been found to meet the Essential

Requirement of the following European Directives:

Gas appliance Directive (90/396/EEC)

Machinery Directive (89/392/EEC) 91368/EEC 93/44/EEC 93/65/EEC

Low Voltage Directive (73/23/EEC

Electromagnetic Compatibility Directive (98/336/EEC and 91/31/EEC)

Product Liability Directive (65/374/EEC)

The manufacturer has taken reasonable and practical steps to ensure that Benson RS/UHA2 Range of Heaters are safe

and without risk when properly used. These heaters should therefore only be used in the manner and purpose for which

they were intended, and in accordance with the recommendations detailed herewith.

The heaters have been designed, manufactured, assembled, inspected, and tested, with safety and quality in mind, there

are certain basic precautions which the installer and user should be aware of, and they are strongly advised to read the

appropriate sections of the information pack accompanying the heater, prior to installation or use.

Benson Heating supports all new products being supplied to their customers with a comprehensive information pack; this

clearly defines mandatory instructions for the safe installation, use, and maintenance, of the appliance(s).

Where proprietary items are incorporated into Benson Heating products, detailed information and instructions are also

provided as part of the information pack.

It is the responsibility of the installer, owner, user, or hirer, of such products supplied by Benson Heating, to ensure that

they are familiar with the appropriate information/manuals, supplied by the manufacturer, and that they are suitably

aware of the purpose of the manuals and the safety instructions. In addition, operators must be suitably trained in the use

of the appliance so as to ensure its continued safe and efficient use.

Benson Heating has a commitment to continuous improvement, and therefore reserves the right to amend or change the

specification of the RS/UHA2Heater range subject to agreement from The Notified Body.

Contained within the text of the manual, the words 'Caution' and 'Warning' are used to highlight certain points.

Caution is used when failure to follow or implement the instruction(s) can lead to premature failure or damage to the

heater or its component parts.

Warning is used when failure to heed or implement the instruction(s) can lead to not only component damage, but also

to a hazardous situation being created where there is a risk of personal injury.

Notified Body PIN Reference is

RANGE

Type Model Code

1 RS/UHA2 50

3TAIT2C016

2 RS/UHA2 80

3TAIT2C026

3 RS/UHA2 105

3TAIT2C036

4 RS/UHA2 140

3TAIT2C046

5 RS/UHA2 200

3TAIT2C066

6 RS/UHA2 260

3TAIT2C086

7 RS/UHA2 325

3TAIT2C106

INDEX

GENERAL

Description of equipment page.

Identification “

Description “

Identification “

Description “

Technical data “

Wiring diagram “

Remote control connections “

Regulating air flow “

FOR THE USER

Operation “

Servicing “

Heater indication lights “

Receipt of product “

Transport “

Dimension “

FOR THE INSTALLER

Location “

Wall bracket dimensions “

Gas connection “

Flue and combustion options “

Electrical control panel “

Electrical connections “

TECHNICAL ASSISTANCE SERVICE

Pre commissioning checks “

Initial start up “

Gas conversion “

Thermostat operation “

Control “

Maintenance “

Fault finding “

Heaters type 1-2-3-4-5

C

FAN 1

C

FAN 2

IMT

J6

NL

F2

F1

N

J5

II°

I°

SF

230V 50Hz

EF

SE

J4

J8

IGN1

PA

COMCOM

NA NC

ION

EA1

J11

J17

J2

J14

VM

TA

J16 J13

J7

RSTR

MS

EVG1-I°

EVG1-II°

RST

LB

LL

LF

J10

J9 J12

SND

LM

TR

J15J18

J1

KEY:

SND Temperature probe

TR Regulatory control thermostat (auto reset)

LM LIMIT thermostat (manual reset)

EVG1-I° Gas solenoid valve1

EVG1-II° Second stage gas valve 2

CFan capacitor

FAN 1 Axial fan 1

FAN 2 Axial fan 2 (type 5)

F1-F2 Line fuse (6,3 A)

LF Green working light

LL High temperature indication light

LB Lockout indication

RST Lockout reset

EF Flue venter

PA Differential pressure switch

IGN1 Ignition transformer

EA1 Spark electrode

ION Ionisation probe

SE Electrical control board

IMT (*) Fused isolator

MS (*) Fire damper connection (accessory)

RSTR (*) Remote reset connection

TA (*) Room thermostat connection

VM (*) Fan switch connection

SF (*) Second stage gas valve connection

(*) External to the heater customer supply.

Heater type 6-7

IGN2

EA2

EF

SE

J4

J8

IGN1

PA

COMCOM

NA NC

ION

EA1

J11

J17

J2

J14

VM

TA

J16 J13

J7

RSTR

MS

EVG2-I°

EVG1-I°

EVG2-II°

EVG1-II°

RST

LL

LB

LF

J10

J9 J12

SND

LM

TR

J15J18

J1

IMT

J6

230V ~50Hz

NL

F2

F1

N

J5

II°

I°

SF

C

FAN 1

C

FAN 2 FAN 3

C

KEY:

SND Temperature probe

TR Regulatory control thermostat (auto reset)

LM LIMIT thermostat (manual reset)

EVG1-I° Gas solenoid valve 1

EVG2-I° Gas solenoid valve 2

EVG1-II° Second stage gas valve 1

EVG2-II° Second stage gas valve 2

CFan capacitor

FAN 1 Axial fan 1

FAN 2 Axial fan 2

FAN 3 Axial fan 3(Type 7)

F1-F2 Line fuse

LF Green working light

LL High temperature indication light

LB Lockout indication

RST Lockout reset button

EF Flue venter

PA Differential pressure switch

IGN1 Ignition transformer 1

IGN2 Ignition transformer 2

EA1 Spark electrode 1

EA2 Spark electrode 2

ION Ionisation probe

SE Electrical control board

IMT (*) Fused isolator

MS (*) Fire damper connection (accessory)

RSTR (*) Remote reset connection

TA (*) Room thermostat connections

VM (*) Fan switch connections

SF (*) Second stage gas valve connection

(*) External to the heater customer supply.

GAS CONVERSION

The heaters are supplied ready for use with (G20) Natural Gas as per the table below Conversion kits are available from

the manufacturer:

Natural Gas (G20)

TYPE 1 234567

Number of injectors 1 1 1 1 2 2 4 N°

Diameter of injectors 3,10 410 480 555 500 540 450 mm/100

Gas supply pressure 20 mBar

Head pressure high fire 11,0 13,0 13,0 13,0 10,0 13,0 10,5 mBar

Head pressure low fire 6,0 7,0 6,5 6,5 7,0 6,5 5,0 mBar

BEFORE CHANGING INJECTORS ENSURE GAS SUPPLY IS ISOLATED

INSTRUCTIONS FOR CONVERSION TO PROPANE GAS G(31)

1. Change the injectors

2. Adjust the gas inlet pressure

3. Adjust the head pressure

4. Fit primary air diaphragm (if required )

5. Fit adhesive label supplied with kit indicating gas type

6. Ensure settings are correct as per the manual and data plate

CHANGE INJECTORS:

To change injectors:

Unscrew the natural gas injectors and replace them with the correct size injectors for propane as shown in table below:

Propane gas (G31)

TYPE 1 234567

Number of injectors 1 1 1 1 2 2 4 N°

Diameter of injectors 190 250 280 335 285 320 255 mm/100

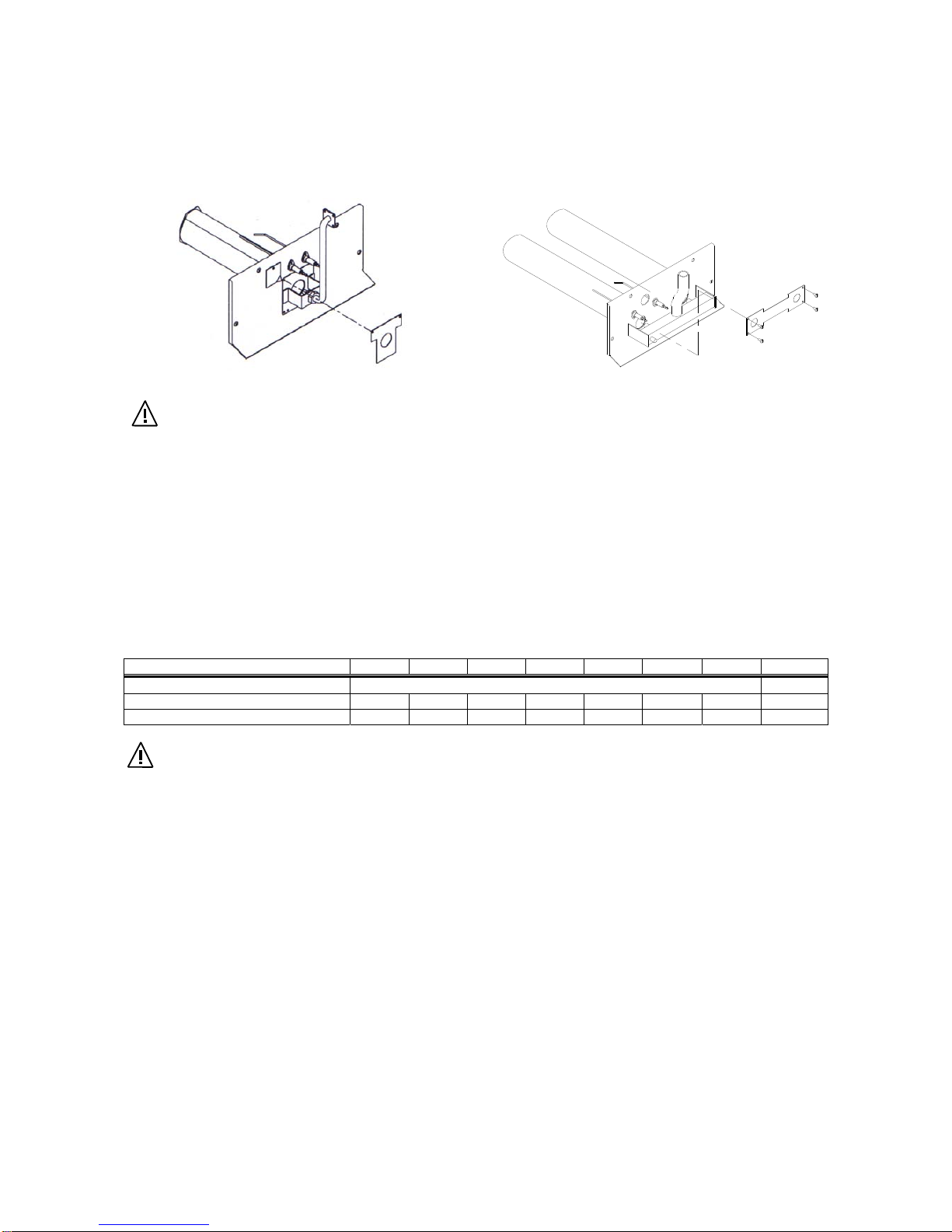

Replacing injectors single manifold (type 1-2-3-4-6)

Replacing injectors 2 per manifold (type 5-7)

Check the size stamped on the side of the

injector is correct to the data in the manual.

Ensure that the new injectors are correctly fitted

in the manifold and are gas tight, When the

conversion is complete fix the transfer supplied

with the kit showing the correct gas pressure on

to the manifold

Test for gas soundness on completion

Ensure that the aluminium washers supplied for

(types 5–7) are fitted when changing the

injectors.

If the gas line has not been correctly purged ignition

may not take place at the first attempt resulting in

the heater going to lockout

Reset the lockout before re starting ignition sequence

Before each attempt at ignition it is necessary

to wait at least 10 seconds

•Connect the manometer on to the pressure test

point PM and check inlet gas pressure if correct

connect manometer to test point PV and start heater

with heater running ensure the gas pressure

corresponds to that shown on the data plate adjust

by altering the screws RP1 and RP2 on the gas

valve

•Check that the gas consumption reading

corresponds with that indicated in the TECHNICAL

DATA section Set on/standby switch to standby

when heater is sufficiently cool isolate gas supply

•Remove manometer ensure the screw at the test

point is tightened test for gas leaks

•Open the gas isolating cock switch on the electrical

supply set the room thermostat to the desired

temperature.

•The heater is now ready for operation

GAS VALVE

Model SIT 843 (two stage)

The heater must only be operated with the

burner compartment door(s) closed

STOPPING

To stop the heater use only the room thermostat Set it

to the minimum temperature The fan will stop after 3

minutes or when the heat exchanger is sufficiently cool

If required switch off the electricity supply at the isolator

!

The main electrical supply must not be switched off

or used as a method of stopping the heater except

in an emergency until the heater has cooled down

sufficiently preventing damage to the heat

exchanger

Interruption of electrical supply whilst heater is in

operation will cause it to go to overheat and may

damage the heat exchanger the LIMIT thermostat

will operate and this will have to be manually re set.

PM Inlet pressure test point.

PV Head pressure test point

RP1 Cross cut screw low fire adjuster

RP2 Hexagonal screw high fire adjuster

Assembly of primary air diaphragm:

Diagram showing the fitting of a primary air

diaphragm to single burner manifold (1-2-3-4-6)

Diagram showing the fitting of a primary air

diaphragm for a two burner manifold type (7)

Warning the diaphragm plates should only

be used when using propane gas G31.

Gas conversion adhesive label:

Once the heater has been converted to propane ensure

that the correct label is fitted to the burner overtop of

the factory fitted one covering it completely. It is

recommended that the diameter of the nozzles be

checked also that the pressure corresponds to that

shown on the data plate provided

Ensure that all of the additional gas components are

correct for the installation (including storage tank, pipes

and pressure valves etc

Ensure that the pressure regulators are sealed after

carrying out the conversion.

GAS PRESSURE REGULATION

To regulate the gas inlet pressure :

•Connect a manometer onto the gas valve test

point (PM)

•Adjust the inlet gas supply regulator (customer

installation) to pressure indicated on data

plate:

To regulate the gas head pressure to the burner:

•Connect a manometer onto the gas valve test

point (PV)

•Adjust the pressure regulating adjusters RP1/

RP2 as detailed on next page to obtain correct

pressures indicated in table below:

Propane gas (G31)

TYPE 1 234567

Gas supply pressure 37 mBar

Head pressure max 35,5 35,0 35,5 35,5 34,5 35,5 34,5 mBar

Head pressure min 20,0 18,0 18,5 18,0 18,0 18,0 18,5 mBar

Gas inlet pressure must not exceed 60 mbar at the gas valve inlet.

Gas valve head pressure setting high fire Propane G31:

When setting the gas pressure for propane high fire

(second stage ) contact SF should be closed the high

fire pressure adjusting screw on the gas valve must be

excluded.

Connect a manometer on test point PV

Remove the plastic cover from the adjuster RP1 RP2

With a screw driver hold the adjuster RP1 stationary

and using a spanner, screw adjuster RP2 clockwise to

the bottom of the thread until the correct pressure

according to the data plate is achieved .

Gas valve head pressure setting low fire Propane G31 :

When setting the gas pressure for propane low fire

(first stage) contact SF should be open. The low fire

pressure should be adjusted to the settings shown on

the data plate and the data in the manual provided by

adjusting screw RP1

Clockwise increases the pressure

Anti clockwise to decrease the pressure

On completion replace the plastic cover and seal with

paint

Remove manometer ensuring that the test point screw

is gas tight

Gas valve gas SIT 843

On heaters with 2 gas valves the pressure regulation must be carried out on both gas valves

FAULT FINDING

If the heater is not working firstly check the following :

•Check electrical supply

•Check voltage is as stated +15%, -15%

•Check gas supply is on

•Check that the pressure is as stated in the TECHNICAL DATA

FAULT CAUSE SOLUTION

No operation No electrical supply

Check main isolator.

Check supply cables

Check line fuses.

Check electrical connections

No spark ignition.

Flue venter working

No indication lights on

Differential pressure switch not

working Check flue pipe and combustion

air pipe are clear.

Faulty differential pressure

switch Replace differential pressure

switch

Poor connection at pressure

switch Check air pipe to switch is

connected and not damaged

Check electrical connections

Check that pipes are

condensate free .

Faulty flue venter Replace flue venter

Faulty control panel Replace control panel

Faulty ignition electrode Check ignition probe is not

cracked or damaged

Replace the ignition probe

No ignition

Flue venter working

No indication lights on Room thermostat open Check room thermostat.

Faulty flue venter Replace flue venter

Faulty control panel Replace control panel

Burner lights but locks out

after 5 seconds Live and neutral inverted

Poor earth Check electrical connections

Faulty ionisation probe

Check electrical connection on

probe.

Check probe for cracks or

damage.

Replace ionisation probe .

Faulty ignition

Check the gas type is suitable

for the heater.

Check the inlet gas pressure.

Check the head pressure.

Check the gas supply pipes

have been properly purged of

air .

Explosive start up. Faulty ignition electrode Replace ignition electrode

Incorrect electrode position Reposition electrode correctly

over the burner bar.

Faulty burner tube Replace the burner tube

Faulty ignition transformer Replace ignition transformer

Faulty ignition

Check the gas type is suitable

for the heater.

Check the inlet gas pressure.

Check the head pressure.

Check the gas supply pipes

have been properly purged of

air .

heat exchanger dirty Check / clean heat exchanger

Burner shuts down then

re lights automatically .

No indication lights on.

Pressure differential switch not

operating correctly

Check that air pipe to switch not

damaged or blocked.

Check that the flue and

combustion air pipes are clear.

Check that the thermal overload

on the flue venter has not

operated

Faulty pressure differential

switch Replace differential switch

Room thermostat in warm air

flow Check position of thermostat

Burner goes out due to the

intervention of the SND

thermostat and is restarted

automatically when the heater

has cooled down .

Yellow indication light on.

Excessive heat exchanger

temperature

Check inlet gas pressure

Check burner head pressure

Check that gas type is suitable

for heater

Check injector size is correct for

the heater.

Excessive air temperature due

to insufficient air flow over heat

exchanger.

Check the fan blades are clean

Check that the horizontal and

(vertical if fitted) louvers are

sufficiently open. (see in

installation section of manual)

Check that the fan speed is

correct and the air flow over the

chamber is sufficient.

Faulty SND thermostat or

control panel Replace SND thermostat or

control panel

Burner goes out due to the

intervention of the TR

thermostat and is restarted

automatically when the heater

has cooled down .

Yellow indication light on.

Excessive heat exchanger

temperature

Check inlet gas pressure

Check burner head pressure

Check that gas type is suitable

for heater

Check injector size is correct for

the heater.

Excessive air temperature due

to poor air flow

Check the fan blades are clean

Check that the horizontal and

(vertical if fitted) louvers are

sufficiently open. (see in

installation section of manual)

Check that the fan speed is

correct and the air flow over the

chamber is sufficient.

Faulty thermostat Replace thermostat

Burner goes out due to the

intervention of the LIMIT

thermostat (LM).

Yellow light flashing

Excessive heat exchanger

temperature.

Check inlet gas pressure

Check burner head pressure

Check that gas type is suitable

for heater

Check injector size is correct for

the heater.

Excessive air temperature due

to poor air flow over heat

exchanger

Check the fan blades are clean

Check that the horizontal and

(vertical if fitted) louvers are

sufficiently open. (see in

installation section of manual)

Check that the fan speed is

correct and the air flow over the

chamber is sufficient..

Faulty thermostat Replace thermostat

Faulty fan Check fan capacitor

Check fan motor.

Intervention of thermal overload

on fan Check electrical absorption

Replace fan motor

Faulty fan operation Change fan control or SND

thermostat

Heater at lockout

Red lamp illuminated Faulty ignition

Check inlet gas pressure

Check burner head pressure

Check that gas type is suitable

for heater

Check that gas line has been

purged correctly.

Faulty ionisation probe

Check electrical connection to

the probe.

Check probe is not cracked or

damaged

Change probe or probe lead

Faulty ignition electrode Replace ignition electrode.

Faulty solenoid Replace solenoid

Dirty gas filter Clean filter

The control panel will not

reset .

Red light on

Faulty flame control module Replace the flame control

module after first checking the

electrical connections

Fan works intermittently Defective fan control Change fan control or SND

thermostat

Insufficient gas pressure

Check that the gas type is

suitable for the heater .

Check the gas pressure

Check burner head pressure.

The fan does not work. Defective fan control Change fan control or SND

thermostat

Faulty fan Check fan capacitor.

Check the fan motor .

The heater works

continuously with out

reaching the required

temperature

Heater to small for application

Insufficient gas pressure

Re check heat output required

for the application

Check that the gas type is

suitable for the heater .

Check gas pressure.

Check burner head pressure.

Dirty heat exchanger Clean heat exchanger

B22: Single flue option with condensate tee and roof terminal combustion air from

inside the room

Type 1 – 2 – 3 – 4

MIN 300

MAX 10000

140

132

U

970

410

*

Ø100

A

T

V

✴157 mm type 1 – 2 – 3

165 mm type 4

ITEM DESCRIPTION

A Pipe M/F ∅100 L=1000 with seal

T Terminal with guard

∅

100

U Condensate Tee with drain point

V Pipe M/M ∅100 L=200 without seal

NOTE IMPORTANT:

MODEL 1-2-3-4

∅FLUE SPIGOT

∅

100 female

∅COMBUSTION AIR SPIGOT

∅

100 female

INSTALLATION Flue should be adequately supported

each bend corresponds to approx 0,8-1 meter of horizontal pipe work

B22: Single flue option with condensate tee and roof terminal combustion air from

inside the room

Type 5 – 6 – 7

A

T

410

970

Ø100

Z

U

MIN 340

MAX 10000

132

165

ITEM DESCRIPTION

A Pipe M/F ∅100 L=1000 with seal

T Terminal with guard

∅

100

U Condensate tee with drain point

Z Pipe M/F ∅100 L=250 with seal

NOTE IMPORTANT:

MODEL 5-6-7

∅FLUE SPIGOT SIZE

∅

100 male

∅COMBUSTION AIR SPIGOT SIZE

∅

150 male

INSTALLATION Flue should be adequately supported

Each bend corresponds to approx 0,8-1 meters of horizontal pipe work

MAX 10000

Ø100

Ø100

H

H

U

175

132

970

235

140 *

MIN 300

A

Ø150

L

A

V

C32 Installation showing Vertical co axial flue terminal with condensate drain

Type 1 – 2 – 3 – 4

✴157 mm type 1 – 2 – 3

165 mm type 4

ITEM DESCRIPTION

A Flue pipe M/F ∅100 L=1000 with seal

H Bend 90° M/F ∅100 with seal

L Vertical co axial roof terminal kit

∅

100-100

U Condensate tee with drain point

V pipe M/M ∅100 L=200 without seal

NOTE IMPORTANT:

MODEL 1-2-3-4

∅FLUE SPIGOT SIZE

∅

100 female

∅COMBUSTION AIR SPIGOT SIZE

∅

100 female

INSTALLATION Flue should be adequately supported

each bend corresponds to about 0,8-1 meters of horizontal pipework

MIN 10000

115

970

410

MIN 340

185

U

Ø100

Ø150

165

Z

A

NØ160

C32 Installation showing Vertical co axial roof terminal with condensate drain

Type 5 – 6 – 7

ITEM DESCRIPTION

A Pipe M/F ∅100 L=1000 with seal

F Pipe M/F ∅150 L=1000 with seal

I Bend 90° M/F ∅150 with seal

N Vertical co axial roof terminal kit

∅

100-150

P Adaptor F/F ∅150 L=200 with seal

Q Bend 45° M/F ∅150 with seal

R Pipe M/F ∅150 L=140 with seal

S Bend 90° F/F ∅100 with seal

U Condensate tee with drain point

Z Pipe M/F ∅100 L=250 with seal

NOTE IMPORTANT:

MODEL 5-6-7

∅FLUE SPIGOT SIZE

∅

100 male

∅COMBUSTION AIR SPIGOT SIZE

∅

150 male

INSTALLATION Flue should be adequately supported

each bend corresponds to about 0,8-1 meters of horizontal pipework

This manual suits for next models

6

Table of contents

Other BENSON HEATING Heater manuals

Popular Heater manuals by other brands

Mesko

Mesko MS 7736 user manual

L.B. White

L.B. White CP125AK Owner's manual and instructions

Whale

Whale Heat Air SL5501 operating instructions

Frico

Frico Aquaztrip P Series Installation instruction

Detroit Radiant Products

Detroit Radiant Products Re-Verber-Ray DTH Series troubleshooting guide

Dimplex

Dimplex CXLN operating manual

EINHELL

EINHELL NKH 1500 D operating instructions

Radialight

Radialight DEVA Installation and operating manual

L.B. White

L.B. White Premier 80 Owner's manual and instructions

Wetekom

Wetekom 81 50 10 instruction manual

Marley

Marley L series Installation & maintenance instructions

Stelpro

Stelpro SC series user guide