Benton Harbor Michigan 49022 User manual

IMPORTANT:

Read and save

these instructions. 30” Freestanding

m Range

Part No. 76948-00/4363032

IMPORTANT:

Installer: Leave Installation Instructions with

the homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector’s use.

Before vou start...

Check location where range will be

installed. The range should be located

WARNING: If the information

in this manual is not

followed exactly, a fire or

explosion may result

causing property damage,

personal injury or death.

- Do Not store or use

gasoline or other

flammable vapors and

liquids in the vicinity of

this or any other

appliance.

- WHAT TO DO IF YOU SMELL

GAS

l

Do Not try to light any

appliance.

l

Do Not touch any

electrical switch; Do Not

use any phone in your

building.

l

Immediately call your

gas supplier from a

neighbor’s phone.

Follow gas supplier’s

instructions.

l

If you cannot reach your

gas supplier, call the fire

department.

- Installation and service

must be performed by a

qualified installer, service

agency or the gas

supplier.

&

Proper installation isyour responsibility. Make

sure you have everything necessary for correct

installation. It isthe responsibility of the installer

away from strong draft areas, such as

windows, doors and strong heating vents

or fans. The range should be located for

convenient use in the kitchen. Recessed

to comply with the installation clearances

specified on the serial/rating plate. The

serial/rating plate islocated under the maintop.

Important: Observe all governing

codes and ordinances. Failure to

meet codes and ordinances

could lead to fire or electrical

shock hazard.

installation must provide complete

enclosure of the sides and rear of range.

.

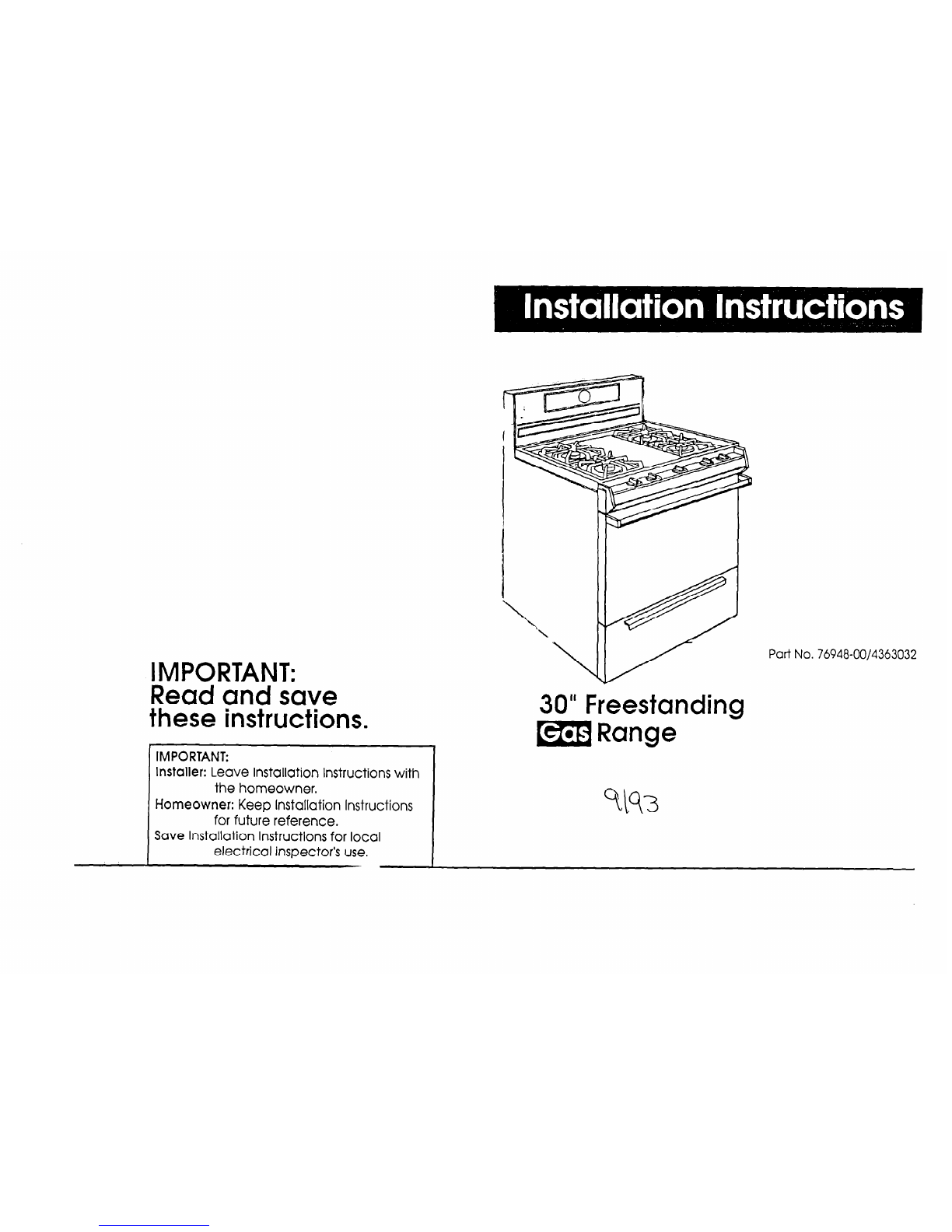

Cabinet opening dimensions that

are shown must be used. Given

1 dimensions provide 0” clearance.

Grounded electrical

outlet isrequired. See

Electrical requirements.

Proper gas supply

connection must be

available. See Gas

supply requirements.

J

For minimum

clearances,

see Note.“’

4’ min.

countertop

space to side

ALL OPENINGS IN

wall or other

combustible

material.

,/ IH’\A/Al I CTD

L ““r\LL “1.

t~00R WHERE

THERANGE ISTO

BEINSTALLED

MUSTBESEALED.

18” min. clearance

upper cabinet

to countertop

/------

30-l 14”

opening

width

I

i

center of

i

range

i ’

wall gas line’

opening -

3” min. 4” max.

from left side of

cabinet

4” 7’ or 9” backguard

I

YF-

.

overall

height

36”

cooktop

height

27-t 14”

depth with

handle

Do Not pinch the

power cord

between the range

and wall.

Do Not seal range

to the side cabinets. Oven frame must

extend beyond

cabinet lronts

by l/2”.

Electrical Shock Hazard

0Take special care when cutting holes

in wall. Electrical wires may be

concealed behind the wall covering

and contact with them could result in

electrical shock.

l

locate any electrical circuits that

could be affected by the installation

of this product and disconnect

power circuit.

Failure to do so could result in

electrical shock.

NOTE:(

Clearances specified are for

\

24”

Fire Hazard

Do Not obstruct the flow of

combustion and ventilation air.

Personal Injury Hazard

Avoid installing cabinet storage

above the cooking surface. If

cabinets are already installed, reduce

the hazard of reaching over a heated

cooking surface by installing a range

hood. The range hood should extend

a minimum of 5 inches out from the

bottom front of the cabinets.

Reaching over a heated cooking

surface could result in a serious burn

or other personal injury.

Electrical Shock Hazard

It is the customer’s responsibility:

l

To contact a qualified electrical

installer.

l

To assure that electrical installation

is adequate and in conformance

with National Electrical Code,

ANSI/NFPA 70-latest edition,* and

all local codes and ordinances.

Failure to do so could result in fire,

electrical shock or other personal

injury.

***Note: 30” min. when bottom of

wood or metal cabinet is protected

by not less than l/4” flame

retardant millboard covered with

not less than No. 28 MSG sheet

steel,.O.OlS” stainless steel, 0.024”

alumrnum or 0.020” copper.

36” min. clearance between the

top of the cooking platform and

the bottom of an unprotected

wood or metal cabinet.

combustible walls and materials that have

a density of 20 or more pounds per cubic

foot. No evaluation of clearances has

been made for installation adiacent to

materials that are lessthan 20*pounds per

cu. ft. or to plastic tiles and sheeting.

Tools needed for

Mobile home installation

The installation of this range must

conform to the Manufactured Home

Construction and Safety Standards, Title

24 CFR, Part 3280 (formerly the Federal

Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280) or

when such standard is not applicable,

the Standard for Manufactured Home

Installation 1982 (Manufactured Home

Sites, Communities and Setups), ANSI

2225.1-1987, or latest edition, or with

local codes.

When this range isinstalled in a mobile

home, it must be secured to the floor

during transit. Any method of securing

the range isadequate as long as it

conforms to the standards listed above.

Copies of the standards listed may be

obtained from:

l

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

**American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

tnstaffatton:

. hand or eleclrlc

drill

. concrele/ceramlc Iloors:

l/4’

masonry

drill bit

. wood floors: l/8’ drill bit

. gas line shutoff valve

. L,P.-reslslanl plpe-Joint compound

. AGA deslgn-cetlilied flexible metal connector (4-5 Ieel)

Property Damage

l

Contact a qualified floor covering

installer to check that the floor

covering can withstand heat at least

90°F above room temperature.

l

Use an insulated pad or l/4”

plywood under range if installing

range over carpeting.

Failure to do so may result in damage

to floor covering.

Panel A

Gas supply

requirements

Observe all governing codes and

ordinances.

Fire Hazard

l

Range must be connected to a

regulated gas supply.

l

L.P.gas supply must Not

exceed a pressure of 14” water

column. This must be checked by

a qualified technician before

installing this range.

l

Do Not use an open flame to

test for leaks from gas

connections.

l

New, A.G.A. design-certified

flexible gas line should be used

when local codes permit.

Failure to follow these instructions

could result in a fire, explosion or

personal injury.

A.

This installation must conform with local

codes and ordinances. In the absence

of local codes, installations must

conform with American National

Standard, National Fuel Gas Code ANSI

Z223.1-latest edition‘*.

B

n

Input ratings shown on the serial/rating

plate are for elevations up to 2,000 feet.

For elevations above 2,000 feet, ratings

are reduced at a rate of 4% for each

1,000 feet above sea level.

C

This r&ge isequipped for use with

NATURALgas. It isdesign-certified by

A.G.4. for NATURALand L.P.gases with

appropriate conversion, The

serial/rating plate, located under the

maintop, has information on the type of

gas that can be used. If this information

does not agree with the type of gas

available, check with the local gas

supplier. See Panel Efor L.P. gas

conversion instructions.

D.

Provide a gas supply line of 3/4” rigid

pipe to the range location. A smaller

size pipe on long runs may result in

insufficient gas supply. Pipe-joint

compounds made for use with L.P.gas

must be used. With L.P.gas, piping or

tubing size can be l/2” minimum. L.P.

gas suppliers usually determine the size

and materials used on the system.

t n

If local codes permit, a new, A.G.A.

design-certified, 4-5 foot long, l/2” or 3/4”

I.D., flexible metal appliance connector is

recommended for connecting this range

to the gas supply line. Do Not kink or

damage the flexible tubing when moving

the range. A l/2” male pipe thread is

needed for connection to pressure

regulator female pipe threads.

F.

The supply line shall be equipped with

an approved shutoff valve. This valve

should be located in the same room as

the range and should be in a location

that allows ease of opening and

closing. Do Not block access to shutoff

valve.

G

If rigid’pipe isused as a gas

supply line, a combination of

pipe fittings must be used to

obtain an in-line connection to the

range. All strains must be removed

from the supply and fuel lines so

range will be level and in line.

H.

The inlet pressure to the regulator should

be as follows for both operation and

checking regulator setting:

NATURALGAS:

Set pressure 6 inches

Maximum inlet pressure 14 inches

L.P.GAS:

Set pressure 11 inches

Maximum inlet pressure 14 inches

I wLine pressure testing:

Testing above l/2 lb psi (gauge)

The range and its individual shutoff

valve must be disconnected from the

gas supply piping system by closing its

individual manual shutoff valve during

any pressure testing of the gas supply

piping system at test pressures equal to

or greater than l/2 psig (3.5 kPa).

Testing at l/2 lb psi (gauge)

The range must be isolated from the

gas supply piping system by closing its

individual manual shutoff valve during

any pressure testing of the gas supply

piping system at test pressures equal to

or lessthan l/2 psig (3.5 kPa).

Electrical

requirements

Electrical Shock Hazard

l

Electrical ground is required on

this appliance.

l

If cold water pipe is interrupted

by plastic, non-metallic gaskets

or other insulating materials, Do

Not use for grounding.

l

Do Not ground to a gas pipe.

l

Do Not modify the power supply

cord plug. If it does not fit the

outlet, have a proper outlet

installed by a qualified

electrician.

l

Do Not have a fuse in the

neutral or grounding circuit. A

fuse in the neutral or grounding

circuit could result in electrical

shock.

l

Do Not use an extension cord

with this appliance.

l

Check with a qualified

electrician if you are in doubt as

to whether the appliance is

properly grounded.

Failure to follow these instructions

could result in serious injury or

death.

If codes permit and a separate

grounding wire is used, it is

recommended that a qualified

electrician determine that the

grounding path is adequate.

A 120-volt, 60-Hz, AC-only, 15ampere,

fused electrical supply isrequired. A

time-delay fuse or circuit breaker is

recommended. It isrecommended that

a separate circuit serving only this

appliance be provided.

Electronic ignition systems operate

within wide voltage limits, but proper

grounding and polarity are necessary.

In addition to checking that the outlet

provides 120-volt power and iscorrectly

grounded, the outlet must be checked

by a qualified electrician to see if it is

wired with correct polarity.

A wiring diagram is included in the

literature package. The wiring diagram

isalso located on the back of the

range.

Recommended

grounding method

For your personal safety, this appliance

must be grounded. Thisappliance is

manufactured with a power supply

cord having a 3-prong grounding plug.

To minimize possible shock hazard, the

cord must be plugged into a mating, 3-

prong, grounding-type, wall

receptacle, grounded in accordance

with the National Electrical Code,

ANSI/NFPA 70-latest edition*, and all

local codes and ordinances. (See

Figure 1.) If a mating wall receptacle is

not available, it isthe personal

responsibility and obligation of the

customer to have a properly grounded,

3-prong, wall receptacle installed by a

qualified electrician.

J-prong

grounding-type

wall receptacle

supply cord

Figure 1

Panel B

Now start...

with range in kitchen.

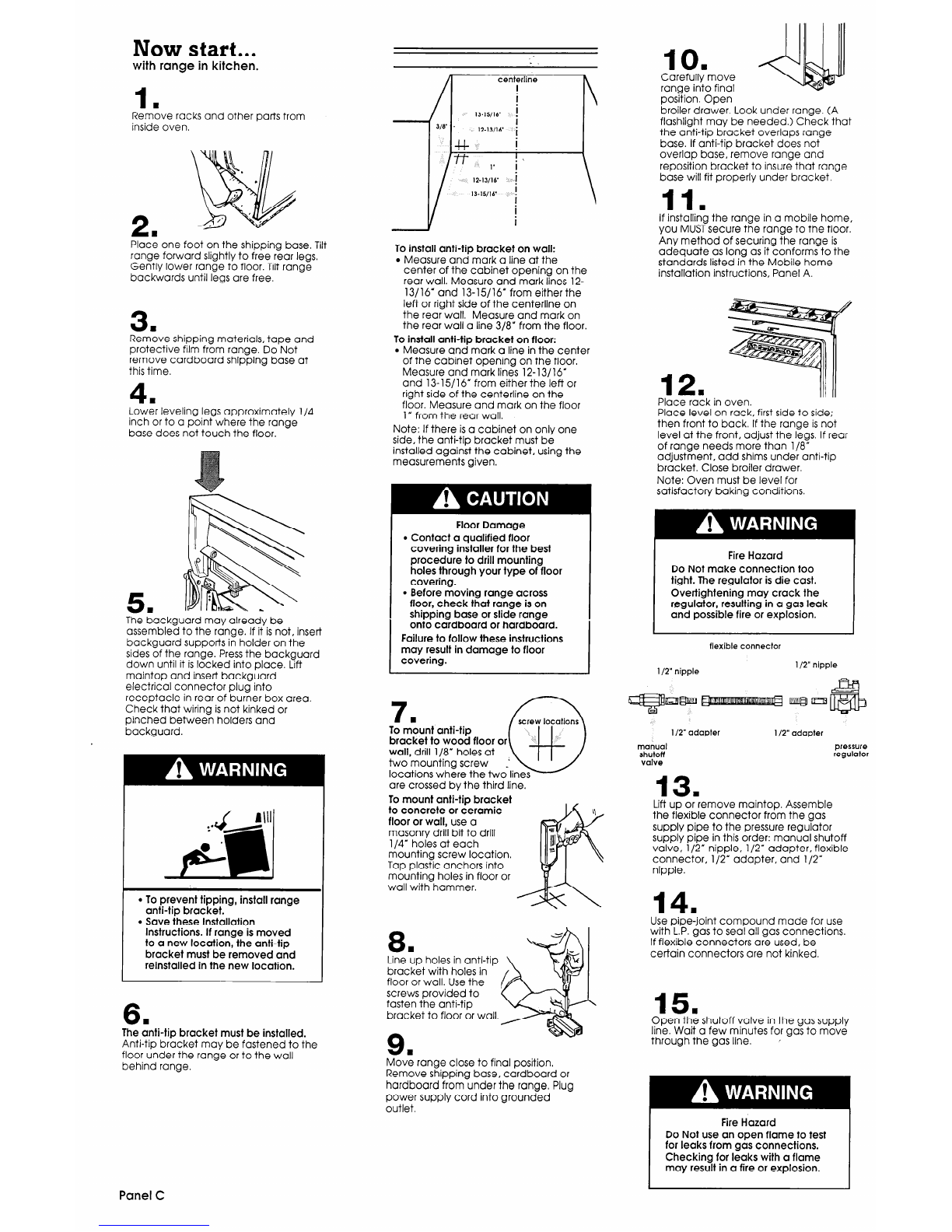

1

n

Remove racks and other parts from

inside oven.

2

n

Place one foot on the shipping base. Tilt

range forward slightly to free rear legs,

Gently lower range to floor. Tilt range

backwards until legs are free.

3

Rem:ve shipping materials, tape and

protective film from range. Do Not

remove cardboard shipping base at

this time.

4

LowE leveling legs approximately l/4

inch or to a point where the range

base does not touch the floor.

5 1

The backguard may already be

assembled to the range. If it isnot, insert

backguard supports in holder on the

sides of the range. Pressthe backguard

down until it islocked into place. Lift

maintop and insert backguard

electrical connector plug into

receptacle in rear of burner box area.

Check that wiring isnot kinked or

pinched between holders and

backguard.

l

To prevent tipping, install range

anti-tip bracket.

l

Save these Installation

Instructions. If range is moved

to a new location, the anti-tip

bracket must be removed and

reinstalled in the new location.

6.

The anti-tip bracket must be installed.

Anti-tip bracket may be fastened to the

floor under the range or to the wall

behind range.

centerline

J/8’ -

1%13/16’

i

+I-

i

ff‘ ,. i\

1%WI6

-i

13-15/16

i

i

i

i

To install anti-tip bracket on wall:

l

Measure and mark a line at the

center of the cabinet opening on the

rear wall. Measure and mark lines 12-

13/16” and 13-15/16” from either the

left or right side of the centerline on

the rear wall. Measure and mark on

the rear wall a line S/8” from the floor.

To install anti-tip bracket on floor:

l

Measure and mark a line in the center

of the cabinet opening on the floor.

Measure and mark lines 12-13/16’

and 13-15/l 6’ from either the left or

right side of the centerline on the

floor. Measure and mark on the floor

1” from the rear wall.

Note: If there isa cabinet on only one

side, the anti-tlp bracket must be

installed against the cabinet, using the

measurements given.

Floor Damage

l

Contact a qualified floor

covering installer for the best

procedure to drill mounting

holes through your type of floor

covering.

l

Before moving range across

floor, check that range is on

shipping base or slide range

onto cardboard or hardboard.

Failure to follow these instructions

may result in damage to floor

covering.

screw locations

To mount anti-tip

bracket to wood floor or

wall, drill l/8’ holes at

two mounting screw

locations where the twdlines

are crossed by the third line.

To mount anti-tip bracket

to concrete or ceramic

floor or wall, use a

masonry drill bit to drill

l/4” holes at each

mounting screw location.

Tap plastic anchors into

mounting holes in floor or

wall with hammer.

8 1

Line up holes in anti-tip

bracket with holes in

floor or wall. Use the

screws provided to

fasten the anti-tip

bracket to floor or wall

9w

Move range close to final position.

Remove shipping base, cardboard or

hardboard from under the range. Plug

power supply cord into grounded

outlet.

10

Carefull;move

ranae into final

pos%on. Open

broiler drawer. Look under range. (A

flashlight may be needed.) Check that

the anti-tip bracket overlaps range

base. If anti-tip bracket does not

overlap base, remove range and

reposition bracket to insure that range

base will fit properly under bracket.

11.

If installing the range in a mobile home,

you MUSTsecure the range to the floor.

Any method of securing the range is

adequate as long as it conforms to the

standards listed in the Mobile home

installation instructions, Panel A.

Place rack in oven.

Place level on rack, first side to side;

then front to back. If the range isnot

level at the front, adjust the legs. If rear

of range needs more than l/8”

adjustment, add shims under anti-tip

bracket. Close broiler drawer.

Note: Oven must be level for

satisfactory baking conditions.

Fire Hazard

Do Not make connection too

tight. The regulator is die cast.

Overtightening may crack the

regulator, resulting in a gas leak

and possible fire or explosion.

flexible connector

l/2” nipple l/2” nipple

I/2” adapter l/2” adapter

manual pressure

shutoff regulator

valve

13 w

Lift up or remove maintop. Assemble

the flexible connector from the gas

supply pipe to the pressure regulator

supply pipe in this order: manual shutoff

valve, l/2” nipple, l/2” adapter, flexible

connector, l/2’ adapter, and l/2”

nipple.

14 1

Use pipe-joint compound made for use

with L.P.gas to seal all gas connections.

If flexible connectors are used, be

certain connectors are not kinked.

15.

Open the shutoff valve in the gas supply

line. Wait a few minutes for gas to move

through the gas line. ’

Fire Hazard

Do Not use an open flame to test

for leaks from gas connections.

Checking for leaks with a flame

may result in a fire or explosion.

Panel C

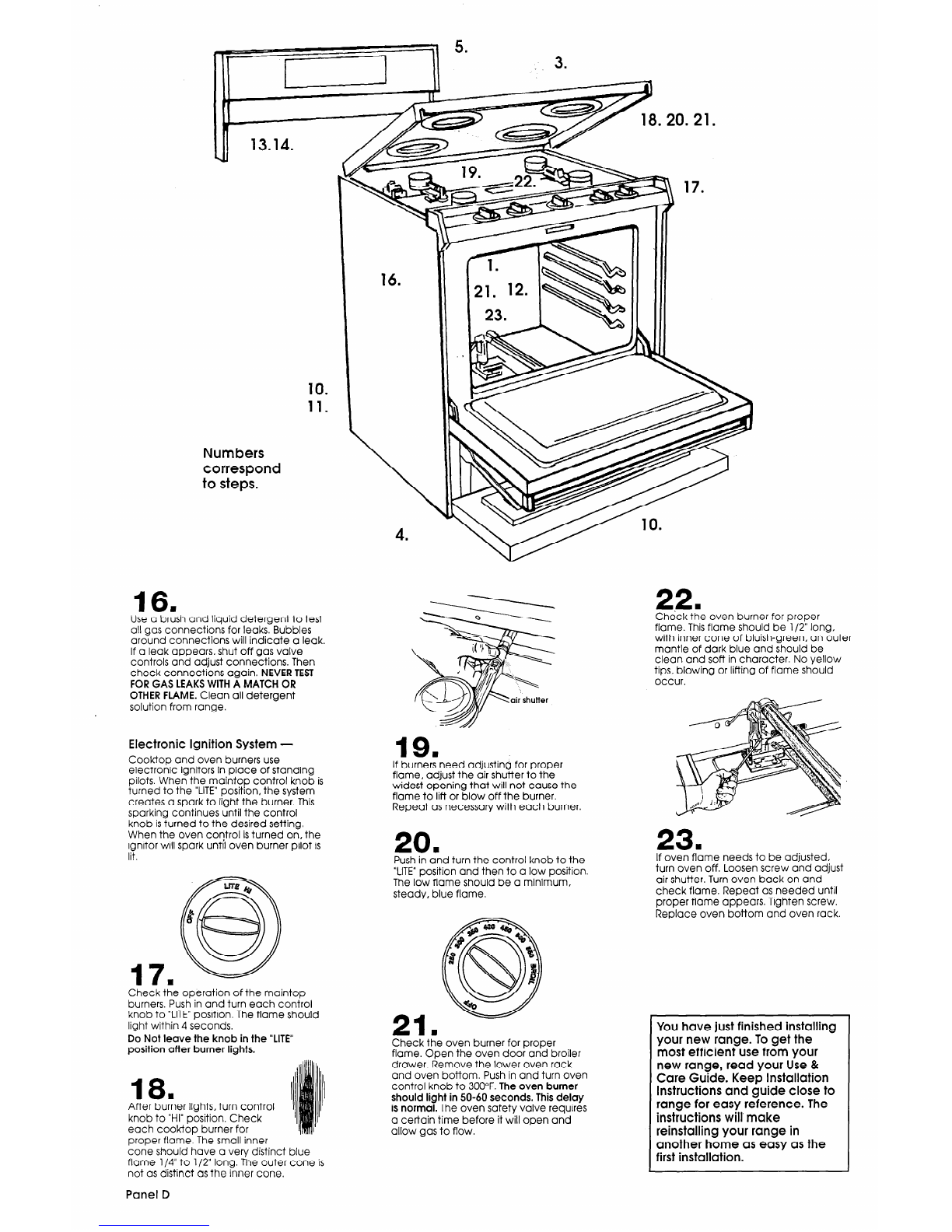

16

m

Use a brush and liquid detergent to test

all gas connections for leaks. Bubbles

around connections will indicate a leak.

If a leak appears, shut off gas valve

controls and adjust connections. Then

check connections again. NEVERTEST

FORGAS LEAKSWITHA MATCH OR

OTHERFLAME.Clean all detergent

solution from range.

Numbers

correspond

to steps.

Electronic Ignition System -

Cooktop and oven burners use

electronic ignitors in place of standing

pilots. When the maintop control knob is

turned to the “LITE”position, the system

creates a spark to light the burner. This

sparking continues until the control

knob isturned to the desired setting.

When the oven control isturned on, the

ignitor will spark until oven burner pilot is

lit.

Check the operation of the maintop

burners. Push in and turn each control

knob to “LITE”position. The flame should

light within 4 seconds.

Do Not leave the knob in the “LITE”

position after burner lights.

18

After buter lights, turn control

knob to “HI” position. Check

each cooktop burner for

proper flame. The small inner

cone should have a very distinct blue

flame l/4” to l/2” long. The outer cone is

not as distinct as the inner cone.

19 w

If burners need adjusting for proper

flame, adjust the air shutter to the

widest opening that will not cause the

flame to lift or blow off the burner.

Repeat as necessary with each burner.

Push in and turn the control knob to the

20

“LITE”position and then to a low position.

n

The low flame should be a minimum,

steady, blue flame.

Check the oven burner for proper

flame. Open the oven door and broiler

drawer. Remove the lower oven rack

and oven bottom. Push in and turn oven

control knob to 300°F. The oven burner

should light in SO-60seconds. This delay

is normal. The oven safety valve requires

a certain time before it will open and

allow gas to flow.

22.

Check the oven burner for proper

flame. Thisflame should be l/2” long,

with inner cone of bluish-green, an outer

mantle of dark blue and should be

clean and soft in character. No yellow

tips, blowing or lifting of flame should

occur.

If oven flame needs to be adjusted,

turn oven off. Loosen screw and adjust

air shutter. Turn oven back on and

23.

check flame. Repeat as needed until

proper flame appears. Tighten screw.

Replace oven bottom and oven rack.

You have just finished installing

your new range. To get the

most efficient use from your

new range, read your Use &

Care Guide. Keep Installation

Instructions and guide close to

range for easy reference. The

instructions will’ make

reinstalling your range in

another home as easy as the

first installation.

Panel D

L.F!

gas

conversion

Fire Hazard

l

Locate gas supply valve between

pressure regulator and gas valve.

Shut off gas supply valve in range

before converting to L.P.gas.

l

Make all maintop and oven

burner conversions before turning

gas supply valve back on.

Failure to follow these instructions

could result in fire, explosion or

other personal injury.

Converting to L.P. gas

Converting to L.P.gas should be done

by a qualified installer.

A

n

Complete installation Steps 1-12 before

converting your range to L.P.gas.

Remove oven racks and oven bottom.

Open broiler drawer. Shut off gas supply

valve in range. Remove burner grates

and carefully lift up or remove maintop.

Pressure regulator:

Use a wrench to unscrew the cap from

the top by turning counterclockwise.

Turn the cap over so the hole end isup.

Replace the cap and gasket on the

regulator. DO NOT REMOVETHE

PRESSUREREGULATOR.

D.

Oven burner:

Turn the orifice hood down

snug onto pins (approximately 2 to 2-l /2

turns.) DO NOT OVERTIGHTEN.The

burner flames cannot be properly

adjusted if this conversion isnot made.

E

Afteryhe burners have been converted

to L.P.gas usage, complete Steps 13-16,

Panels C and D.

Adjusting for proper flame

Cooktop burners:

Adjust the air shutters for proper flame

by sliding the air shutter to close or

open the shutter as needed. See Panel

D, Steps 17-20. L.P.gas has a slightly

yellow tip on top of burner flames in

addition to the other proper

characteristics.

B.

Oven burners:

Adjust the air shutters as needed for

proper flame. See Panel D, Steps 2l-23.

C

Rep&e oven bottom and oven racks.

Reinstall the maintop and burner grates.

C

Cookyop burners:

Turn the orifice hoods down

snug onto pins (approximately 2 to 2-l/2

turns.) DO NOT OVERTIGHTEN.The

burner flames cannot be properly

adjusted if this conversion isnot made.

Panel E

If range does not

operate...

l

Check that the circuit breaker is

not tripped or the house fuse blown.

l

Check that power supply cord is

plugged into wall receptacle.

l

Check that the gas supply isturned

on.

NOTE:

Refer to Use and Care Guide for

opero-ting instructions and cleaning

instructions.

Personal Injury/

Product Damage Hazard

Do Not step, lean or sit on ttie range

drawer or door.

Failure to follow these instructions

could result in personal injury

and/or product damage.

For cleaning and

maintenance...

If removing the range is necessary for

cleaning and maintenance, shut off

gas supply to the range. Disconnect the

gas and electrical supply.

If the gas or electrical supply is

inaccessible, lift the range slightly at the

front

and pull the range away from the

wall. Pull the range out only as far as

necessary to disconnect the gas and

electric supply lines.

Remove the range to complete

cleaning or maintenance.

Move range back into operating

position. Level the range. Connect the

gas line to the range and check for

leaks. Plug electric power supply cord

into outlet.

Make sure the anti-tip bracket overlaps

range base.

If you need

assistance...

Check your Use and

Care Guide for a

toll-free number to call, or call the

dealer from whom you purchased this

appliance. The dealer islisted in the

Yellow Pages of your phone

directory

under “Appliances - major.”

When you call, you will need the range

model number and serial

number. Both

numbers can be found on the

serial/rating plate located

under the

maintop.

Part No. 76948-OOl4363032

0 1992 Benton Harbor, Michigan 49022 Printed in U.S.A.

Table of contents

Other Benton Harbor Range manuals

Popular Range manuals by other brands

Maytag

Maytag MGR5875QDW - 30 Inch Gas Range Use and care guide

Frigidaire

Frigidaire FFGF3024SS use & care

Capital

Capital Precision Series GCR484W Specifications

Officine Gullo

Officine Gullo GGS8P Installation and use instruction

LG

LG LSD4913 Series owner's manual

Kenmore

Kenmore 4101 - Elite 30 in. Slide-In Electric Range installation instructions